Академический Документы

Профессиональный Документы

Культура Документы

JF

Загружено:

rajarathnam.kАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JF

Загружено:

rajarathnam.kАвторское право:

Доступные форматы

Fan solutions

for underground and car parks

Issue 2.0 EN

The Jetfan more safety for

underground car parks and passages

The architects of today are designing buildings on a larger scale

than ever before. Giant buildings are being erected, often with

labyrinthine underground car parks and passages.

The result: people often cant find their way back to ground level

in a fire. Those trapped are placed in serious danger. It is therefore

crucial that effective smoke ex traction systems are installed in

underground public spaces. The new Jetfan concept from Nicotra

Gebhardt is pioneering a new generation of smoke extraction

solutions to meet this need.

The system. The safety. The service.

Ductless ventilation and safe smoke

extraction the Jetfan provides both

Jetfan serves to provide both normal ventilation and smoke

extraction in equal measure.

In doing so, it has a twofold function: it improves the air quality

during normal operation and guarantees a higher level of safety

in a fire. And all this at a fraction of the price of conventional

systems.

Cost, safety, design

the benefits of Jetfan

Jetfan has many advantages over classic duct systems:

A The Jetfan can partially ventilate or extract smoke

A The dynamic airflow means that all layers of air throughout

the entire car park are intermingled; the concentration of toxic

substances is much lower than in the case of conventional units

with ventilation ducts.

A The flexible positioning of Jetfans means that dead spots

(where there is no airflow) are prevented.

A Jetfans are flexible and can be adapted to suit changes in the

use of space.

A Expensive large-scale ducts are not required. Such ducts are

not effective if air inlet and outlet ducts are more than a certain

distance apart.

A The car park becomes lighter and more pleasing for clients, as

no bulky ventilation ducts impinge upon the environment. This

means an enormous saving of space, along with increased

efficiency in comparison with conventional systems.

A Air outlet fans operate at significantly lower thrust levels, as no

duct network is required (energy saving).

A Air inlet fans are not required at all if free slipstreaming is in

place.

available as a one-way airflow or reversible fan.

Each type of fan is available in two sizes.

The principle

behind Jetfan air extraction systems:

construction and positioning

As with tunnel ventilation, Jetfans are

mounted on the ceiling and achieve their effect by means of

the thrust (impulse) of the air outflow. A high induction of the

surround ing air is produced here, and after a short time the

volume of air in the entire space begins to circulate. This effect

results in the transferred volume of air being several times greater

than the actual flow volume of the fan. This central airflow is then

drawn into the low-pressure area of the centrally aligned outlet air

channel. The advantage: duct systems are not re quired.

Both the alignment of fans and the positioning and dimensions

of the slipstream air vents are of decisive importance for the

effectiveness of such a system. The formation of a continuous

airflow in the direction of the outlet air channel is significant here.

Technology and material:

Jetfan AGM 01/11, RGM 91/96

and Jetfan premium

AGM 02/12, AGM 06/16

Jetfan is available in the form of a reasonably priced standard

version and an elaborately designed premium version.

All three of these models are available in two versions, which are

in turn available in two sizes. The casing for all of these products

is made of galvanised sheet steel and features noise suppressors

integrated on both sides.

The axial fan built into the AGM 01 transports the air by exerting

pressure from the motor as standard. The AGM 11, on the other

hand, is designed for reversible operation. It can exert both

pressure, via the motor, and suction on the flow medium. The

radial fan built into the RGM transports the air from an vertical inlet

to horizontal discharge.

The impeller wheel of the AGM is made of pressure die-cast

aluminium, the centrifugal impeller of the RGM is made of sheet

steel, welded and coated. They are balanced according to

DIN ISO 1940. The impellers adopted flying on the shaft of the

drive motor located within the flow of air.

The thermally resistant connecting cable is protected against

mechanical damage.

A temperature-resistant, metal connection box is located on the

side of the casing. An air-conveyance unit made of sheet steel

slats is mounted on the pressure side (AGM 01/02, RGM) or on

the pressure and suction side (AGM 11). This serves to draw the

airflow in the direction required. On the suction side of the AGM

01/02 and RGM there is protective grating made of steel.

Jetfan AGM 01/11, premium AGM 02/12 and RGM 91 have been

tested according to EN 12101-3 at 300 C 120 min in a testing

laboratory at TUM (Munich Technical University) and exceed the

legally required standards.

Jetfan premium AGM 06/16 and RGM 96 is suited for the

ventilation of dangerous CO-gases up to +40 C.

available as a one-way airflow or reversible fan.

Each type of fan is available in two sizes.

Jetfan RGM:

with vertical discharge.

A reason for he is suitable for narrow installation dimensions.

Ventilation

the Jetfan air outlet system

In normal day-to-day operation, the Jetfans are controlled by the

CO system in accordance with the concentration threshold

setting. In this way, carbon monoxide-contaminated air is

extracted from the car park. This takes place with either just a few

Jetfans operating at a low speed, or with all system components

operating at a higher output level, depending on the concentration

in the air.

Our service: smoke flow simulation for

perfect planning

We will assist you in the detailed planning and dimensioning of car

park ventilation equipment, by means of a smoke flow simulation

using computational fluid dynamics (CFD).

With the help of CFD, the ideal smoke extraction and ventilation

system including the number and positioning of Jetfans required

can be determined for each construction project, based on the

legal requirements (GarVO).

We recommend the use of an airflow-simulation for large garages

with difficult geometries.

It offers maximum planning security and is an invaluable tool for

assessing the entire system.

Smoke extraction

the Jetfan smoke extraction system

In the event of smoke needing to be extracted, the Jetfans are

immediately activated at maximum speed by smoke detectors,

regardless of the CO system setting, in order to extract smoke

from the area of the fire. The central ventilation shafts are switched

to full power at the same time.

A significant advantage of the Jetfan smoke extraction system

lies in the fact that smoke can be partially extracted from the

immediate area of the fire. In other words, the Jetfans can be used

to control smoke levels as well. This avoids the costly process of

dividing a car park up into separate sections to reduce the spread

of fire.

No penetration of the ceiling is required for the installation

of Jetfans either, meaning that the structural concept of the

underground car park is simplified significantly as well, therefore

contributing further to the reduction of investment costs. Jetfans

can also be expected to generate very low operating costs on the

whole because partial ventilation is also possible.

And in addition to all of this: Jetfan systems offer maximum safety

in a fire and meet all statutory requirements.

Your contact at Nicotra Gebhardt will be happy to provide you with

further information. Alternatively, you can contact us by telephone

on +49(0)7942101-0.

In short:

more safety, less costs

The largest financial benefit of Jetfans lies in the savings made

in investment costs. Depending on the results of the smoke flow

simulation, experience shows that lower investment costs are

involved in installing the respective number of Jetfans, compared

with the complete installation of a duct system with a central air

outlet unit.

Jetfan AGM premium Jetfan AGM

300 C 120 min.

No. 0036 CPD RG01 09

300 C 120 min.

No. 0036 CPD RG01 09

Jetfan RGM

300 C 120 min.

No. 0036 CPD RG01 11

What should the perfect smoke extraction system for underground

car parks offer? This was the question on our minds when we

came up with our new pulse fan system. The result

is the Jetfan, a solution which boasts impressive

technology, functionality and a striking design.

Interested in

rock-bottom prices?

With the Jetfan, you save on investments across the board. Thanks

to the pulse fan system, there is no need to invest in expensive,

large-scale duct systems and high-maintenance smoke extraction

flaps. The bigger the garage or ventilation

system, the more money you save with the jet system. Whats

more, you will benefit from our computer-aided smoke flow

simulation during the planning stage. Discover low, low prices for

underground car park smoke extraction: with the Jetfan.

Cleaner air for underground car parks:

Pulse fan systems

with thrust up to 52 N

Pulse fan systems

with thrust up to 52 N

Pulse centrifugal fan systems

with thrust up to 75 N

A

G

M

|

R

G

M

3

0

0

C

A All models have CE certification.

A The Jetfan can be used for partial smoke extraction or ventilation.

A The flexible positioning of the Jetfan makes sure there are no

areas where air does not circulate.

A The Jetfan makes expensive, large-scale duct systems

unnecessary.

A Fresh air fans can become superfluous if there is a free flow of

new air.

A The flexible fans can be adapted to cater for a change in the use

of space.

A The Jetfan is available as an affordable standard version or as the

Jetfan premium with a high-end design.

A Then Jetfan is available in two sizes and as a reversible fan.

A Pole-changing motors offer greater ventilation flexibility.

A Non-corrosive materials guarantee a long life.

A Integrated silencers for quieter permanent ventilation (approved

for up to +40 C)

A Nicotra Gebhardt offers the complete system solution:

- Jetfan for smoke extraction up to +300 C for 120 min.

