Академический Документы

Профессиональный Документы

Культура Документы

07 BMS CheckList

Загружено:

amhosny64Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

07 BMS CheckList

Загружено:

amhosny64Авторское право:

Доступные форматы

BRIEF SCOPE OF WORK

The brief scope of work comprises of, but not limited to, the following:

a. Design, supply, installation and commissioning of Integrated Building Management system

comprising of the following:

i. Building Automation system for

HVAC Lower Side (AHUs etc). Electrical System (HT/LT) including DG operation, Vertical Transportation

(Lift Management) system and Water Management System

ii. Integrated building management system including the IBMS software to integrate and monitor

the following services from a central location

Fire Detection & Alarm

Public Address

Access Control

Closed Circuit Surveillance & Digital Video Recording

Lighting Control

Water Management

Fire Fighting

Iii The following system specific to the requirement of the Data centre.:

Gas based Fire Suppression systems.

Water leak detection

Smoke Detection

Ultrasonic Pest Repellent system

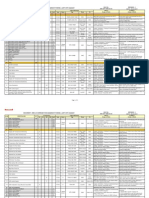

CHECK LIST FOR BMS

SUB-SECTION-1

INPUT AND OUTPUT SUMMARY FOR BAS.

S l.

NO

DESCRIPTION FUNCTI ONS LOCA

TION

AI AO D

I

D

O

STA

TUS

ALA

RM

CON

TROL

CONTROL/

MONITORING

1 DDC TYPE - A (For chiller) -

Chillers: - AHU

ROO

M - 1

AT

SEC

O

N D

FLO

O R.

1

Chiller ON/OFF command. Command from

PC/DDC to the chi l l er

MCC panel.

2 Chiller ON/OFF status. From chiller panel

3 Chiller Auto / Manual status. signal from A/M switch.

4

Chiller trip status. signal from potential

free contact.

5

Motorized Vavle ON/OFF Command signal from potential

free contact.

6 Motorized Vavle ON/OFF Status

7

Immersion type Temp sensor for In

and out

Signal from Immersion

type Temp sensor .

Primary Chilled Water Pumps-

8

Primary Chilled Water pumps ON /

OFF command.

Command from

PC/DDC to the primary

CHW Pumps panel.

9

Primary Chilled Water pumps ON /

OFF Status.

Differential pressure

switch.

10

Primary Chilled Water pumps Auto /

Manual status.

signal from A/M switch.

11

Primary Chilled Water pumps trip

status.

signal from potential

free contact.

12

Immersion type Flow switch signal For dry run

status

13 Secondary Chilled Water Pumps-

14 Secondary CHW pumps ON / OFF

Command.

Command from

PC/DDC to the

MCC panel.

15 Secondary CHW pumps ON / OFF

status.

Differential

pressure switch.

16 Secondary CHW pumps VFD speed

Control.

Proportional

signal from

DDC to the VFD

panel.

17 Secondary CHW pumps VFD speed

feedback.

signal from VFD.

18 Secondary CHW pumps trip status. VFD trip status .

19 Secondary CHW pumps A/M status &

Bypass status.

signal from A/M

switch.

20 Immersion type Flow switch signal for Dry

Run status

21 Differential pressure Switch across the

supply & return headers.(4 nos Pr

Pump, 3 Nos Sec pump)

Signal from DP

switch for flow.

22 Differential pressure sensor across the

common supply & return headers.

Differential

pressure

sensor.

23 CHW flow measurement Pulse O/P from

flow meter.

24 MCC power supply status. Command from

PC/DDC to the

MCC panel.

Total

2 TYPE - B ( For 1 NO AHU with VFD.) -

4Nos

1 AHU ON/OFF Command. 1 * At local control

panel

R E

F

D D

C

LO

CA

TI O

N

DR

2

AHU ON/OFF Status. 1 * At local control

panel

3

AHU Auto/Manual Status 1 * At Auto / Manual

switch

4 Filter status. 1 * DP switch

5

RA Temparature status 1 * F r o m

Temparature

sensor

7 CHW 2-Way Valve Control. 1 2 Way Valve

6 RA Rh status From Rh sensor AWI

NG.

with Actuator

8

Fire trip status. From Fire Relay

9

Fire Damper On/Off Status At local control

panel

10

VFD speed control. At VFD Panel

11

VFD speed refference. At VFD Panel

12

VFD trip status. At VFD Panel

13

Duct static pressure sensor. Pressure sensor

14

VFD Bypass status. At VFD Panel

Total

3 TYPE - C (3 Nos AHU's/CAHU with Starter

) - 2 Nos

1 AHU ON/OFF Command. At local control

panel

REF

DDC

LOCA

TION

DRA

W

ING.

