Академический Документы

Профессиональный Документы

Культура Документы

MTD 21 Guide for Visual Aids Selection

Загружено:

bsk20070 оценок0% нашли этот документ полезным (0 голосов)

14 просмотров2 страницыThis document provides guidelines for selecting visual aids for inspecting surfaces to detect imperfections. It discusses types of visual aids including single-element magnifiers up to 0.4x magnification (Type A) and multi-element magnifiers up to 0.8x magnification (Type B). The document also briefly outlines visual inspection techniques, qualifications for inspection personnel, factors that influence temperature measurement, and reporting requirements.

Исходное описание:

IRT draft

Оригинальное название

MTD21_5035W

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides guidelines for selecting visual aids for inspecting surfaces to detect imperfections. It discusses types of visual aids including single-element magnifiers up to 0.4x magnification (Type A) and multi-element magnifiers up to 0.8x magnification (Type B). The document also briefly outlines visual inspection techniques, qualifications for inspection personnel, factors that influence temperature measurement, and reporting requirements.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

14 просмотров2 страницыMTD 21 Guide for Visual Aids Selection

Загружено:

bsk2007This document provides guidelines for selecting visual aids for inspecting surfaces to detect imperfections. It discusses types of visual aids including single-element magnifiers up to 0.4x magnification (Type A) and multi-element magnifiers up to 0.8x magnification (Type B). The document also briefly outlines visual inspection techniques, qualifications for inspection personnel, factors that influence temperature measurement, and reporting requirements.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

1

Doc: MTD 21 (5035)W

For Comments Only

BUREAU OF !DA! "TA!DARD"

Draft n#$%n "t%n#%r#

&UDE'!E" FOR "E'ECTO! OF AD" FOR ("UA' E)AM!ATO!

C" 1*+100

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

!ot to -e re.ro#/ce# 0$t1o/t .erm$ss$on '%st #%te 2or rece$.t

o2 B" or /se# %s % "TA!DARD o2 comments $s 15 34 2012

1 "CO5E

1+1 This standard is intended to provide general guidance on the choice of visual

aids used in the visual examination of surfaces in order to detect the presence of

imperfections or to asses condition and texture.

This standard specifies the characteristics of the following types of visual aids and

gives recommendations for their selection for the inspection of surfaces.

--Single-element magnifiers of magnification typically up to 0.4 (Type A).

-- ulti-element magnifiers of magnification typically up to 0.!0 (Type ").

2 REFERE!CE

2+1 The following standards contain provisions which# through reference in this text#

constitute provisions of this standard. At the time of pu$lication# the edition indicated

was valid. All standard are su$%ect to revision and parties to agreements $ased on

this standard are encouraged to investigate the possi$ility of applying the most

recent edition of the standards indicated $elow &

'S (). Title

!*+0,&-004 .eneral standards for /ualification and certification

of non destructive testing personnel (first revision )

3 "&!FCA!CE A!D U"E

3+1 0isual inspection is a non destructive testing method that provides a means of

detecting a variety of surface flaws# and discontinuities such as crac1s# undercuts#

corrosion# cavities etc on surfaces of welds# castings and other metallic and non

metallic products. .iven the wide variety of surface flaws that can $e detected $y

visual examination# the use of visual inspection may encompass different techni/ues

and different types of aids# depending on the product and the type of surface flaw

$eing monitored.

The methods of visual inspection involve a wide variety of e/uipment# ranging from

examination with the na1ed eye to the use of magnifiers# rigid and flexi$le

$orescopes and microscopes for /ualitative and /uantitative inspection of surfaces.

Some of the e/uipment used to aid visual inspection includes&

- 2lexi$le or rigid $orescopes for illuminating and o$serving internal#

closed or otherwise inaccessi$le areas.

2

- 'mage sensors for remote sensing or for the development of permanent

visual records in the form of photograph# video tapes# or computer-enhances

images.

- agnifying systems for evaluating surface finish# surface shapes (profile and

contour gauging)and surface microstructures.