- Jetfan for ventilation of CO-gases up to +40 C

- axial or radial shaft fans and roof fans

- switchgear cabinets with or without CO warning systems or

SPS control

- complete system sensors

- right the way through to commissioning and official approval

The ultimate system

for ultimate safety

The Jetfan is the ideal solution for heightened safety in underground

car parks and underpasses.

Choose the ultimate system for safer and more aesthetic

underground constructions.

10

544

580

3

4

9

3

4

1

1000 1000

2400

185 185

420

500

14

110

544

580

3

4

9

3

4

1

1000 1000

2400

185 185

420

500

14

110 100

AGM 01-0315-..

AGM 11-0315-..

AGM 01-/11-0315, 300 C 120 min.

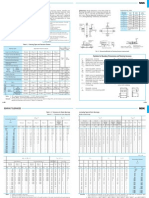

5 N m/s V (3~) Hz 1/min kW A dB AT kg

AGM 01-

0315-2D-10 30 21 2 230/400 /Y 50 2830 0.75 3.70/2.10 5.6 80 64 92

0315-FD-11 30/7.5 21/10 2/4 400 YY/Y 50 2820/1385 0.95/0.25 2.35/0.63 4.2/3.8 80 64/46 92

AGM 11-

0315-2D-10 18 16 2 230/400 /Y 50 2830 0.75 3.70/2.10 5.6 80 62 93

0315-FD-11 18/4.5 16/ 8 2/4 400 YY/Y 50 2820/1385 0.95/0.25 2.35/0.63 4.2/3.8 80 62/46 93

not reversible

reversible

- Smoke detecting switch unit

- Optical smoke detector with mounting base

- Manual switch

- CO-measuring unit

Accessories / Index

5 Connection diagrams see www.nicotra-gebhardt.com

AT Sound pressure measurement measured at the centre line below the fan

Smoke Extract Pulse Fans / AGM/RGM / Technical Data

Accessories (on request)

Technical Data

Thrust Discharge Poles Voltage/ Fre- Speed Nominal Nominal Starting/Full Motor Sound pressure level

Weight

speed Connection quency power current load current size L

pA

at 1 m distance

not reversible

reversed operation - data indicating flow direction over motor

Fan and accessories

tested to EN 12101-3

Certicate of EC conformity:

0036 CPD RG01 09

Impulse smoke extraction fan

AGM 01

Air flow in direction of motor

(pressure) - not reversible

AGM 11

Air flow in direction of motor

(pressure/suction) - reversible

Dimensions in mm, Subject to change.

11

644

680

4

3

5

4

2

7

1000 1000

2450

210 210

470

600

14

110

644

680

4

3

5

4

2

7

1000 1000

2450

210 210

470

600

14

110 100

AGM 01-/11-0400, 300 C 120 min.

AGM 01-0400-..

AGM 11-0400-..

5 N m/s V (3~) Hz 1/min kW A dB AT kg

AGM 01-

0400-2D-11 52 21 2 230/400 /Y 50 2845 1.10 4.70/2.70 6.1 80 65 114

0400-FD-11 52/13 21/10 2/4 400 YY/Y 50 2820/1385 0.95/0.25 2.35/0.63 4.2/3.8 80 65/48 114

AGM 11-

0400-2D-11 45 20 2 230/400 /Y 50 2845 1.10 4.70/2.70 6.1 80 68 115

0400-FD-11 45/11 20/10 2/4 400 YY/Y 50 2820/1385 0.95/0.25 2.35/0.63 4.2/3.8 80 68/51 115

Fan and accessories

tested to EN 12101-3

Certicate of EC conformity:

0036 CPD RG01 09

Impulse smoke extraction fan

AGM 01

Air flow in direction of motor

(pressure) - not reversible

AGM 11

Air flow in direction of motor

(pressure/suction) - reversible

Smoke Extract Pulse Fans / AGM/RGM / Technical Data

Dimensions in mm, Subject to change.

not reversible

reversible

Technical Data

- Smoke detecting switch unit

- Optical smoke detector with mounting base

- Manual switch

- CO-measuring unit

Accessories / Index

5 Connection diagrams see www.nicotra-gebhardt.com

AT Sound pressure measurement measured at the centre line below the fan

Accessories (on request)

Thrust Discharge Poles Voltage/ Fre- Speed Nominal Nominal Starting/Full Motor Sound pressure level

Weight

speed Connection quency power current load current size L

pA

at 1 m distance

not reversible

reversed operation - data indicating flow direction over motor

12

370

406

3

5

4

1000 1000

2400

165 165

390

500

14

110

700

3

6

2

370

406

3

6

2

3

5

4

1000 1000

2400

165 165

390

14

110 100

500

700

AGM 02-/12-0315, 300 C 120 min.

AGM 02-0315-..

AGM 12-0315-..

5 N m/s V (3~) Hz 1/min kW A dB AT kg

AGM 02-

0315-2D-10 30 21 2 230/400 /Y 50 2830 0.75 3.70/2.10 5.6 80 64 92

0315-FD-11 30/7.5 21/10 2/4 400 YY/Y 50 2820/1385 0.95/0.25 2.35/0.63 4.2/3.8 80 64/46 92

AGM 12-

0315-2D-10 18 16 2 230/400 /Y 50 2830 0.75 3.70/2.10 5.6 80 62 93

0315-FD-11 18/4.5 16/ 8 2/4 400 YY/Y 50 2820/1385 0.95/0.25 2.35/0.63 4.2/3.8 80 62/46 93

Smoke Extract Pulse Fans / AGM/RGM / Technical Data

Fan and accessories

tested to EN 12101-3

Certicate of EC conformity:

0036 CPD RG01 10

Impulse smoke extraction fan

premium

AGM 02

Air flow in direction of motor

(pressure) - not reversible

AGM 12

Air flow in direction of motor

(pressure/suction) - reversible

Dimensions in mm, Subject to change.

not reversible

reversible

- Smoke detecting switch unit

- Optical smoke detector with mounting base

- Manual switch

- CO-measuring unit

Accessories / Index

5 Connection diagrams see www.nicotra-gebhardt.com

AT Sound pressure measurement measured at the centre line below the fan

Accessories (on request)

Technical Data

not reversible

reversed operation - data indicating flow direction over motor

Thrust Discharge Poles Voltage/ Fre- Speed Nominal Nominal Starting/Full Motor Sound pressure level

Weight

speed Connection quency power current load current size L

pA

at 1 m distance

13

456

492

4

4

0

1000 1000

2450

190 190

440

600

14

110

840

4

4

8

456

492

4

4

8

4

4

0

1000 1000

2450

190 190

440

14

110 100

600

840

AGM 02-/12-0400, 300 C 120 min.

AGM 02-0400-..

AGM 12-0400-..

5 N m/s V (3~) Hz 1/min kW A dB AT kg

AGM 02-

0400-2D-11 52 21 2 230/400 /Y 50 2845 1.10 4.70/2.70 6.1 80 65 114

0400-FD-11 52/13 21/10 2/4 400 YY/Y 50 2820/1385 0.95/0.25 2.35/0.63 4.2/3.8 80 65/48 114

AGM 12-

0400-2D-11 45 20 2 230/400 /Y 50 2845 1.10 4.70/2.70 6.1 80 68 115

0400-FD-11 45/11 20/10 2/4 400 YY/Y 50 2820/1385 0.95/0.25 2.35/0.63 4.2/3.8 80 68/51 115

Smoke Extract Pulse Fans / AGM/RGM / Technical Data

Fan and accessories

tested to EN 12101-3

Certicate of EC conformity:

0036 CPD RG01 10

Impulse smoke extraction fan

premium

AGM 02

Air flow in direction of motor

(pressure) - not reversible

AGM 12

Air flow in direction of motor

(pressure/suction) - reversible

Dimensions in mm, Subject to change.

not reversible

reversible

- Smoke detecting switch unit

- Optical smoke detector with mounting base

- Manual switch

- CO-measuring unit

Accessories / Index

5 Connection diagrams see www.nicotra-gebhardt.com

AT Sound pressure measurement measured at the centre line below the fan

Accessories (on request)

Technical Data

not reversible

reversed operation - data indicating flow direction over motor

Thrust Discharge Poles Voltage/ Fre- Speed Nominal Nominal Starting/Full Motor Sound pressure level

Weight

speed Connection quency power current load current size L

pA

at 1 m distance

14

834

870

8

5

2

5

9

1265

185

395

790

2

2

7

14

787

185

RGM 91-0600, 300 C 120 min.

5 N m/s V (3~) Hz 1/min kW A kg

RGM 91-0600, 300 C 120 min.

0600-4D-15 50 25.0 4 230/400 /Y 50 1435 1.5 5.80/3.30 5.8 90 L 130

0600-ID-15 50/23 25.0/17.0 4/6 400 YY/Y 50 1425/955 1.5/0.55 3.60/1.80 7.4/3.9 90 L 130

0600-GD-15 50/13 25.0/13.0 4/8 400 YY/Y 50 1420/720 1.3/0.22 3.00/1.15 5.4/3.4 90 L 130

RGM 91-0600, 300 C 120 min.