2 AHU ON/OFF Status. At local control

panel

3 AHU Auto/Manual Status At Auto / Manual

switch

4 Filter status. DP switch

5 RA Temparature status F r o m

Temparature

sensor

6 RA Rh status From Rh sensor

6 CHW 2-Way Valve Control. 2 Way Valve with

Actuator

7 Fire trip status. From Fire Relay

8 Fire Damper On/Off Status At local control

panel

9 Duct static pressure sensor. Pressure sensor

Total

4 TYPE -D(4 Nos CAHU's with Starter )- 1

No

1 AHU ON/OFF Command. At local control

panel

REF

DDC

LOCA

TION

DRA

W

ING.

2 AHU ON/OFF Status. At local control

panel

3 AHU Auto/Manual Status At Auto / Manual

switch

4 Filter status. DP switch

5 RA Temparature status F r o m

Temparature

sensor

6 RA Rh status From Rh sensor

6 CHW 2-Way Valve Control. 2 Way Valve with

Actuator

7 Fire trip status. From Fire Relay

8 Fire Damper On/Off Status At local control

panel

9 Duct static pressure sensor. Pressure sensor

Total

5 TYPE -E (22 Nos PAC )- 1 No

1 AHU ON/OFF Command. At local control

panel

PAC

ROO

M AT

1ST

FLOO

R

Total

6 TYPE -F (7 Nos PAC )- 1 No

1 AHU ON/OFF Command. At local control

panel

PAC

ROO

M AT

1ST

FLOO

R

Total

SUB-SECTION 2

I/O SUMMARY

SECTION I: I/O LIST FOR HT/LT ELECTRICAL MONITORING

S.No

.

DESCRIPTION DI AI STATUS ALARM CONTR

OL

LINK LOCATI

ON

SUBSTATIION FUNCTIONS Signals

are

to be

acquired

from

Circuit

Breakers

&

Relays

over

serial

interface.

Electrical

contractor

shall

make

available

CBs and

relays

with

RS 485

port and

MODBUS

RTU

PROTOC

OL

SUB-

STATION

BLDG-

HT

ROOM

1. 0 11KV SWITCHGEAR SIGNALS

(HPCL HT PANEL SIDE)

1. 1 11 KV INCOMING VCB 630A

350 MVA

ON/OFF/Auto trip - functions

I n c o m i n g H T

voltage/current/frequency,pow

er,M VA - Measurements

1.2 MICROPROCESSOR BASED

RELAYS - Trip circuit Un-

Healthy

1.3 MANUAL OPERATION

STATUS -

1.4 11 KV RECEIVING VCB 630A

350 MVA

ON/OFF/trip - functions

I n c o m i n g H T

voltage/current/frequency,pow

er,M VA - Measurements

1.5 MANUAL OPERATION

STATUSon/off

1.6 MICROPROCESSOR BASED

RELAYS - Trip circuit Un-

Healthy

BATTERY CHARGER:

1.7 BATTERY CHARGER - Mains

on/ DC supply on/fails

1.8 BATTERY VOLTAGE -

Measurement

S.No

.

DESCRIPTION DI AI STATUS ALARM CONTR

OL

LINK LOCATI

ON

MAIN POWER CONTROL

CENTER

Signals

are

to be

acquired

from

Circuit

Breakers

&

Relays

over

serial

interface.