- 3ye and fluorescent penetrants and magnetic particles for enhancing the

o$servation of surface crac1s (and sometimes near-surface conditions in the

case of magnetic particle inspection).

6 BAC7&ROU!D

6+1 4rinciple of 'nfrared Themography

6+2 Techni/ues in 'nfrared Themography

5 !"5ECTO! 5ER"O!!E'

5+1 The personnel deployed for inspection shall have necessary technical

/ualifications and experience with ade/uate and sound 1nowledge on inspection

techni/ue# and capa$ility to interpret the o$served temperature patterns.

5+2 The inspector should have ade/uate 1nowledge and shall comply with all the

safety precautions and procedures stipulated $y the end user and or competent

electrical authorities especially when examination of live systems are involved.

5+3 The inspector shall use an appropriate thermal imaging system with ade/uate

capa$ilities to meet the examination re/uirements.

5+6 The thermography personnel shall not touch any electrical e/uipment

open5remove any cover etc.

5+5 The end user is primarily responsi$le for a) ensuring compliance to all safety

procedures $) conse/uences of all actions resulting of application5non application of

thermal imaging experimental data ac/uired and interpreted $y the thermographer.

8 E9U5ME!T

8+1 The right choice of infrared camera with appropriate accessories and filters is

essential for successfully carrying out the inspection of electrical installations.

4 !"5ECTO! 5RACTCE

: 5ROCEDURE

* FACTOR" T;AT !F'UE!CE T;E TEM5ERATURE MEA"UREME!T

10 RE5ORT!& T;E RE"U'T"

"efore the actual thermographic inspection is performed# the inspection agency shall

su$mit detailed procedures that shall $e approved $y the end-user. After the

inspection all documented details shall $e provided as report. A typical procedure

format of report page is given $elow.

Вам также может понравиться

- NDT ProceduresДокумент2 страницыNDT Proceduresyeezee100% (1)

- Electrical Testing and Commissioning ProceduresДокумент11 страницElectrical Testing and Commissioning Procedureseng_asayedОценок пока нет

- NCASP 2013 OTS AnnexNДокумент7 страницNCASP 2013 OTS AnnexNChristoОценок пока нет

- Basic Principles of Non-Destructive TestingДокумент13 страницBasic Principles of Non-Destructive TestingNDT Consultancy Services Inc0% (2)

- Paper NDTДокумент11 страницPaper NDTAllwin AntonyОценок пока нет

- N D T (NDT) : Seed GДокумент10 страницN D T (NDT) : Seed GShishir Kant SinghОценок пока нет

- NDT ProceduresДокумент7 страницNDT ProceduresDavid DaemmejОценок пока нет

- RESIDUAL LIFE ASSESSMENT AND MODERNIZATION OF STEAM TURBINESДокумент22 страницыRESIDUAL LIFE ASSESSMENT AND MODERNIZATION OF STEAM TURBINESkrlalitОценок пока нет

- Methodology LEO-Scan Reformer Tube Inspection 2017 Rev 1Документ6 страницMethodology LEO-Scan Reformer Tube Inspection 2017 Rev 1hoangviet20006Оценок пока нет

- 14 Inspection FundamentalДокумент50 страниц14 Inspection FundamentalDimas Anggoro Nazara Putra100% (3)

- Electrical CommissioningДокумент19 страницElectrical CommissioningLuis EnriqueОценок пока нет

- List NDT Techniques Commonly Used For Inspecting and ComponentsДокумент12 страницList NDT Techniques Commonly Used For Inspecting and ComponentscollinsОценок пока нет

- Dacon AndtДокумент30 страницDacon AndtCepi Sindang Kamulan100% (1)

- Using safety cases to regulate complex systemsДокумент9 страницUsing safety cases to regulate complex systemsghanbari8668Оценок пока нет

- Agemp Model 2 ANSWER KEYДокумент13 страницAgemp Model 2 ANSWER KEYAnonymous P0rZmU100% (2)