L

pA, 1m

dB 63 125 250 500 1000 2000 4000 8000 Hz

RGM 91-0600-..

4 77 64 79 75 75 71 69 66 60 dB

6 66 66 70 65 64 61 57 54 48 dB

8 59 68 62 58 57 54 49 46 39 dB

Dimensions in mm, Subject to change.

- Smoke detecting switch unit

- Optical smoke detector with mounting base

- Manual switch

- CO-measuring unit

Accessories / Index

5 Connection diagrams for fan and isolator to be found online at www.nicotra-gebhardt.com

Smoke Extract Pulse Fans / AGM/RGM / Technical Data

Accessories (on request)

Technical Data

Thrust Discharge Poles Voltage/ Fre- Speed Nominal Nominal Starting/Full Motor appr.

speed Connection quency power current load current size weight

Attention! In the case of fire fans with 2-speed motors must only be operated at high speed.

Sounds

Fan type Poles

L

pfc, 1m

at f

c

The sound pressure level was measured in a distance of 1 m in two positions. The average values are shown in the table.

15

1194

1230

1

0

0

3

1

9

1902

210

575

1150

2

7

9

14

1150

210

L

pA, 1m

dB 63 125 250 500 1000 2000 4000 8000 Hz

RGM 91-0610-..

4 83 74 87 81 80 77 75 68 63 dB

6 71 72 79 71 68 66 62 55 50 dB

8 63 74 68 61 61 58 52 45 40 dB

5 N m/s V (3~) Hz 1/min kW A kg

RGM 91-0610, 300 C 120 min.

0610-4D-16 75 23.5 4 230/400 /Y 50 1435 2.2 8.60/5.00 6.4 100 L 180

0610-ID-16 75/34 23.5/16.0 4/6 400 YY/Y 50 1425/955 2.2/0.75 5.00/2.60 7.1/4.0 100 L 180

0610-GD-16 75/19 23.5/12.0 4/8 400 YY/Y 50 1430/715 2.2/0.37 5.10/1.60 6.3/3.8 100 L 180

RGM 91-0610, 300 C 120 min.

RGM 91-0610, 300 C 120 min.

Dimensions in mm, Subject to change.

- Smoke detecting switch unit

- Optical smoke detector with mounting base

- Manual switch

- CO-measuring unit

Accessories / Index

5 Connection diagrams for fan and isolator to be found online at www.nicotra-gebhardt.com

Smoke Extract Pulse Fans / AGM/RGM / Technical Data

Accessories (on request)

Technical Data

Thrust Discharge Poles Voltage/ Fre- Speed Nominal Nominal Starting/Full Motor appr.

speed Connection quency power current load current size weight

Attention! In the case of fire fans with 2-speed motors must only be operated at high speed.

Sounds

Fan type Poles

L

pfc, 1m

at f

c

The sound pressure level was measured in a distance of 1 m in two positions. The average values are shown in the table.

16

AGM 01-0315/-0400, 300 C 120 min.

Smoke extract jetfan AGM 01

Suitable for smoke extraction in the case of fire

up to 300 C 120 min,

tested to DIN EN 12101-3 and CE certified.

Certificate of EC conformity: 0036 CPD RG01 09

DIBt approval number: Z-78.11-153

Suitable as fan for continuous standard ventilation up to 40 C.

Certified for horizontal installation inside of a room where fire may occur.

Conveying direction blowing over motor (pressure).

Casing made of galvanised sheet steel and equipped with silencer at both ends.

Integrated air flow straightener for achieving a turbulence free air stream.

Adjustable guide vanes made of galvanised steel sheet at discharge, intake guard at

suction side.

Axial fan impeller with aerofoil blades made of corrosion resistant cast aluminium, ba-

lanced to DIN ISO 1940 Class G 6,3.

Certified motor for smoke gases, protection IP 55, ISO H, maximum operation allo-

wed to ISO F.

Protected, heat resistant electrical feed cable,

leading to metal connection box fixed on fan casing,

Tappings provided for high temperature resistance.

Options (at choice)

l single speed (3~)

l two speed (3~)

l speed controlled by inverter during standard ventilation operation

(max. working frequency admitted 50 Hz)

Fan type AGM 01-

Thrust F =

. . . . . . . . . . . . . . . . . . . . .

N

Discharge velocity v =

. . . . . . . . . . . . . . . . . . . . .

m/s

Reference density r

1

=

. . . . . . . . . . . . . . . . . . . . .

kg/m

max. smoke extract temp. t/T =

. . . . . . . . . . . . . . . . . . . . .

C/min

max. ventilation temperature t =

. . . . . . . . . . . . . . . . . . . . .

C

Rated speed N =

. . . . . . . . . . . . . . . . . . . . .

1/min

Nominal power P

N

=

. . . . . . . . . . . . . . . . . . . . .

kW

Nominal current I

N

=

. . . . . . . . . . . . . . . . . . . . .

A

Voltage/Frequency U/f =

. . . . . . . . . . . . . . . . . . . . .

V/Hz

A-Sound pressure level L

pA

=

. . . . . . . . . . . . . . . . . . . . .

dB

Dimensions (LWH) =

. . . . . . . . . . . . . . . . . . . . .

mm

Weight m =

. . . . . . . . . . . . . . . . . . . . .

kg

Fan and accessories tested

to EN 12101-3

Certicate of EC conformity:

0036 CPD RG01 09

General technical approval;

Approval number: Z-78.11-153

Specication

Smoke Extract Pulse Fans / AGM/RGM / Specications

Special paint on request

Simulation on request

Switch and control cabinet with or w/o CO-warning system including all necessary equipment (CO-

sensors, signal horn, blinking lamp, warning panels, etc.)

Optical smoke detector

Manual trigger switch

Description see accessories

Connection diagrams see www.nicotra-gebhardt.com

Special ttings (at extra cost)

Accessories (on request)

17

AGM 11-0315/-0400, 300 C 120 min.

Smoke extract jetfan AGM 11

Suitable for smoke extraction in the case of fire

up to 300 C 120 min,

tested to DIN EN 12101-3 and CE certified.

Certificate of EC conformity: 0036 CPD RG01 09

DIBt approval number: Z-78.11-153

Suitable as fan for continuous standard ventilation up to 40 C.

Certified for horizontal installation inside of a room where fire may occur.

Reversible - Conveying direction blowing over motor or inverse (pressure or suction)

Casing made of galvanised sheet steel and equipped with silencer at both ends.

Two integrated air flow straighteners for achieving a turbulence free air stream. Adju-

stable guide vanes made of galvanised steel sheet at discharge and intake.

Axial fan impeller with aerofoil blades made of corrosion resistant cast aluminium, ba-

lanced to DIN ISO 1940 Class G 6,3.

Certified motor for smoke gases, protection IP 55, ISO H, maximum operation allo-

wed to ISO F.

Protected, heat resistant electrical feed cable,

leading to metal connection box fixed on fan casing,

Tappings provided for high temperature resistance.

Options (at choice)

l single speed (3~)

l two speed (3~)

l speed controlled by inverter during standard ventilation operation

(max. working frequency admitted 50 Hz)

Fan type AGM 11-

Thrust F =

. . . . . . . . . . . . . . . . . . . . .

N

Discharge velocity v =

. . . . . . . . . . . . . . . . . . . . .

m/s

Reference density r

1

=

. . . . . . . . . . . . . . . . . . . . .

kg/m

max. smoke extract temp. t/T =

. . . . . . . . . . . . . . . . . . . . .

C/min

max. ventilation temperature t =

. . . . . . . . . . . . . . . . . . . . .

C

Rated speed N =

. . . . . . . . . . . . . . . . . . . . .

1/min

Nominal power P

N

=

. . . . . . . . . . . . . . . . . . . . .

kW

Nominal current I

N

=

. . . . . . . . . . . . . . . . . . . . .

A

Voltage/Frequency U/f =

. . . . . . . . . . . . . . . . . . . . .

V/Hz

A-Sound pressure level L

pA

=

. . . . . . . . . . . . . . . . . . . . .

dB

Dimensions (LWH) =

. . . . . . . . . . . . . . . . . . . . .

mm

Weight m =

. . . . . . . . . . . . . . . . . . . . .

kg

Fan and accessories tested

to EN 12101-3

Certicate of EC conformity:

0036 CPD RG01 09

General technical approval;

Approval number: Z-78.11-153

Specication

Smoke Extract Pulse Fans / AGM/RGM / Specications

Special paint on request

Simulation on request

Switch and control cabinet with or w/o CO-warning system including all necessary equipment (CO-

sensors, signal horn, blinking lamp, warning panels, etc.)

