Академический Документы

Профессиональный Документы

Культура Документы

Design Guideline For Hydraulic Fluid Cleanliness

Загружено:

CarlosИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design Guideline For Hydraulic Fluid Cleanliness

Загружено:

CarlosАвторское право:

Доступные форматы

x

= ?

x

= ?

Design Guideline

for Hydraulic Fluid

Cleanliness

Technical

Information

100

75

50

10

10 20

5

0.5 1 5

10

-

v

a

lu

e

Differential pressure (bar)

P001 322E

13 m

d = 13 m

Square 78.5 m

2

d = 10 m

Old: New:

P001 935E

78.5 m

2

4

d = = 10 m

2 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

This leaet is intended to assist the designer of an installation, a set or a hydrostatic

drive to ensure that the requirement for a specic minimum cleanliness of the hydraulic

uid is met by means of design measures such as the selection of an optimal lter, or

preferably of an economically efcient ltration concept. This includes start-up, operation

and topping up of hydraulic uid.

In hydrostatic systems a series of sliding surfaces act as hydrostatic-hydrodynamic

bearings with gap heights in the range of 10 m. That is why dirt is the greatest enemy of

hydraulic systems, since depending on its nature and composition it generates wear and

thus shortens service lives.

This is true for all elds of mechanical engineering and it cannot be repeated often

enough. At the present time it is not possible to predict the length of the service life of a

hydrostatic unit as a function of the cleanliness of the hydraulic uid. The fact that these

constraints are not known for roller bearings either, even though very many parameters

have been researched for these parts in particular, shows just how complicated these

wear mechanisms are.

Although more effort is currently being concentrated on trying to measure dirt

sensitivity of hydrostatic units in short-term contamination tests, such experiments are

unsuccessful because contamination sensitivity cannot be measured like pressures or

speeds. The leading manufacturers of hydrostatic equipment have therefore decided

to give priority to investigating the fundamentals of wear caused by contamination in

hydrostatic units within the framework of a joint research project.

It is uncertain to what extent service life prognoses will be possible at the end of the

research project, if at all. It can, however, be stated that the cleaner a system, the higher

its service life expectancy.

A satisfactory service life is achieved if the cleanliness level as required below is

maintained.

Initial Questions and Answers

PURPOSE OF THIS

LEAFLET

WHY IS FILTRATION

NECESSARY?

2008, Sauer-Danfoss. All rights reserved. Printed in Europe.

Sauer-Danfoss accepts no responsibility for possible errors in catalogs, brochures and other printed material.

Sauer -Danfoss reserves the right to alter its products without prior notice. This also applies to products already

ordered provided that such alterations can be made without affecting agreed specications. All trademarks

in this material are properties of their respective owners. Sauer-Danfoss and the Sauer-Danfoss logotype are

trademarks of the Sauer-Danfoss Group.

Front cover illustrations: P001 317 and P001 322E.

3 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Contents

Purpose of this leaet ................................................................................................................................... 2

Why is ltration necessary? ......................................................................................................................... 2

Where does the dirt come from? .............................................................................................................. 4

How can the required cleanliness level be achieved? ...................................................................... 4

Assembly dirt.............................................................................................................................................. 4

Operating dirt ............................................................................................................................................ 4

Denition of -ratio, efciency, lter neness ..................................................................................... 6

Cleanliness features ....................................................................................................................................... 8

Denition of cleanliness levels per ISO 4406 .................................................................................. 8

New particle size denition .................................................................................................................10

Recommendation for lter neness / retaining rates (Beta-ratios) ......................................10

Technical .........................................................................................................................................................11

Requirements of hydraulic uids ............................................................................................................11

Fluid cleanliness requirements ..........................................................................................................11

Closed circuit .................................................................................................................................................13

Design of a lter in the suction line .................................................................................................13

Design of a lter in the charge circuit .............................................................................................13

Open circuit ....................................................................................................................................................14

Design of a lter in the suction line .................................................................................................14

Design of a lter in the return line ....................................................................................................14

Filtration in circuits with multiple pumps ......................................................................................14

Recommendations for differential pressure (pressure drop) of a new lter element

and -ratios for closed and open circuit .........................................................................................14

Dirt absorption capacity, maximum differential pressure ........................................................15

Why a bypass? ...............................................................................................................................................16

Contamination indicator ...........................................................................................................................17

What is to be done if the required cleanliness class is not achieved? .......................................18

Why loop ushing? ......................................................................................................................................18

Taking of uid samples ...............................................................................................................................19

Sampling according to ISO 4021 from a system in operation .....................................................19

Sampling device ......................................................................................................................................19

Sampling method ...................................................................................................................................19

Sampling from a tank according to CETOP RP 95 H ..................................................................20

Working hints.................................................................................................................................................21

Scavenging and running in .................................................................................................................21

Monitoring of contamination ..................................................................................................................22

Permanent .................................................................................................................................................22

Cyclical ........................................................................................................................................................22

Topping up hydraulic uid ..................................................................................................................22

Changing the element ..........................................................................................................................23

INITIAL QUESTIONS AND

ANSWERS

REQUIRED FLUID

CLEANLINESS

SELECTION OF AN

APPROPRIATE FILTER

AND FILTRATION SYSTEM

TAKING OF FLUID

SAMPLES

WORKING HINTS

4 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Initial Questions and Answers

WHERE DOES THE DIRT

COME FROM?

HOW CAN THE REQUIRED

CLEANLINESS LEVEL BE

ACHIEVED?

We distinguish between two essential sources of dirt:

contamination occurring during assembly assembly dirt

contamination occurring during operation operating dirt

Assembly dirt

Different kinds of dirt occur during the various production operations: chips, moulding

sand, core residues, cleaning-rag lint, welding beads, scale etc. Products supplied by

Sauer-Danfoss are therefore cleaned in modern cleaning installations after completion of

machining operations on the individual parts. Careful attention is also paid to cleanliness

when these clean individual parts are assembled to form highgrade hydrostatic units.

However, since dirt occurs during the nal assembly in a vehicle, of a set etc., especially

during the piping work, it is advisable to ush the whole system prior to commissioning.

The basic contamination of the clean hydraulic uid supplied must also be added to

the assembly dirt. As investigations have shown, new hydraulic uid can contain basic

dirt levels in excess of the cleanliness level admissible for optimum operation

(see section Cleanliness requirements, page 11). That is why a system should always be

lled up via a lter assembly. Particles of the same order of magnitude as the gap widths

are to be considered as especially critical.

Operating dirt

Fine dirt from the surrounding environment is drawn into the hydraulic system during

operation via piston rods or other moving seals. Abrasive particles from the components

are also pumped through the system with the uid. A frequently underestimated source

of contamination is from unsuitable venting facilities of uid tanks. Fluctuations in

volume cause ne dust to be drawn into the tanks, from where it causes abrasion of the

sliding combinations in the system.

A ltration system must be designed in such a way that it is able to retain the new dirt

entering the overall system in the lter in order to maintain the required cleanliness level

throughout the whole operating life.

An example of this is described below:

If a lter is used in the suction line or the charge circuit, the charge pump size selected

- in our example 17 cm

3

- determines the volume ow available for ltering as a function

of the speed. The following theoretical calculation serves to illustrate this (see illustration

P001 318, page 5).

Assuming that the pump runs at a nominal speed of 1500 min

-1

, then at an assumed

volumetric efciency of 90 %, a charge pump volume ow of approx. 23 l/min results.

