Академический Документы

Профессиональный Документы

Культура Документы

Types of Diodes

Загружено:

jucsxxxАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Types of Diodes

Загружено:

jucsxxxАвторское право:

Доступные форматы

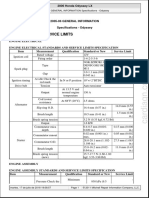

Types of Diodes.

Various types of diodes are available which enable different kinds of applications to be met. Diodes for high current and voltage, for small

signal applications, light emission and detection, as well as for giving variable capacitance and low forward voltage drops are available

today. Moreover, various types of diodes are used in microwave application...

A diode is a two-terminal device, having two active electrodes, between which it allows the transfer of current in one direction only. Diodes

are known for their unidirectional current property, wherein, the electric current is allowed to flow in one direction. Basically, diodes are

used for the purpose of rectifying waveforms, and can be used within power supplies or within radio detectors. They can also be used in

circuits where 'one way' effect of diode is required. Most diodes are made from semiconductors such as silicon, however, germanium is also

used sometimes. Diodes transmit electric currents in one direction, however, the manner in which they do so can vary. Several types of

diodes are available for use in electronics design. Some of the different types of diodes are:

Light Emitting Diode (LED): It is one of the most popular type of diodes and when this diode permits the transfer of electric current

between the electrodes, light is produced. In most of the diodes, the light (infrared) cannot be seen as they are at frequencies that do not

permit visibility. When the diode is switched on or forward biased, the electrons recombine with the holes and release energy in the form of

light (electroluminescence). The color of light depends on the energy gap of the semiconductor.

Avalanche Diode: This type of diode operates in the reverse bias, and used avalanche effect for its operation. The avalanche breakdown

takes place across the entire PN junction, when the voltage drop is constant and is independent of current. Generally, the avalanche diode is

used for photo-detection, wherein high levels of sensitivity can be obtained by the avalanche process.

Laser Diode: This type of diode is different from the LED type, as it produces coherent light. These diodes find their application in DVD

and CD drives, laser pointers, etc. Laser diodes are more expensive than LEDs. However, they are cheaper than other forms of laser

generators. Moreover, these laser diodes have limited life.

Schottky Diodes: These diodes feature lower forward voltage drop as compared to the ordinary silicon PN junction diodes. The voltage

drop may be somewhere between 0.15 and 0.4 volts at low currents, as compared to the 0.6 volts for a silicon diode. In order to achieve this

performance, these diodes are constructed differently from normal diodes, with metal to semiconductor contact. Schottky diodes are used in

RF applications, rectifier applications and clamping diodes.

Zener diode: This type of diode provides a stable reference voltage, thus is a very useful type and is used in vast quantities. The diode runs

in reverse bias, and breaks down on the arrival of a certain voltage. A stable voltage is produced, if the current through the resistor is limited.

In power supplies, these diodes are widely used to provide a reference voltage.

Photodiode: Photodiodes are used to detect light and feature wide, transparent junctions. Generally, these diodes operate in reverse bias,

wherein even small amounts of current flow, resulting from the light, can be detected with ease. Photodiodes can also be used to generate

electricity, used as solar cells and even in photometry.

Varicap Diode or Varactor Diode: This type of diode feature a reverse bias placed upon it, which varies the width of the depletion layer as

per the voltage placed across the diode. This diode acts as a capacitor and capacitor plates are formed by the extent of conduction regions

and the depletion region as the insulating dielectric. By altering the bias on the diode, the width of the depletion region changes, thereby

varying the capacitance.

Rectifier Diode: These diodes are used to rectify alternating power inputs in power supplies. They can rectify current levels that range from

an amp upwards. If low voltage drops are required, then Schottky diodes can be used, however, generally these diodes are PN junction

diodes.

PI N diode: This type of diode is typified by its construction. It has the standard P type and N-type areas, but between them there is an area

of Intrinsic semiconductor which has no doping. The area of the intrinsic semiconductor has the effect of increasing the area of the depletion

region which can be useful for switching applications as well as for use in photodiodes, etc.

PN J unction: The standard PN junction may be thought of as the normal or standard type of diode in use today. These diodes

can come as small signal types for use in radio frequency, or other low current applications which may be termed as signal

diodes. Other types may be intended for high current and high voltage applications and are normally termed rectifier diodes.