Optical smoke detector

Manual trigger switch

Description see accessories

Connection diagrams see www.nicotra-gebhardt.com

Special ttings (at extra cost)

Accessories (on request)

18

AGM 02-0315/-0400, 300 C 120 min.

Fan type premium AGM 02-

Thrust F =

. . . . . . . . . . . . . . . . . . . . .

N

Discharge velocity v =

. . . . . . . . . . . . . . . . . . . . .

m/s

Reference density r

1

=

. . . . . . . . . . . . . . . . . . . . .

kg/m

max. smoke extract temp. t/T =

. . . . . . . . . . . . . . . . . . . . .

C/min

max. ventilation temperature t =

. . . . . . . . . . . . . . . . . . . . .

C

Rated speed N =

. . . . . . . . . . . . . . . . . . . . .

1/min

Nominal power P

N

=

. . . . . . . . . . . . . . . . . . . . .

kW

Nominal current I

N

=

. . . . . . . . . . . . . . . . . . . . .

A

Voltage/Frequency U/f =

. . . . . . . . . . . . . . . . . . . . .

V/Hz

A-Sound pressure level L

pA

=

. . . . . . . . . . . . . . . . . . . . .

dB

Dimensions (LWH) =

. . . . . . . . . . . . . . . . . . . . .

mm

Weight m =

. . . . . . . . . . . . . . . . . . . . .

kg

Smoke extract jetfan premium AGM 02

Suitable for smoke extraction in the case of fire

up to 300 C 120 min,

tested to DIN EN 12101-3 and CE certified.

Certificate of EC conformity: 0036 CPD RG01 10

DIBt approval number: Z-78.11-153

Suitable as fan for continuous standard ventilation up to 40 C.

Certified for horizontal installation inside of a room where fire may occur.

Conveying direction blowing over motor (pressure)

Stylish, elliptical design and equipped with silencer made of galvanised sheet steel at

both ends. Centre part with fixing brackets coated black.

Integrated air flow straightener for achieving a turbulence free air stream.

Adjustable guide vanes made of galvanised steel sheet at discharge, intake guard at

suction side.

Axial fan impeller with aerofoil blades made of corrosion resistant cast aluminium, ba-

lanced to DIN ISO 1940 Class G 6.3.

Certified motor for smoke gases, protection IP 55, ISO H, maximum operation allo-

wed to ISO F.

Protected, heat resistant electrical feed cable,

leading to metal connection box fixed on fan casing,

Tappings provided for high temperature resistance.

Options (at choice)

l single speed (3~)

l two speed (3~)

l speed controlled by inverter during standard ventilation operation

(max. working frequency admitted 50 Hz)

Fan and accessories tested

to EN 12101-3

Certicate of EC conformity:

0036 CPD RG01 10

General technical approval;

Approval number: Z-78.11-153

Smoke Extract Pulse Fans / AGM/RGM / Specications

Specication

Special paint on request

Simulation on request

Switch and control cabinet with or w/o CO-warning system including all necessary equipment (CO-

sensors, signal horn, blinking lamp, warning panels, etc.)

Optical smoke detector

Manual trigger switch

Description see accessories

Connection diagrams see www.nicotra-gebhardt.com

Special ttings (at extra cost)

Accessories (on request)

19

AGM 12-0315/-0400, 300 C 120 min.

Fan type premium AGM 12-

Thrust F =

. . . . . . . . . . . . . . . . . . . . .

N

Discharge velocity v =

. . . . . . . . . . . . . . . . . . . . .

m/s

Reference density r

1

=

. . . . . . . . . . . . . . . . . . . . .

kg/m

max. smoke extract temp. t/T =

. . . . . . . . . . . . . . . . . . . . .

C/min

max. ventilation temperature t =

. . . . . . . . . . . . . . . . . . . . .

C

Rated speed N =

. . . . . . . . . . . . . . . . . . . . .

1/min

Nominal power P

N

=

. . . . . . . . . . . . . . . . . . . . .

kW

Nominal current I

N

=

. . . . . . . . . . . . . . . . . . . . .

A

Voltage/Frequency U/f =

. . . . . . . . . . . . . . . . . . . . .

V/Hz

A-Sound pressure level L

pA

=

. . . . . . . . . . . . . . . . . . . . .

dB

Dimensions (LWH) =

. . . . . . . . . . . . . . . . . . . . .

mm

Weight m =

. . . . . . . . . . . . . . . . . . . . .

kg

Smoke extract jetfan premium AGM 12

Suitable for smoke extraction in the case of fire

up to 300 C 120 min,

tested to DIN EN 12101-3 and CE certified.

Certificate of EC conformity: 0036 CPD RG01 10

DIBt approval number: Z-78.11-153

Suitable as fan for continuous standard ventilation up to 40 C.

Certified for horizontal installation inside of a room where fire may occur.

Reversible - Conveying direction blowing over motor or inverse (pressure or suction)

Stylish, elliptical design and equipped with silencer made of galvanised sheet steel at

both ends. Centre part with fixing brackets coated black.

Two integrated air flow straighteners for achieving a turbulence free air stream.

Adjustable guide vanes made of galvanised steel sheet at discharge and intake.

Axial fan impeller with aerofoil blades made of corrosion resistant cast aluminium, ba-

lanced to DIN ISO 1940 Class G 6,3.

Certified motor for smoke gases, protection IP 55, ISO H, maximum operation allo-

wed to ISO F.

Protected, heat resistant electrical feed cable,

leading to metal connection box fixed on fan casing,

Tappings provided for high temperature resistance.

Options (at choice)

l single speed (3~)

l two speed (3~)

l speed controlled by inverter during standard ventilation operation

(max. working frequency admitted 50 Hz)

Fan and accessories tested

to EN 12101-3

Certicate of EC conformity:

0036 CPD RG01 10

General technical approval;

Approval number: Z-78.11-153

Smoke Extract Pulse Fans / AGM/RGM / Specications

Specication

Special paint on request

Simulation on request

Switch and control cabinet with or w/o CO-warning system including all necessary equipment (CO-

sensors, signal horn, blinking lamp, warning panels, etc.)

Optical smoke detector

Manual trigger switch

Description see accessories

Connection diagrams see www.nicotra-gebhardt.com

Special ttings (at extra cost)

Accessories (on request)

20

RGM 91-0600/-0610, 300 C 120 min.

Smoke extract jetfan RGM 91

Suitable for smoke extraction in the case of fire

up to 300 C 120 min,

tested to DIN EN 12101-3 and CE certified.

Certificate of EC conformity: 0036 CPD RG01 11

DIBt approval number: Z-78.11-163

Suitable as fan for continuous standard ventilation up to 40 C.

Certified for horizontal installation inside of a room where fire may occur.

Especially slim casing construction made of galvanised sheet steel, equipped with

mounting bracket at both ends.

Protection guard at inlet side and integrated guide vanes made of galvanised steel

sheet at discharge.

Centrifugal impeller with backward curved blades made of sheet steel, welded and

coated, balanced in according to ISO 1940.

Certified motor for smoke gases, protection IP 55, ISO H, maximum operation allo-

wed to ISO F. Protected heat resistant electrical feed cable, leading to metal connec-

tion box fixed on fan casing, Tappings provided for high temperature resistance.

Options (at choice)

l single speed (3~)

l two speed (3~)

(High speed for smoke extraction, low speed for continuous standard ventilation)

Fan type RGM 91-

Thrust F =

. . . . . . . . . . . . . . . . . . . . .

N

Discharge velocity v =

. . . . . . . . . . . . . . . . . . . . .

m/s

Reference density r

1

=

. . . . . . . . . . . . . . . . . . . . .

kg/m

max. smoke extract temp. t/T =

. . . . . . . . . . . . . . . . . . . . .

C/min

max. ventilation temperature t =

. . . . . . . . . . . . . . . . . . . . .

C

Rated speed N =

. . . . . . . . . . . . . . . . . . . . .

1/min

Nominal power P

N

=

. . . . . . . . . . . . . . . . . . . . .

kW

Nominal current I

N

=

. . . . . . . . . . . . . . . . . . . . .

A

Voltage/Frequency U/f =

. . . . . . . . . . . . . . . . . . . . .

V/Hz

A-Sound pressure level L

pA

=

. . . . . . . . . . . . . . . . . . . . .

dB

Dimensions (LWH) =

. . . . . . . . . . . . . . . . . . . . .

mm

Weight m =

. . . . . . . . . . . . . . . . . . . . .

kg

Fan and accessories tested

to EN 12101-3

Certicate of EC conformity:

0036 CPD RG01 11

General technical approval;

Approval number: Z-78.11-163

Specication

Smoke Extract Pulse Fans / AGM/RGM / Specications

Special paint on request

Simulation on request

Switch and control cabinet with or w/o CO-warning system including all necessary equipment (CO-

sensors, signal horn, blinking lamp, warning panels, etc.)

