Академический Документы

Профессиональный Документы

Культура Документы

Sec5 B Se1114

Загружено:

arianaseri0 оценок0% нашли этот документ полезным (0 голосов)

44 просмотров6 страницSEC5_B_SE1114

Оригинальное название

SEC5_B_SE1114

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документSEC5_B_SE1114

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

44 просмотров6 страницSec5 B Se1114

Загружено:

arianaseriSEC5_B_SE1114

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

STANDARD TEST METHOD FOR DETERMINING

THE FOCAL SIZE OF IRIDIUM-192 INDUSTRIAL

RADIOGRAPHIC SOURCES

SE-1114

[Identical with ASTM Specication E 1114-92 (R1997)]

1. Scope

1.1 This test method covers the determination of the

focal size of an iridium-192 radiographic source. The

determination is based upon measurement of the image

of the iridium metal source in a projection radiograph

of the source assembly and comparison to the measure-

ment of the image of a reference sample in the same

radiograph.

1.2 This standard does not purport to address all

of the safety concerns, if any, associated with its use.

It is the responsibility of the user of this standard to

establish appropriate safety and health practices and

determine the applicability of regulatory limitations

prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E 999 Guide for Controlling the Quality of Industrial

Radiographic Film Processing

E 1316 Terminology for Nondestructive Testing

3. Terminology

3.1 For denitions of terms relating to this test

method, refer to Terminology E 1316.

4. Signicance and Use

4.1 One of the factors affecting the quality of a

radiographic image is geometric unsharpness. The de-

gree of geometric unsharpness is dependent upon the

328

focal size of the source, the distance between the source

and the object to be radiographed, and the distance

between the object to be radiographed and the lm.

This test method allows the user to determine the focal

size of the source and to use this result to establish

source to object and object to lm distances appropriate

for maintaining the desired degree of geometric un-

sharpness.

5. Apparatus

5.1 Subject Iridium-192 Source, the focal size of

which is to be determined. The appropriate apparatus

and equipment for the safe storage, handling, and

manipulation of the subject source, such as a radio-

graphic exposure device (also referred to as a gamma

ray projector or camera), remote control, source guide

tube, and source stop are also required.

5.2 Reference Sample (see Figs. 1,2, and 3) The

reference sample shall be of material which is not

radioactive. The recommended material is iridium. How-

ever, substitutes such as platinum, tungsten, or other

material of similar radiopacity may be used. The sample

should be of the same geometric shape as the subject

source, should be approximately the same size as the

subject source, and should be positioned on or within

a shim or envelope to simulate the source capsule wall.

The resulting radiographic contrast, with reference to

adjacent background density of the image of the refer-

ence sample, should be approximately the same as that

of the subject source. The actual dimensions of the

reference sample should be determined to the nearest

0.025 mm (0.001 in.).

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SE-1114 ARTICLE 22 RADIOGRAPHIC STANDARDS

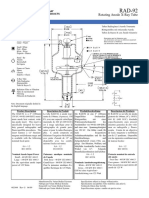

FIG. 1 REFERENCE SAMPLE IN STANDARD SOURCE ENCAPSULATION

FIG. 2 ALTERNATE REFERENCE SAMPLE ARRANGEMENT

FIG. 3 ALTERNATE REFERENCE SAMPLE ARRANGEMENT

329

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SE-1114 2001 SECTION V

TABLE 1

EXAMPLES OF TYPICAL X-RAY GENERATOR

OUTPUT REQUIREMENTS FOR RELATED IRIDIUM

192

SOURCE ACTIVITIES

Subject Iridium

192

Source Typical X-ray Generator

Radiation Output Requirements

Activity Output

(Curie) (Rh at 1 m) Potential Current

30 14.4 160 kV 5 mA

or 200 kV 3 mA

100 48.0 160 kV 10 mA

or 250 kV 4 mA

200 96.0 160 kV 20 mA

or 250 kV 8 mA

or 300 kV 6 mA

5.3 X-ray Generator, capable of producing a radiation

intensity (roentgen per hour at one metre) at least ten

times greater than that produced by the subject source.

Examples of typical X-ray generator output requirements

that satisfy this criterion are presented in Table 1.

5.4 Film, industrial type ne grain, extra ne grain,

or ultra ne grain as dened by the lm manufacturer

shall be used. Selection of lm type should be deter-

mined by such factors as the required radiographic

quality level, equipment capability, materials, and so

forth. The lms selected must be capable of demonstra-

ting the required image quality. No intensifying screens

should be used. The lm should be processed in accord-

ance with Guide E 999.

