Академический Документы

Профессиональный Документы

Культура Документы

Safety Alert: Tong Incident Results in A Fatality

Загружено:

Vimal Singh0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров1 страницаThe snub line was reportedly longer than normally installed due to a non-routine operation prior to the incident. The cathead breakout line was jammed at the cathead giving the appearance that the sab line was tensioned. The IP was evacuated from the rig and later died from the injuries. To address this incident, this company issued the following Corrective Actions to rig supervisors and rig personnel.

Исходное описание:

Оригинальное название

sa03-28

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe snub line was reportedly longer than normally installed due to a non-routine operation prior to the incident. The cathead breakout line was jammed at the cathead giving the appearance that the sab line was tensioned. The IP was evacuated from the rig and later died from the injuries. To address this incident, this company issued the following Corrective Actions to rig supervisors and rig personnel.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров1 страницаSafety Alert: Tong Incident Results in A Fatality

Загружено:

Vimal SinghThe snub line was reportedly longer than normally installed due to a non-routine operation prior to the incident. The cathead breakout line was jammed at the cathead giving the appearance that the sab line was tensioned. The IP was evacuated from the rig and later died from the injuries. To address this incident, this company issued the following Corrective Actions to rig supervisors and rig personnel.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

Safety Alert

From the International Association of Drilling Contractors

The Corrective Actions stated in this alert are one companys attempts to address the incident, and do not

necessarily reflect the position of IADC or the IADC HSE Committee.

This material is presented for information purposes only. Managers & Supervisors should

evaluate this information to determine if it can be applied to their own situations and practices.

Copyright 2003 International Association of Drilling Contractors. All Rights Reserved

Issued July 2003

ALERT 03 28

TONG INCIDENT RESULTS IN A FATALITY

WHAT HAPPENED:

The rig floor crew was making up drill pipe prior to running into the hole to land the PBR on the tubing

string. The rotary brake was used to hold the pipe in the rotary from turning. The Lead Floorman (Injured

Person - IP) was operating a backup manual pipe tong while torquing a stand of drill pipe with the top drive

system. As the Driller began to see the spinner torque-up the drill pipe, he released the rotary brake, to

transfer the torque to the backup manual pipe tong. As the torque was transferred to the backup pipe tong

it moved in a clockwise position and the IP became caught between the snub line and backup pipe tong

lever. The IP was evacuated from the rig and later died from the injuries.

WHAT CAUSED IT:

The snub line was reportedly longer than normally installed due to a non-routine operation prior to the

incident.

The breakout tong appeared to be tensioned by the snub line, when in fact it was the cathead breakout

line.

The cathead breakout line and snub line were both attached to the tong.

The cathead breakout line was jammed at the cathead giving the appearance that the snub line was

tensioned.

CORRECTIVE ACTIONS: To address this incident, this company issued the following instructions to

rig supervisors and rig personnel:

The Rig Manager should review and confirm the current operating practices for torquing tubulars at the

rotary table.

Review tong management on the drill floor. Confirm correct operation of pipe tongs during routine and

non-routine operations.

Include a review of safe positioning of people, supervision by Driller and Asst Driller, and the hazards

associated with pipe tong operations.

Length of snub lines and angle to anchor point to be physically verified to ensure no pinch point

hazards exist for a Floorman while operating manual pipe tongs.

Вам также может понравиться

- Safety Alert: Driller Inattention Results in Dropped BlocksДокумент1 страницаSafety Alert: Driller Inattention Results in Dropped Blockscase013Оценок пока нет

- 00-24 Proper Clamps Mud HoseДокумент2 страницы00-24 Proper Clamps Mud Hoseforajistu100% (1)

- Safety Alert: From The International Association of Drilling ContractorsДокумент1 страницаSafety Alert: From The International Association of Drilling ContractorsJohnHynesОценок пока нет

- Data Book #Eest-Po-18-004479 Wetorq 100Документ237 страницData Book #Eest-Po-18-004479 Wetorq 100Mai KawayapanikОценок пока нет

- Procedura de Inspectie Utilaje BentecДокумент192 страницыProcedura de Inspectie Utilaje BentecadrianОценок пока нет

- l3070 e 0 0 PDFДокумент128 страницl3070 e 0 0 PDFAdhita MeryantoОценок пока нет

- Zj704500drigcomponentsspecificationagreement PDF FreeДокумент102 страницыZj704500drigcomponentsspecificationagreement PDF FreeH 8CОценок пока нет