Optical smoke detector

Manual trigger switch

Description see accessories

Connection diagrams see www.nicotra-gebhardt.com

Special ttings (at extra cost)

Accessories (on request)

21

RGM 91-0600/-0610, 300 C 120 min.

Smoke Extract Pulse Fans / AGM/RGM / Description

Samples

Inlet

Inlet

Discharge

Discharge

CO Gas warning system

Enabling to switch an alarm on in the

case of harmful carbon monoxide

concentration in car parks

Tested and certified by TV acc. to VDI-Regulation 2053, latest

issue (Certificate 09-92-0121)

The system and its function

The CO warning system is made of 2 functional groups:

- central warning unit

- bus capable CO measuring unit (max. 48 off)

The measuring units are fed with 24 V from the central unit. Their

continuous measuring of the CO content supplies via bus lead to

the central unit. There the signal is processed in order to get:

- Average half hour concentration value

- measured concentration against a CO concentration limit -> alarm

In the standard mode the alarm is set on only if the average half

hour concentration value at one measuring point is higher than the

fixed limit value.

1. Central unit

flush-mounted into switchboard consisting of:

Control module, processor controlled digital display for:

- Number of measuring point (control section)

- Actual CO concentration

- Unit parameters

LED display for:

- Alarm for every alarm group

- Excess of setting limits

- operation failures (buffered)

- Alarm group of the measuring point

- Operational data

Technical data

- Measuring area: 0...300 ppm CO

- Number of measuring points from 148

- 4 adjustable alarm thresholds

Works-Settings

1. Alarm: 40 ppm

2. Alarm: 60 ppm

half hour average, freely programmable

3. Alarm: 100 ppm

4. Alarm: 250 ppm maximum value

Number of alarm groups:

as a standard feature up to 4, more with optionally module.

Manual and automatic alarm confirmation (after 2 minutes).

Manual activation of system functions and threshold values for

testing the fans and alarms without test gas.

RS232-intersection for documentation of alarm-, status-, and

measured data.

Switching contacts:

Per every alarm threshold and group 2 switching contacts, potential

free.

- Switching rating of the relay contacts 2000 VA/8 A/250 V

- Voltage: 230 V* 10 %, 50 Hz

C

O

G

a

s

-

S

y

s

t

e

m

s

2. CO measuring unit

Inside wall fitted casing made of plastic

- Protection class IP 42

- Cable entry from above

- Dimensions: 9413057 mm (WHD)

Connection to central unit by 4-wire signal cable

- Cable type to be used: IY (ST)Y.

- Supply: 24 V (from central unit)

- Signal via RS 484 bus

4. Echem-Sensor CO 300 ppm

Electro chemical measuring CO

5. NOX sensor

freely programmable

6. Central emergency power supply USV 2000

for uninterrupted power supply of the central unit and the warning

panel in the case of power supply failure according to the national

prescriptions. Wall casing with key lock.

- Period of power supply: 1 hour

- Power: 230 V/50 Hz, 1000 VA

- Dimensions app. 600400210 mm (WHD)

- Weight: ca. 50 kg

- Protection class: IP 54

7. Warning panel

Yellow body with aluminium frame, pictogram panel, execution acc.

to car park regulations.

- Dimensions: 64220322 mm (WHD)

- Supply: 24 VDC

(Alternative for item 5. and 7.)

8. Warning panel

Yellow body with black writing - 3 lines, blinking light in the case

of alarm. Power supply failure compensation for 1 hour by NiCd-

Batteries, loading automatically acc. to VDI 2053.

- Dimensions: 64220322 mm (WHD)

- Supply: 230 V/50 Hz, 60 VA

9. Flash light WBL

Optical warning signal for inside or outside installation. Thermo

plastic/Aluminium casing with yellow spherical cap.

- Protection class: IP 54

- Flashing sequence: 60/min

- Flash energy: 5 Joule

- Dimensions: 2355466 mm

- Supply: 230 V/50 Hz

10. Signal panel for flash light

- Dimensions: ca. 250100 mm

- Black letters on white panel and red border

11. Signal horn

into connection box warning panel integrated

- Sound level: ca. 85 dB (A)/300 mm

- Dimensions: 757537 mm

- Supply: 24 VDC

12. Connecting cables

to connect the measuring unit, 420.8 mm supply and wiring

either on existing cable ways or with copper tubes with distance

holder clips.

13. Supply and Control line

for connection of the warning panels with integrated uninterrupted

power supply NYM-J 51.5 mm supply and wiring either on

existing cable ways or with copper tubes.

14. Supply and Control line

NYM-J 31.5 mm for connection of the warning panels without

integrated uninterrupted power supply or other means.

15. Traffic light

2 lights signal red/green: 200 mm incl. two sets of fixing material.

16. Signal panel

for installation in the office of the manager equipped with 3 signal

lamps.

- Dimensions: 20010080 mm

17. Commissioning of the gas warning and control central unit

including the demonstration of alarm- and switching functions by

using test gases. Instruction of the personnel, support of the expert

for certification.

24

456

492

4

4

0

1000 1000

2450

190 190

440

600

14

110

840

4

4

8

456

492

4

4

8

4

4

0

1000 1000

2450

190 190

440

14

110 100

600

840

370

406

3

5

4

1000 1000

2400

165 165

390

500

14

110

700

3

6

2

370

406

3

6

2

3

5

4

1000 1000

2400

165 165

390

14

110 100

500

700

AGM 06-0315/-0400, 40 C CO

AGM 16-0315/-0400, 40 C CO

5 N m/s V (3~) Hz 1/min kW A dB AT kg

AGM 06-

0315-2W-10

AK

30 21 2 230/400 /Y 50 2805 0.75 2.89/1.67 80 64 92

0315-FD-11 30/7.5 21/10 2/4 400 YY/Y 50 2780/1385 0.95/0.25 2.40/0.61 4.2/3.8 80 64/46 92

0400-2W-11

AK

52 21 2 230/400 /Y 50 2830 1.10 4.16/2.40 80 65 114

0400-FD-11 52/13 21/10 2/4 400 YY/Y 50 2780/1385 0.95/0.25 2.40/0.61 4.2/3.8 80 65/48 114

5 N m/s V (3~) Hz 1/min kW A dB AT kg

AGM 16-

0315-2W-10

AK

18 16 2 230/400 /Y 50 2805 0.75 2.89/1.67 80 62 93

0315-FD-11 18/4.5 16/8 2/4 400 YY/Y 50 2780/1385 0.95/0.25 2.40/0.61 4.2/3.8 80 62/46 93

0400-2W-11

AK

45 20 2 230/400 /Y 50 2830 1.10 4.16/2.40 80 68 115

0400-FD-11 45/11 20/10 2/4 400 YY/Y 50 2780/1385 0.95/0.25 2.40/0.61 4.2/3.8 80 68/51 115

- CO measuring unit

Accessories / Index

5 Connection diagrams see www.nicotra-gebhardt.com

AT Sound pressure measurement measured at the centre line below the fan

AK Motor according to efficiency class IE2.

Accessories (on request)

Technical Data

Thrust Discharge Poles Voltage/ Fre- Speed Nominal Nominal Starting/Full Motor Sound pressure level

Weight

speed Connection quency power current load current size L

pA

at 1 m distance

CO - Pulse Fans / AGM/RGM / Technical Data

Dimensions in mm, Subject to change.

AGM 06-0400-.. not reversible

AGM 16-0400-.. reversible

Impulse Jetfan

premium

AGM 06

Air flow in direction of motor

(pressure) - not reversible

AGM 16

Air flow in direction of motor

(pressure/suction) - reversible

not reversible

reversed operation - data indicating flow direction over motor

AGM 06-0315-.. not reversible

AGM 16-0315-.. reversible

25

834

870

8

5

2

5

9

1265

185

395

790

2

2

7

14

787

185

1194

1230

1

0

0

3

1

9

1902

210

575

1150

2

7

9

14

1150

210

RGM 96-0600/-0610, 40 C CO

5 N m/s V (3~) Hz 1/min kW A kg

RGM 96-0600, 40 C CO

0600-4W-15 AK 50 25.0 4 230/400 /Y 50 1445 1.5 5.57/3.20 5.5 90 L 130

0600-ID-15 50/23 25.0/17.0 4/6 400 YY/Y 50 1425/940 1.5/0.55 3.60/2.20 6.1/3.3 90 L 130

0600-GD-15 50/13 25.0/13.0 4/8 400 YY/Y 50 1459/732 1.5/0.25 4.20/1.60 5.5/3.1 90 L 130

5 N m/s V (3~) Hz 1/min kW A kg

RGM 96-0610, 40 C CO

0610-4W-16 AK 75 23.5 4 230/400 /Y 50 1440 2.2 7.65/4.40 6.3 100 L 180

0610-ID-16 75/34 23.5/16.0 4/6 400 YY/Y 50 1400/940 2.2/0.75 4.80/2.30 6.8/4.2 100 L 180

0610-GD-16 75/19 23.5/12.0 4/8 400 YY/Y 50 1446/726 2.2/0.37 5.50/2.00 5.2/3.2 100 L 180

L

pA, 1m

dB 63 125 250 500 1000 2000 4000 8000 Hz

RGM 91-0600-..