A contamination level of 230 particles larger than 10 m/ml has developed in the oil tank

and a lter with

35

= 75,

10

= 2 (= 50 % ltration efciency, see table below) is tted in the

suction line. The contamination is also distributed uniformly in the uid. Approximately

5.3 x 10

6

particles larger than 10 m per minute are now drawn from the tank with the

charge pump ow. The lter element holds back 50 % of the particles larger than 10 m,

so that 2.65 x 10

6

particles larger than 10 m reach the charge pump each minute.

5 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Initial Questions and Answers

HOW CAN THE REQUIRED

CLEANLINESS LEVEL BE

ACHIEVED?

(continued)

If 2.65 x 10

6

particles larger than 10 m are also passed to the system per minute (via

ventilation lters, piston rods or abrasion), there is no change in the cleanliness level.

If fewer than 2.65 x 10

6

particles larger than 10 m are passed to the system, a lower i. e. a

better cleanliness level is achieved. However if more than 2.65 x 10

6

particles larger than

10 m are passed to the system, a higher i. e. a worse cleanliness level is achieved.

As mentioned at the beginning, this calculation is very close to conditions encountered

in practice, but these will never be so exact because particles will settle at the bottom of

the tank in areas with a low ow velocity. Nor are the particles so uniformly distributed

when they pass through the lter. This example is merely intended to illustrate the

principle and it can be established that:

The cleanliness level is improved if:

the lter neness is improved

(higher -value for a certain particle size, i. e.

10

= 2 becomes

10

= 2.5)

the volume ow* via the lter is increased

The cleanliness level deteriorates if:

the lter neness deteriorates

(lower -value for a certain particle size, i. e.

10

= 2 becomes

10

= 1.8)

the volume ow* via the lter is reduced

The ow volume cannot generally be selected freely since it is determined in a closed

circuit by the size of the charge pump. However other operating factors take priority

when the charge pump size is selected. In these cases, therefore, the -value must be

varied. However, if the -value is increased (different lter material) without the structural

dimensions of the lter being increased, then the consequence is that:

the differential pressure rises (applies for new, uncontaminated lter element)

the dirt absorption capacity drops (reduced service life)

Schematic Series 90 variable pump with suction lter

P001 318E

2.65 x 10

6

particles > 10 m/min

35

= 75 (

10

= 2 equivalent 50 %)

Q = 23 l/min

5.3 x 10

6

particles > 10 m/min

230 particles > 10 m/ml

L2 S

S

e

rv

o

M

A

B

L1

* Note the change of the

-value shown on page 15,

diagram P001 322E.

The alteration of the

volume ow also changes

the differential pressure

and hence the value too.

However the volume ow

has more inuence on the

cleanliness level.

6 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Initial Questions and Answers

The -ratio is dened and determined in ISO 16 889-1999 Multi-pass test

(old: ISO 4572-1982) as:

Number of particles > x m upstream of the lter

X

=

Number of particles > x m downstream of the lter

As a characteristic number the

10

-ratio is to be specied.

Example:

500 particles > 10 mm upstream of the lter

10

= = 50

10 particles > 10 mm downstream of the lter

This number denes the ratio of the number of particles before and after the lter. This

means from 500 particles larger than 10 m before the lter, 490 particles are retained

in the element and only 10 pass through or from 50 particles before the lter, 49 are

retained and only 1 passes through. This can be expressed as lter efciency:

500 - 10 50 - 1

Filter efciency = = = 98 %

500 50

or:

1 1

Filter efciency = 1 - = 1 - = 98 %

10

50

This efciency makes the lter performance more understandable. Table below shows

clearly the relationship between -ratio and efciency. In practice the following term is

often used:

X

= 75 (= 98,67 % efciency)

The observant reader will notice that increasing the -ratio by 50 % (from 50 to 75) the

efciency only increases by 0.67 %, therefore

X

-ratios above 75 % are not reasonable.

In some lter manufacturers catalogues you sometimes nd

X

larger than 2000.

The real efciency increase is shown in the table on page 7. The

10

= 75-ratio has been

established as a standard. This species the particle size (indicated as

X

) were the -ratio

is equal to 75. This particle size is used to classify the lter neness.

Example:

35

= 75 equals a lter neness of 35 m

The term absolute lter neness may not be used for this.

Together with the -ratio the related differential pressure at the lter element has to be

specied. Unfortunately this is not always specied in the lter manufacturers catalogue.

DEFINITION OF -RATIO,

EFFICIENCY, FILTER

FINENESS

7 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Initial Questions and Answers

DEFINITION OF -RATIO,

EFFICIENCY, FILTER FINE-

NESS (continued)

-ratio efciency -ratio efciency

1.0 0.0 6.4 84.4

1.1 9.1 6.8 85.3

1.2 16.7 7.0 85.7

1.3 23.1 7.2 86.1

1.4 28.6 7.4 86.5

1.5 33.3 7.6 86.8

1.6 37.5 7.8 87.2

1.7 41.1 8.0 87.5

1.8 44.5 8.2 87.8

1.9 47.3 8.4 88.1

2.0 50.0 8.6 88.4

2.1 52.4 8.8 88.6

2.2 54.4 9.0 88.9

2.3 56.5 9.2 89.1

2.4 58.3 9.4 89.4

2.5 60.0 9.6 89.6

2.6 61.5 9.8 89.8

2.7 62.9 10 90.0

2.8 64.3 11 90.9

2.9 65.5 12 91.6

3.0 66.6 13 92.3

3.1 67.7 14 92.9

3.2 68.8 15 93.3

3.3 69.7 16 93.8

3.4 70.6 17 94.1

3.5 71.4 18 94.4

3.6 72.2 19 94.5

3.7 72.9 20 95.0

3.8 73.7 30 96.7

3.9 74.4 40 97.5

4.0 75.0 50 98.0

4.2 76.2 60 98.3

4.4 77.3 70 98.6

4.6 78.3 75 98.67

4.8 79.2 80 98.7

5.0 80.0 90 98.9

5.2 80.8 100 99.0

5.4 81.5 200 99.5

5.6 82.1 500 99.8

5.8 82.8 1000 99.9

6.0 83.3 2000 99.95

6.2 83.8

-ratio versus efciency

8 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

The old ISO 4406-1987 denes the cleanliness level of particles larger than 5 m and

15 m. As an example: if 1910 particles/ml larger than 5 m and 71 particles/ml larger

than 15 m are counted, the ISO 4406-1987 code level is 18/13.

In 1999 both, the denition for particle counting and the denition of ISO code was

changed. The required cleanliness class denition is now determined by ISO 4406-1999.

The allocated particle sizes are:

Comparison of old and new standard ISO 4406

Please note, that (c) must be added to the new denition in order to identify that it is

the new ISO 4406. The old method for particle counting may still be used.

The ISO 4406-1999 cleanliness class 22/18/13 means:

22 species the number of particles larger than 4 m (c),

18 species the number of particles larger than 6 m (c), and

13 species the number of particles larger than 14 m (c) related to 1 ml respectively

100 ml of the inspected uid.

CLEANLINESS FEATURES

d e n i f e d t o n ) c ( m 4

m 5 ) c ( m 6

m 5 1 ) c ( m 4 1

Old ISO 4406-1987 New ISO 4406-1999

Required Fluid Cleanliness

Denition of cleanliness levels per ISO 4406

The cleanliness level of a hydraulic uid is determined by counting number and size of

particles in the uid. The number of particles is dened as a cleanliness level according to

ISO 4406.

