Академический Документы

Профессиональный Документы

Культура Документы

Prosthetic Sockets Fabrication Using Rapid Prototyping Technology

Загружено:

Haider Neama0 оценок0% нашли этот документ полезным (0 голосов)

35 просмотров7 страницThis paper presents the development of a prosthetics computer-aidedmanufacturing (CAM) system. The system reduces the socket making time from days to less than 4 h. Clinical and biomechanical studies are conducted to evaluate the comfort and fit of the new socket during gait.

Исходное описание:

Оригинальное название

877432

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis paper presents the development of a prosthetics computer-aidedmanufacturing (CAM) system. The system reduces the socket making time from days to less than 4 h. Clinical and biomechanical studies are conducted to evaluate the comfort and fit of the new socket during gait.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

35 просмотров7 страницProsthetic Sockets Fabrication Using Rapid Prototyping Technology

Загружено:

Haider NeamaThis paper presents the development of a prosthetics computer-aidedmanufacturing (CAM) system. The system reduces the socket making time from days to less than 4 h. Clinical and biomechanical studies are conducted to evaluate the comfort and fit of the new socket during gait.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

Prosthetic sockets

fabrication using rapid

prototyping technology

P. Ng

P.S.V. Lee and

J.C.H. Goh

The authors

P. Ng, P.S.V. Lee and J.C.H. Goh are at the Department of

Orthopaedic Surgery, National University of Singapore

Keywords

Rapid prototyping, Computer-aided manufacturing

Abstract

The traditional way of making a prosthetic socket is by

draping a heated thermoplastic sheet over the positive

mould, or by applying layers of woven materials together

with acrylic resins over the positive mould. This process is

extremely labour intensive, and it usually takes two to

three days to make one socket. This paper presents the

development of a prosthetics Computer-Aided-

Manufacturing (CAM) system that utilises Rapid

Prototyping (RP) technology. The system reduces the

socket making time from days to less than 4 h. Clinical and

biomechanical studies are conducted to evaluate the

comfort and t of the new socket during gait. Preliminary

investigation of the new socket shows that its functional

characteristics are very similar to that of a traditional

socket

Electronic access

The research register for this journal is available at

http://www/emeraldinsight.com./research_registers

The current issue and full text archive of this journal is

available at

http://www/emeraldinsight.com/1355-2546.htm

Introduction

Rapid prototyping (RP) technology has

changed the way products are being designed

and manufactured. Being rst introduced in

1987, the technology has made a quantum

leap in all aspects over the past 10 years. The

building speed has been drastically increased,

parts dimensional accuracy has been

signicantly improved, and a wide variety of

new building materials have also been

identied. With these improvements, many

new uses for RP have been discovered.

Medical application is perhaps one of the

most mentioned new uses of RP in recent

years. Applications of RP in the medical eld

cover a variety of areas, like pre-operative

planning, surgical rehearsal, making of

prosthetic and orthotic devices, etc. While

some of these applications are still in their

infancies, others have already shown

promising results, as in the making of RP

prosthetic sockets.

Prosthetic socket fabrication and rapid

prototyping

The traditional way of creating a prosthetic

socket is a labour intensive process. Three

stages can be observed, namely,

measurement, rectication and fabrication.

The physical measurements of the amputees

stump are recorded in detail and a plaster

wrap cast is taken (Figure 1a). A positive

mould is subsequently created by lling the

wrap cast with plaster of Paris (Figure 1b).

Rectications to the plaster mould begin by

taking measurements of the mould, and

comparing them with those previously taken

on the stump. Based on information from past

experience, the mould is further altered by

removing or adding plaster to it. The aim is to

create a comfortable weight-bearing socket

that enables the soft tissue of the stump to be

compressed at pressure tolerant areas, and

relieved at pressure intolerant areas. Once

rectication is completed, draping clear

plastics over the positive plaster mould creates

a check socket (Figure 1c). Preliminary tting

is carried out using the clear check socket,

Rapid Prototyping Journal

Volume 8 Number 1 2002 pp. 5359

q MCB UP Limited ISSN 1355-2546

DOI 10.1108/13552540210413310

The authors wish to acknowledge the help provided

by the staff of the Prosthetic and Orthotic

Laboratory and the Gait Analysis Laboratory,

National University of Singapore.

