Академический Документы

Профессиональный Документы

Культура Документы

Specifications 160kVA

Загружено:

Lalantha Kodikara0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров7 страницgood

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документgood

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров7 страницSpecifications 160kVA

Загружено:

Lalantha Kodikaragood

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

TECHNICAL SPECIFICATIONS - PRIME RATED DIESEL GENERATOR 160 kVA

PROPOSED OPERATING THEATER AND WARD COMPLEX AT DISTRICT

HOSPITAL - POTHUWIL

1.1. GENERAL AND SCOPE OF SUPPLY

This section specifies the design, manufacture, supply to the site, install, testing and

commissioning of one three phase, low voltage silenced type Prim r!"# diesel generator

with !$"% &"!r" '!"$r and enclosed in a '!("%r) 'i""# (!*%+) at the generator

manufactures work. The generator set should be provided with main failure automatic starter,

automatic change over switch which will start on failure of Supply authority and ,"*&i%* "%

&i-*(r ,.!$&".

The work should be carried out by a firm specialised in this kind of work and having an

accredited agency in Sri Lanka. The generator set shall be new, using approved and reliable

known makes of diesel engine and alternator. They shall also be a make already operations in Sri

Lanka for which maintenance facilities are already available during last five years.

The diesel generator set shall be supplied complete with all ancillary equipment necessary

for starting and running of the set, including cooling systems, fuel storage and supply

system, instrumentation, control and protection arrangements, spares and special tools. The

generator set and the ancillary equipment shall be installed in the generator room. Diesel

generator metal part shall be earthed. Generator eutral shall be solidly earthed. The set is to

be reasonably self!contained to minimi"e the work of installation at site. The engine,

alternator and cooling radiator should be mounted on a combined under base of stress relieved

fabricated steel and engine accessories shall also be mounted on the under base where

appropriate, provided that this does not result in difficulty of access for maintenance.

The set is to be mounted on suitable arrangement of anti!vibration mounting designed to

minimi"e the transmission of vibration but without resulting in e#cessive amplitudes of

$ovement of any parts of the set. %f rubber is employed in the mounts, their design should

incorporate means of preventing deterioration due oil leakages.

The generator set shall be provided with sound attenuated canopy fitted at the generators

manufactures work, so that the noise level shall not e#ceed &'d( at )m distance and *+

d( at )'m distance from the machine at full load operating condition at any direction.

,le#ible connection shall be provided to all e#haust, water, air, fuel and oil piping that

leaves the engine to prevent the transmission of vibration and the fracture of the piping

due to movement of the set. The choice of connections and their installation is to be such as to

give long life under normal operating condition of the set.

-age 1 of /

1.0. STANDARDS

The following Standards apply.

(S +''' -art / ! Generators to be driven by 0eciprocating %nternal 1ombustion 2ngines.

(S ++)3 4%S5/'3*6 ! Specification for 0eciprocating %nternal 1ombustion 2ngines. -art )!*

(S +3&* 4%21 3/76 ! ,actory (uilt assemblies of Low 8oltage Switchgear and 1ontrol Gear.

(S 37774%21/3!)6 ! General requirements for 0otating 2lectrical $achines

1.1 DESIGN DATA

1.1.1 ENGINE

0ated continuous output 9 )*' k8: at '.& pf at generator output terminals. 4(ased on ;< 1

ambient temperatures and a relative humidity of 7'=6.

The unit should be capable of delivering the rated output for continuous period of not less

than ); hours at a time. 5verload capacity of ))'= for one hour during a period of ); hours.

umber of strokes ! 3

Speed ! )+'' rpm

1ooling ! fan!cooled closed cooling water circuit.

Loading ! :synchronous motor loads of up to )''= may be switched on with a

ma#imum admissible speed droop of twelve 4);6 percent.

1.1.0 GENERATOR

0ated 5utput 9 160kVA

-ower ,actor ! '.&

,requency ! +' > ;= ?"

8oltage ! 3''@;/' 8 > += / phase A neutral

Speed ! )+'' rpm

Deviation ,actor of voltage Bave form ! +=

%nsulation 1lass for 0otor and stator windings ! , or higher

-rotection class of enclosure ! %- ;/

1.1.1 ENGINE

Diesel engine shall be of a well!proven make, complying with the requirements of (S

++)3 4%S5 /'3*6. The engine shall meet all the performance requirements of the set under

the specified operating conditions.

: sturdy elastic coupling shall connect the engine and the generator, and both shall be

mounted on a common base plate forming part of the supply, -roven and highly effective

anti!vibrating mountings shall be provided between base plate.