5.5 Image Measurement Apparatus This apparatus

is used to measure the size of the image of the focal

spot. The apparatus shall be an optical comparator with

built-in graticule with 0.1 mm divisions or 0.001 in.

divisions and magnication of 5 to 10.

6. Procedure

6.1 Set up the exposure arrangement as shown in

Figs. 4, 5, 6, and 7. Position the X-ray tube directly

over the center of the lm. The lm plane must be

normal to the central ray of the X-ray beam. The X-

ray focal spot should be 0.90 m (36 in.) from the lm.

Position the reference sample and apparatus used to

locate the subject source (source stop) as close together

as possible and directly over the center of the lm.

The plane of the source stop and reference sample

must be parallel to the lm and normal to the central

330

FIG. 4 TYPICAL EXPOSURE ARRANGEMENT

FIG. 5 TYPICAL ARRANGEMENT USING A

SPECIALLY DESIGNED GUIDE TUBE

ray of the X-ray beam. The source stop and reference

sample should be 0.15 m (6 in.) from the lm. The

source stop should be connected to the radiographic

exposure device by the shortest source guide tube

practicable in order to minimize fogging of the lm

during source transit.

6.2 Place identication markers to be imaged on the

lm to identify, as a minimum, the identication (serial

number) of the subject source, the size of the reference

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SE-1114 ARTICLE 22 RADIOGRAPHIC STANDARDS

FIG. 6 TYPICAL ARRANGEMENT USING A

STANDARD GUIDE TUBE AND SPECIAL

POSITIONING FIXTURE

sample, the identication of the organization performing

the determination, and the date of the determination.

Care should be taken to ensure that the images of

the subject source and reference sample will not be

superimposed on the image of the identication markers.

6.3 Exposure Select the X-ray tube potential (kV),

X-ray tube current (mA), and exposure time such that

the density in the image of the envelope surrounding

the reference sample does not exceed 3.0 and that the

density difference between the image of the reference

sample and the image of the envelope surrounding the

reference sample is at least 0.10.

NOTE The actual parameters that will produce acceptable results

may vary between X-ray units, and trial exposures may be necessary.

6.3.1 Energize the X-ray generator and, at the

same time, manipulate the subject source into the

exposure position in the source stop. It is important

that this be performed as quickly as possible to minimize

fogging of the lm.

6.3.2 At the conclusion of the exposure time,

deenergize the X-ray generator and, at the same time,

return the subject source to the proper shielded storage

position.

6.3.3 Process the lm.

7. Measurement of Focal Dimensions

7.1 View the radiograph with sufcient light intensity

for adequate viewing. Using an optical comparator with

built-in graticule as described in 5.5, measure the linear

dimensions of the image of the focal spot of the subject

331

source and the reference sample. Take measurements

from the perceptible edges of the image. When per-

forming the physical measurements with the optical

comparator, the actual measured values shall be to the

nearest graduation on the graticule scale being used.

7.2 The focal size for a given technique is the

maximum projected dimension of the source in the

plane perpendicular to a line drawn from the source

to the object being radiographed. Therefore, sufcient

measurements of the image of the iridium must be

made to determine the focal size of the source in

any orientation. Sections 7.2.1 through 7.2.4 serve as

examples.

7.2.1 Uniform Right Circular Cylinder (see Fig.

8) Determine the focal size of a uniform right

circular cylindrical source by measuring the diameter,

d, the height, h, and the diagonal, m, as illustrated in

Fig. 8 and computing the actual dimensions as described

in 8.1.

7.2.2 Sphere (see Fig. 9) Determine the focal

size of a spherical source by measuring the diameter,

d, as illustrated in Fig. 9 and computing the actual

dimension as described in 8.1.

7.2.3 Nonuniform Stack of Right Circular Cylinders

(see Fig. 10) Determine the focal size of a nonuni-

form stack of right circular cylindrical components of

a source by measuring the intrinsic diameter, d, the

height, h, and the effective maximum dimension, m,

as illustrated in Fig. 10 and computing the actual

dimensions as described in 8.1.

7.2.4 Separated Stack of Right Circular Cylinders

(see Fig. 11) Determine the focal size of a separated

stack of right circular cylindrical components of a

source by measuring the intrinsic diameter, d, the

effective height, h, and the effective maximum dimen-

sion, m, as illustrated in Fig. 11 and computing the

actual dimensions as described in 8.1.