53

where minor shape adjustment can be

achieved by reheating the socket (Figure 1d).

Once a good t has been assured, a denitive

socket is fabricated. This is accomplished by

re-creating a positive plaster mould from the

check socket. Depending on the nal material

of the socket, it can be vacuum formed by

draping heated thermoplastics over the

positive mould or by applying layers of woven

materials together with acrylic resins over the

positive mould. Upon completion of the

socket, the other components of the articial

limb are incorporated.

Different rapid prototyping technologies

have been investigated recently for prosthetic

socket fabrication. The technology has shown

enormous potential in eliminating the tedious

and time-consuming steps involved in

traditional socket fabrication. In a cost benet

analysis conducted by Freeman and

Wontorcik, 1998, two trans-tibial check

sockets were fabricated using

Stereolithography (SLA-250/40). The

traditional casting process was eliminated; the

sockets were fabricated directly from digitised

data. The time taken to fabricate the two

check sockets were 58 and 26h. Though these

gures can be reduced with faster systems like

the SLA-350/10 or SLA500/40, the real

concern with Stereolithography is the hefty

capital and manufacturing cost. Freeman et al.

also highlighted that the photopolymer

resins used in Stereolithography might be

strong enough for making check sockets, but

would be too brittle and weak for denitive

sockets.

To investigate the possibility of making

denitive sockets using RP technology, a

feasibility study was conducted by Tan et al.

(1998). The Fused Deposition Modelling

(FDM) process was chosen for the study

because of its minimum post-processing

requirement, and the superior mechanical

properties of the building material (P301

polyamide). The positive mould of a trans-

tibial socket was created and scanned using

the Digibot 3D laser digitising system

(Digibotics Inc, USA). The acquired shape is

represented by a mass of spatial points,

known as the points-cloud. These points were

reconstructed in 3D and a solid model was

generated using a CAD software. The solid

model was then converted to STL model/

format for rapid prototyping.

The physical and fabrication data of the

FDM socket is summarised in Table I. The

wall thickness of the socket varied from 3 mm

at the distal end to 7mmat the proximal brim,

to ensure rigidity at the proximal end for

supracondylar suspension. Gait analysis

showed that there were insignicant

deviations of gait parameters when

comparing the FDM socket to the

traditional socket that was created based on

the same positive mould. The investigation

demonstrated that FDM could be used to

produce prosthetic socket with functional

characteristics similar to that of a traditional

one. However, Tan et al. (1998) remarked

that the major drawback with the FDM

method was its long building time and high

manufacturing cost.

The ability to create freeform surfaces and

hidden features makes rapid prototyping an

ideal technology for automated socket

fabrication. However, to make SLA, FDM, or

any other commercial RP systems a practical

Figure 1 Measurement and rectication stage

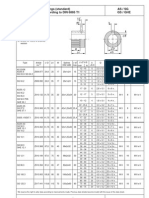

Table I Fabrication data of the FDM socket

Height (mm) 228

Wall thickness (mm) 37

Weight (g) 332

Fabrication time (h) 29

a

a

Note: Using 3D Modelerw

Source: (Tan et al., 1998)

Prosthetic sockets fabrication using rapid prototyping technology

P. Ng, P.S.V. Lee and J.C.H. Goh

Rapid Prototyping Journal

Volume 8 Number 1 2002 5359

54

means of fabricating denitive sockets, the

manufacturing time and cost must be

signicantly reduced. As this may be difcult

to accomplish at the present moment, a

customised RP system specically designed

for socket fabrication is a pertinent

alternative.

Overview of rapid manufacturing

machine (RMM)

A customised system named the Rapid

Manufacturing Machine (RMM) was

developed for automated socket fabrication.

The requirements of the RMM were stated

below to ensure quick and economical

production of denitive sockets:

.

Most of the building materials used by

current RP systems are expensive and

may not be suitable for denitive sockets.

Therefore, the building material for

RMM must be inexpensive and must

meet the strength requirement of

denitive sockets.

.

Commercial RP systems usually have

precision and accuracy that is beyond the

requirement for socket fabrication; a

diametrical accuracy of ^ 1.0mm is

normally sufcient for prosthetic socket.

Therefore, the hardware and software

design of the RMM should make use of

the lower accuracy requirement to reduce

system cost and building time.