-age 0 of /

The engine shall be started by ;3 8 starter motor engaging with the fly wheel ring gear

and disengaging automatically when the engine starts. The equipment shall include an

adequately rated lead@acid battery together with an automatic mains energi"ed battery

charger. The charger shall have a continuous output rating sufficient to recharge the battery from

).& 8@cell to a fully charged condition in a period of & hours. The battery shall be capable of

providing at least si# starting cycles within a period of + minutes.

The engine shall be water cooled. : sectional radiator shall be provided and mounted on the

combined under base and arranged to cool the engine Cacket water, lubricating oil and charge air

as appropriate. 1irculation of cooling water through the engine and radiator shall be by means of

engine driven pump. The water circuits shall be fitted with an easily accessible drain point.

The cooling fan shall be arranged to drive directly by the engine and the hot air shall ducted to

suitable openings in the generator room wall. The duct shall be incorporated with a suitable

fle#ible section to prevent the transmission of vibration from the engine and the discharge end shall

be provided with louvers and an insect screen.

Lubrication of the engine shall be by means of an engine driven integral pump. The

pump shall have on the suction side a coarse strainer and on the delivery side a duple# Dfull flowE

fine filter complete with changeover cock incorporating pressure by!passes to facilitate oil

flow to the engine should the filter become blocked. The lubricating oil system capacity

shall be sufficient to enable the engine to run continuously for ); hours at any load

without replenishment.

The governor of the engine shall be electronic type and be capable of fine governing of speed to

1lass :; of (SS ++)3@)7<<, %S5 /'3*@%8.

The engine shall be efficiently silenced with suitable noise attenuators provided at

cooling@combustion air inlets and outlets and e#haust silencers complete with interconnecting

pipe and fittings. Supports for each complete system shall be of the anti!vibration type and due

allowance for e#pansion of the e#haust system shall be made by the inclusion of

e#pansion bellows.

2#haust pipe shall be lagged with a removable :luminium cladding. The engine shall be

provided with following protection devices for alarm and shutting down the engine

automatically.

! Low lubricating oil pressure ! two stage

! 2ngine over speed

! ?igh cooling water temperature ! two stage

! 5ver crank

1.1.2 GENERATOR

Generator shall comply with (S +''' 4%21 /3!)6 and shall be brushless, self!e#citing and

self!regulating type. The e#citer shall be with rotating silicon rectifiers, au#iliary e#citer of

permanent magnet type, damper cage, static voltage regulator and compounding equipment.

-age 1 of /

The voltage regulator shall maintain its setting for long periods without adCustment.

$eans shall be provided for a limited degree of manual adCustment of the output voltage setting.

Generator shall be directly coupled to and share a common high bedplate with the prime

mover. The degree of protection for the generator and e#citer shall be not less than %- ;/.

1ooling of the generator shall be by a radial!flow fan. Generator bearings shall be of the ball

or roller type, rated for long life and prepacked with sufficient grease for operating over

long periods without replenishment. The stator and field windings shall consist of electrolytic

copper conductors insulated throughout with 1lass , or higher materials as defined in %21

&+. : generator winding temperature detector 4thermostat6 installed at the hottest spot and wired to

give alarm and shutdown.

8oltage regulation should be maintained within > ;F= from no load to full load including

cold to hot variation at any power factor from '.& to unity.

eutral shall be solidly earthed.

1.1.3 FUEL STORAGE

The following shall be supplied with the unit.

1.1.3.1 4!& T!*k

The machine shall have one integral metal fuel tank 4capacity sufficient for '& hours

operation at full load but not less than 7'' litres6 and shall be installed in a position where any

fuel leakage cannot impinge on e#haust pipe or other hot engine surfaces. The tank shall be

provided with all necessary fittings including fill, vent, drain and overflow line, level indication

and access for inspection and maintenance. Level switches shall be provided for the following

services.

4a6 Low level alarm

4b6 ?igh level alarm

1.1.6 CONTROL E5UIPMENT

: control cubicle fabricated with welded steel panels supported by structural steel frame, shall

be provided and installed for the stand!by plant, together with all necessary inter!connections,

anti!condensation heaters etc. The primary function of the control equipment shall be

! :utomatic starting and stopping of the generator on receipt of signal from main

panel board.

! ,ault indicating and appropriate action.

! $anual starts and stops operations in remote and local positions.

The operation of the diesel generator set shall be as follows. Bhen a power failure occurs, this

information is available to control panel via power incomer panel board. The relays in the control

panels will start the generator and power will fed to the main distribution board.