Electrical

contractor

shall

make

available

CBs and

relays

with

RS 485

port and

MODBUS

RTU

PROTOC

OL

SUB-

STATION

BLDG-

MPCC

ROOM

2.0 433 V INCOMING FEEDERS

For TRANSFORMERS

2.1 INCOMING 433 V 3200 AMPS

ACBS

2.2 ON/OFF/Auto trip - functions

2.3 I n c o m i n g L T

voltage/current/frequency,power,

M VA - Measurements

2.4 MICROPROCESSOR BASED

RELAYS - Trip circuit Un-

Healthy

2.5 MANUAL OPERATION

STATUS

BUSCOUPLER: - 1 NO

2.6 BUS Coupler - On/off/trip

2.7 MANUAL OPERATION STATUS

- On/off

DG INCOMER feeders: - 2 NOS

2.8 DG INCOMER - ACBS -

On/off/trip

2.9 I n c o m i n g L T

voltage/current/frequency, KW,

kVA - Measurements

3.0 MICROPROCESSOR BASED

RELAYS - Trip circuit Un-

Healthy

3.1 MANUAL OPERATION

STATUS-

4.0 UPS MONITORING

1.0 STATUS MONITORING,

VOLTAGE, CURRENT, LOAD,

BATTERY VOLTAGE ETC

6 NOS 200 AND 2 NOS 100

KVA UPS - Total around 80

soft points

RS 485

port and

MODBUS

RTU

PROTOC

OL t o be

provided

by UPS

vendor

Ground

floor

U P S

room

S.No

.

DESCRIPTION DI AI STATUS ALARM CONTR

OL

LINK LOCATI

ON

2.0 KW. Voltage, Amps from each

feeder through DATA Load

manager meter - Total 28

feeder each 5 soft points =

140 soft points

* RS 485

port and

MODBUS

RTU

PROTOC

O L t o

be

provided

by

Electrical

vendor

AT

METER

LEVEL

SUB-

STATION

BLDG-

MPCC.

The

wiring

shall be

takenout

and

terminte

d at one

common

chamber

by

electrical

vendor.

3.0 DG set - ON/Off status, KW,

Amps, Voltage, Frequency

etc through PLC -

Approximately - 50 soft point

RS 485

port and

MODBUS

RTU

PROTOC

O L t o

be

provided

by

Electrical

vendor IN

PLC

PANEL

SUB-

STATION

BLDG-

MPCC

ROOM

Total

DI = DIGITAL INPUTS AI= ANALOG INPUTS

SECTION-II

I/O LIST FOR /LT ELECTRICAL MONITERING

S.No

.

DESCRIPTION DI AI STATUS

ALAR

M

CONTRO

L

LINK

4.00

433V OUTGOING FEEDERS -

On/off/Trip status

LIFT FEEDER- 2NOS

4.10 FIRE HYDRANT PANEL--1

Thorugh

DDC

controllers.

BMS

vendor

to provide

the

controller

along with

wiring.

Electrical

vendor to

provide the

necessary

Potential

free

contact in

the each

breakers.

The wiring

shall be

taken out

and

terminated

at

one

common

chamber

by

electrical

vendor

4.20

CHILLER NO.1 ,2,3, AND STAND BY

FEEDER

4.30 CHILLER PUMPS PANEL - 2 NOS

4.40 WORKSTATION UPS- 2NOS

4.50 APFC PANEL - 2 NOS

4.60 SPARES- 4 NOS

4.70 SUBSTATIION PANEL

4.80 EMERGENCY LIGHTING FEEDER

4.90 AC PANELS- 5 NOS

5.00

LIGHTING AND POWER FEEDER -

2NOS

5.10 UPS FEEDERS- 2NOS

SECTION-III

WATER MANAGEMENT SYSTEM I/O LIST

FUNCTIONS

S. No DESCRIPTION AI DO AO STATUS ALARM CONTROL CONTROL/

MONITORING

LOCATION

THROUGH

DDC.

Local display

shall be

provided

indicating water

level and

pumps status

UG SUMP

AREA

AND

TERRACE

OH TANK

1 Pump ON/OFF

2 P u m p

trip,ON/OFF status

3 Linear levels for all

the sumps and tanks

Total

SECTION-IV

LIGHTING MANAGEMENT SYSTEM - I/O LIST

Sr

No.