The working principle of the RMM is similar

to that of FDM, which dispenses semi-molten

material onto the machine table, layer by

layer, to form 3D objects. Polypropylene (PP)

is selected to be the building material for the

RMM because of its rigidity, strength and

resistance to fatigue; and most importantly, it

is inexpensive and has been used by

prosthetists for making above-knee and

below-knee prosthetic sockets.

There are two main components in the

RMM, namely the robotic system and the

dispenser. The schematic of the RMM is

shown in Figure 2.

The schematic of the dispenser is shown in

Figure 3. Polypropylene lament (4 mm) is

fed into the heating barrel. The lament

moves along the barrel, and is melted near the

exit, which is where the heating element is

mounted. The in-coming lament acts as a

piston to push the molten polypropylene out

of the nozzle.

The molten polypropylene forms a

continuous strand as it leaves the nozzle. The

strand is dispensed onto the machine table

according to the cross-sectional contour of the

stump. The second layer is laid in the similar

manner on top of the rst. The process

continues until the whole socket is built (see

Figure 4).

RMM design considerations

File format

Stereolithography Interface Specication, or

STL, is the most widely used format in rapid

prototyping (Georges and Chuck, 1996;

Chua and Leong, 1996). STL model is

formed by tessellation of the original model. It

is excellent for describing model with planar

surfaces, but when one turns to medical

applications, the limitations of STL models

become obvious (Dolenc and Makela, 1996).

The highly complex shape of a prosthetic

socket usually results in large le size when

tessellated. This in turn results in long data

verication and processing time, as in the

making of the FDM socket.

Figure 2 Schematic of RMM

Figure 3 Schematic of dispenser

Prosthetic sockets fabrication using rapid prototyping technology

P. Ng, P.S.V. Lee and J.C.H. Goh

Rapid Prototyping Journal

Volume 8 Number 1 2002 5359

55

As the STL format is apparently not a good

format for representing prosthetic sockets, the

RMM has discarded the format. At this

moment, the system accepts the following

data formats:

.

IGES (by Capod Systems/Digibotic).

.

Points cloud (by Digibotic).

Additional data lters can be developed if

required.

Nozzle

The nozzle used by the 3D Modeler FDM

machine (Stratasys Inc, USA) has a

relatively small diameter. Such conguration

enables the machine to build small and

delicate parts with good dimensional

accuracy. However, small nozzle diameter

has its trade-off in terms of the building speed.

This is particularly apparent when building

parts that are wider than the process road

width.

The road width of the FDM process ranges

from 0.254 to 2.54 mm, depending on the

diameter of the nozzle, the input speed of the

material and the extrusion head pressure. In

the case of making prosthetic sockets, the

required socket wall thickness is usually

thicker than the maximum road width. As it is

impossible to achieve the required wall

thickness in one pass, additional steps are

needed to form a thicker wall, as illustrated

in Figure 5.

However, if the road width is designed to be

the same as the required socket wall thickness,

fabrication time can be signicantly reduced.

To achieve this, the nozzle diameter has to be

increased accordingly. This modication is

justiable for this application as building

speed is the priority, and extreme precision in

the xy plane is normally not required. The

nozzle diameter used in the RMM is 3mm,

with a resultant road width or socket wall

thickness of 4 mm.

Figure 4 Various stages in the manufacturing of a trans-tibial prosthetic socket

Figure 5 Building a thick wall with narrow road width

Prosthetic sockets fabrication using rapid prototyping technology

P. Ng, P.S.V. Lee and J.C.H. Goh

Rapid Prototyping Journal

Volume 8 Number 1 2002 5359

56

Awider road width also increases the process

ability to build slanted surface without

external supports, as illustrated in Figure 6 at

the sockets patellar tendon-bearing (PTB)

region. Generating and building external

supports can be extremely tedious and time

consuming.

With a wider road width, the contact area

between layers is also increased. This gives a

better inter-layer bonding, which is an

important factor when socket strength is

concerned. The inter-layer bonding is further

enhanced with the nozzle pressing the current

layer against the previous, as shown in

Figure 7.

System accuracy

Besides manufacturing speed, socket accuracy

is also an important issue. An experiment was

conducted to determine the accuracy of the

system. Based on the normal working

diameter range, three cylinders of internal

diameters 60, 80 and 100 mm were

fabricated. The internal surfaces of these

cylinders were digitised by a 3D probe.