Denition of cleanliness levels per ISO 4406

Number of particles per 100 ml Number of particles per 1 ml Cleanliness levels per ISO 4406

1-2 0.01 - 0.02 1

2-4 0.02 - 0.04 2

4-8 0.04 - 0.08 3

8-16 0.08 - 0.16 4

16-32 0.16 - 0.32 5

32-64 0.32 - 0.64 6

etc. etc. etc.

4 x 10

3

- 8 x 10

3

40 - 80 13

8 x 10

3

- 16 x 10

3

80 - 160 14

16 x 10

3

- 32 x 10

3

160 - 320 15

32 x 10

3

- 64 x 10

3

320 - 640 16

64 x 10

3

- 130 x 10

3

640 - 1300 17

130 x 10

3

- 250 x 10

3

1300 - 2500 18

250 x 10

3

- 500 x 10

3

2500 - 5000 19

The step to the next cleanliness level means double or half the number of particles.

9 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

The new method counts more smaller

particles and less larger particles.

For better understanding please see the

graph beside. This graph demonstrates

the effect of the change to the new

particle sizes 4 m (c), 6 m (c), and

14 m (c).

Again, the actual number of particles of

a sample is of course the same, only the

counting method is different. Although

it may look like, the new method does

not allow more particles.

CLEANLINESS FEATURES

(continued)

Measurements with the same uid sample will result in the same cleanliness class for

both methods as shown in the table below.

Number of particles per milliliter, particle count comparison

Together with this ISO 4406 change a new calibration standard ISO 11 171-1999 and

a new Multi-pass test ISO 16 889-1999 for lters have been developed.

0

0

5 10

1000

2000

3000

4000

5000

15 17

Particle size (?m)

N

u

m

b

e

r

o

f

p

a

r

t

i

c

l

e

s

p

e

r

m

l

ISO 4406-1987

ISO 4406-1999

P001 948E

s d r a d n a t s d l O n o i t p i r c s e d t s e T s d r a d n a t s w e N

1 9 9 1 - 2 0 4 4 O S I n o i t a r b i l a c ) C P A ( r e t n u o c e l c i t r a p c i t a m o t u A 9 9 9 1 - 1 7 1 1 1 O S I

7 8 9 1 - 6 0 4 4 O S I e d o c s s e n i l n a e l C 9 9 9 1 - 6 0 4 4 O S I

2 8 9 1 - 2 7 4 5 O S I s r e t l i f r o f t s e t s s a p i t l u M 9 9 9 1 - 9 8 8 6 1 O S I

Comparison between old and new standards

Required Fluid Cleanliness

ISO 4406-1999 versus prior cleanliness classes

Comparison between old and new standards

e z i s e l c i t r a P m 1 ) c ( m 4 m 5 ) c ( m 6 ) c ( m 4 1 m 5 1

d e z i d r a d n a t s t o N 0 0 0 4 - - - - -

7 8 9 1 - 6 0 4 4 O S I d l O - - 0 0 0 2 - - 0 8 1

9 9 9 1 - 6 0 4 4 O S I w e N - 0 0 0 4 - 0 0 0 2 0 8 1 -

s s a l c s s e n i l n a e l c 6 0 4 4 O S I 9 1 9 1 8 1 8 1 5 1 5 1

10 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Required Fluid Cleanliness

For charge pressure and return line ltration a suction screen with a mesh width of

100 125 m must be used in the suction line to prevent sudden damage due to large

particles.

Recommendation for lter neness / retaining rates (Beta-ratios)

CLEANLINESS FEATURES

(continued)

13 m

d = 13 m

Square 78.5 m

2

d = 10 m

Old: New:

P001 935E

New particle size denition

The particle size denition has been changed also. The old standard dened the largest

particle extension as the particle size. The new standard uses the projected square area

and converts this to an equivalent diameter, please see the picture below.

Old versus new particle size denition

78.5 m

2

4

d = = 10 m

ISO 4407 (under revision) species particle counting with a microscope. Only particles

larger 5 m and 15 m are manually counted and specied as /18/13. The is used in

place of the rst scale number, while 18 is allocated to 5 m and 13 to 15 m.

) t i u c r i c n e p o + d e s o l c ( n o i t a r t l i f n o i t c u S

5 4 - 5 3

( 5 7 =

0 1

> ) 2

) t i u c r i c d e s o l c ( n o i t a r t l i f e r u s s e r p e g r a h C

0 2 - 5 1

( 5 7 =

0 1

> ) 0 1

) t i u c r i c n e p o ( n o i t a r t l i f e n i l n r u t e R

l a r e n e g

5 4 - 5 3

( 5 7 =

0 1

> ) 2

s r o t o m d n a s p m u p r a e g r o f

0 2 - 5 1

( 5 7 =

0 1

> ) 0 1

Recommended -ratios

11 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Required Fluid Cleanliness

Fluid cleanliness requirements

To achieve the specied unit life a cleanliness level as shown below must be met. Fluid

samples shall be taken either in the loop or at the entry to the pump, which is typically

the suction line. Fluid cleanliness requirements depends on the product and the

products acceptable continuous or rated pressure limits.

Fluid cleanliness requirements according to product

Product

Required cleanliness class

ISO 4406-1999

Curve in the diagram

on page 12

Steering components with open center 22/20/17 A

Orbital motors 22/20/16 B

Steering components with LS and closed center

21/19/16 C

Proportional spool valves

Axial + radial piston pumps and motors

22/18/13 D

Gear pumps and motors

Cartridge and electrohydraulic valves 18/16/13 E

These cleanliness levels can not be applied for hydraulic uid residing in the component

housing/case or any other cavity after transport.

In general for uid change and new uid top up minimum cleanliness class 23/21/15 and

for rst machine start up at the factory minimum cleanliness 25/22/17 must be met if not

otherwise specied. Exceeding these levels may result in start-up damage.

The before mentioned requirements reect the experience gained from a broad range of

applications. For very high lifetime requirements or contamination sensitive components

(e. g. servo valves) better cleanliness levels are necessary.

TECHNICAL

REQUIREMENTS OF

HYDRAULIC FLUIDS

12 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Required Fluid Cleanliness

TECHNICAL

REQUIREMENTS OF

HYDRAULIC FLUIDS

(continued)

10

100

1000

10 000

100 000

11

12

13

14

15

16

17

18

19

20

21

22

23

1 10 100

N

u

m

b

e

r

o

f

p

a

r

t

i

c

l

e

s

p

e

r

m

l

>

I

n

d

i

c

a

t

e

d

s

i

z

e

I

S

O

c

l

a

s

s

n

u

m

b

e

r

Particle size m (c)

4 14 6

24

25

ISO Solid Contaminant Code per ISO 4406-1999

(Automatic Particle Counter (APC) calibration per ISO 11 171-1999)

1 000 000

26

P001 683E

First machine start up

ISO 25/22/17

Fluid change + top up

ISO 23/21/15

A = ISO 22/20/17

B = ISO 22/20/16

C = ISO 21/19/16

D = ISO 22/18/13

E = ISO 18/16/13

Required uid cleanliness diagram

13 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

The design is explained below taking an SPV 9/075 with a charge pump volume of

17 cm

3

by way of example. A continuous pressure of 240 bar is assumed. Accordingly in

section 3 the cleanliness class 18/13 to ISO 4406 results from curve A.

Design of a lter in the suction line

Examinations have revealed that a lter in the suction line with a

35

45

= 75

at a differential pressure of 0.25 bar achieves the required cleanliness level18/13 under

normal operating conditions. In some applications even better cleanliness levels are

achieved. In order to assure that the cleanliness class is maintained we recommend that

samples of the hydraulic uid be drawn during the running-in time and that the particles

be counted. A certain, constant cleanliness level will emerge during the operating time

(see the illustration below).