- Cameron ValvesДокумент44 страницыCameron Valvesadrian villaОценок пока нет

- Product Information Bulletin: Handling ToolsДокумент7 страницProduct Information Bulletin: Handling ToolsghanОценок пока нет

- Commander Manual TitanДокумент40 страницCommander Manual TitanjohnfcortesОценок пока нет

- Nsiw em CatalogueДокумент68 страницNsiw em Cataloguejavier06.678061Оценок пока нет

- IADC Safety Alert Mud Pumps GDДокумент1 страницаIADC Safety Alert Mud Pumps GDlucas ronaldo coronel mendozaОценок пока нет

- 4197 Emsco 602 DWR SignedДокумент11 страниц4197 Emsco 602 DWR SignedMohammed Ali YoussefОценок пока нет

- TITAN Neumáticos MineríaДокумент20 страницTITAN Neumáticos MineríaFranco Rojas BozaОценок пока нет

- 10745350-Pib Sola 24v电源故障Документ4 страницы10745350-Pib Sola 24v电源故障xlzyydf2015Оценок пока нет

- Arabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationДокумент5 страницArabian Drilling Company Rig Specific Procedure AD - 32 Manriding OperationinfonexusОценок пока нет

- Stacey Oil Services Drill Pipe Float Valves Pullers Baffle Plates Float Subs BrochureДокумент27 страницStacey Oil Services Drill Pipe Float Valves Pullers Baffle Plates Float Subs BrochureKeshav Pujeri100% (1)

- RBC Cat SPBДокумент68 страницRBC Cat SPBAl ArdhiОценок пока нет

- Soft Torque Plugin For Precise PsДокумент1 страницаSoft Torque Plugin For Precise PsJulio Alejandro Rojas BarbaОценок пока нет

- Hse Manual: VIKING 01-01Документ168 страницHse Manual: VIKING 01-01AF Dowell MirinОценок пока нет

- Safety For Hydraulics: Compac Type Proportional Valves Series CVДокумент32 страницыSafety For Hydraulics: Compac Type Proportional Valves Series CVthierrylindoОценок пока нет

- ERP Travelling Block - Hook BlockДокумент9 страницERP Travelling Block - Hook BlocknobodymagdesignОценок пока нет

- 3500b IntroductionДокумент36 страниц3500b IntroductionNader abobakrОценок пока нет

- Dive MateДокумент2 страницыDive MateAdrian RayosОценок пока нет

- Mud Pump Bearing Life 11338 1Документ12 страницMud Pump Bearing Life 11338 1Hassan KhattabОценок пока нет

- TM 80 Daily and Weekly Inspection and Maintenance TasksДокумент25 страницTM 80 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoОценок пока нет

- Ton Torque ManometrosДокумент16 страницTon Torque ManometrosEliecer DiazОценок пока нет

- D392004720 MKT 001 PDFДокумент28 страницD392004720 MKT 001 PDFsorangel_123Оценок пока нет

- g312 ManualДокумент14 страницg312 Manualflasher_for_nokiaОценок пока нет

- Setting The HYDRAULIC VALVE BANKДокумент6 страницSetting The HYDRAULIC VALVE BANKAlex RamirezОценок пока нет

- Injector Cut-Out Test ProcedureДокумент9 страницInjector Cut-Out Test ProcedureEd CalheОценок пока нет

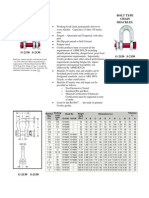

- Crosby ShacklesДокумент6 страницCrosby Shacklessabah8800Оценок пока нет

- Guidance Checklist WebДокумент5 страницGuidance Checklist WebmeidiansyahОценок пока нет

- Top Drive PB169 - Blower - Motor - U-Bolt - SupportДокумент6 страницTop Drive PB169 - Blower - Motor - U-Bolt - SupportJoseMi Vacaflor Illanes100% (1)

- D399 Testing and AdjustingДокумент73 страницыD399 Testing and AdjustingNOUR ZAIN100% (1)

- Caterpillar Drilling Rig Repower Brochure PDFДокумент10 страницCaterpillar Drilling Rig Repower Brochure PDFAhmed EzzeddineОценок пока нет

- Candoc - Es 120 Top Drive Electrical System 1Документ160 страницCandoc - Es 120 Top Drive Electrical System 1JHON JAIRO VALENCIA NIÑOОценок пока нет

- Hi Kal Catalogue New OptДокумент16 страницHi Kal Catalogue New Optask101Оценок пока нет