4 77 64 79 75 75 71 69 66 60 dB

6 66 66 70 65 64 61 57 54 48 dB

8 59 68 62 58 57 54 49 46 39 dB

RGM 91-0610-..

4 83 74 87 81 80 77 75 68 63 dB

6 71 72 79 71 68 66 62 55 50 dB

8 63 74 68 61 61 58 52 45 40 dB

RGM 96-0600, 40 C CO

RGM 96-0610, 40 C CO

- CO measuring unit

Accessories / Index

5 Connection diagrams for fan and isolator see www.nicotra-gebhardt.com

AK Motor according to efficiency class IE2.

Accessories (on request)

Technical Data

Thrust Discharge Poles Voltage/ Fre- Speed Nominal Nominal Starting/Full Motor appr.

speed Connection quency power current load current size Weight

CO - Pulse Fans / AGM/RGM / Technical Data

Dimensions in mm, Subject to change.

Sounds

Fan type Poles

L

pfc, 1m

at f

c

The sound pressure level was measured in a distance of 1 m in two positions. The average values are shown in the table.

26

AGM 06-0315/-0400, 40 C CO

AGM 16-0315/-0400, 40 C CO

Fan type AGM 06-/16-

Thrust F =

. . . . . . . . . . . . . . . . . . . . .

N

Discharge velocity v =

. . . . . . . . . . . . . . . . . . . . .

m/s

Reference density r

1

=

. . . . . . . . . . . . . . . . . . . . .

kg/m

max. ventilation temperature t =

. . . . . . . . . . . . . . . . . . . . .

C

Rated speed N =

. . . . . . . . . . . . . . . . . . . . .

1/min

Nominal power P

N

=

. . . . . . . . . . . . . . . . . . . . .

kW

Nominal current I

N

=

. . . . . . . . . . . . . . . . . . . . .

A

Voltage/Frequency U/f =

. . . . . . . . . . . . . . . . . . . . .

V/Hz

A-Sound pressure level L

pA

=

. . . . . . . . . . . . . . . . . . . . .

dB

Dimensions (LWH) =

. . . . . . . . . . . . . . . . . . . . .

mm

Weight m =

. . . . . . . . . . . . . . . . . . . . .

kg

Jetfan premium AGM 06/16

for ventilation of CO-gases

Suitable for continuous standard ventilation up to 40 C.

Certified for horizontal installation.

Conveying direction blowing over motor (pressure)

Stylish, elliptical design and equipped with silencer made of galvanised sheet steel at

both ends. Centre part with fixing brackets coated black.

Integrated air flow straightener for achieving a turbulence free air stream.

Adjustable guide vanes made of galvanised steel sheet at discharge, intake guard at

suction side.

Axial fan impeller with aerofoil blades made of corrosion resistant cast aluminium, ba-

lanced to DIN ISO 1940 Class G 6.3.

Electrical feed cable leading to connection box fixed on fan casing.

Options (at choice)

l single speed (3~)

l two speed (3~)

l speed controlled by external frequency inverter

(max. working frequency admitted 50 Hz)

CO - Pulse Fans / AGM/RGM / Specications

Specication

Special paint on request

Simulation on request

Switch and control cabinet with CO-warning system including all necessary equipment (CO-sensors,

signal horn, blinking lamp, warning panels, etc.)

Description see accessories

Connection diagrams see www.nicotra-gebhardt.com

Special ttings (at extra cost)

Accessories (on request)

27

RGM 96-0600, 40 C CO

RGM 96-0610, 40 C CO

Fan type premium RGM 96-

Thrust F =

. . . . . . . . . . . . . . . . . . . . .

N

Discharge velocity v =

. . . . . . . . . . . . . . . . . . . . .

m/s

Reference density r

1

=

. . . . . . . . . . . . . . . . . . . . .

kg/m

max. ventilation temperature t =

. . . . . . . . . . . . . . . . . . . . .

C

Rated speed N =

. . . . . . . . . . . . . . . . . . . . .

1/min

Nominal power P

N

=

. . . . . . . . . . . . . . . . . . . . .

kW

Nominal current I

N

=

. . . . . . . . . . . . . . . . . . . . .

A

Voltage/Frequency U/f =

. . . . . . . . . . . . . . . . . . . . .

V/Hz

A-Sound pressure level L

PA

=

. . . . . . . . . . . . . . . . . . . . .

dB

Dimensions (LWH) =

. . . . . . . . . . . . . . . . . . . . .

mm

Weight m =

. . . . . . . . . . . . . . . . . . . . .

kg

Jetfan RGM 96

for ventilation of CO-gases

Suitable for continuous standard ventilation up to 40 C.

Certified for horizontal installation.

Especially slim casing construction made of galvanised sheet steel, equipped with

mounting bracket at both ends.

Protection guard at inlet side and integrated guide vanes made of galvanised steel

sheet at discharge.

Centrifugal impeller with backward curved blades made of sheet steel, welded and

coated, balanced in according to ISO 1940.

Electrical feed cable leading to connection box fixed on fan casing.

Options (at choice)

l single speed (3~)

l two speed (3~)

l speed controlled by external frequency inverter

(max. working frequency admitted 50 Hz)

CO - Pulse Fans / AGM/RGM / Specications

Specication

Special paint on request

Simulation on request

Switch and control cabinet with CO-warning system including all necessary equipment (CO-sensors,

signal horn, blinking lamp, warning panels, etc.)

Description see accessories

Connection diagrams see www.nicotra-gebhardt.com

Special ttings (at extra cost)

Accessories (on request)

E

N

-

B

R

2

-

J

e

t

F

a

n

2

.

0

P

D

F

1

-

0

4

.

2

0

1

1

nicotra-gebhardt.com

AUSTRALIA

65 Yale Drive,

Epping, VIC 3076

Phone +61 3 9017 5333

Fax +61 3 8401 3969

E-mail info@nicotra.com.au

BELGIUM

Haeghensgoed, 13 - 00/01

9270 Laarne

Phone +32 (0)9-336-00-01

Fax +32 (0)9-336-00-05

E-mail info.nicotra@nicotra.be

CHINA

88 TaiAn Road, XinQiao, ShiJi, Panyu

Guangzhou 511450

PR CHINA

Phone +86 (0)20-39960570

Fax +86 (0)20-39960569

E-mail sales@nicotra-china.com

FRANCE

Leader's Park Bat A1

3 chemin des Cytises

69340 Francheville

Phone +33 (0)4 72 79 01 20

Fax +33 (0)4 72 79 01 21

E-mail g.cauche@nicotra-gebhardt.com

GERMANY

Gebhardtstrae 19-25

74638 Waldenburg

Phone +49 (0)7942 101 0

Fax +49 (0)7942 101 170

E-mail info@nicotra-gebhardt.com

GREAT BRITAIN

Unit D, Rail Mill Way

Parkgate Business Park

Rotherham

South Yorkshire

S62 6JQ

Phone +044 01709-780760

Fax +044 01709-780762

E-mail sales@nicotra.co.uk

INDIA

Plot no 28F & 29, Sector-31,Kasna,

Greater Noida-201 308 U.P (India)

Phone +91 120 4783400

Phone +91 22 65702056 (Mumbai)

Phone +91 80 25727830 (Bangalore)

E-mail info@nicotraindia.com

ITALY

Via Modena, 18

24040 Zingonia (BG)

Phone +39 035 873 111

Fax +39 035 884 319

E-mail info@nicotra-gebhardt.com

MALAYSIA

Lot 1799, Jalan Balakong

Taman Perindustrian Bukit Belimbing

43300 Seri Kembangan

Selangor

Phone +603 8961-2588

Fax +603 8961-8337

E-mail info_malaysia@nicotra-gebhardt.com

SPAIN

Ctra. Alcal-Villar del Olmo, Km. 2,830

28810 Villalbilla-Madrid

Phone +34 918-846110

Fax +34 918-859450

E-mail info@nicotra.es

SINGAPORE

3, Science Park Drive, # 04-07, The Franklin

Singapore Science Park 1

Singapore 118223

Phone +65 6265 1522

Fax +65 6265 2400

E-mail info_singapore@nicotra-gebhardt.com

SWEDEN

Kraketorpsgatan 30

43153 Mlndal

Phone 0046 31-874540

Fax 0046 31-878590

E-mail info.se@nicotra-gebhardt.com

THAILAND

6/29 Soi Suksawadi 2, Moo 4, Suksawadi Road,

Kwang Jomthong, Khet Jomthong,

Bangkok 10150

Phone +662 476-1823-6

Fax +662 476-1827

E-mail sales@nicotra.co.th

UNITED STATES

PO BOX 900921

Sandy, Utah 84090

Phone 001(801) 733-0248

Fax 001(801) 315-9400

Mobile 001(801) 682 0898

E-mail mike.sehgal@gebhardtfans.com

http://www.gebhardtfans.com/

Nicotra Gebhardt worldwide

Nicotra Gebhardt Germany

Nicotra Gebhardt GmbH

Gebhardtstrae 19-25

74638 Waldenburg

Germany

Phone +49 (0)7942 101 0

Fax +49 (0)7942 101 170

E-Mail info@nicotra-gebhardt.com

Nicotra Gebhardt Italy

Nicotra Gebhardt S.p.A

Via Modena, 18

24040 Zingonia (BG)

Italy

Phone +39 035 873 111

Fax +39 035 884 319

E-Mail info@nicotra-gebhardt.com

Вам также может понравиться

- Jet FansДокумент8 страницJet FansTin ThanОценок пока нет

- Jet-Fan-Systems 2017-02 en E1749Документ34 страницыJet-Fan-Systems 2017-02 en E1749MOHAN L BUJJIОценок пока нет