Figure 8 shows the surface prole of the

80 mm cylinder. The centre and diameter of

the circle will be determined by circle

tting.

There are many ways to t a circle, the

simplest way is perhaps the least square

method. An initial guess is made to

determine the centre (X

0

,Y

0

) and diameter

(D

0

). A range will be specied, say 2d, for

iteration. The rst iteration can be obtained

by offsetting the centre and diameter by d.

Therefore, the centre and diameter of the rst

circle is given by (X

0

2d,Y

0

2d) and (D

0

2d)

respectively. The root-mean-square (RMS)

error can be obtained by comparing the circle

with the actual prole. Three nested loops are

required to complete the iteration. The last

circle will be at centre (X

0

+d,Y

0

+d), with

diameter (D

0

+d ). The circle with the

minimum RMS error during iteration gives

the best t.

This algorithm may not give the most

accurate t, and is denitely not the most

efcient. However, the algorithm is easy to

implement, and the t is considered

reasonably accurate when the targeted system

accuracy is ^1.0 mmdiametrically. The circle

tting results of the three cylinders are given

in Table II.

Discussion and conclusion

To compare the RMM process with the FDM

process, the positive mould of the trans-tibial

socket that was used by Tan et al. (1998) in

their study was re-scanned using the Capod

AK/BK scanner (Capod Systems, Sweden).

Figure 6 Building slanted surface without external

support

Figure 7 Nozzle pressing current layer against the

previous layer

Figure 8 Circle tting results

Prosthetic sockets fabrication using rapid prototyping technology

P. Ng, P.S.V. Lee and J.C.H. Goh

Rapid Prototyping Journal

Volume 8 Number 1 2002 5359

57

The scanned data was exported to the

RMM for fabrication. A comparison of the

physical and fabrication data of the RMM and

FDM socket is summarised in Table III.

The RMM process proved to be more

superior in all respects, except that the

RMM socket was slightly heavier than the

FDM socket.

Due to better inter-layer bonding, the

RMM socket does not require any

increment of wall thickness at the proximal

end for rigidity. This simplies the tool

paths generation, and in turn, helps

reduce the data processing and manufacturing

time.

Clinical and biomechanical studies were

also conducted to evaluate the comfort and t

of the RMM socket during gait. A prosthetic

socket for a volunteer trans-tibial amputee

subject was manufactured using the RMM

(see Figure 9). The time taken to build the

socket was 3.5 h, and the complete prosthesis

weighed approximately 1.6 kg, which was

about 0.3 kg heavier than the traditional

prosthesis.

The comparison of the average temporal-

distance data of the stump wearing the RMM

and traditional socket is summarised in Table

IV. Preliminary investigation of the RMM

socket showed that its functional

characteristics were very similar to that of a

traditional socket.

Current/future work

Prosthetic sockets are commonly reported to

fail as a result of local bending and buckling at

the distal region, where the pylon is connected

(Wevers and Durance, 1987). Therefore, to

ensure that the RMM socket is safe for

patients usage, the prosthesis is currently

undergoing the ISO 10328 principal structure

tests. More clinical and biomechanical studies

will also be conducted in the future, to

evaluate the comfort and t of the RMM

socket during gait.

Table II Accuracy of the RMM

60 mm 80 mm 100 mm

Diameter 59.723 80.036 99.757

Centre (114.741,73.674) (111.321,71.879) (113.453,89.570)

RMS error 0.205 0.161 0.257

Deviation 2 0.277 0.036 2 0.243

Table III Fabrication data of the RMM and FDM socket

RMM FDM

Height (mm) 230 228

Wall thickness (mm) 4 37

Weight (g) 426 332

Fabrication time (h) 31/4 29

Table IV Biomechanical evaluation of the RMM socket

Trad RMM

Cadence (steps/min) 91 86

Walking speed (m/s) 0.85 0.81

Stride time (s) 1.32 1.39

Step time (s) 0.64 0.68

Single support (s) 0.34 0.38

Double support (s) 0.54 0.54

Stride length (m) 1.13 1.11

Step length (m) 0.61 0.59

Stance (percent) 66.67 65.83

Figure 9 A trans-tibial amputee with the RMM socket

Prosthetic sockets fabrication using rapid prototyping technology

P. Ng, P.S.V. Lee and J.C.H. Goh

Rapid Prototyping Journal

Volume 8 Number 1 2002 5359

58

References

Chua, C.K. and Leong, K.F. (1996), Rapid Prototyping:

Principles and Applications in Manufacturing, John

Wiley & Sons, Inc, Singapore.