Read more about the diode

Step recovery diode: A form of microwave diode used for generating and shaping pulses at very high frequencies. These diodes rely on a

very fast turn off characteristic of the diode for their operation.

Tunnel diode: Although not widely used today, the tunnel diode was used for microwave applications where its performance exceeded that

of other devices of the day.

Diodes are used widely in the electronics industry, right from electronics design to production, to repair. Besides the above mentioned types

of diodes, the other diodes are PIN diode, point contact diode, signal diode, step recovery diode, tunnel diode and gold doped diodes. The

type of diode to transfer electric current depends on the type and amount of transmission, as well as on specific applications.

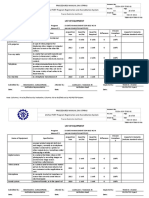

Types of Capacitor

The capacitor's function is to store electricity, or electrical energy.

The capacitor also functions as a filter, passing alternating current (AC), and blocking direct current (DC).

This symbol is used to indicate a capacitor in a circuit diagram.

The capacitor is constructed with two electrode plates facing eachother, but separated by an insulator.

When DC voltage is applied to the capacitor, an electric charge is stored on each electrode. While the capacitor is charging up, current

flows. The current will stop flowing when the capacitor has fully charged.

There are a very, very large variety of different types of capacitor available in the market place and each one has its own set of

characteristics and applications from small delicate trimming capacitors up to large power metal-can type capacitors used in high voltage

power correction and smoothing circuits. Like resistors, there are also variable types of capacitors which allow us to vary their capacitance

value for use in radio or "frequency tuning" type circuits.

Commercial types of capacitor are made from metallic foil interlaced with thin sheets of either paraffin-impregnated paper or Mylar as the

dielectric material. Some capacitors look like tubes, this is because the metal foil plates are rolled up into a cylinder to form a small package

with the insulating dielectric material sandwiched in between them. Small capacitors are often constructed from ceramic materials and then

dipped into an epoxy resin to seal them. Either way, capacitors play an important part in electronic circuits so here are a few of the more

"common" types of capacitor available.

Dielectric Capacitor

Dielectric Capacitors are usually of the variable type were a continuous variation of capacitance is required for tuning transmitters,

receivers and transistor radios. Variable dielectric capacitors are multi-plate air-spaced types that have a set of fixed plates (the stator vanes)

and a set of movable plates (the rotor vanes) which move in between the fixed plates. The position of the moving plates with respect to the

fixed plates determines the overall capacitance value. The capacitance is generally at maximum when the two sets of plates are fully meshed

together. High voltage type tuning capacitors have relatively large spacings or air-gaps between the plates with breakdown voltages reaching

many thousands of volts.

Variable Capacitor Symbols

As well as the continuously variable types, preset type variable capacitors are also available called Trimmers. These are generally small

devices that can be adjusted or "pre-set" to a particular capacitance value with the aid of a small screwdriver and are available in very small

capacitances of 500pF or less and are non-polarized.

Film Capacitor

Film Capacitors are the most commonly available of all types of capacitors, consisting of a relatively large family of capacitors with the

difference being in their dielectric properties. These include polyester (Mylar), polystyrene, polypropylene, polycarbonate, metallised paper,

Teflon etc. Film type capacitors are available in capacitance ranges from as small as 5pF to as large as 100uF depending upon the actual

type of capacitor and its voltage rating. Film capacitors also come in an assortment of shapes and case styles which include:

Wrap & Fill (Oval & Round) - where the capacitor is wrapped in a tight plastic tape and have the ends filled with epoxy to seal

them.

Epoxy Case (Rectangular & Round) - where the capacitor is encased in a moulded plastic shell which is then filled with epoxy.

Metal Hermetically Sealed (Rectangular & Round) - where the capacitor is encased in a metal tube or can and again sealed with

epoxy.

with all the above case styles available in both Axial and Radial Leads.

Film Capacitors which use polystyrene, polycarbonate or Teflon as their dielectrics are sometimes called "Plastic capacitors". The

construction of plastic film capacitors is similar to that for paper film capacitors but use a plastic film instead of paper. The main advantage

of plastic film capacitors compared to impregnated-paper types is that they operate well under conditions of high temperature, have smaller

tolerances, a very long service life and high reliability. Examples of film capacitors are the rectangular metallised film and cylindrical film

& foil types as shown below.