:utomatic changeover from utility supply to diesel generator supply is done by auto transfer

switch. Bhen in a similar manner when the utility power returns the machine should be

-age 2 of /

taken off the system and stopped.

Bhen the mains power is restored, a time delay between + to )' sec. Should be introduced

before the removal of generator power and the reintroduction of mains power.

:dCustable timer to protect generator against repeated transient power failures should also

be provided.

The starting period for the machine should not e#ceed )+ sec. should this period be

e#ceeded without speed sense switch cancelling the starting cycle all starting circuits shall be

switched out and an indication shall be displayed on generator control panel.

:utomatic shutdown of the set and lockout of the starting system shall result from any of

the following.

! Low lubricating oil pressure

! ?igh cooling water temperature

! ,ailed to start

! 2ngine over speed 4if speed e#ceed ;'= above normal6

! ?igh stator temperature

The control system shall include the following.

! 5verload protection

! 0estricted 2arth fault protection

! 8isual A :udible ,ault indication and alarm accept@reset

! :ll necessary controls needed to prevent starting of machines on momentary

fluctuations of main voltage

! : selector switch for operation of the equipment in automatic and manual mode

and off position

! : selector switch for operation of the equipment in local and remote position :utomatic

start sequence control.

The following equipment shall be included in the control panel

! 8oltmeter and selector switch to indicate individual phase and line voltage

! :mmeter and selector switch to indicate the line current

! ,requency meter

! ?our run counter

! 2ngine EstartE A EstopE push button and lock switch

! E0emoteE A ELocalE selector switch with provision for start A stop at main panel board

! E:utoE, E$anualE A E5ffE selector switch

! E2mergency StopE push button

! $ains operated battery charger of the constant potential type with $11(,

ammeter, incorporating mains failure relay

! 0un indicator lamp

! ,ault indicator lamp

! :udible :larm

! Lamp test push buttons, :larm accept and reset buttons

! Tachometer and Speed indicator

! / -ole $11( with neutral link

-age 3 of /

The following engine related items shall be mounted separate from the control cubicle.

! (attery charge indicator

! Lubrication oil pressure indicator

! 1ooling water temperature indicator

! 2ngine speed adCustment 4speed droop between ' and * =6

! ,uel level in integral fuel tank low

! ,uel level in integral fuel tank high

$icroprocessor 1ontrol -anel with :lphaneumerical character digital display is acceptable

alternative to hardwired equipments. $icroprocessor 1ontrol -anel shall incorporate all above

mentioned facilities.

The $icroprocessor 1ontrol -anel shall be able to connect to Standard -ersonal 1omputer to

download data and information from module and to programme the $odule. The tenderer

shall tabulate all parameters, signals, safety devices and other facilities available in the

$icroprocessor 1ontrol -anel.

%t should be noted that control equipments should be suitable for tropical climatic

conditions so that their parameters shall not vary due to ambient temperature or aging.

1.2 TESTS

1.2.1 SHOP TESTS

The following tests and checks shall be carried out in the manufacturerEs shops. Test

reports shall be submitted for 2ngineerEs approval.

! :ll tests as required by the manufacturerEs practice or by applicable standards

during the manufacture stage.

! -erformance tests on the assembled diesel generating set with sound proof canopy

4with voltage regulator6

! 1heck of fuel consumption at different loads

! Dielectric and insulation tests

! 0outine tests on voltage regulator

! ?ydrostatic pressure test on fuel tank 4at ; bars6.

1.2.0 SITE TESTS

The following tests shall be carried out after installation at the Site.

! Load tests

+'= load )+ minutes

)''= load )+ minutes

))'= load )+ minutes

$easurement of vibration

:ll necessary resistive loads shall be provided by the contractor at his own e#pense.

! ,unctional testing of all alarm devices

! 1hecking of the starting time and time up to taking!over full load.

! Testing of noise levels at )m A )'m distances.

! Load reCection test

-age 6 of /

1.3 FREE MAINTENANCE AND DEFECTS LIA4ILITY PERIOD

,ollowing are the works shall be carried out during the free maintenance period.

! 2mergency calls back service.

! %nspect, clean, oil and grease where necessary.

! :dCustment of machinery.

! 0eplacement of any defective parts in suitable.

5T2. -lease submit Generator set manufacturers specifications@1atalogues.