- Sa-07-09.PDF 4 Part ShackleДокумент2 страницыSa-07-09.PDF 4 Part ShackleSafety VirtueОценок пока нет

- Safety Spinning Wrench SSW 40Документ88 страницSafety Spinning Wrench SSW 40Beitsaeed SinaОценок пока нет

- Canrig Tops DrivesДокумент4 страницыCanrig Tops DrivesAlejandro GomezОценок пока нет

- WashpipeInst and RemovalFlyerДокумент1 страницаWashpipeInst and RemovalFlyerBabi LakhdariОценок пока нет

- TA Elevators MaintenanceДокумент8 страницTA Elevators MaintenanceBahman MatouriОценок пока нет

- KT13625 FarrBackup CompressionCellManual Rev072011Документ129 страницKT13625 FarrBackup CompressionCellManual Rev072011enuvos engineeringОценок пока нет

- TM 120 Daily and Weekly Inspection and Maintenance TasksДокумент23 страницыTM 120 Daily and Weekly Inspection and Maintenance TasksAlejandra Noguera GiraldoОценок пока нет

- Gripper Die Block: Removal and InstallationДокумент5 страницGripper Die Block: Removal and InstallationJuan Pablo Villazon RichterОценок пока нет

- Drilling Rig Selection Guide Page 06 of 13Документ1 страницаDrilling Rig Selection Guide Page 06 of 13Shodji Mabunga100% (1)

- 1-11-B 1. Tools and Equipment: Deadline Anchor MaintenanceДокумент2 страницы1-11-B 1. Tools and Equipment: Deadline Anchor MaintenanceAbdul Hameed OmarОценок пока нет

- CalemEAM Functionality AjaxДокумент8 страницCalemEAM Functionality Ajaxเกียรติศักดิ์ ภูมิลาОценок пока нет

- Rotary TableДокумент4 страницыRotary TableUsman AhmedОценок пока нет

- Electric Top Drive ETD 500Документ76 страницElectric Top Drive ETD 500SMEETОценок пока нет

- HY10 1630US 5 2012-Bladder AccumulatorsДокумент14 страницHY10 1630US 5 2012-Bladder AccumulatorsAlejandro GilОценок пока нет

- TDS 93 1 Pib PDFДокумент6 страницTDS 93 1 Pib PDFMohamed HashemОценок пока нет

- Mission Magnum I Pump Spare PartsДокумент2 страницыMission Magnum I Pump Spare PartsEleazar GallegosОценок пока нет

- Mechanical Type J Rotary Jar: Instruction Manual 4170Документ13 страницMechanical Type J Rotary Jar: Instruction Manual 4170Foros IscОценок пока нет

- Handing Tools CPMCДокумент32 страницыHanding Tools CPMCcristinelb100% (1)

- Wearlimitgauge PDFДокумент1 страницаWearlimitgauge PDFAbrar HussainОценок пока нет

- Sucker Rod Overshots: Instruction Manual 1010Документ14 страницSucker Rod Overshots: Instruction Manual 1010Foros IscОценок пока нет

- Emsco FB13/1600 Module Exploded ViewДокумент3 страницыEmsco FB13/1600 Module Exploded ViewJESUS ANTONIOОценок пока нет

- 2008-IADC Alerts PDFДокумент66 страниц2008-IADC Alerts PDFAnsarMahmood100% (1)

- YARD - WEEKLY SOC TRACKING - (Week Ending 14th Sept 2014) : S.No ObservationsДокумент3 страницыYARD - WEEKLY SOC TRACKING - (Week Ending 14th Sept 2014) : S.No ObservationsVimal SinghОценок пока нет

- EYE WASH Weekly InspectionДокумент1 страницаEYE WASH Weekly InspectionVimal SinghОценок пока нет

- Ethical Conduct Presentation - MOM Dated 4062014Документ8 страницEthical Conduct Presentation - MOM Dated 4062014Vimal SinghОценок пока нет

- F0556 Crane Weekly Check (Offshore)Документ2 страницыF0556 Crane Weekly Check (Offshore)Vimal Singh0% (1)

- F0555 Crane Daily Checklist (Offshore)Документ2 страницыF0555 Crane Daily Checklist (Offshore)Vimal SinghОценок пока нет

- Check List For SOBM Take On BoardДокумент5 страницCheck List For SOBM Take On BoardVimal SinghОценок пока нет

- HSSE Orientation VerificationДокумент1 страницаHSSE Orientation VerificationVimal SinghОценок пока нет