Ceramic Capacitors

Ceramic Capacitors or Disc Capacitors as they are generally called, are made by coating two sides of a small porcelain or ceramic disc

with silver and are then stacked together to make a capacitor. For very low capacitance values a single ceramic disc of about 3-6mm is used.

Ceramic capacitors have a high dielectric constant (High-K) and are available so that relatively high capacitances can be obtained in a small

physical size. They exhibit large non-linear changes in capacitance against temperature and as a result are used as de-coupling or by-pass

capacitors as they are also non-polarized devices. Ceramic capacitors have values ranging from a few picofarads to one or two microfarads

but their voltage ratings are generally quite low.

Ceramic Capacitor

Ceramic types of capacitors generally have a 3-digit code printed onto their body to identify their capacitance value in pico-farads.

Generally the first two digits indicate the capacitors value and the third digit indicates the number of zero's to be added. For example, a

ceramic disc capacitor with the markings 103 would indicate 10 and 3 zero's in pico-farads which is equivalent to 10,000 pF or 10nF.

Likewise, the digits 104 would indicate 10 and 4 zero's in pico-farads which is equivalent to 100,000 pF or 100nF and so on. Then on the

image of a ceramic capacitor above the numbers 154 indicate 15 and 4 zero's in pico-farads which is equivalent to 150,000 pF or 150nF.

Letter codes are sometimes used to indicate their tolerance value such as: J = 5%, K = 10% or M = 20% etc.

Electrolytic Capacitors

Electrolytic Capacitors are generally used when very large capacitance values are required. Here instead of using a very thin metallic film

layer for one of the electrodes, a semi-liquid electrolyte solution in the form of a jelly or paste is used which serves as the second electrode

(usually the cathode). The dielectric is a very thin layer of oxide which is grown electro-chemically in production with the thickness of the

film being less than ten microns. This insulating layer is so thin that it is possible to make capacitors with a large value of capacitance for a

small physical size as the distance between the plates, d is very small.

Electrolytic Capacitor

The majority of electrolytic types of capacitors are Polarised, that is the DC voltage applied to the capacitor terminals must be of the correct

polarity, i.e. positive to the positive terminal and negative to the negative terminal as an incorrect polarisation will break down the insulating

oxide layer and permanent damage may result. All polarised electrolytic capacitors have their polarity clearly marked with a negative sign to

indicate the negative terminal and this polarity must be followed.

Electrolytic Capacitors are generally used in DC power supply circuits due to their large capacitances and small size to help reduce the

ripple voltage or for coupling and decoupling applications. One main disadvantage of electrolytic capacitors is their relatively low voltage

rating and due to the polarisation of electrolytic capacitors, it follows then that they must not be used on AC supplies. Electrolytic's

generally come in two basic forms; Aluminum Electrolytic Capacitors and Tantalum Electrolytic Capacitors.

Electrolytic Capacitor

1. Aluminium Electrolytic Capacitors

There are basically two types of Aluminium Electrolytic Capacitor, the plain foil type and the etched foil type. The thickness of the

aluminium oxide film and high breakdown voltage give these capacitors very high capacitance values for their size. The foil plates of the

capacitor are anodized with a DC current. This anodizing process sets up the polarity of the plate material and determines which side of the

plate is positive and which side is negative. The etched foil type differs from the plain foil type in that the aluminium oxide on the anode and

cathode foils has been chemically etched to increase its surface area and permittivity. This gives a smaller sized capacitor than a plain foil

type of equivalent value but has the disadvantage of not being able to withstand high DC currents compared to the plain type. Also their

tolerance range is quite large at up to 20%. Typical values of capacitance for an aluminium electrolytic capacitor range from 1uF up to

47,000uF.