Dolenc, A. and Ma kela , I. (1996), Rapid prototyping from

a computer scientists point-of-view, Rapid

Prototyping Journal, Vol. 2 No. 2, pp. 18-25.

Freeman, D. and Wontorcik, L. (1998), Stereolithography

and prosthetic test socket manufacture: a cost/

benet analysis, Journal of Prosthetics and

Orthotics, Vol. 10 No. 1, pp. 17-20.

Georges, M.F. and Chuck, K. (1996), Accuracy issues in

CAD to RP translations, Rapid Prototyping Journal,

Vol. 2 No. 2, pp. 4-17.

Tan, K.C., Lee, V.S., Tam, K.F. and Lye, S.L. (1998),

Automation of prosthetic socket design and

fabrication using CAD/CAM and RP technique, in,

Proceedings of the 1st National Symposium on

Prosthetics and Orthotics, pp. 19-22.

Wevers, H.W. and Durance, J.P. (1987), Dynamic testing

of below-knee prosthesis: assembly and

components, Prosthetics and Orthotics

International, Vol. 11, pp. 117-23.

Prosthetic sockets fabrication using rapid prototyping technology

P. Ng, P.S.V. Lee and J.C.H. Goh

Rapid Prototyping Journal

Volume 8 Number 1 2002 5359

59

Вам также может понравиться

- Screw Extrusion Based 3D Printing, A Novel Additive Manufacturing TechnologyДокумент7 страницScrew Extrusion Based 3D Printing, A Novel Additive Manufacturing TechnologyPaulo Canedo da SilvaОценок пока нет

- Use of Rapid Prototyping in Rapid ToolingДокумент11 страницUse of Rapid Prototyping in Rapid ToolingSudhanwa KulkarniОценок пока нет

- Alex Do MSthesis PDFДокумент18 страницAlex Do MSthesis PDFgajaramilloОценок пока нет

- Sheet Incremental Forming: Advantages of Robotised Cells vs. CNC MachinesДокумент23 страницыSheet Incremental Forming: Advantages of Robotised Cells vs. CNC MachinesManolo GipielaОценок пока нет

- 064 Optimizing The Tensile Strength For 3D Printed PLAДокумент21 страница064 Optimizing The Tensile Strength For 3D Printed PLAnamasse.medamineОценок пока нет

- Rapid Pro To Typing PrimerДокумент13 страницRapid Pro To Typing Primersinghsujit1Оценок пока нет

- Final Report On 3D Printed Battery BracketДокумент57 страницFinal Report On 3D Printed Battery BracketAkshay bypОценок пока нет

- Rapid Investment Casting: Direct and Indirect Approaches Via Fused Deposition ModellingДокумент9 страницRapid Investment Casting: Direct and Indirect Approaches Via Fused Deposition ModellingNitin GroverОценок пока нет

- Dimensional Evaluation of Tailor-Made Cranioplasty Implants: Dalberto Dias Da Costa, Sérgio Fernando LajarinДокумент6 страницDimensional Evaluation of Tailor-Made Cranioplasty Implants: Dalberto Dias Da Costa, Sérgio Fernando LajarinElizandro SordiОценок пока нет

- RPT Sheet Metal FormingДокумент9 страницRPT Sheet Metal FormingdevheadbotОценок пока нет

- 2021+FDM+IOP Conference PaperДокумент12 страниц2021+FDM+IOP Conference Paperkuldeep sharmaОценок пока нет

- Inverse Engineering and Preliminary Simulation of A Closed Profile Roll-Forming LineДокумент8 страницInverse Engineering and Preliminary Simulation of A Closed Profile Roll-Forming LinebkhmohamedОценок пока нет

- Rapid PrototypingДокумент82 страницыRapid Prototypingts619469Оценок пока нет

- E Thesis Nitrkl AcДокумент6 страницE Thesis Nitrkl AcRaquel Pellicier100% (1)