DESCRIPTION FUNCTION CONTROL /

MONITORI

NG

DI AI DO AO STATU

S

ALARM CONTROL LOCATI

ON

I LIGHTING

MANAGEMENT

SYSTEM -

Controller-1

1 External Street Lighting

&

ON/OFF

Contactor

shall be

provided by

the

Electrical

vendor.

Controllojng

through

DDC

by BMS

vendor

SUB

STATIO

N

FACADE LIGHTING SUB

STATIO

N

Lighting MCCB

ON/OFF

SUB

STATIO

N

Controller-2 - 6 sets

2 Incomer MCCB switch

on/OFF at Ground floor,

Second floor LSSB

At floor level,

shall be

provided by

the

Electrical

vendor.

Controllojng

through DDC

by BMS

vendor

At floor

level

3 Induvidual circuit

ON/OFF controlls -

Each controller - 20

circuits

TOTAL

SECTION-V

FIRE FIGHTING PUMPS I/O LIST

FUNCTION

Sr.No DESCRIPTION DI DO AI AO STATUS ALARM CONTROL CONROL

/MONITORING

A) HYDRANT and

SPRINKLER PUMPS:

Status

monitoring

through DDC.

Suitable

potential-free

contacts shall be

Made available

by the Fire

Fighting

contractor

1 JOCKEY

PUMP: -1 NOS

Pump Trip

/ON/OFF

Status

2 HYDRANT

PUMP:- 2NOS

Pump Trip

ON/OFF Status

3 SPRINLER

PUMP

STANDBY

PUMP- 2 NOS

Pump Trip/

ON/OFF Status

TOTAL

SECTION-VI

I/O LIST FOR LIFTS

FUNCTION CONTROL

/MONITORI

NG

LOCAT

ION

Sr.

NO

DISCRIPTION SP DI AI DO AO STATU

S

ALARM CONTRO

L

1 Monitor alarm

bell status of

lifts

For

monitoring

through

DDG.

Potential free

contacts

shall be

made

available

by

Elevators

supplier.

L i f t

machin

e room

2 Mo n i t o r

Fireman's

emergency

operation

status

3 Monitor

operation of

elevator in

'Attendant

mode'

4 Monitor lift

u n d e r

inspection/test

drive

5 Moni t or l i f t

under fire drive

6 Trip Alarm

7 ON/OFF Status

8 FLOOR LEVEL

Status(each

lift 3 levels= 2

nos x 3 levels)

Total

Вам также может понравиться

- BMS Sample IO Point ScheduleДокумент31 страницаBMS Sample IO Point ScheduleIshan Ranganath100% (2)

- I/O Summary For BMSДокумент2 страницыI/O Summary For BMSsafwan10100% (7)

- Testing and Commissioning Procedure For Building Management SystemДокумент8 страницTesting and Commissioning Procedure For Building Management SystemJane NixonОценок пока нет

- Wiring Diagram For BMS (DDC Panel)Документ40 страницWiring Diagram For BMS (DDC Panel)Slobodan80% (15)

- Checklist For Installation of BMS M Tower PDFДокумент2 страницыChecklist For Installation of BMS M Tower PDFAndrew Hiv100% (1)

- Sequence of Operation ChillerДокумент2 страницыSequence of Operation ChillerOoi Tze Hoong60% (5)

- I O Summary For BMSДокумент2 страницыI O Summary For BMSN Faathimaa Shabrina67% (3)

- BMS Sequence of OperationsДокумент18 страницBMS Sequence of OperationsRa Ar100% (2)

- BMS Commissining ChecklistДокумент52 страницыBMS Commissining ChecklistAnvay Patil100% (1)

- BMS Sequence of OperationДокумент29 страницBMS Sequence of Operationmohmmad alam Khan100% (1)

- BMS Single Line Diagram & Schedule of PointsДокумент11 страницBMS Single Line Diagram & Schedule of PointsChim Con86% (7)

- Chilled Water Sequence of OperationДокумент8 страницChilled Water Sequence of OperationRaulSaavedra100% (1)

- IO Summary For BMSДокумент2 страницыIO Summary For BMSAmol Bengiri75% (8)

- Appendix J - Qq01 Bms Io Points ListДокумент19 страницAppendix J - Qq01 Bms Io Points Listkkppkk1100% (4)