Cleanliness level evolving as a function of operating hours for particles larger than

15 m

Selection of an Appropriate Filter and Filtration System

EXAMPLE

CLOSED CIRCUIT

Filter A

Filter B

16

15

14

13

12

11

10

C

l

e

a

n

l

i

n

e

s

s

l

e

v

e

l

(

I

S

O

4

4

0

6

)

1 10 100

P001 320E

Operating hours

An analogous graph can be drawn up for

any particle size. The following reference

can serve as a further guide.

A lter element with a

10

= 2.0 1.5 at

0.25 bar differential pressure (50 % - 33 %

ltration efciency for particles > 10 m)

generally reaches the above mentioned

35

45

= 75 value.

Design of a lter in the charge circuit

We recommend using lter elements with

15

20

= 75 (

10

= 10 corresponding to 90 %

ltration efciency) at the differential pressure occurring in the application. A strainer

with a mesh of 100 m 125 m has to be used to protect the charge pump against

coarse contamination. However the actual ltering work has to be performed by the

lter in the charge circuit.

On the basis of what has been said so far the question arises:

Why is a higher lter neness (-value) necessary in a lter in the charge circuit?

Answer:

The Multi-pass test per ISO 16 889 determines the -values at constant volume ow

and almost constant differential pressure increase. These optimal conditions do not

exist in the charge circuit so that a reduced -value sets in as a result of volume ow

and pressure uctuations. The lter industry and research institutes are in the process

of developing practice-oriented test methods to solve this problem. Furthermore, the

possible level of pressure uctuations is much lower in a suction lter. Moreover in

certain circuits the lter is arranged behind the charge circuit pressure limiting valve, so

that the whole charge pump volume ow does not constantly pass the lter. Related to

the whole charge pump volume ow, an arithmetically lower -value emerges here too.

As already said above for the lter in the suction line, it is recommended that the

cleanliness level actually existing or evolving in the course of time be determined here

too.

14 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Design of a lter in the suction line

Unlike the situation in the closed circuit, the whole main volume ow is taken from

the tank. That is why these suction lters must be adequately dimensioned in order

to achieve appropriate differential pressures and service lives. On the other hand a

lower lter neness can be selected, since a higher volume ow is available. For further

information, please see next page.

Design of a lter in the return line

In the case of return line lters in open circuits, special attention must be paid to

discontinuous volume ows through working cylinders with differing area ratio. Under

certain circumstances it might therefore be advisable to select a larger lter than would

be necessitated by the suction line alone. In any case a strainer with a mesh size of 100

125 m should be provided in the suction line.

Filtration in circuits with multiple pumps

A machine with several pumps using the same reservoir may use one lter only to save

costs. Every circuit must be protected by a suction strainer with 100 125 m mesh.

This mesh equals theoretically:

100-150

= 75

This term should not be used for a screen. The off-line ltration may feed other functions

and circuits like the steering equipment.

Recommendations for differential pressure (pressure drop) of a new lter element

and -ratios for closed and open circuit

In suction line (closed and open circuit):

Differential pressure: 0.1 bar (clean element) at:

Viscosity: 30 mm

2

/s [141.2 SUS]

Flow: closed circuit: charge pump displacement x rated speed

open circuit: pump displacement x rated speed

-ratio:

35-45

= 75 (

10

2)

In charge line (for closed circuit):

Differential pressure: 0.7 bar (clean element) at:

Viscosity: 30 mm

2

/s [141.2 SUS]

Flow: charge pump displacement x rated speed

-ratio:

15-20

= 75 (

10

10)

In return line (only open circuit):

Differential pressure: 0.5 bar (clean element) at:

Viscosity: 30 mm

2

/s [141.2 SUS]

Flow: charge pump displacement x rated speed

-ratio: general:

35-45

= 75 (

10

2)

for gear pumps and motors:

15 - 20

= 75 (

10

10)

By-pass ltration

As in charge line.

There will and must be exceptions to these recommendations to ensure an economic

ltration system.

Selection of an Appropriate Filter and Filtration System

OPEN CIRCUIT

15 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Dirt absorption capacity, maximum differential pressure

A further criterion for selecting the lter size is the dirt absorption capacity and

differential pressure rise in the case of increasing contamination, see the illustration

below.

When the Multi-pass test to ISO 16 889 is performed, the dirt absorption capacity is also

determined. It is important to distinguish between the apparent dirt absorption capacity,

which is the amount of dirt added during the test, and the real dirt absorption capacity,

which is the amount of dirt actually retained in the lter.

The following equation applies:

Added dirt quantity (apparent dirt absorption capacity) minus dirt quantity

remaining in the oil is the actual dirt absorption capacity.

Selection of an Appropriate Filter and Filtration System

OPEN CIRCUIT

(continued)

Change filter!

6

4

3

2

D

i

f

f

e

r

e

n

t

i

a

l

p

r

e

s

s

u

r

e

(

b

a

r

)

10 20 30

P001 321E

Dirt Capacity (g)

5

1

In the illustration beside the rise in

the differential pressure starts in an

approximately linear manner before

rising exponentially. Once this zone is

reached it is time to change the lter,

since a little dirt means a large increase

in the differential pressure.

In the case of the above lter element,

the contamination indicator should

respond either optically or electrically

at approximately 2.2 bar and indicate

that it is time to change the elements

concerned.

Rise of the differential pressure when dirt

is added

Depending on the lter material, certain

maximum differential pressures must not

be exceeded since the lter material may

be damaged and dirt already retained

will be released again, i. e. the dirt is

pumped through.

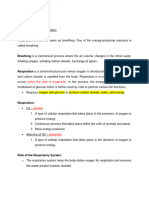

The curve of the -value versus the

differential pressure shows this

(see the illustration beside).

If it is expected that the lter element

will not be changed in time before the

rupture point is achieved, a bypass valve

(see below) must be installed.

A bypass valve must also be provided

if the differential pressure rises to an

inadmissible level during cold starts,

which is usually the case.

Retention rate as a function of the

differential pressure

100

75

50

10

10 20

5

0.5 1 5

10

-

v

a

l

u

e

Differential pressure (bar)

P001 322E

16 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Selection of an Appropriate Filter and Filtration System

WHY A BYPASS? Function of a bypass During operation the differential

pressure at the lter element rises due

to contamination. Without a bypass,

especially during cold starts, this would

lead to demage to the lter element or

collapse of the support elements. This

can be effectively prevented by the use

of a bypass.

Although the effective lter efciency

is reduced by the short opening of the

bypass during cold starts, the hydrostatic

unit is not immediately damaged as a

result of this. P001 324E

The cleanliness level simply deteriorates as a function of the time during which the

bypass is in operation and as a function of the newly generated particles. Working with

an open bypass for several hours or days should be avoided. This condition can be

monitored reliably with a contamination indicator (see section Contamination indicator,

page 17). The system operator thus determines the service life of the hydrostatic units

and the rest of the system by regularly checking the contamination level of the lter and

changing the lter elements in time.

It is important to understand that if used as explained above, a bypass is always better

than the sudden release of a particle or a dirt cloud due to damage to an element

whereby the cloud is passed through the whole system (including the high-pressure

circuit) and nally lands in the tank after irreparable damage is sustained by the sliding

parts. If there is no contamination indicator either, this damage is not noticed and it may

be that the system is operated for a long time with this unintentional bypass (after

the element has been destroyed!) until overheating caused by reduced efciency of the

hydrostatic units is recognized. This then turns out to be much more expensive than

the additional bypass and the contamination indicator would have been (see section

Contamination indicator, page 17).