-age / of /

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- CG Drive SGДокумент1 страницаCG Drive SGmanchem sreeram sanjay67% (3)

- Tech Spec For Plate Heat ExchangersДокумент37 страницTech Spec For Plate Heat ExchangersSHIVAJI CHOUDHURY50% (2)

- Riello Burner Handbook PDFДокумент169 страницRiello Burner Handbook PDFfsijest50% (2)

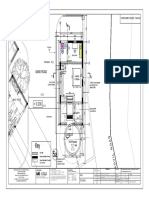

- 14 - Generator Room Revised 16.05.2018-Layout1Документ1 страница14 - Generator Room Revised 16.05.2018-Layout1Lalantha KodikaraОценок пока нет

- Current Transformer - Electrical Notes & ArticlesДокумент28 страницCurrent Transformer - Electrical Notes & ArticlesLalantha KodikaraОценок пока нет

- MCB - MCCB - ELCB - RCCB - Electrical Notes & ArticlesДокумент11 страницMCB - MCCB - ELCB - RCCB - Electrical Notes & ArticlesLalantha KodikaraОценок пока нет

- Sizing The Generator Three Phase PowerДокумент11 страницSizing The Generator Three Phase PowerLalantha KodikaraОценок пока нет

- Application Members IESL ADCДокумент1 страницаApplication Members IESL ADCLalantha KodikaraОценок пока нет

- P & I DiagramsДокумент26 страницP & I Diagramsengrfarhansiddiqui100% (3)

- Plastic WeldingДокумент8 страницPlastic WeldingMichelleAdanteMorongОценок пока нет

- Deventci-R1, A-Lovech Block, North-West BulgariaДокумент10 страницDeventci-R1, A-Lovech Block, North-West BulgariaLeon100% (1)

- How Air Compressor WorksДокумент3 страницыHow Air Compressor WorksPinak ParkhiОценок пока нет

- Shibaura Diesel Engine S773L - Tier4 XXДокумент28 страницShibaura Diesel Engine S773L - Tier4 XXMihai PopaОценок пока нет

- GenSet Power Selector Unregulated Iss2 2014 - PN3012Документ2 страницыGenSet Power Selector Unregulated Iss2 2014 - PN3012Md ShОценок пока нет

- Commander GP: General Purpose AC Variable Speed Drive (0.75 To 110 KW)Документ6 страницCommander GP: General Purpose AC Variable Speed Drive (0.75 To 110 KW)carlosorizabaОценок пока нет

- Back Corona in ESPДокумент4 страницыBack Corona in ESPewfsd67% (3)

- Industrial Training DiaryДокумент31 страницаIndustrial Training DiaryAaditya PalkarОценок пока нет

- Chapter8-Kaplon Turbine10Документ10 страницChapter8-Kaplon Turbine10fazarbadhushaОценок пока нет

- Abb LV139Документ20 страницAbb LV139Ahmad Shaikh NooruddinОценок пока нет

- Earthing 1Документ9 страницEarthing 1renjithas2005Оценок пока нет

- Republic v. Pilipinas Shell, GR 173918Документ10 страницRepublic v. Pilipinas Shell, GR 173918Glenn FortesОценок пока нет

- MCWДокумент2 страницыMCWfaisal ahmedОценок пока нет

- Auma - Electric ActuatosДокумент44 страницыAuma - Electric ActuatosRakesh Karan Singh100% (1)

- 1025936797Документ184 страницы1025936797Wilson AgudeloОценок пока нет

- D2060-M - Medical Vacuum and Gas SystemsДокумент7 страницD2060-M - Medical Vacuum and Gas Systemspaintbrush793053Оценок пока нет

- Max Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Документ106 страницMax Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Vashish Ramrecha100% (1)

- Lab 5 - Wireless Power Transfer PDFДокумент2 страницыLab 5 - Wireless Power Transfer PDFRuben CollinsОценок пока нет

- Propane Workshop PPTДокумент71 страницаPropane Workshop PPTch.kashifpervez100% (1)

- WAG-9 at A GlanceДокумент29 страницWAG-9 at A GlancePrem VeerОценок пока нет

- Edexcel PLC Student Checklist Single Chemistry Paper 2Документ2 страницыEdexcel PLC Student Checklist Single Chemistry Paper 2rbehwnsОценок пока нет

- Comparison Used in IeltsДокумент3 страницыComparison Used in IeltsDuyen HongОценок пока нет

- Referencias Electrodos FujikuraДокумент1 страницаReferencias Electrodos FujikuraAlexander GuzmanОценок пока нет

- Designing A DC MotorДокумент7 страницDesigning A DC MotorPravat SatpathyОценок пока нет

- ElectricityДокумент11 страницElectricityi919647Оценок пока нет

- Boiler Design ReviewДокумент4 страницыBoiler Design ReviewKR PAОценок пока нет