Etched foil electrolytic's are best used in coupling, DC blocking and by-pass circuits while plain foil types are better suited as smoothing

capacitors in power supplies. But aluminium electrolytic's are "polarised" devices so reversing the applied voltage on the leads will cause the

insulating layer within the capacitor to become destroyed along with the capacitor. However, the electrolyte used within the capacitor helps

heal a damaged plate if the damage is small. Since the electrolyte has the properties to self-heal a damaged plate, it also has the ability to re-

anodize the foil plate. As the anodizing process can be reversed, the electrolyte has the ability to remove the oxide coating from the foil as

would happen if the capacitor was connected with a reverse polarity. Since the electrolyte has the ability to conduct electricity, if the

aluminum oxide layer was removed or destroyed, the capacitor would allow current to pass from one plate to the other destroying the

capacitor, "so be aware".

2. Tantalum Electrolytic Capacitors

Tantalum Electrolytic Capacitors and Tantalum Beads, are available in both wet (foil) and dry (solid) electrolytic types with the dry or

solid tantalum being the most common. Solid tantalum capacitors use manganese dioxide as their second terminal and are physically smaller

than the equivalent aluminium capacitors. The dielectric properties of tantalum oxide is also much better than those of aluminium oxide

giving a lower leakage currents and better capacitance stability which makes them suitable for use in blocking, by-passing, decoupling,

filtering and timing applications.

Also, Tantalum Capacitors although polarised, can tolerate being connected to a reverse voltage much more easily than the aluminium

types but are rated at much lower working voltages. Solid tantalum capacitors are usually used in circuits where the AC voltage is small

compared to the DC voltage. However, some tantalum capacitor types contain two capacitors in-one, connected negative-to-negative to form

a "non-polarised" capacitor for use in low voltage AC circuits as a non-polarised device. Generally, the positive lead is identified on the

capacitor body by a polarity mark, with the body of a tantalum bead capacitor being an oval geometrical shape. Typical values of

capacitance range from 47nF to 470uF.

Aluminium & Tantalum Electrolytic Capacitor

Electrolytic's are widely used capacitors due to their low cost and small size but there are three easy ways to destroy an electrolytic

capacitor:

Over-voltage - excessive voltage will cause current to leak through the dielectric resulting in a short circuit condition.

Reversed Polarity - reverse voltage will cause self-destruction of the oxide layer and failure.

Over Temperature - excessive heat dries out the electrolytic and shortens the life of an electrolytic capacitor..

3 Multilayer Ceramic Capacitors

The multilayer ceramic capacitor has a many-layered dielectric. These capacitors are small in size, and have good temperature and

frequency characteristics.

Square wave signals used in digital circuits can have a comparatively high frequency component included.

This capacitor is used to bypass the high frequency to ground.

4 Polystyrene Film Capacitors

In these devices, polystyrene film is used as the dielectric. This type of capacitor is not for use in high frequency circuits, because they are

constructed like a coil inside. They are used well in filter circuits or timing circuits which run at several hundred KHz or less.

Polyester Film Capacitors

This capacitor uses thin polyester film as the dielectric.

They are not high tolerance, but they are cheap and handy. Their tolerance is about 5% to 10%.

5 Polypropylene Capacitors

This capacitor is used when a higher tolerance is necessary than polyester capacitors offer. Polypropylene film is used for the dielectric. It is

said that there is almost no change of capacitance in these devices if they are used with frequencies of 100KHz or less.

The pictured capacitors have a tolerance of 1%.

Mica Capacitors

These capacitors use Mica for the dielectric. Mica capacitors have good stability because their temperature coefficient is small. Because

their frequency characteristic is excellent, they are used for resonance circuits, and high frequency filters. Also, they have good insulation,

and so can be utilized in high voltage circuits. It was often used for vacuum tube style radio transmitters, etc.

Mica capacitors do not have high values of capacitance, and they can be relatively expensive.

Metallized Polyester Film Capacitors

These capacitors are a kind of a polyester film capacitor. Because their electrodes are thin, they can be miniaturized.

These capacitors have no polarity.