8. Calculation and Evaluation

8.1 Measure the linear dimension of interest in the

subject source image and measure the same linear

dimension in the reference sample image (that is, the

diameter of each). The actual dimension of the subject

source is computed from the following:

a p

bc

d

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SE-1114 2001 SECTION V

FIG. 7 TYPICAL ARRANGEMENT USING REFERENCE SAMPLE POSITIONING DEVICE

FIG. 8 UNIFORM RIGHT CIRCULAR CYLINDER

FIG. 10 NONUNIFORM CYLINDRICAL STACK

332

FIG. 9 SPHERE

FIG. 11 SEPARATED CYLINDRICAL STACK

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

SE-1114 ARTICLE 22 RADIOGRAPHIC STANDARDS

where:

apactual dimension of the subject source,

bpactual dimension of the reference sample,

cpmeasured dimension of the subject source im-

age, and

dpmeasured dimension of the reference sample

image.

9. Report

9.1 A report of the focal size of an iridium-192

source should indicate the model number and serial

333

number of the source, the name of the organization

making the determination, the date the determination

was made, a description of the shape of the source

(or an appropriate sketch), and the calculated actual

dimensions. The actual radiograph should accompany

the report.

10. Keywords

10.1 cylinder(s); focal size; iridium 192; radiographic

source; reference sample; sphere

COPYRIGHT American Society of Mechanical Engineers

Licensed by Information Handling Services

Вам также может понравиться

- 1.vendor List - Rev.6Документ174 страницы1.vendor List - Rev.6arianaseri100% (1)

- Ati 316 316l 317 317l Tds En2 v1Документ15 страницAti 316 316l 317 317l Tds En2 v1arianaseriОценок пока нет

- Three-phase induction motor data sheetДокумент2 страницыThree-phase induction motor data sheetarianaseriОценок пока нет

- VistiДокумент3 страницыVistiarianaseriОценок пока нет

- Engineers Australia Code of Ethics 2010Документ3 страницыEngineers Australia Code of Ethics 2010matthew1ferreiraОценок пока нет

- ProNest Programming Guide PDFДокумент48 страницProNest Programming Guide PDFBurhan ÇamОценок пока нет

- Brochure Air Cooled CondenserДокумент8 страницBrochure Air Cooled CondenserFathur Rahman Handoko100% (1)

- Ati Corrosion Resistant Titanium Alloys Tds En4 v1Документ5 страницAti Corrosion Resistant Titanium Alloys Tds En4 v1HMMSPОценок пока нет

- 5S Checklist ReaderДокумент1 страница5S Checklist ReaderarianaseriОценок пока нет

- 30-05-09 Proposal Caribbean Emergency Legislation Project Activity 201 2Документ19 страниц30-05-09 Proposal Caribbean Emergency Legislation Project Activity 201 2Amit OzaОценок пока нет

- Joint VentureДокумент12 страницJoint VentureJeree Jerry AzreeОценок пока нет

- 6 Polley Compabloc FДокумент5 страниц6 Polley Compabloc FarianaseriОценок пока нет

- WKM Pow R Seal Gate Valves BrochureДокумент28 страницWKM Pow R Seal Gate Valves BrochureKhai Huynh100% (1)

- Neway International Group Head Office: CNC Equipment (Suzhou) Co.,LtdДокумент18 страницNeway International Group Head Office: CNC Equipment (Suzhou) Co.,LtdarianaseriОценок пока нет

- Ni-Base Superalloy 718 (VIM+VAR) : Z Equivalent SpecificationДокумент2 страницыNi-Base Superalloy 718 (VIM+VAR) : Z Equivalent SpecificationpvdangОценок пока нет

- Reference DataДокумент20 страницReference DataarianaseriОценок пока нет

- Thyssenkrupp Materials International: Material Data SheetДокумент4 страницыThyssenkrupp Materials International: Material Data SheetGopal RamalingamОценок пока нет

- 04 035 042 Corrugated GasketsДокумент8 страниц04 035 042 Corrugated Gasketsdane05Оценок пока нет

- 2015 Membership ApplicationДокумент4 страницы2015 Membership ApplicationarianaseriОценок пока нет

- Grooved Kempchen PDFДокумент11 страницGrooved Kempchen PDFAnonymous Iev5ggSRОценок пока нет

- لکش 1 یهد ششوپ کیتامش شیامن CVD و PVDДокумент5 страницلکش 1 یهد ششوپ کیتامش شیامن CVD و PVDarianaseriОценок пока нет

- Sales Proposal Sales Proposal Template 1.doctemplate 1Документ5 страницSales Proposal Sales Proposal Template 1.doctemplate 1arianaseriОценок пока нет

- High Perf Metals Brochure v1Документ5 страницHigh Perf Metals Brochure v1arianaseriОценок пока нет

- OG Brochure - Alloys InsertДокумент2 страницыOG Brochure - Alloys InsertarianaseriОценок пока нет

- James Walker o Ring GuideДокумент32 страницыJames Walker o Ring Guidecvishwas1159Оценок пока нет