- Design of Hot Forging Process of Parts With Complex Geometry in Digital EnvironmentДокумент4 страницыDesign of Hot Forging Process of Parts With Complex Geometry in Digital Environmentsandeep5Оценок пока нет

- Rapid Prototyping in DentistryДокумент13 страницRapid Prototyping in DentistryManjeevОценок пока нет

- Wear Assessment of 3-D Printed Parts of PLA (Polylactic Acid) Using Taguchi Design and Artificial Neural Network (ANN) TechniqueДокумент16 страницWear Assessment of 3-D Printed Parts of PLA (Polylactic Acid) Using Taguchi Design and Artificial Neural Network (ANN) TechniqueArturo CervantesОценок пока нет

- The Influence of Operational Settings On The Tensile Strength of An FDM-Printed Abs ComponentДокумент12 страницThe Influence of Operational Settings On The Tensile Strength of An FDM-Printed Abs ComponentIJRASETPublicationsОценок пока нет

- Procast 2009 Steel ExampleДокумент11 страницProcast 2009 Steel ExampleKimberly KingОценок пока нет

- Comparison of RP Techniques PDFДокумент31 страницаComparison of RP Techniques PDFSantoshОценок пока нет

- Additive Manufacturing: Alberto Boschetto, Luana Bottini, Francesco VenialiДокумент11 страницAdditive Manufacturing: Alberto Boschetto, Luana Bottini, Francesco VenialiAbdullah UYSALОценок пока нет

- Experimental Investigation of Effects of Build Parameters On Flexural Properties in Fused Deposition Modelling PartsДокумент15 страницExperimental Investigation of Effects of Build Parameters On Flexural Properties in Fused Deposition Modelling PartsAnonymous 5AmJ13mLkОценок пока нет

- RTM CompositesДокумент21 страницаRTM CompositesBarath IyerОценок пока нет

- AM Tech Brief PolymerДокумент9 страницAM Tech Brief Polymermanoj smОценок пока нет

- UNIT1,3Документ14 страницUNIT1,3Sagar BatraОценок пока нет

- RP Lab ReportДокумент10 страницRP Lab ReportaayushiОценок пока нет

- Investigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingДокумент5 страницInvestigations For Deducing Wall Thickness of Aluminium Shell Casting Using Three Dimensional PrintingR Moses KrupavaramОценок пока нет

- Numerical Optimization On Hot Forging PRДокумент7 страницNumerical Optimization On Hot Forging PRAnkit SahuОценок пока нет

- 2020 ETFA CosiMoДокумент5 страниц2020 ETFA CosiMoRodríguez EdwardОценок пока нет

- 1 Overview of Rapid Prototyping: o o o o o oДокумент15 страниц1 Overview of Rapid Prototyping: o o o o o oVaisakh SomakumarОценок пока нет

- Polymers 13 04126 v2Документ21 страницаPolymers 13 04126 v2moraleslaureanoОценок пока нет

- A Decomposition-Based Approach To Layered ManufacturingДокумент35 страницA Decomposition-Based Approach To Layered Manufacturingdangquang_k46Оценок пока нет

- Paul Bere Mat PlastДокумент8 страницPaul Bere Mat Plast19MECH052 SYED YOUNUSОценок пока нет

- A Rapid Prototyping of Composite Materials: J. Manoj Kumar & P. NagabharamДокумент6 страницA Rapid Prototyping of Composite Materials: J. Manoj Kumar & P. NagabharamTJPRC PublicationsОценок пока нет

- Parametric Process Optimization To Improve The Accuracy of Rapid Prototyped Stereolithography PartsДокумент23 страницыParametric Process Optimization To Improve The Accuracy of Rapid Prototyped Stereolithography Partsasdada1428Оценок пока нет

- New Design of Process For Cold Forging To Improve Multi-Stage Gas FittingДокумент12 страницNew Design of Process For Cold Forging To Improve Multi-Stage Gas FittingDegaga KebedeОценок пока нет

- The Effects of Processing On Thermoplastics: White PaperДокумент10 страницThe Effects of Processing On Thermoplastics: White PaperPedrito CalapuchaОценок пока нет

- Extrusion Simulation and Experimental Validation To Optimize Precision Die DesignДокумент5 страницExtrusion Simulation and Experimental Validation To Optimize Precision Die DesignFethi Arslan KılınçОценок пока нет