A bypass should be arranged as shown above or even further away from the element if

the design allows this. Under certain circumstances it may even be a design advantage

if the lter elements are to be bolted directly on to the pump (charge circuit ltration). A

bypass may never be situated in the base of the lter element since the dirt settles in this

area and is ushed into the system again.

17 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Selection of an Appropriate Filter and Filtration System

CONTAMINATION

INDICATOR

AIR BREATHER

The contamination indicator responds when a predetermined differential pressure

occurs as a result of growing contamination of the lter element. An optical signal

appears, or an electrical contact is energized.

Function of the contamination indicator (differential pressure)

1. Pressure before the lter element

2. Pressure behind the lter element

3. Position of the magnets in a clean

element

4. Position of the magnets in a

contaminated element

P001 323

Sufcient attention must also be devoted to air breathers, since a considerable portion

of the contamination makes its way into hydraulic systems via unsuitable ventilation

systems. Design measures such as pressurizing reservoirs are often not economically

efcient by comparison with todays air breathers. Under certain circumstances it may

be necessary to observe the Pressurized Container Regulations if the pressure content

product derived from tank volume times pressure exceeds a certain value.

Unfortunately there is no standard for air breathers corresponding to the Multi-pass test

to ISO 16 889. The lter neness quoted by the manufacturer of the air breathers has to

be relied on. This does not permit comparisons between manufacturers A and B since, as

already mentioned, there are no standardized tests. Generally speaking the neness of

the air breathers must be equivalent to or better than the working lters present in the

system. Therefore only the

x

= 75 values and the given lter neness of the air breathers

can be taken as standard values.

18 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Selection of an Appropriate Filter and Filtration System

As a brief reminder:

It was explained before that the cleanliness level is inuenced by:

the -value (lter neness, ltration ratio)

the volume ow through the lter

If the required cleanliness level is not achieved using the 17 cm

3

/U charge pump and

the

10

= 75 lter, it is not necessarily expedient to use a larger charge pump. This may

necessitate a larger lter since the differential pressure more quickly reaches the limit

of p = 0.25 bar (risk of cavitation) with a clean lter element, which leads to insufcient

service life of the element. The energy balance also deteriorates as a result of the higher

power loss.

In this case lters with a higher -value must be used. However, since the higher -values

generally also involve higher differential pressures, it is often also necessary to move

the lter to the charge circuit. If the lter elements are designed accordingly, higher

differential pressures are admissible here so that the overall dimensions of the lter

can be reduced - representing an installation advantage. It must also be claried and

checked to what extent new contamination can be reduced and prevented.

It was explained before that inadequate ventilation facilities are a cause of fresh

contamination. An improvement of the cleanliness level can often be achieved by using

ventilation lters with better lter neness, especially for applications with working

cylinders with differing area ratios.

For the design of the ventilation lter the differential pressure (caused by the differential

air volume ow) must be kept as low as possible in order to prevent cavitation in the

suction area of the pumps. It should also be checked whether unsuitable piston rod seals

or leaks are the cause.

Remember:

Dirt which does not enter the system or is not caused by wear need not be removed by

ltration.

Filtration is intended to remove contamination from the hydraulic uid. For this, however,

the contamination must be passed to the lter element. In a closed circuit without circuit

purging, existing contamination can only be removed from the system with the oil

leaking from the pistons, the control valve etc. Since only particles smaller than the leak

gap width can leave the closed circuit, the remaining particles stay in the circuit and can

lead to erosion damage in areas with high ow velocities.

This can be avoided by circuit purging, i. e. by forcing 56 l/min from the low pressure

circuit via an spool valve and a purge relief valve.

The contamination ushed out in this way (including particles larger than the leak gap

width) can now be passed to the lter element installed in the system and be removed.

WHAT IS TO BE DONE

IF THE REQUIRED

CLEANLINESS CLASS IS

NOT ACHIEVED?

WHY LOOP FLUSHING?

19 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Taking of Fluid Samples

Fluid samples must be drawn very carefully into appropriate bottles to prevent

extraneous dirt from, falsifying the sample result.

The sample bottle should contain a label with the following information:

Sample number

Source of sample

Sampling method

Date and time of sampling

Nature of uid

Comments/remarks if necessary

Sampling points should be provided at the design stage of the hydraulic installation.

They should be arranged in the turbulent main ow.

Sampling device

Important: Take precautionary measures to protect personnel and equipment.

If turbulent ow conditions prevail in the main ow, a typical sampling device as

illustrated in the illustration P001 325, page 20

A quick fastening coupling 6 is permanently attached to the opening through which

the sample is to be withdrawn

A dust protection cap 1 is provided for the part 6

The remaining part of the unit 2-5 is secured for sampling

The inner diameter and length of the capillary tube are selected in agreement with

the desired sample quantity

Capillary tubes with an inner diameter of less than 1.25 mm may not be used. Other

cross-sectional forms (e. g. rectangular) can be used, provided that the smallest

internal dimension is not less than 1 mm

The end of the capillary tube is sharpened and deburred in order to facilitate the

subsequent penetration of the lm which covers the opening of the sample bottles

If no turbulence can be guaranteed in the ow, a device for generating turbulence

must be used, e. g. a turbulent sampler

Sampling method

Ball valve 5 is opened

Allow at least 200 ml uid to ow through the sampling device before collecting the

uid

Without closing the ball valve, place the sample bottle in the position for collecting

the uid

Pierce the protective lm covering the bottle opening with the sharp end of the

capillary tube

Draw a sample of not more than 90 % and not less than 50 % of the bottle volume.

When a sufcient sample quantity has been collected, remove the sample bottle

before stopping the ow with the ball valve

Seal the sample bottle immediately after withdrawing the capillary tube

If a sampling device with quick-fastening coupling is used, the removable parts

of the sampling device are to be dismantled and all other uid traces are to be

removed by ushing with a suitable solvent

Immediately after dismantling the dust protection cap is replaced on the

permanently mounted part of the quick fastening coupling.

TAKING OF FLUID

SAMPLES

SAMPLING ACCORDING

TO ISO 4021 FROM

A SYSTEM IN OPERATION

20 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Taking of Fluid Samples

Typical sampling device in practice SAMPLING ACCORDING

TO ISO 4021 FROM

A SYSTEM IN OPERATION

(continued)

Sampling from a tank according to CETOP RP 95 H

Sampling from the tank should only be carried out if it is not possible to sample from the

main ow.

Clean the outer surface of the tank around the places from which the sample is to be

drawn.

Sampling:

The uid in the tank should be mixed well in order to ensure that the sample is typical.

To this end warm up the system by running it under operating conditions. Then draw a

sample (at least 150 ml) with the aid of a pipette or a cleaned disposable syringe. Pass

the pipette about half way down into the uid.

Ensure that the pipette does not touch the side walls of the tank or come too close to

the bottom. Fill the contents of the pipette into the sample bottle and seal this carefully.

Cover the tank again or close it with clean covering lm if further samples are required.

P001 325

1. Dust protection cap

2. Valve without check device

3. Capillary tube for drawing off uid

4. Cover cap with capillary tube

5. Ball valve

6. Check valve, outer part for quick

fastening

21 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

The frequency and intensity of the maintenance work to be performed depend on the

burden generated by environmental inuences and on the workload.

Special attention must always be paid to the operational suitability and cleanness of the

hydraulic uid.