- Manual BPV UkДокумент12 страницManual BPV UkarianaseriОценок пока нет

- Cameron Style Back Pressure Valve Replacement PartsДокумент1 страницаCameron Style Back Pressure Valve Replacement Partskaveh-bahiraeeОценок пока нет

- Ma30 WДокумент2 страницыMa30 WarianaseriОценок пока нет

- Smo 254 Uns S31254Документ8 страницSmo 254 Uns S31254sateesh chandОценок пока нет

- Fouling in Plate Heat ExchangersДокумент18 страницFouling in Plate Heat ExchangersKarina Yesenia Salinas100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- MCPS RadiologyДокумент32 страницыMCPS Radiologyg138182171% (7)

- A Study and Optimization of Lumbar Spine X-Ray ImagingДокумент12 страницA Study and Optimization of Lumbar Spine X-Ray ImagingMatt ParkmanОценок пока нет

- bm5602 Unit 1Документ147 страницbm5602 Unit 1sfssssОценок пока нет

- Jolly 20 Plus (Pd-83-E - Rev. 07)Документ3 страницыJolly 20 Plus (Pd-83-E - Rev. 07)Juan CartayaОценок пока нет

- Revision History: Service Manual Rex - R (F)Документ70 страницRevision History: Service Manual Rex - R (F)fugarisaОценок пока нет

- Diagnostic Angiography LabДокумент31 страницаDiagnostic Angiography LabPrakash SapkaleОценок пока нет

- The X-Ray Imaging System 1Документ15 страницThe X-Ray Imaging System 1Je Visuals100% (2)

- Mindray DigiEye 280Документ4 страницыMindray DigiEye 280irwin kurniadiОценок пока нет

- Philips BV Pulsera Specs PDFДокумент20 страницPhilips BV Pulsera Specs PDFjose ivan carvajal cortizosОценок пока нет

- Siemens CT - Low - Dose - GuideДокумент66 страницSiemens CT - Low - Dose - GuideSyazwanee Nasir100% (1)

- Product Information: Analix™ A-41L SeriesДокумент6 страницProduct Information: Analix™ A-41L SeriesDongKyu SeolОценок пока нет

- ASR-3000 Service ManualДокумент26 страницASR-3000 Service ManualYoussry Elsayed MohamedОценок пока нет

- Manual de Servicio MUX-100DДокумент124 страницыManual de Servicio MUX-100DJacobo VazquezОценок пока нет

- Giotto Ims T. DataДокумент8 страницGiotto Ims T. DatalUIS fERNANDO gARCIA sANCHEZОценок пока нет

- RAD-92 PdsДокумент12 страницRAD-92 PdspietrokoОценок пока нет

- Computed TomographyДокумент49 страницComputed TomographyHuma raoОценок пока нет

- Exposcop 7000 Service Manual PDFДокумент355 страницExposcop 7000 Service Manual PDFTodd50% (2)

- Technical Proficiency CriteriaДокумент61 страницаTechnical Proficiency CriteriaMOHD AZUAN ABDUL RASHIDОценок пока нет

- Hologic Insight Service Manual PDFДокумент200 страницHologic Insight Service Manual PDFImagex Raios xОценок пока нет

- C3003 With Crawler Control Unit CCU186Документ38 страницC3003 With Crawler Control Unit CCU186Felix U Onojeta67% (3)

- Chapter 3 X-RayДокумент32 страницыChapter 3 X-RayKhalid AhmedОценок пока нет

- SPXMANДокумент51 страницаSPXMANJose SoaresОценок пока нет

- E7239FX Data SheetДокумент10 страницE7239FX Data SheetLuis Fernando Garcia SОценок пока нет

- X-Ray Generators: Resident Physics LecturesДокумент54 страницыX-Ray Generators: Resident Physics LecturesAhmed TorkyОценок пока нет

- Activion 1600Документ16 страницActivion 1600JhonnathanL.BarraganBaronОценок пока нет

- XR Canon Radrex enДокумент6 страницXR Canon Radrex enNam LeОценок пока нет

- Clarox VX 30 Portable X Ray MachineДокумент2 страницыClarox VX 30 Portable X Ray MachineSam Al AbabОценок пока нет

- Chapter 8 X-Ray ProductionДокумент3 страницыChapter 8 X-Ray ProductionAnne LimpinОценок пока нет

- Genesis DT/DTS: Installation Manual - X-Ray GeneratorДокумент135 страницGenesis DT/DTS: Installation Manual - X-Ray GeneratorRubén Díaz HernándezОценок пока нет

- OEC 9800+ SpecificationsДокумент6 страницOEC 9800+ SpecificationsxrayserviceОценок пока нет