- OUT2YN1IMTT0kxeQh PDFДокумент5 страницOUT2YN1IMTT0kxeQh PDFSriram SuryaОценок пока нет

- Mohamed 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012090Документ7 страницMohamed 2018 IOP Conf. Ser. Mater. Sci. Eng. 310 012090Ximena Merma SОценок пока нет

- Improved Inverse Design Method For Thin-Wall Hollow Profiled Polymer Extrusion Die Based On FEM-CFD SimulationsДокумент11 страницImproved Inverse Design Method For Thin-Wall Hollow Profiled Polymer Extrusion Die Based On FEM-CFD SimulationsARSALAN AHMADОценок пока нет

- Module 3 Lesson 4Документ6 страницModule 3 Lesson 4subha_aeroОценок пока нет

- Vonpetersdorff Campen2018Документ10 страницVonpetersdorff Campen2018tehtnicaОценок пока нет

- CH 34Документ40 страницCH 34Ganapathy VigneshОценок пока нет

- Rap ToolДокумент15 страницRap Toolmedane_saad6707Оценок пока нет

- Recent Advancement of Rapid Prototyping in Aerospace Industry - A ReviewДокумент19 страницRecent Advancement of Rapid Prototyping in Aerospace Industry - A Reviewmahe2kumarОценок пока нет

- Additive Manufacturing A Framework For ImplementationДокумент8 страницAdditive Manufacturing A Framework For Implementationnicero555Оценок пока нет

- Performance Evaluation of An Airfoil Fabricated Through Additive Manufacturing, Using Simulation and Experimental TechniquesДокумент15 страницPerformance Evaluation of An Airfoil Fabricated Through Additive Manufacturing, Using Simulation and Experimental TechniquesIJRASETPublicationsОценок пока нет

- Fatigue Performance of Fused Filament Fabrication PLA SpecimensДокумент8 страницFatigue Performance of Fused Filament Fabrication PLA SpecimensMechanical ClassОценок пока нет

- Investigations of The Plastics Flow During The Injection Molding Process - Selected ResultsДокумент4 страницыInvestigations of The Plastics Flow During The Injection Molding Process - Selected ResultsMohammed KhatibОценок пока нет

- cf3d CharcterizingДокумент32 страницыcf3d CharcterizingPravin LuthadaОценок пока нет

- Mechanical Characterization of Talc Particle Filled ThermoplasticsДокумент14 страницMechanical Characterization of Talc Particle Filled ThermoplasticsideepujОценок пока нет

- Rapid Prototyping Full Seminar Report 989Документ17 страницRapid Prototyping Full Seminar Report 989Girish JawalageriОценок пока нет

- Experimental Investigation Using Taguchi Method To Optimize Process Parameters of Fused Deposition Modeling For ABS and Nylon MaterialsДокумент9 страницExperimental Investigation Using Taguchi Method To Optimize Process Parameters of Fused Deposition Modeling For ABS and Nylon MaterialsArukana KotoОценок пока нет

- Rapid PrototypingДокумент18 страницRapid Prototypingrippervasu100% (2)

- Production Technology of ROPS Cab: Technical PaperДокумент8 страницProduction Technology of ROPS Cab: Technical Paperjose rosasОценок пока нет

- Contact Control Concepts in Manipulation Robotics-An: Miomir andДокумент13 страницContact Control Concepts in Manipulation Robotics-An: Miomir andHaider NeamaОценок пока нет

- Force/Motion Control of Constrained Robots Using Sliding ModeДокумент5 страницForce/Motion Control of Constrained Robots Using Sliding ModeHaider NeamaОценок пока нет

- Lectures Notes On: Machine Dynamics IIДокумент145 страницLectures Notes On: Machine Dynamics IIHaider NeamaОценок пока нет

- Project 3: The Watt Governor, Feedback Control, and StabilityДокумент5 страницProject 3: The Watt Governor, Feedback Control, and StabilityHaider NeamaОценок пока нет

- Design and Implementation of Space Vector PWM Inverter Based On A Low Cost MicrocontrollerДокумент12 страницDesign and Implementation of Space Vector PWM Inverter Based On A Low Cost MicrocontrollerHaider NeamaОценок пока нет