Scavenging and running in

Before a hydraulic system is commissioned, the assembly dirt must be removed. This

is best done by ushing the whole installation with a portable lter unit. Mineral oil

(or another medium compatible with the hydraulic uid to be used subsequently) is

pumped through the whole system or parts of the system at the highest possible ow

velocity. The assembly dirt is ltered in the lter unit.

During this process the elements of the built-in lters are to be removed. Small or less

sensitive systems can also be scavenged with the built-in lters during the running-in

process. It must be ensured that the system is run without load but with a displacement

which is gradually increased up to maximum. The illustration below shows the relation

between the design-specic, admissible cleanliness level and the actual cleanliness prior

to commissioning.

Working Hints

WORKING HINTS

Typical relation between the design-

specic, admissible cleanliness level A

and the actual cleanliness level prior to

commissioning D.

It is vital that the system be ushed and

run at low pressure until the required

cleanliness level is achieved.

P

a

r

t

i

c

l

e

c

o

u

n

t

p

e

r

u

n

i

t

v

o

l

u

m

e

Particle size in m (log

2

)

10

2

10 15 50 25 100

P001 326E

5

10

3

10

4

10

5

10

6

D

A

22 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Permanent

Every lter should be equipped with an optical/electrical indicator of the contamination

level at the lter. In this way it is possible to establish at any time whether there is still any

dirt absorption capacity or whether the elements have to be changed. The checks should

be carried out daily once the operating temperature is achieved.

If a contamination indicator with electrical signal device is used, the selected signal is

emitted at operating temperature when the lter element is contaminated. During the

warming up phase a contaminated signal is nearly always emitted due to the higher

differential pressure unless the contamination indicator is equipped with a signal cut-out

for the cold start phase.

Cyclical

With regular monitoring, lters are suitable as wear surveillance elements for the

components of the hydraulic system. If the operator keeps a log of lter changes, it

can be assumed in the event of shorter changing intervals that the wear of the system

components is increasing. The origin of the main contamination can be ascertained by

analysing a uid sample and the contaminated element. A comparison of the results with

the materials used allows preventive maintenance before a complete failure interrupts

production or operation. Adherence to the required cleanliness level is checked by

measuring the contamination and this ensures that no premature wear or failure occurs.

These samples must be drawn at specially designed sampling points as explained before.

Topping up hydraulic uid

Any uid used to top up losses should always be poured in via a ne lter in order to

maintain the cleanliness class. Where appropriate facilities are available, the return ow

lter can be used. It is advisable to provide a permanent connection which should be

included in considerations at the design stage. Any opening of the tank/reservoir for

maintenance purposes (topping up hydraulic uid, sampling, changing lter elements in

built-in tanks etc.) should always be avoided as far as possible by an expedient design.

Even though some ventilation lters have a so-called lling screen (mesh width >

100 m), this still does not afford any protection against the penetration of particles of

the order of magnitude of 10 100 m.

MONITORING

OF CONTAMINATION

Working Hints

23 520L0467 Rev GC Feb 2008

Design Guideline for Hydraulic Fluid Cleanliness

Technical Information

Changing the element

If the contamination indicator shows a contaminated element, this must be changed

without delay due to the high rate of increase of pressure drop as the element becomes

more contaminated. Extreme care must be taken when changing the element.

The operating instructions must be followed precisely.

The following standard values apply for lter maintenance intervals:

1. 24 hours after commissioning the system

2. After the running-in period (50 - 100 hours of service)

3 Normal maintenance after 300 - 500 hours of service

Literature:

1. Guidelines to Contamination Control in Hydraulic Fluid Power Systems (1985),

AHEM (The Association of Hydraulic Equipment Manufacturers, London)

2. Filterbel fr Hydraulikssigkeiten und Schmierstoffe,

MAHLE Industrielter, hringen

3. Leitfaden zur Optimalen Auswahl von Argo Filtertypen fr Hydrauliksysteme,

ARGO Filter, Kraichtal-Menzingen.

Figure and text source: 9, 17, 18, 20, 21, 22, 23 MAHLE Industrielter

MONITORING

OF CONTAMINATION

(continued)

Working Hints

Sauer-Danfoss Hydraulic Power Systems

Market Leaders Worldwide

Sauer-Danfoss is a comprehensive supplier providing complete

systems to the global mobile market.

Sauer-Danfoss serves markets such as agriculture, construction, road

building, material handling, municipal, forestry, turf care, and many

others.

We offer our customers optimum solutions for their needs and

develop new products and systems in close cooperation and

partnership with them.

Sauer-Danfoss specializes in integrating a full range of system

components to provide vehicle designers with the most advanced

total system design.

Sauer-Danfoss provides comprehensive worldwide service for its

products through an extensive network of Authorized Service

Centers strategically located in all parts of the world.

Sauer-Danfoss (US) Company

2800 East 13th Street

Ames, IA 50010, USA

Phone: +1 515 239-6000, Fax: +1 515 239 6618

Sauer-Danfoss (Neumnster) GmbH & Co. OHG

Postfach 2460, D-24531 Neumnster

Krokamp 35, D-24539 Neumnster, Germany

Phone +49 4321 871-0, Fax: +49 4321 871 122

Sauer-Danfoss (Nordborg) ApS

DK-6430 Nordborg, Denmark

Phone: +45 7488 4444, Fax: +45 7488 4400

www.sauer-danfoss.com

OUR PRODUCTS

Hydrostatic transmissions

Hydraulic power steering

Electric power steering

Electrohydraulic power steering

Closed and open circuit axial piston

pumps and motors

Gear pumps and motors

Bent axis motors

Orbital motors

Transit mixer drives

Planetary compact gears

Proportional valves

Directional spool valves

Cartridge valves

Hydraulic integrated circuits

Hydrostatic transaxles

Integrated systems

Fan drive systems

Electrohydraulic controls

Digital electronics and software

Electric motors and inverters

Joysticks and control handles

Displays

Sensors

520L0467 Rev GC Feb 2008

Вам также может понравиться

- Profile of the International Pump Industry: Market Prospects to 2010От EverandProfile of the International Pump Industry: Market Prospects to 2010Рейтинг: 1 из 5 звезд1/5 (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОт EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОценок пока нет

- Hyd Drive MtceДокумент52 страницыHyd Drive Mtceramanujam59Оценок пока нет

- DA-2002 Hydraulic Fluid Power-General Rules Related To Systems Ver2SE07Документ15 страницDA-2002 Hydraulic Fluid Power-General Rules Related To Systems Ver2SE07Maximiliano DreyerОценок пока нет

- HYDAC Understanding Hydraulics1 MAR 2015Документ5 страницHYDAC Understanding Hydraulics1 MAR 2015marc271986Оценок пока нет

- Hydraulic Commissioning ManualДокумент7 страницHydraulic Commissioning Manualranjit2150Оценок пока нет

- BLN 9884Документ24 страницыBLN 9884Rachan EngchanilОценок пока нет

- WalvoilДокумент64 страницыWalvoilSamad A BakarОценок пока нет

- Manifolds and Connectors For Fluidic ApplicationsДокумент16 страницManifolds and Connectors For Fluidic ApplicationsNéstor Valles VillarrealОценок пока нет

- ISO-4409-07-Hydraulic Fluid Power - PositivedisplacementДокумент30 страницISO-4409-07-Hydraulic Fluid Power - PositivedisplacementantonioОценок пока нет

- 4 Pumps 95Документ126 страниц4 Pumps 95Rafael Santos100% (2)

- Parker Hose Technical Handbook PDFДокумент63 страницыParker Hose Technical Handbook PDFAnonymous HvDSpkgV100% (1)