- Commissioning: Commissioning High Voltage EquipmentДокумент14 страницCommissioning: Commissioning High Voltage Equipment2091979Оценок пока нет

- NB-CPR 14-594 Use of Facilities Outside The Laboratory of The NBДокумент5 страницNB-CPR 14-594 Use of Facilities Outside The Laboratory of The NBIoana SperleaОценок пока нет

- Module 9.qualification 1.welding PerformanceДокумент6 страницModule 9.qualification 1.welding PerformanceMohd NizamОценок пока нет

- 01-Visual Inspection & Welding InspectorsДокумент7 страниц01-Visual Inspection & Welding InspectorsSaif UllahОценок пока нет

- Aramco Specific Evaluations For WeldingДокумент6 страницAramco Specific Evaluations For WeldingSiddiqui Abdul Khaliq89% (9)

- Visual InspectionДокумент24 страницыVisual Inspectionaby100% (2)

- ISA CCST Task List Reference GuideДокумент13 страницISA CCST Task List Reference GuideNaseer HydenОценок пока нет

- Railway Welding InspectionДокумент16 страницRailway Welding InspectionQuality MSIPLОценок пока нет

- MOS For T&C Data & Telecommunication NetworkДокумент11 страницMOS For T&C Data & Telecommunication NetworkTarek Mahmoud GhazyОценок пока нет

- Nondestructive Testing - WikipediaДокумент7 страницNondestructive Testing - Wikipediaaniket waghОценок пока нет

- Non-Destructive Methods in AviationДокумент6 страницNon-Destructive Methods in AviationAmeem TariqОценок пока нет

- B Gas Examination RequirementsДокумент25 страницB Gas Examination RequirementsNnamdi Celestine Nnamdi100% (1)

- Codigo ASME (Arrastrado)Документ3 страницыCodigo ASME (Arrastrado)Mou RmzОценок пока нет

- Edm ErrorДокумент14 страницEdm ErrorFaizan FathizanОценок пока нет

- Cable Termination Method StatementДокумент7 страницCable Termination Method StatementMohamed KasemОценок пока нет

- Cswip 3.0 SyllabusДокумент2 страницыCswip 3.0 SyllabusAbu HurairaОценок пока нет

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesДокумент10 страницProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaОценок пока нет

- Electrical Specifications, Division 16, SECTION 16140 WIRING DEVICESДокумент7 страницElectrical Specifications, Division 16, SECTION 16140 WIRING DEVICESeng_asayedОценок пока нет

- API RP 2A Platform Inspection Procedure REV 0Документ21 страницаAPI RP 2A Platform Inspection Procedure REV 0Putu Yusna Armita100% (3)

- Fda Implantable Pacemaker Testing GuidanceДокумент11 страницFda Implantable Pacemaker Testing Guidanceapi-255072282Оценок пока нет

- Checking Machine Tools: Their Uses Keywords: Machines Tols, Measurements, Mini-Lathe, Accuracy, CNCДокумент5 страницChecking Machine Tools: Their Uses Keywords: Machines Tols, Measurements, Mini-Lathe, Accuracy, CNCMihai GhitulescuОценок пока нет

- Non Destructive Testing NDTPDFДокумент30 страницNon Destructive Testing NDTPDFLong BinОценок пока нет

- Module 7 Essay Questions 1Документ3 страницыModule 7 Essay Questions 1Jonathan100% (2)

- Ansaldo NDT Specifications 22GRKW v1 0Документ117 страницAnsaldo NDT Specifications 22GRKW v1 0pvssrh9929Оценок пока нет

- Qualification Process For Phased Array UT Using DNV RP-F118Документ12 страницQualification Process For Phased Array UT Using DNV RP-F118aztec20100% (1)

- Construction Method Statement: Fabrication & Erection of Piping SystemДокумент24 страницыConstruction Method Statement: Fabrication & Erection of Piping SystemHarun Akkaya100% (2)