- Biped Landing Pattern Modification Method With Nonlinear Compliance ControlДокумент6 страницBiped Landing Pattern Modification Method With Nonlinear Compliance ControlHaider NeamaОценок пока нет

- Refrence List Middle EastДокумент7 страницRefrence List Middle EastazeemОценок пока нет

- Mail Scanner - Community Ubuntu DocumentationДокумент4 страницыMail Scanner - Community Ubuntu DocumentationAjith PathiranaОценок пока нет

- Double Effect EvaporatorДокумент4 страницыDouble Effect EvaporatorAditiJain100% (1)

- ST 010 ISBT 128 Standard Product Description Code Database v6.0.0Документ34 страницыST 010 ISBT 128 Standard Product Description Code Database v6.0.0Patrick Ramos100% (1)

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Документ1 страницаAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeОценок пока нет

- Operaional Manual: YZBF-120LDДокумент16 страницOperaional Manual: YZBF-120LDMohamed AnwarОценок пока нет

- Lesson 1 DataДокумент4 страницыLesson 1 Dataapi-435318918Оценок пока нет

- Microsoft Word - CHALLAN DHSK - 5th - Sem - Challan - 22-23Документ1 страницаMicrosoft Word - CHALLAN DHSK - 5th - Sem - Challan - 22-23YoUnG PrINCeОценок пока нет

- Philips HeartStart MRX EMS BrochureДокумент12 страницPhilips HeartStart MRX EMS BrochureEnerspect Medical Solutions100% (1)

- Chapter 8 - 1935 Rife Ray #4 Rife MachineДокумент2 страницыChapter 8 - 1935 Rife Ray #4 Rife MachineKhalid IbrahimОценок пока нет

- Active Suspension System of Quarter CarДокумент70 страницActive Suspension System of Quarter CarMarcu SorinОценок пока нет

- Reciprocating Compressor Discharge TemperatureДокумент6 страницReciprocating Compressor Discharge TemperaturesalleyОценок пока нет

- Draw 224-1Документ8 страницDraw 224-1Alther Dabon33% (3)

- Re InviteДокумент16 страницRe InviteAjay WaliaОценок пока нет

- Physics 2Документ2 страницыPhysics 2MarcusKlahnTokoeJr.Оценок пока нет

- Arni AdvertisementДокумент2 страницыArni AdvertisementHemanthОценок пока нет

- SSMT Solution ManualДокумент12 страницSSMT Solution ManualPraahas Amin0% (1)

- SPC & MSA PresentationДокумент84 страницыSPC & MSA PresentationRaajha Munibathiran100% (3)

- Masonry - Block Joint Mortar 15bДокумент1 страницаMasonry - Block Joint Mortar 15bmanish260320Оценок пока нет

- CBB Exam Preparation CourseДокумент2 страницыCBB Exam Preparation CourseaadmaadmОценок пока нет

- G3616 Gas Engine Electrical System: Mids AdvisorДокумент2 страницыG3616 Gas Engine Electrical System: Mids AdvisorDiego Ruben PalavecinoОценок пока нет

- Chapter 3: Operating-System StructuresДокумент31 страницаChapter 3: Operating-System StructuresDiamond MindglanceОценок пока нет

- NEF 50006 BSI WidescreenДокумент13 страницNEF 50006 BSI Widescreenmiguelq_scribdОценок пока нет

- SE440BX-2 Motherboard: Technical Product SpecificationДокумент90 страницSE440BX-2 Motherboard: Technical Product SpecificationEvelio MorenoОценок пока нет

- Zf6 6r60 Zip BookletДокумент8 страницZf6 6r60 Zip BookletPablo Farfan Alvarez100% (1)

- Edtpa 2nd Lesson PlanДокумент5 страницEdtpa 2nd Lesson Planapi-297045693Оценок пока нет

- Pump Primer 1 AssДокумент34 страницыPump Primer 1 AssGkou DojkuОценок пока нет

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Документ2 страницыIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)AmriteshbhaskarОценок пока нет

- Colphenebswh 1816Документ2 страницыColphenebswh 1816vinoth kumar SanthanamОценок пока нет

- HARTING Industrial Connectors Han: Short Form CatalogueДокумент40 страницHARTING Industrial Connectors Han: Short Form CatalogueFabrizio AugustoОценок пока нет