- HG ServoProportional Valves Cut-Sheet Web PDFДокумент2 страницыHG ServoProportional Valves Cut-Sheet Web PDFEslamAldenAbdoОценок пока нет

- Load Sensing HydraulicsДокумент12 страницLoad Sensing HydraulicsKishore Kandikunta100% (1)

- Hydraulic FiltrationДокумент35 страницHydraulic FiltrationDhanraj PatilОценок пока нет

- Installation and Maintenance Manual: Compact CA MotorsДокумент48 страницInstallation and Maintenance Manual: Compact CA MotorsAngga Septiawan100% (1)

- Fluids Entry HBV Cetop 7 & 8 Series 101109Документ12 страницFluids Entry HBV Cetop 7 & 8 Series 101109Enhtuwshin BarkhasbadiОценок пока нет

- 010 - Denison Control Valve 3-EN2400-AДокумент15 страниц010 - Denison Control Valve 3-EN2400-Agustavo aguilarОценок пока нет

- Transmission Circuit RecommendationsДокумент40 страницTransmission Circuit RecommendationsanandsubbiahОценок пока нет

- Instrument Tube Fitting Installation ManualДокумент76 страницInstrument Tube Fitting Installation Manualmdtaheri100% (2)

- Re 10460Документ20 страницRe 10460Ahmed Abd ElhakeemОценок пока нет

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMДокумент8 страниц4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd ElhakeemОценок пока нет

- Hydraulics Excavator PDFДокумент16 страницHydraulics Excavator PDFChandaKunda100% (1)

- Chapter 3 Design Methodology: 3.1 IntroductionДокумент10 страницChapter 3 Design Methodology: 3.1 Introductionsushil100% (1)

- Lames Equation & JustificationДокумент14 страницLames Equation & Justificationjamil voraОценок пока нет

- NAHAD Hydraulic Hose Assembly GuidelinesДокумент65 страницNAHAD Hydraulic Hose Assembly GuidelinesLuhur BudiОценок пока нет

- D155E 10.02 (DOWMAX English)Документ50 страницD155E 10.02 (DOWMAX English)Nastase Dan NicusorОценок пока нет

- Scanwill Pressure IntensifierДокумент12 страницScanwill Pressure IntensifierÁlvaro Conti FilhoОценок пока нет

- Training CoursesДокумент9 страницTraining CoursesHYDRAULICGURUОценок пока нет

- Pipe Fittings and Port AdaptersДокумент26 страницPipe Fittings and Port AdaptersdekgaleОценок пока нет

- Hydraulic Motors: What Is A Hydraulic Motor and Why Do You Need It?Документ7 страницHydraulic Motors: What Is A Hydraulic Motor and Why Do You Need It?Anil NairОценок пока нет

- Hydraulic Training Release 14082002Документ62 страницыHydraulic Training Release 14082002rdragomiОценок пока нет

- Troubleshoooting Hydraulic System71742 - 10Документ7 страницTroubleshoooting Hydraulic System71742 - 10honeyvish92Оценок пока нет

- Vane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Документ5 страницVane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Lucas CardosoОценок пока нет

- Poclain Hydraulics Training Guide (Closed Loop Pump)Документ5 страницPoclain Hydraulics Training Guide (Closed Loop Pump)NBRellos100% (3)

- Hydraulic CylinderДокумент11 страницHydraulic Cylindersrinathgudur11Оценок пока нет

- 3 Handout Pilot-Controls enДокумент14 страниц3 Handout Pilot-Controls enluisОценок пока нет

- Batch Mixer ManualДокумент40 страницBatch Mixer ManualAndrew ArОценок пока нет

- Hydraulic CylindersДокумент7 страницHydraulic Cylinderspacopil34Оценок пока нет

- Industrial Hydraulic CircuitsДокумент16 страницIndustrial Hydraulic CircuitskingkakingОценок пока нет

- HYdraulics Lab Manual - New1Документ115 страницHYdraulics Lab Manual - New1Fati Mah100% (2)

- Technical Information K and L MotorДокумент40 страницTechnical Information K and L MotorEduardo CramerОценок пока нет

- CRT 350 Interlock Panel User ManualДокумент74 страницыCRT 350 Interlock Panel User ManualAliHabesОценок пока нет

- Ra92100 1997-10Документ48 страницRa92100 1997-10mmaldonado10Оценок пока нет

- Holland KingpinsДокумент8 страницHolland KingpinsPablo César Suárez NogalesОценок пока нет

- Full Text 02Документ112 страницFull Text 02Như Nguyễn Trần ThảoОценок пока нет

- Technical Manual ICVD 1111Документ24 страницыTechnical Manual ICVD 1111Angelo MedinaОценок пока нет

- Parker - General TechnicalДокумент34 страницыParker - General TechnicalClarence SmithОценок пока нет

- Industrial Hydraulics - SPSДокумент72 страницыIndustrial Hydraulics - SPSPrakash KumarОценок пока нет

- Technical Overview and Specification Summary Ps 00232 Data PDFДокумент24 страницыTechnical Overview and Specification Summary Ps 00232 Data PDFmmilovanmОценок пока нет

- DNV-RU-SHIP Pt.4 Ch.7Документ140 страницDNV-RU-SHIP Pt.4 Ch.7Tord MartinsenОценок пока нет

- Proportional Pressure Relief Valve R4V DENISONДокумент15 страницProportional Pressure Relief Valve R4V DENISONBerenice Bautista BelmontesОценок пока нет

- Hänchen Overview PDFДокумент19 страницHänchen Overview PDFBruno CecattoОценок пока нет

- Denison Hydraulics Pressure Relief Valves: Series R1E02Документ5 страницDenison Hydraulics Pressure Relief Valves: Series R1E02Leonardo ViilalobosОценок пока нет

- Hydraulic FluidДокумент4 страницыHydraulic FluidBaskar KannaiahОценок пока нет

- lt3 00032 2 A p24 p30sДокумент67 страницlt3 00032 2 A p24 p30sBruno SamaeianОценок пока нет

- FPI Technical CharacteristicsДокумент36 страницFPI Technical Characteristicsfahimshah1301Оценок пока нет

- 1901 Flowtite TechCharacteristics enДокумент36 страниц1901 Flowtite TechCharacteristics enandruis martinezОценок пока нет

- Proportional Directional ValvesДокумент12 страницProportional Directional ValvesMartinez Mauricio Martinez GomezОценок пока нет

- Hydac FAMH ManualДокумент28 страницHydac FAMH ManualDavid A. LópezОценок пока нет

- SB 100 Eriez Plate MagnetДокумент8 страницSB 100 Eriez Plate MagnetSuyapa Lainez LainezОценок пока нет

- Designed To Produce High Quality CompostДокумент2 страницыDesigned To Produce High Quality CompostCarlosОценок пока нет

- PrimeMover en LRДокумент12 страницPrimeMover en LRCarlosОценок пока нет

- Blower TruckДокумент2 страницыBlower TruckCarlosОценок пока нет

- Soil Under Control TrafficДокумент13 страницSoil Under Control TrafficCarlosОценок пока нет

- Tea Research - Harvester - Module No. 3 PLUCKINGДокумент47 страницTea Research - Harvester - Module No. 3 PLUCKINGCarlosОценок пока нет

- Lennox AirHandler BrochureДокумент6 страницLennox AirHandler BrochureCarlosОценок пока нет

- Compresor A Diafragma CurvaДокумент1 страницаCompresor A Diafragma CurvaCarlosОценок пока нет