- Inspection Plan (Draft)Документ5 страницInspection Plan (Draft)pioneerinvincibleОценок пока нет

- Acoustic EmissionДокумент5 страницAcoustic EmissionYasir MehmoodОценок пока нет

- Corning Recommended Fiber Optic Test Guidelines - LAN-1561-AEN - PAGE 1Документ12 страницCorning Recommended Fiber Optic Test Guidelines - LAN-1561-AEN - PAGE 1Karthikeyan RОценок пока нет

- LBS-RC-EO001-MS-MEP-ELE-0015 Method Statement For Testing and Commissioning of Emergency Lighting SystemДокумент9 страницLBS-RC-EO001-MS-MEP-ELE-0015 Method Statement For Testing and Commissioning of Emergency Lighting SystemfidgetyОценок пока нет

- Guide To InstrumentationДокумент52 страницыGuide To InstrumentationHumberto Diomedi MirandaОценок пока нет

- SoW - DW FPSO Integrity PDFДокумент20 страницSoW - DW FPSO Integrity PDFUzezi oОценок пока нет

- Set StandardsДокумент83 страницыSet Standardsnikola5702Оценок пока нет

- Mechanical Integrity Inspections For Ammonia Refrigeration SystemsДокумент3 страницыMechanical Integrity Inspections For Ammonia Refrigeration Systemsعزت عبد المنعمОценок пока нет

- CAES-OPE-UT-PRO-001(ASME) Rev.0 ENGДокумент29 страницCAES-OPE-UT-PRO-001(ASME) Rev.0 ENGMA GPОценок пока нет

- Nde Uesl Utm NDT 0005Документ7 страницNde Uesl Utm NDT 0005George OgbecheОценок пока нет

- Electrical Equipment Risk AssessmentДокумент6 страницElectrical Equipment Risk AssessmentPuppy Ayu Jatmiko100% (1)

- NDE NDT Inspection BrochureДокумент16 страницNDE NDT Inspection BrochureEngr Arfan Ali DhamrahoОценок пока нет

- Verification of Lifting EquipmentДокумент14 страницVerification of Lifting EquipmentsurnaikОценок пока нет

- Inspection Instrument&Control EquipmentДокумент43 страницыInspection Instrument&Control EquipmentModestyОценок пока нет

- Saep 1146Документ8 страницSaep 1146Ronanki RaviОценок пока нет

- Sop Iii-306 R00Документ23 страницыSop Iii-306 R00Bepdj100% (1)

- The Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsОт EverandThe Safety Relief Valve Handbook: Design and Use of Process Safety Valves to ASME and International Codes and StandardsРейтинг: 3.5 из 5 звезд3.5/5 (14)

- Reliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisОт EverandReliability of High-Power Mechatronic Systems 2: Aerospace and Automotive Applications: Issues,Testing and AnalysisОценок пока нет

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsОт EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsОценок пока нет

- De So 2 de Kiem Tra Giua Ki 2 Tieng Anh 8 Moi 1677641450Документ4 страницыDe So 2 de Kiem Tra Giua Ki 2 Tieng Anh 8 Moi 1677641450phuong phamthihongОценок пока нет

- Surah 25. Al-Furqan, Ayat 63-69 PDFДокумент1 страницаSurah 25. Al-Furqan, Ayat 63-69 PDFMusaab MustaphaОценок пока нет

- Manila Pilots Association Immune from Attachment for Member's DebtДокумент2 страницыManila Pilots Association Immune from Attachment for Member's DebtAngelic ArcherОценок пока нет

- The Insanity DefenseДокумент3 страницыThe Insanity DefenseDr. Celeste Fabrie100% (2)

- Phasin Ngamthanaphaisarn - Unit 3 - Final Assessment Literary EssayДокумент4 страницыPhasin Ngamthanaphaisarn - Unit 3 - Final Assessment Literary Essayapi-428138727Оценок пока нет

- Astrology - House SignificationДокумент4 страницыAstrology - House SignificationsunilkumardubeyОценок пока нет