- BMSДокумент44 страницыBMSHari Krishna100% (5)

- Chiller Plant Manager - IO Summary-200219 PDFДокумент1 страницаChiller Plant Manager - IO Summary-200219 PDFShruti NandОценок пока нет

- Package Units ChecklistДокумент11 страницPackage Units Checklistemanuel92Оценок пока нет

- IO Summary - CPMДокумент4 страницыIO Summary - CPMapsinghformalОценок пока нет

- AHU OQ & PQ DocumentДокумент12 страницAHU OQ & PQ DocumentAnurag KumbhareОценок пока нет

- Air Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationДокумент6 страницAir Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationGopinath GopiОценок пока нет

- BMS Point ScheduleДокумент4 страницыBMS Point ScheduleGlishna Peushan WidanapathiranaОценок пока нет

- BMS Method StatementДокумент8 страницBMS Method StatementIbrahim A. Hajjaj80% (5)

- Chiller Operating SequenceДокумент3 страницыChiller Operating Sequencejomy_pj8106Оценок пока нет

- Commissioning Check List For Access Control SystemДокумент2 страницыCommissioning Check List For Access Control SystemTamer Eid50% (2)

- BMS Point Schedule - ExhaustiveДокумент2 страницыBMS Point Schedule - Exhaustiveabdullah sahibОценок пока нет

- BMS CatalogДокумент28 страницBMS CatalogdeepakajaydasОценок пока нет

- BMS Dependancy ListДокумент6 страницBMS Dependancy ListHemantSharmaОценок пока нет

- RFP - Services Related To Distributed Antenna System (DAS)Документ62 страницыRFP - Services Related To Distributed Antenna System (DAS)amhosny64Оценок пока нет

- 1159 To 11510 UpgradeДокумент16 страниц1159 To 11510 UpgradeMabu DbaОценок пока нет

- How To Build A Payment Integration With ATG CommerceДокумент5 страницHow To Build A Payment Integration With ATG CommerceVishnu Vardhan100% (1)

- Strategy of Bill GatesДокумент26 страницStrategy of Bill GatesDipen PatelОценок пока нет

- BMS-Concept IO Schedule For MEPДокумент8 страницBMS-Concept IO Schedule For MEPSINTO THOMASОценок пока нет

- Data Point Summary For Building Management SystemДокумент3 страницыData Point Summary For Building Management SystemBasil Oguaka100% (2)

- BMT Check List - XLSXДокумент6 страницBMT Check List - XLSXNedunuri.Madhav MurthyОценок пока нет

- IO SummaryДокумент8 страницIO SummaryVineeth VKОценок пока нет

- BMS IO Summary For QC2 R1 20.02.2013Документ9 страницBMS IO Summary For QC2 R1 20.02.2013Nedunuri.Madhav Murthy100% (2)

- BMS Control Cable SpecificationДокумент3 страницыBMS Control Cable SpecificationAddis Tesfaye67% (3)

- BMS Design - Interface RequirementsДокумент4 страницыBMS Design - Interface RequirementsJoanne Castro Agustin75% (4)

- CPD Elv BMSДокумент93 страницыCPD Elv BMSscribd99190Оценок пока нет

- 2727 Input Output SummaryДокумент4 страницы2727 Input Output SummaryMinh Nhut LuuОценок пока нет

- BMS ProcedureДокумент138 страницBMS ProcedureEnar Pau100% (3)

- HVAC System: Fan Coil UnitsДокумент11 страницHVAC System: Fan Coil UnitsmohamednavaviОценок пока нет

- Honeywell Building Management SystemДокумент26 страницHoneywell Building Management SystemDuy Phạm Văn100% (2)

- Sequence of OperationsДокумент12 страницSequence of Operationseyad100% (2)

- Bms Design Guide PDFДокумент95 страницBms Design Guide PDFalmig200100% (3)

- Boq VRFДокумент3 страницыBoq VRFPatrick Lincuna50% (2)

- IO Summary For IBMS Service PDFДокумент348 страницIO Summary For IBMS Service PDFpratimОценок пока нет

- IBMS & HVAC SpecsДокумент156 страницIBMS & HVAC SpecsHumaid ShaikhОценок пока нет