- Logical Troubleshooting in Hydraulic SystemsДокумент37 страницLogical Troubleshooting in Hydraulic Systemsg665013100% (18)

- Specifications Model 32000 Series Transmission: Spicer Off-Highway ProductsДокумент2 страницыSpecifications Model 32000 Series Transmission: Spicer Off-Highway ProductsCarlosОценок пока нет

- Ds 47592Документ1 страницаDs 47592CarlosОценок пока нет

- Ds 47963Документ1 страницаDs 47963CarlosОценок пока нет

- Air - Understanding Fan Curves PDFДокумент4 страницыAir - Understanding Fan Curves PDFCarlos100% (1)

- Three-Point Free-LinkДокумент10 страницThree-Point Free-LinkCarlosОценок пока нет

- Isulating Brick High TempДокумент2 страницыIsulating Brick High TempCarlosОценок пока нет

- Ceramic Honeycombs: Inspection GuideДокумент5 страницCeramic Honeycombs: Inspection GuideCarlosОценок пока нет

- Bowex Bowex Fle-Pa Bowex-Elastic Monolastic Pump Mounting FlangesДокумент34 страницыBowex Bowex Fle-Pa Bowex-Elastic Monolastic Pump Mounting FlangesCarlosОценок пока нет

- ASTM A106 Seamless Carbon Steel PipeДокумент2 страницыASTM A106 Seamless Carbon Steel PipeCarlosОценок пока нет

- Bronce Al Aluminio - ASTM B150Документ5 страницBronce Al Aluminio - ASTM B150CarlosОценок пока нет

- Isulating Brick Low TempДокумент2 страницыIsulating Brick Low TempCarlosОценок пока нет

- Hydraulic Fluid and LubricantsДокумент48 страницHydraulic Fluid and LubricantsCarlos100% (1)

- Ceramic Honeycombs: For Regenerative Catalytic Oxidizer (RCO)Документ5 страницCeramic Honeycombs: For Regenerative Catalytic Oxidizer (RCO)CarlosОценок пока нет

- Ceramic Materials PropertiesДокумент1 страницаCeramic Materials PropertiesIntanasa NurdentiОценок пока нет

- 3 Puntos - CategoriasДокумент2 страницы3 Puntos - CategoriasCarlosОценок пока нет

- Mecanismo Dirección - Buggy PDFДокумент8 страницMecanismo Dirección - Buggy PDFCarlosОценок пока нет

- Ceramic Honeycombs: For Regenerative Thermal Oxidizers (RTO)Документ5 страницCeramic Honeycombs: For Regenerative Thermal Oxidizers (RTO)CarlosОценок пока нет

- How To Repair Tire and Roller WearДокумент7 страницHow To Repair Tire and Roller WearzementheadОценок пока нет

- Rotary Dryer HandbookДокумент34 страницыRotary Dryer Handbook11331490% (10)

- Design, Modeling and Control of Steering and Braking For An Urban Electric VehicleДокумент34 страницыDesign, Modeling and Control of Steering and Braking For An Urban Electric VehicleAmit SinghОценок пока нет

- Steam - Sizing Condensate PipesДокумент4 страницыSteam - Sizing Condensate PipesCarlosОценок пока нет

- Welding Consumables - 2010 - EN PDFДокумент698 страницWelding Consumables - 2010 - EN PDFErick HoganОценок пока нет

- TS TVS TFS ProtocolsДокумент16 страницTS TVS TFS ProtocolsTaulehia Pulefou SemisiОценок пока нет

- 2015-08-20 St. Mary's County TimesДокумент32 страницы2015-08-20 St. Mary's County TimesSouthern Maryland OnlineОценок пока нет

- Biology Notes - Respiratory SystemДокумент9 страницBiology Notes - Respiratory SystemnoorbdeirОценок пока нет

- AMPCO 18 SandДокумент1 страницаAMPCO 18 SandS BHATTACHARYYAОценок пока нет

- Behavioral Based Safety Observation Checklist: ErgonomicsДокумент2 страницыBehavioral Based Safety Observation Checklist: ErgonomicsRyan CyrillaОценок пока нет

- Ambasador AntalisДокумент136 страницAmbasador AntalisNostalgia 80Оценок пока нет

- 316 On 6mo - White PaperДокумент13 страниц316 On 6mo - White Papermarvin_slОценок пока нет

- Test To Check Quality of Bitumen For Use in Road WorkДокумент13 страницTest To Check Quality of Bitumen For Use in Road WorkTajdaarОценок пока нет

- Efinal Format AppendicesДокумент13 страницEfinal Format AppendicesRRОценок пока нет

- MSDS HF - PV KPMДокумент8 страницMSDS HF - PV KPMPrabuEswarОценок пока нет

- Solution Chemistry OPTandonДокумент24 страницыSolution Chemistry OPTandonCaleb AsharleyОценок пока нет

- Predicting Production Performance of A Field With Complex Reservoir Heterogeneities Undergoing Water Injection - A Case Study of A Niger-Delta FieldДокумент14 страницPredicting Production Performance of A Field With Complex Reservoir Heterogeneities Undergoing Water Injection - A Case Study of A Niger-Delta FieldnoorОценок пока нет

- An Introduction To Electronic Theories of Organic ChemistryДокумент1 страницаAn Introduction To Electronic Theories of Organic ChemistryMuhammad AbdulazizОценок пока нет

- ChemistryДокумент6 страницChemistryMuhammad umarОценок пока нет

- WAEC Chemistry Syllabus 2022 PDF Download AvailableДокумент26 страницWAEC Chemistry Syllabus 2022 PDF Download AvailableSamuel AikinsОценок пока нет

- Design of Concrete Buildings For Disassembly: An Explorative ReviewДокумент19 страницDesign of Concrete Buildings For Disassembly: An Explorative Reviewmonica singhОценок пока нет

- Benzopyrylium Ions PDFДокумент74 страницыBenzopyrylium Ions PDFNaresh kumarОценок пока нет

- Different Types of ConductorsДокумент5 страницDifferent Types of ConductorseuniczelОценок пока нет

- O - LEVEL CHEMISTRY WORKSHEETS - Reactions QuestionsДокумент21 страницаO - LEVEL CHEMISTRY WORKSHEETS - Reactions QuestionsFahim Ahmed75% (4)

- 2023 o Level Chemistry SyllabusДокумент56 страниц2023 o Level Chemistry SyllabusFooxОценок пока нет

- Modal FibreДокумент10 страницModal Fibresaran7ran100% (5)

- Varshini KO-Araviind SДокумент178 страницVarshini KO-Araviind SDhaksha AnieshОценок пока нет

- Advanced Construction MaterialsДокумент37 страницAdvanced Construction MaterialsZara AliОценок пока нет

- Fluitest Uric Acid AnalyticonДокумент4 страницыFluitest Uric Acid AnalyticonTjakraHarjoWiboewoОценок пока нет

- Paper - I - General: Previous Year Paper GPAT DIДокумент20 страницPaper - I - General: Previous Year Paper GPAT DIVikash KushwahaОценок пока нет

- Color Coding The Periodic Table - InstructionsДокумент2 страницыColor Coding The Periodic Table - InstructionsVictoria LowmanОценок пока нет

- Valve StandardsДокумент15 страницValve StandardsabduОценок пока нет

- Ammonia Waste WaterДокумент19 страницAmmonia Waste WaterAnonymous GfPSYi4nОценок пока нет

- Metabolit SekunderДокумент76 страницMetabolit SekunderCempaka Kusuma DewiОценок пока нет