- Flaring Check List: Before Beginning Flaring OperationsДокумент2 страницыFlaring Check List: Before Beginning Flaring OperationsVimal SinghОценок пока нет

- Tugger - Foundation Bolt FailureДокумент1 страницаTugger - Foundation Bolt FailureVimal SinghОценок пока нет

- Final Qhse Planner 2014Документ1 страницаFinal Qhse Planner 2014Vimal SinghОценок пока нет

- ARCO Final - GIL - Isolation Cert Proof - (07.10.09)Документ1 страницаARCO Final - GIL - Isolation Cert Proof - (07.10.09)Vimal SinghОценок пока нет

- Safety Alert-Offshore OISDДокумент1 страницаSafety Alert-Offshore OISDVimal SinghОценок пока нет

- Fatality - Tong Snub LineДокумент1 страницаFatality - Tong Snub LineVimal SinghОценок пока нет

- OSO-50-R0 PPE Issuance FormДокумент1 страницаOSO-50-R0 PPE Issuance FormVimal SinghОценок пока нет

- PTW Checklist AssessmentДокумент1 страницаPTW Checklist AssessmentVimal SinghОценок пока нет

- Smart Document Review For Hsse ManualДокумент2 страницыSmart Document Review For Hsse ManualVimal SinghОценок пока нет

- OSO-15-R0 Elementry Basic Safety FamiliarisationДокумент1 страницаOSO-15-R0 Elementry Basic Safety FamiliarisationVimal SinghОценок пока нет

- Drilling Waste MGT TechДокумент50 страницDrilling Waste MGT TechVimal SinghОценок пока нет

- FINAL Shivani Confined Space PermitДокумент1 страницаFINAL Shivani Confined Space PermitVimal SinghОценок пока нет

- Course Feedback FormДокумент1 страницаCourse Feedback FormVimal SinghОценок пока нет

- HSSE Manual Smaple FormatДокумент3 страницыHSSE Manual Smaple FormatVimal SinghОценок пока нет

- Working at Height Check ListДокумент1 страницаWorking at Height Check ListVimal SinghОценок пока нет

- Oth 351Документ93 страницыOth 351Vimal SinghОценок пока нет

- Emergency Response Plan 2012Документ22 страницыEmergency Response Plan 2012Vimal Singh100% (2)

- Inspection ReportДокумент5 страницInspection ReportVimal SinghОценок пока нет

- Catalogue EquipmentДокумент64 страницыCatalogue EquipmentVimal SinghОценок пока нет

- Drill Matrix Shivani HeritageДокумент1 страницаDrill Matrix Shivani HeritageVimal SinghОценок пока нет

- CAP437Документ164 страницыCAP437universidaddistritalОценок пока нет

- 25 OISD STD Pertain Directly To E&PДокумент1 страница25 OISD STD Pertain Directly To E&PVimal Singh0% (1)

- JAKARTA - by by ANDRE VLTCHEK PDFДокумент23 страницыJAKARTA - by by ANDRE VLTCHEK PDFRany FuadОценок пока нет

- Explosion Venting RequirementsДокумент6 страницExplosion Venting Requirementsamariei_niculinaОценок пока нет

- Repair and Strengthening of Brick & Concrete Block Masonry Ho..Документ11 страницRepair and Strengthening of Brick & Concrete Block Masonry Ho..Magdy BakryОценок пока нет

- Detailed-Lesson-Plan-for-Demo in DRRДокумент9 страницDetailed-Lesson-Plan-for-Demo in DRRcamille baybayonОценок пока нет

- A Night To Remember Q1 Cinematic AnalysisДокумент4 страницыA Night To Remember Q1 Cinematic AnalysisKathryn GrayОценок пока нет

- PDFДокумент146 страницPDFClash of HackersОценок пока нет

- Brochure 1Документ1 страницаBrochure 1janice lopezОценок пока нет

- WoT Card AppendixДокумент12 страницWoT Card AppendixLeonardoPalharesОценок пока нет

- Republicans For Kansas Values Steering Com. MembersДокумент11 страницRepublicans For Kansas Values Steering Com. MembersdavisforkansasОценок пока нет

- Lived Experiences of Flood in Riverine CommunitiesДокумент33 страницыLived Experiences of Flood in Riverine CommunitiesHAIDEE VASQUEZОценок пока нет

- IMPLAN To OPLAN SAKLOLOДокумент19 страницIMPLAN To OPLAN SAKLOLOTerrence33% (3)