- Part 8 - Exhaust Fan PDFДокумент7 страницPart 8 - Exhaust Fan PDFhvacsriniОценок пока нет

- Parking Garage Ventlation1Документ2 страницыParking Garage Ventlation1MOHAMED ELKHASHABОценок пока нет

- GREENHECK - JET FAN Catalog - GJ-AU GJ-AB - ENДокумент12 страницGREENHECK - JET FAN Catalog - GJ-AU GJ-AB - ENSebastian RamosОценок пока нет

- E Covent FanДокумент2 страницыE Covent FanEko ParjonoОценок пока нет

- Mechanical Ventilation Smoke Control SystemsДокумент26 страницMechanical Ventilation Smoke Control SystemsRohit Upadhyay100% (1)

- Solar Hot Water System SpecificationsДокумент22 страницыSolar Hot Water System Specificationspsn_kylmОценок пока нет

- Fire Fighting Specifications SummaryДокумент50 страницFire Fighting Specifications SummaryPabbathi VinayОценок пока нет

- Domestic Catalogue05 PDFДокумент26 страницDomestic Catalogue05 PDFAshraf Adel Nashed ZakiОценок пока нет

- Fire Alarm Sequence of EventsДокумент1 страницаFire Alarm Sequence of EventstechnomuraliОценок пока нет

- NN 100 Nitrogen Gas Fire Suppression SystemДокумент4 страницыNN 100 Nitrogen Gas Fire Suppression SystemJulius BravoОценок пока нет

- Rain Water HarvesitingДокумент10 страницRain Water HarvesitingSyed Roshan AliОценок пока нет

- Technical Brochures AW HT 0031 0071 enДокумент50 страницTechnical Brochures AW HT 0031 0071 endouslasОценок пока нет

- Garage Ventilation System DesignДокумент8 страницGarage Ventilation System DesignDiego PovedaОценок пока нет

- Tornatech Brochure JPYДокумент2 страницыTornatech Brochure JPYedward baskara100% (1)

- Unit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Документ21 страницаUnit 3-Fire Safety: Portable Fire Fighting Equipment - (Write Short Notes On Portable Equipment-2010)Navya chowdaryОценок пока нет

- Horizontal Sidewall Sprinklers Technical Data SheetДокумент6 страницHorizontal Sidewall Sprinklers Technical Data SheetAhrian BenaОценок пока нет

- Fire Pump Compliance MatrixДокумент5 страницFire Pump Compliance Matrixshakil612Оценок пока нет

- Medical Gas Pipeline SystemДокумент16 страницMedical Gas Pipeline Systemshivangiis0796511Оценок пока нет

- Integration - H VAC Fans and Smoke Control - Control EngineeringДокумент5 страницIntegration - H VAC Fans and Smoke Control - Control EngineeringMohamedAhmedFawzyОценок пока нет

- HVAC Ductwork SpecificationДокумент4 страницыHVAC Ductwork SpecificationhvacwallyОценок пока нет

- A Guide To Ventilation Exhaust FansДокумент4 страницыA Guide To Ventilation Exhaust FansLoter BelautОценок пока нет

- Romold TrapДокумент2 страницыRomold Traprajkumar_chinniah100% (1)

- Staircase PressurizationДокумент8 страницStaircase PressurizationKrishna PATEL100% (1)

- Revit Mep FundДокумент5 страницRevit Mep FundChandra NurikoОценок пока нет

- Duct Sealing in Large BuildingsДокумент31 страницаDuct Sealing in Large BuildingsShiyamraj ThamodharanОценок пока нет

- Autodesk Revit MEP Fundamentals: Course Length: 4 DaysДокумент5 страницAutodesk Revit MEP Fundamentals: Course Length: 4 Daysroger njeimОценок пока нет

- SANS 1128 1 2010 (Ed. 2.01)Документ29 страницSANS 1128 1 2010 (Ed. 2.01)Olefile Mark MolokoОценок пока нет

- FI NotesДокумент1 069 страницFI NotesparadoxendazzlingОценок пока нет

- Axial Fan SpecificationДокумент9 страницAxial Fan SpecificationRamakrishnan100% (1)

- Technical Journal Fire PumpДокумент7 страницTechnical Journal Fire PumpIzallmachineОценок пока нет

- Water Meter Design Criteria ManualДокумент21 страницаWater Meter Design Criteria ManualAnonymous M0tjyWОценок пока нет

- Selection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of PracticeДокумент21 страницаSelection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of Practiceabhirami91Оценок пока нет

- Where and How to Install Refuse ChutesДокумент2 страницыWhere and How to Install Refuse ChutesMoloy Das100% (1)

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationДокумент3 страницыGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarОценок пока нет

- Chiller and cooling equipment scheduleДокумент53 страницыChiller and cooling equipment scheduleRaju KsnОценок пока нет

- Fans in Fire SafetyДокумент58 страницFans in Fire SafetyMohammed Majeed Ali100% (1)

- Combined Sprinkler and Standpipe AssemblyДокумент1 страницаCombined Sprinkler and Standpipe Assemblydesign sseОценок пока нет

- Project Report On Sump PumpДокумент20 страницProject Report On Sump PumpAwaisОценок пока нет

- Car Park Ventilation Control SystemДокумент8 страницCar Park Ventilation Control Systemroshan jaiswalОценок пока нет

- Sprinkler Sloped - Ceilings - 2010 PDFДокумент7 страницSprinkler Sloped - Ceilings - 2010 PDFnrodinis7Оценок пока нет

- VRF & DX Split Type ACU Testing MethodologyДокумент1 страницаVRF & DX Split Type ACU Testing MethodologydamianОценок пока нет

- Fire RequermentsДокумент10 страницFire RequermentsAvk SanjeevanОценок пока нет

- General Notes: VC 9003 IN COMPLIANCE WITH SANS 1263-1:2013Документ10 страницGeneral Notes: VC 9003 IN COMPLIANCE WITH SANS 1263-1:2013Ryan SutherlandОценок пока нет

- Prihoda Recycled Fabric Duct SpecificationДокумент5 страницPrihoda Recycled Fabric Duct SpecificationaverentzОценок пока нет

- Fire Fighting Pipe Sizing UAEДокумент2 страницыFire Fighting Pipe Sizing UAEgiemy george100% (1)

- Damper Manual - AMCAДокумент6 страницDamper Manual - AMCASaransh GuptaОценок пока нет

- Construction V2-0 Sept 10 - ACC - WE - DB1000Документ34 страницыConstruction V2-0 Sept 10 - ACC - WE - DB1000vin ssОценок пока нет

- Fire Protection and Suppression SystemДокумент4 страницыFire Protection and Suppression Systemamrit90320Оценок пока нет

- Design Calculation Sheet: Water Demand & Drainage FlowДокумент5 страницDesign Calculation Sheet: Water Demand & Drainage FlowAhmadОценок пока нет

- Mechanical Plan Review GuideДокумент11 страницMechanical Plan Review GuideEngelbert CasanovaОценок пока нет

- Rectify issues from site visitДокумент1 страницаRectify issues from site visitSaqib_Manzoor__9876Оценок пока нет

- Sand Oil Interceptor Sizing Calculations 90 SubmittalДокумент4 страницыSand Oil Interceptor Sizing Calculations 90 SubmittalBRANDONОценок пока нет

- Mechanical PlansДокумент1 страницаMechanical PlansYesTaratОценок пока нет

- Technical Spec for AHUДокумент6 страницTechnical Spec for AHUreddyrioОценок пока нет

- AHU-02 Submittal Saivar Rev-02Документ49 страницAHU-02 Submittal Saivar Rev-02Hossam AttefОценок пока нет

- QCDD BP GuidelinesДокумент6 страницQCDD BP Guidelines남광연0% (1)