- Bms Tender SpecificationДокумент19 страницBms Tender SpecificationharishupretiОценок пока нет

- Marriott O&m Manual HvacДокумент63 страницыMarriott O&m Manual HvacSidharth RajanОценок пока нет

- DDC ControlsДокумент85 страницDDC Controlssui1981100% (1)

- BMS SpecificationДокумент10 страницBMS SpecificationsharafanyОценок пока нет

- 4 Commissioning Report of VRF CassetteДокумент4 страницы4 Commissioning Report of VRF CassetteMohammed IqbalОценок пока нет

- SOP - CPM Chiller Plant Sequence of Operation PDFДокумент10 страницSOP - CPM Chiller Plant Sequence of Operation PDFSuren VelletheryОценок пока нет

- Direct Digital ControlДокумент60 страницDirect Digital ControlAkaka32150% (2)

- Direct Digital Control For HVAC (BMS)Документ56 страницDirect Digital Control For HVAC (BMS)Humaid Shaikh100% (3)

- General Bms PresentationДокумент18 страницGeneral Bms PresentationsinyjoОценок пока нет

- Bms & Hvac SystemДокумент41 страницаBms & Hvac SystemMostafa AliОценок пока нет

- Trosten Ahu CatalogueДокумент88 страницTrosten Ahu CatalogueJohn Son G80% (5)

- AHU Operational Control Spreadsheet TrainingДокумент17 страницAHU Operational Control Spreadsheet Trainingniti860Оценок пока нет

- BMS Technical SubmittalДокумент226 страницBMS Technical SubmittalAZGAR MOHAMMEDОценок пока нет

- Data Point Summary For Building Management SystemДокумент3 страницыData Point Summary For Building Management SystemawadalmekawyОценок пока нет

- STC-TRS-08-Course Contents of Three Phase Loco - System DescriptionДокумент182 страницыSTC-TRS-08-Course Contents of Three Phase Loco - System Descriptionbattery sectionОценок пока нет

- CB Pcs-140E Pump Control System: Features and BenefitsДокумент3 страницыCB Pcs-140E Pump Control System: Features and Benefitsfauzi endraОценок пока нет

- Cyber Threat Intelligence - Maturity and MetricsДокумент37 страницCyber Threat Intelligence - Maturity and Metricsamhosny64100% (2)

- Big Data, The Internet of Things, and The Revised Knowledge PyramidДокумент12 страницBig Data, The Internet of Things, and The Revised Knowledge Pyramidamhosny64Оценок пока нет

- Integrated Active Cyber Defense.Документ10 страницIntegrated Active Cyber Defense.amhosny64Оценок пока нет

- Stages of Team Development & Role of Team LeaderДокумент1 страницаStages of Team Development & Role of Team Leaderamhosny64Оценок пока нет

- It AssessmentДокумент69 страницIt Assessmentamhosny64Оценок пока нет

- Understanding Our Customers 2014Документ14 страницUnderstanding Our Customers 2014amhosny64Оценок пока нет

- Modelling, Simulation and Control Design For Robotic Manipulators PDFДокумент16 страницModelling, Simulation and Control Design For Robotic Manipulators PDFamhosny64100% (2)

- VLAN Trunking Protocol (VTP)Документ12 страницVLAN Trunking Protocol (VTP)amhosny64Оценок пока нет

- PowerShell Vs BashДокумент5 страницPowerShell Vs Bashamhosny64Оценок пока нет

- Feasibility Study and Business PlanДокумент7 страницFeasibility Study and Business Planamhosny64Оценок пока нет

- Solar Powered Motorized Easyshade®: Owner'S Manual & Installation InstructionsДокумент20 страницSolar Powered Motorized Easyshade®: Owner'S Manual & Installation Instructionsamhosny64Оценок пока нет

- Analyst Report Idc Marketscape Web Security 2016 enДокумент27 страницAnalyst Report Idc Marketscape Web Security 2016 enamhosny64Оценок пока нет

- Cisco Aironet 2700 Series Access Points: High Density Experience (HD Experience)Документ10 страницCisco Aironet 2700 Series Access Points: High Density Experience (HD Experience)juanОценок пока нет