- Geo SyntheticsДокумент32 страницыGeo SyntheticsI_am_Pallavi100% (1)

- Explosion ProtectionДокумент20 страницExplosion Protectionzirimia100% (1)

- English and American Literature RedusaДокумент79 страницEnglish and American Literature RedusaTatiana NitaОценок пока нет

- Executive Orders MDRRMCДокумент39 страницExecutive Orders MDRRMCGabriel C. ObiasОценок пока нет

- DRRM Act Primer PDFДокумент24 страницыDRRM Act Primer PDFBajunaid Malaco100% (1)

- Effects of Architectural Stability, Architectural Concept and Building Elements On Disaster Resilient in ArchitectureДокумент11 страницEffects of Architectural Stability, Architectural Concept and Building Elements On Disaster Resilient in ArchitectureSagayo Compas JayОценок пока нет

- She Stoops To ConquerДокумент27 страницShe Stoops To ConquerxsgtОценок пока нет

- Science: Quarter 3 - Module 1Документ17 страницScience: Quarter 3 - Module 1NRIZA MAE CACHOОценок пока нет

- Reactive Chemicals Training PresentationДокумент25 страницReactive Chemicals Training Presentationtatarey79100% (1)

- Blast Effects On Buildings GC Mays PD SmithДокумент68 страницBlast Effects On Buildings GC Mays PD SmithEnrique Flores100% (1)

- ĐỀ CƯƠNG ÔN TẬP GIỮA HỌC KÌ 2Документ4 страницыĐỀ CƯƠNG ÔN TẬP GIỮA HỌC KÌ 2Quỳnh PhạmОценок пока нет

- SLM 2-GradeIII2DRRR-1st Quarter-Concept of Disaster RiskДокумент21 страницаSLM 2-GradeIII2DRRR-1st Quarter-Concept of Disaster RiskJanny MorenoОценок пока нет

- Tsutsumi and Perez Philippine FaultДокумент9 страницTsutsumi and Perez Philippine FaultDavid GarciaОценок пока нет

- Room For The RiverДокумент2 страницыRoom For The RiverAnonymous 1n5HpBjОценок пока нет

- 2 As Exam No Man Is An IslandДокумент3 страницы2 As Exam No Man Is An Islandmaian saja75% (4)

- Great Fire of LondonДокумент3 страницыGreat Fire of Londonmoro206hОценок пока нет

- Chasing Hurricane AndrewДокумент16 страницChasing Hurricane AndrewjohnosborneОценок пока нет

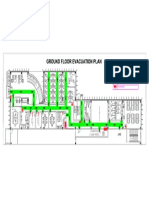

- Ground Floor Evacuation PlanДокумент1 страницаGround Floor Evacuation PlanModular Design TeamОценок пока нет

- Profiling Warning Response Towards Bulusan Volcano, PhilippinesДокумент23 страницыProfiling Warning Response Towards Bulusan Volcano, PhilippinesJoseph BasconcilloОценок пока нет

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaОт EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaРейтинг: 4 из 5 звезд4/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldОт EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldРейтинг: 5 из 5 звезд5/5 (1)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontОт EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontРейтинг: 4.5 из 5 звезд4.5/5 (18)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretОт EverandWaste: One Woman’s Fight Against America’s Dirty SecretРейтинг: 5 из 5 звезд5/5 (1)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionОт Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionОценок пока нет

- Busted!: Drug War Survival Skills and True Dope DОт EverandBusted!: Drug War Survival Skills and True Dope DРейтинг: 3.5 из 5 звезд3.5/5 (7)

- Environmental Education in Practice: Concepts and ApplicationsОт EverandEnvironmental Education in Practice: Concepts and ApplicationsОценок пока нет

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawОт EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawРейтинг: 4 из 5 звезд4/5 (334)

- The Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010От EverandThe Intersection of Intellectual Property Law and the “Green” Movement: RIPL’s Green Issue 2010Рейтинг: 5 из 5 звезд5/5 (2)

- Principles of direct and superior responsibility in international humanitarian lawОт EverandPrinciples of direct and superior responsibility in international humanitarian lawОценок пока нет

- Down to the Wire: Confronting Climate CollapseОт EverandDown to the Wire: Confronting Climate CollapseРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontОт EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933От EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Оценок пока нет

- New Paradigms in Environmental Biomonitoring Using PlantsОт EverandNew Paradigms in Environmental Biomonitoring Using PlantsSupriya TiwariОценок пока нет