- CP13 - 1999 MV and AC in BuildingДокумент56 страницCP13 - 1999 MV and AC in Buildingbozow bozowlОценок пока нет

- Jet Fans for Smoke Extraction & Basement VentilationДокумент10 страницJet Fans for Smoke Extraction & Basement Ventilationabc3579Оценок пока нет

- 2018-June-21-Modello Highs - CFD ResultsДокумент48 страниц2018-June-21-Modello Highs - CFD Resultsrajarathnam.kОценок пока нет

- Innovate - Engineer - ExperienceДокумент6 страницInnovate - Engineer - Experiencerajarathnam.kОценок пока нет

- Sheet Metal Design-Handbook-Rev3 PDFДокумент12 страницSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- CFD REPORT FOR BASEMENT B2 L&T Prolofic-B-1 PDFДокумент31 страницаCFD REPORT FOR BASEMENT B2 L&T Prolofic-B-1 PDFrajarathnam.k100% (1)

- Hydraulics LectureДокумент20 страницHydraulics Lecturee_manpreetОценок пока нет

- 355 & 400 Dia Jet Fan Ga DRGДокумент2 страницы355 & 400 Dia Jet Fan Ga DRGrajarathnam.kОценок пока нет

- Snap-Fit Joints For Plastics (BMS Version)Документ26 страницSnap-Fit Joints For Plastics (BMS Version)Bram Hermans100% (1)

- Co 2 Position PaperДокумент6 страницCo 2 Position PaperMuhammad Faheem ShahbazОценок пока нет

- Basant Kumar Gupta, Anand Patil Zeus Numerix Private Limited, Pune, India Pankaj Dharkar & Associates, Mumbai, IndiaДокумент5 страницBasant Kumar Gupta, Anand Patil Zeus Numerix Private Limited, Pune, India Pankaj Dharkar & Associates, Mumbai, Indiarajarathnam.kОценок пока нет

- Effect of Ventilation Tube Spacing On Refrigerated Warehouse Floor Antifreezing Mechanical Ventilation SystemДокумент6 страницEffect of Ventilation Tube Spacing On Refrigerated Warehouse Floor Antifreezing Mechanical Ventilation Systemrajarathnam.kОценок пока нет

- WEST END - PR - PanelsДокумент1 страницаWEST END - PR - Panelsrajarathnam.kОценок пока нет

- Single Multicore Flexible CablesДокумент4 страницыSingle Multicore Flexible CablesSaurabh DangariaОценок пока нет

- CFD Report For BasementДокумент31 страницаCFD Report For Basementrajarathnam.k100% (1)

- R1 - Brigade Senate - Basement-1 PDFДокумент120 страницR1 - Brigade Senate - Basement-1 PDFrajarathnam.kОценок пока нет

- Mesh Analysis For PipeДокумент2 страницыMesh Analysis For Piperajarathnam.kОценок пока нет

- p058140 Tail SplineДокумент1 страницаp058140 Tail Splinerajarathnam.kОценок пока нет

- 2018-July-11 - STP Ventialtion Layout For Bbcl-ModelДокумент1 страница2018-July-11 - STP Ventialtion Layout For Bbcl-Modelrajarathnam.kОценок пока нет

- Environmental System Performance Program (ESP-r) : A.1 IntroductionДокумент34 страницыEnvironmental System Performance Program (ESP-r) : A.1 Introductionrajarathnam.kОценок пока нет

- Gears and NomenclatureДокумент27 страницGears and NomenclatureJJОценок пока нет

- Performance Based Evaluation of Fire Scenarios Using FluentДокумент9 страницPerformance Based Evaluation of Fire Scenarios Using Fluentrajarathnam.kОценок пока нет

- Jten 2015 1 2.610Документ15 страницJten 2015 1 2.610amojodiОценок пока нет

- PHOENICS Case Study: Wembley Stadium Fire StudyДокумент1 страницаPHOENICS Case Study: Wembley Stadium Fire Studyrajarathnam.kОценок пока нет

- BEARING TOLERANCES TABLEДокумент12 страницBEARING TOLERANCES TABLESandeep MatetiОценок пока нет

- Shaft, DriveДокумент1 страницаShaft, Driverajarathnam.kОценок пока нет

- Spline DIN 5480Документ27 страницSpline DIN 5480ewillia13100% (3)

- 15-5 PH Data Bulletin PDFДокумент12 страниц15-5 PH Data Bulletin PDFAndres Camilo BenitezОценок пока нет

- Paper25 Yunlong LiuДокумент13 страницPaper25 Yunlong Liurajarathnam.kОценок пока нет

- UgДокумент14 страницUgrajarathnam.kОценок пока нет

- Nirmal Presentation FrameworkДокумент33 страницыNirmal Presentation Frameworkrajarathnam.kОценок пока нет

- AdNU SHS Student Handbook, 2019 EditionДокумент122 страницыAdNU SHS Student Handbook, 2019 EditionChona SEVERAОценок пока нет

- Asad Durrani - Pakistan Adrift - Navigating Troubled Waters-Hurst, Oxford University Press (2018)Документ263 страницыAsad Durrani - Pakistan Adrift - Navigating Troubled Waters-Hurst, Oxford University Press (2018)Junaid AliОценок пока нет

- 7 Samples and PopulationsДокумент1 страница7 Samples and Populationsapi-308082215Оценок пока нет

- Compression Ratio PDFДокумент6 страницCompression Ratio PDFRafael LuqueОценок пока нет

- Veritas Netbackup™ For Hbase Administrator'S Guide: Unix, Windows, and LinuxДокумент50 страницVeritas Netbackup™ For Hbase Administrator'S Guide: Unix, Windows, and Linux黃國峯Оценок пока нет

- AcousticophobiaДокумент2 страницыAcousticophobiaAnaCojocariОценок пока нет

- Brand Architecture Assignment Week 2 - LGДокумент3 страницыBrand Architecture Assignment Week 2 - LGDivyanshu JhaОценок пока нет

- Furuno fr2135Документ82 страницыFuruno fr213520004149Оценок пока нет

- eHEALTH - HealthДокумент68 страницeHEALTH - HealthElets TechnomediaОценок пока нет

- The Tempest Gender IssueДокумент2 страницыThe Tempest Gender IssueVijay GoplaniОценок пока нет

- Judgment SheetДокумент12 страницJudgment SheetSyed AzharОценок пока нет

- Benefits of Integrated Modular Avionics 2G for Business AviationДокумент3 страницыBenefits of Integrated Modular Avionics 2G for Business AviationGadadhar DeyОценок пока нет

- Chapter 10Документ51 страницаChapter 10Nayeem HakimОценок пока нет

- Crane 3 GP160-0516-2Документ222 страницыCrane 3 GP160-0516-2cengiz kutukcuОценок пока нет

- Physics 4th Edition Walker Test BankДокумент24 страницыPhysics 4th Edition Walker Test Bankdominichaimre100% (30)

- OCAT Self Assessment ToolДокумент54 страницыOCAT Self Assessment ToolWillie Miyogoh Madete100% (1)

- Role play teaching strategy evaluated for IT courseДокумент9 страницRole play teaching strategy evaluated for IT courseHitesh MishraОценок пока нет

- Hoiij EtДокумент166 страницHoiij Etchristian venegasОценок пока нет

- Differential: Systems OperationДокумент3 страницыDifferential: Systems OperationAhmed RezkОценок пока нет

- SINUMERIK 810M NCnet 7.0 SettingsДокумент3 страницыSINUMERIK 810M NCnet 7.0 SettingsSam eagle good100% (1)

- 15.RF Exp 15 HFSS Ring Hybrid DesignДокумент4 страницы15.RF Exp 15 HFSS Ring Hybrid DesignSolleti Suresh450% (2)

- Deep An GuptaДокумент3 страницыDeep An GuptaArjunОценок пока нет

- CDP AT FINGER PIER - StudyДокумент25 страницCDP AT FINGER PIER - Studyd_mazieroОценок пока нет

- Cleaning Validation EssentialsДокумент29 страницCleaning Validation EssentialsKusum ShresthaОценок пока нет

- Pistachio PPT Research ProposalДокумент7 страницPistachio PPT Research ProposalRyan BermundoОценок пока нет

- Psa 700 Notes and SummaryДокумент10 страницPsa 700 Notes and SummaryEjkОценок пока нет

- Data Structures With JavaДокумент5 страницData Structures With Javadure0% (1)

- Busbar Size Per BreakerДокумент1 страницаBusbar Size Per BreakeribrahimОценок пока нет

- VRLA Battery Operation Manual (AGM) : Huawei Technologies Co., LTDДокумент23 страницыVRLA Battery Operation Manual (AGM) : Huawei Technologies Co., LTDBelghennou Hadj AliОценок пока нет

- College Students' Homesickness: An Interpretative PhenomenologyДокумент9 страницCollege Students' Homesickness: An Interpretative PhenomenologyGodfrey CasinilloОценок пока нет