Variable Capacitors

Variable capacitors are used for adjustment etc. of frequency mainly.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Sony SLV Se100 Se200 Se250 Se300 SexxxДокумент81 страницаSony SLV Se100 Se200 Se250 Se300 Sexxxvideoson100% (2)

- 4.3-10 Right Angle Male Connector For 1/2" Coaxial Cable, OMNI FIT StandardДокумент2 страницы4.3-10 Right Angle Male Connector For 1/2" Coaxial Cable, OMNI FIT StandardLuciano Silvério LeiteОценок пока нет

- En Cat RD2 010 PDFДокумент136 страницEn Cat RD2 010 PDFJi Hwan ParkОценок пока нет

- Cycle AnatomyДокумент2 страницыCycle AnatomyAlvin RajОценок пока нет

- Tapco j1400 Manual de UsuarioДокумент20 страницTapco j1400 Manual de UsuarioIvan mirandaОценок пока нет

- Notes CH 8 Simple Machines - Key 2012 PDFДокумент4 страницыNotes CH 8 Simple Machines - Key 2012 PDFSwapnil Mhamane100% (1)

- BC-5800 Auto Hematology Analyzer Engineer Maintenance ManualДокумент20 страницBC-5800 Auto Hematology Analyzer Engineer Maintenance ManualJaime EspinosaОценок пока нет

- Article 201203 0021 MeidenДокумент11 страницArticle 201203 0021 Meidendcf67myОценок пока нет

- Standards and Service Limits: 2005-06 General InformationДокумент21 страницаStandards and Service Limits: 2005-06 General Informationvadim vadim100% (1)

- HT Distribution SLD ModelДокумент1 страницаHT Distribution SLD ModelsomjitsahaniОценок пока нет

- SAMSUNG (Chassis KS1)Документ12 страницSAMSUNG (Chassis KS1)Dario David DimaroОценок пока нет

- Stock SSD Sata y M.2Документ3 страницыStock SSD Sata y M.2ARIANA PONCEОценок пока нет

- SL1100 Hardware Manual PDFДокумент144 страницыSL1100 Hardware Manual PDFdoraemon007Оценок пока нет

- EE308 Electric DrivesДокумент2 страницыEE308 Electric DrivesMerin MariamОценок пока нет

- MID 130 PID 161 Input Shaft Rotation Speed PDFДокумент4 страницыMID 130 PID 161 Input Shaft Rotation Speed PDFTun Tun Win KseОценок пока нет

- Sheet 3Документ3 страницыSheet 3geo_bi100% (1)

- Datasheet PDFДокумент4 страницыDatasheet PDFJose Luis Guanchez CarrilloОценок пока нет

- MCS025 Synchro-Check Module: InstallationДокумент1 страницаMCS025 Synchro-Check Module: Installationوسام وسامОценок пока нет

- CSS10 - Teacher - Made - Home - Task - MELC 1.2 Computer Hardware IdentificationДокумент7 страницCSS10 - Teacher - Made - Home - Task - MELC 1.2 Computer Hardware IdentificationFaye LouraneОценок пока нет

- Analog MeterДокумент31 страницаAnalog MeterAnooshe Asadian100% (1)

- Review Review Review Review M M M M Ssss OHE OHE OHE OHEДокумент61 страницаReview Review Review Review M M M M Ssss OHE OHE OHE OHETushar100% (2)

- Manual Mbe 4000 TallerДокумент631 страницаManual Mbe 4000 TallerCristian Muñoz100% (19)

- CAN) GLA-Class X156 GLA 250 4MATIC 156.946 (2014-2020)Документ2 страницыCAN) GLA-Class X156 GLA 250 4MATIC 156.946 (2014-2020)sebin134Оценок пока нет

- 2018 DAIKIN Product Line-UpДокумент25 страниц2018 DAIKIN Product Line-UpLhexter Mhervin CoОценок пока нет

- Pilot Circuits: Service Training Manual CM 760/780Документ5 страницPilot Circuits: Service Training Manual CM 760/780victor laraОценок пока нет

- List of Equipment: Procedures Manual On Utpras Unified TVET Program Registration and Accreditation SystemДокумент3 страницыList of Equipment: Procedures Manual On Utpras Unified TVET Program Registration and Accreditation SystemRichardОценок пока нет

- WB31238 Diy-WorkbenchДокумент8 страницWB31238 Diy-WorkbenchFrancois VaaltynОценок пока нет

- Mag B760M Mortar Max Wifi DDR4Документ1 страницаMag B760M Mortar Max Wifi DDR4Taewhan JungОценок пока нет

- Customer Stancil RecorderДокумент21 страницаCustomer Stancil RecorderGS MeenaОценок пока нет

- Substitutionguide NS NSX en NLДокумент40 страницSubstitutionguide NS NSX en NLdkompogiorgasОценок пока нет