- Ultramat 2 instructions for useДокумент2 страницыUltramat 2 instructions for useBalaji BalasubramanianОценок пока нет

- GCSE Ratio ExercisesДокумент2 страницыGCSE Ratio ExercisesCarlos l99l7671Оценок пока нет

- Jaap Rousseau: Master ExtraodinaireДокумент4 страницыJaap Rousseau: Master ExtraodinaireKeithBeavonОценок пока нет

- BI - Cover Letter Template For EC Submission - Sent 09 Sept 2014Документ1 страницаBI - Cover Letter Template For EC Submission - Sent 09 Sept 2014scribdОценок пока нет

- Communicative Competence: Noam ChomskyДокумент2 страницыCommunicative Competence: Noam ChomskyKiara Denise SuarezОценок пока нет

- Tata Hexa (2017-2019) Mileage (14 KML) - Hexa (2017-2019) Diesel Mileage - CarWaleДокумент1 страницаTata Hexa (2017-2019) Mileage (14 KML) - Hexa (2017-2019) Diesel Mileage - CarWaleMahajan VickyОценок пока нет

- Secondary Sources Works CitedДокумент7 страницSecondary Sources Works CitedJacquelineОценок пока нет

- DRRR STEM 1st Quarter S.Y.2021-2022Документ41 страницаDRRR STEM 1st Quarter S.Y.2021-2022Marvin MoreteОценок пока нет

- Preparation For Exercise1-1 CompleteДокумент28 страницPreparation For Exercise1-1 CompleteSimon GranОценок пока нет

- Battery Genset Usage 06-08pelj0910Документ4 страницыBattery Genset Usage 06-08pelj0910b400013Оценок пока нет

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Документ1 страницаTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Pravin AwalkondeОценок пока нет

- Compro Russindo Group Tahun 2018 UpdateДокумент44 страницыCompro Russindo Group Tahun 2018 UpdateElyza Farah FadhillahОценок пока нет

- Prac Research Module 2Документ12 страницPrac Research Module 2Dennis Jade Gascon NumeronОценок пока нет

- Mastering ArpeggiosДокумент58 страницMastering Arpeggiospeterd87Оценок пока нет

- Structural Works - SharingДокумент37 страницStructural Works - SharingEsvimy Deliquena CauilanОценок пока нет

- Barra de Pinos 90G 2x5 P. 2,54mm - WE 612 010 217 21Документ2 страницыBarra de Pinos 90G 2x5 P. 2,54mm - WE 612 010 217 21Conrado Almeida De OliveiraОценок пока нет

- Settlement of Piled Foundations Using Equivalent Raft ApproachДокумент17 страницSettlement of Piled Foundations Using Equivalent Raft ApproachSebastian DraghiciОценок пока нет

- Online Statement of Marks For: B.A. (CBCS) PART 1 SEM 1 (Semester - 1) Examination: Oct-2020Документ1 страницаOnline Statement of Marks For: B.A. (CBCS) PART 1 SEM 1 (Semester - 1) Examination: Oct-2020Omkar ShewaleОценок пока нет

- Tax Q and A 1Документ2 страницыTax Q and A 1Marivie UyОценок пока нет

- York Product Listing 2011Документ49 страницYork Product Listing 2011designsolutionsallОценок пока нет

- EE-LEC-6 - Air PollutionДокумент52 страницыEE-LEC-6 - Air PollutionVijendraОценок пока нет

- Adic PDFДокумент25 страницAdic PDFDejan DeksОценок пока нет

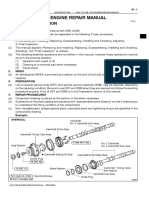

- How To Use This Engine Repair Manual: General InformationДокумент3 страницыHow To Use This Engine Repair Manual: General InformationHenry SilvaОценок пока нет

- Legal validity of minor's contracts under Indian lawДокумент8 страницLegal validity of minor's contracts under Indian lawLakshmi Narayan RОценок пока нет