- P Intlk 2.0 SyslibДокумент40 страницP Intlk 2.0 Syslibcarbono980Оценок пока нет

- ZXCCXДокумент5 страницZXCCXSergiu-Gabriel MaximovОценок пока нет

- Communications Engineering Part 12 Data Communications Multiple Choice: Encircle The Letter That Corresponds To Your AnswerДокумент10 страницCommunications Engineering Part 12 Data Communications Multiple Choice: Encircle The Letter That Corresponds To Your AnswerJesther LiwagОценок пока нет

- Brother Partes NQ 1400 e CompressedДокумент35 страницBrother Partes NQ 1400 e CompressedMichel Saez100% (1)

- ATV21 Programlama Kılavuzu enДокумент145 страницATV21 Programlama Kılavuzu enUsman KhanОценок пока нет

- At A Glance c45-513837Документ5 страницAt A Glance c45-513837Arturo JimenezОценок пока нет

- Thinclient 19Документ9 страницThinclient 19api-3833258100% (2)

- Oil Dielectric Test Sets: 0-60 Kvac and 0-100 KvacДокумент3 страницыOil Dielectric Test Sets: 0-60 Kvac and 0-100 KvacNurhadi SukmanaОценок пока нет

- Hypervisor ComparisonДокумент5 страницHypervisor ComparisonEhtesham OpelОценок пока нет

- Documentation Banana Island+PSD+3DДокумент10 страницDocumentation Banana Island+PSD+3DdededuduОценок пока нет

- Visual Studio Code 2016 SuccinctlyДокумент128 страницVisual Studio Code 2016 SuccinctlyAbul Kashem100% (3)

- The Perfect Start With Smoothwall Express 3.0Документ22 страницыThe Perfect Start With Smoothwall Express 3.0Oswaldo ArchundiaОценок пока нет

- Skid Loader: Service Parts ManualДокумент210 страницSkid Loader: Service Parts Manualtriand87Оценок пока нет

- TOA Ev20rДокумент24 страницыTOA Ev20rCheco PachecoОценок пока нет

- Q250 SM Pneumatic Spinning WrenchДокумент11 страницQ250 SM Pneumatic Spinning WrenchGianna FrolaОценок пока нет

- General Purpose Input/Output (GPIO)Документ6 страницGeneral Purpose Input/Output (GPIO)sweetsureshОценок пока нет

- Module 2: Assigning IP Addresses in A Multiple Subnet NetworkДокумент62 страницыModule 2: Assigning IP Addresses in A Multiple Subnet NetworkAkid AliОценок пока нет

- CT 320: Network and System Administra8on Fall 2014Документ42 страницыCT 320: Network and System Administra8on Fall 2014IjazKhanОценок пока нет

- GUI Implementation of Image Encryption and Decryption Using Open CV-Python Script On Secured TFTP ProtocolДокумент9 страницGUI Implementation of Image Encryption and Decryption Using Open CV-Python Script On Secured TFTP Protocolvijay kumarОценок пока нет

- USG 5000 Introduction PDFДокумент37 страницUSG 5000 Introduction PDFviktor220378Оценок пока нет

- Eng TELE-satellite 1205Документ276 страницEng TELE-satellite 1205Alexander WieseОценок пока нет

- Grundfosliterature 3153315Документ60 страницGrundfosliterature 3153315stuart3962Оценок пока нет

- He Xi DecimalДокумент147 страницHe Xi DecimalJoeandLaura Walk To VegasОценок пока нет

- Sharp Ar 235 275 CopiersДокумент6 страницSharp Ar 235 275 CopiersDepkoОценок пока нет

- IMU Basic Knowledge English Final 11-03-14Документ102 страницыIMU Basic Knowledge English Final 11-03-14ramchandra rao deshpandeОценок пока нет

- IT Task Technology in Military: Muhammad Athallah 107 Ricky Adrianto 114 Dessyana Damayanti 161 Daffa Ramadhan S 293Документ9 страницIT Task Technology in Military: Muhammad Athallah 107 Ricky Adrianto 114 Dessyana Damayanti 161 Daffa Ramadhan S 293LaОценок пока нет