Академический Документы

Профессиональный Документы

Культура Документы

ppt11

Загружено:

BolWolИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ppt11

Загружено:

BolWolАвторское право:

Доступные форматы

C H A P T E R E L E V E N

TOLERANCING

2

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

OBJECTIVES

1. Describe the nominal size, tolerance, limits, and

allowance of two mating parts.

2. Identify a clearance fit, interference fit, and transition fit.

3. Describe the basic hole and basic shaft systems.

4. Dimension mating parts using limit dimensions, unilateral

tolerances, and bilateral tolerances.

5. Describe the classes of fit and give examples of each.

6. Draw geometric tolerancing symbols.

7. Specify geometric tolerances.

8. Relate datum surfaces to degrees of freedom.

3

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

UNDERSTANDING TOLERANCE

To effectively provide tolerances in your

drawings and CAD models, you must:

Understand the fit required between mating

parts.

Have a clear picture of how inspection

measurements are performed.

Be able to apply tolerance symbols to a

drawing or model.

Apply functional tolerancing to individual

features of the part.

Tolerance is the total amount a specific dimension is permitted to vary.

Tolerances are specified so that any two mating parts will fit together.

The inner workings of a watch are

an example of parts that must fit

precisely to work. (Courtesy of

SuperStock, Inc.)

4

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Quality Control

Before paying for parts, most companies have a process to

quality certify (QC) the parts against the drawing or model.

A tolerance must be specified for each

dimension so that it can be determined how

accurately the part must be manufactured

to be acceptable. The tolerances that you

specify are based on the parts function and

fit.

5

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Definitions for Size Designation

Feature

Feature of size

Actual local feature

Nominal size Nominal size

Allowance Allowance

Definitions of size designation terms that apply in tolerancing.

6

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Variations in Form and Envelope

You can sometimes notice variations in

form by placing a machinists scale

along the edge of the part and checking

to see whether you can slip a feeler

gage between the scale and the edge of

the part.

You can think of tolerance as defining a perfect form envelope

that the real produced part must fit inside in order to be

acceptable.

Actual minimum material envelope

This envelope is the counterpart to the

actual mating envelope.

7

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Material Envelope continued

Actual mating envelope The envelope toward the outside of the material, in which the acceptable actual

feature must fit. For external parts, like cylinders, this is the perfect feature at the largest permissible size;

for internal features, like holes, this is the perfect feature at the smallest permissible size.

8

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Implied Right Angles

Implied 90 angles have the same general tolerances applied to them as do any other

angles covered by a general note. The exception is when a geometric tolerance is used

for that feature. When geometric tolerances are specified, implied 90 or 0 angles

between feature centerlines are considered basic dimensions to which no tolerance

applies outside that stated by the geometric tolerance.

The tolerance of plus or

minus 1 applies to the

implied 90 angles as well

as to the dimensioned

angles in the drawing.

9

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Fits between Mating Parts

Fit is the range of tightness or

looseness resulting from the

allowances and tolerances in

mating parts. The loosest fit, or

maximum clearance, occurs

when the smallest internal part

(shaft) is in the largest external

part (hole),

10

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Fits between Mating Parts continued

Clearance Fit A clearance

fit occurs when an internal

part fits into an external part

with space (or clearance)

between the parts.

Interference Fit An

interference fit occurs

when the internal part is

larger than the external part,

so the parts must be forced

together.

11

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Specifying Fit Using Limit Dimensions

Limit dimensions are a method of directly specifying tolerance by providing

dimensions for the upper and lower limits of the features size. The high limit (maximum

value) is placed above the low limit (minimum value) in place of the dimension value.

12

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Selective Assembly

In selective assembly, all parts are inspected and classified into several

grades according to actual sizes, so that small shafts can be matched

with small holes, medium shafts with medium holes, and so on.

Selective Assembly Difference between the sizes of mating

parts is exaggerated for visibility.

13

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Hole System

Toleranced dimensions are commonly

determined using the hole system.

(Lockhart, Shawna D.; Johnson, Cindy M.,

Engineering Design Communication:

Conveying Design Through Graphics, 1st,

2000. Printed and electronically reproduced

by permission of Pearson Education, Inc.,

Upper Saddle River, New Jersey.)

14

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Shaft System

In some industries, such

as textile machinery

manufacturing, which

use a great deal of cold-

finished shafting, the

shaft system is used.

(Lockhart, Shawna D.: Johnson,

Cindy M., Engineering Design

Communication: Conveying Design

Through Graphics, 1st, 2000.

Printed and electronically reproduced

by permission of Pearson Education,

Inc., Upper Saddle River, New

Jersey.)

15

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

GENERAL TOLERANCE NOTES

General notes are usually located in the lower right corner of

the drawing sheet near the title block. Often, general

tolerance notes are included in the title block itself.

ALL TOLERANCES 1 mm

UNLESS OTHERWISE NOTED.

ANGLES 1 DEGREE.

16

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

LIMIT TOLERANCES

Limit tolerances state the upper and lower limits for the dimension range in

place of the dimension values.

Method of Stating Limits

Note: The upper value is

always placed above

the lower value.

17

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

PLUS-OR-MINUS TOLERANCES

Unilateral when the tolerance applies in only one direction

so that one value is zero; or,

Bilateral when either the same or different values are

added and subtracted.

18

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Angular tolerances

Angular tolerances are usually bilateral and given in terms of

degrees, minutes, and seconds, unless geometric dimensioning and

tolerancing is used.

Plus/MinusToleranced

Decimal Dimensions

19

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

TOLERANCE STACKING

A Chained dimension uses the end of one dimension as the beginning of the next.

Tolerance stacking refers to the way the tolerance for one dimension is added to

the next dimension in the chain and so on from one feature to the next, resulting in a

large variation in the location of the last feature in the chain.

Baseline dimensioning locates a series of features from a common base feature.

Tolerances do not stack up because dimensions are not based on other toleranced

dimensions.

20

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

USING AMERICAN NATIONAL

STANDARD LIMITS AND FIT TABLES

Portion of RC8 Fit Table. The International

Organization for Standardization (ISO) publishes

a similar series of fit tables for metric values.

The American National Standards Institute has

issued ANSI B4.1, Preferred Limits and Fits for

Cylindrical Parts, defining terms and

recommending preferred standard sizes,

allowances, tolerances, and fits in terms of the

decimal inch. This standard gives a series of

standard classes of fits on a unilateral-hole basis

so that the fit produced by mating parts of a

class of fit will produce approximately similar

performance throughout the

range of sizes.

21

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

TOLERANCES AND MACHINING

PROCESSES

Tolerances Related to Machining Processes

22

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

METRIC SYSTEM OF TOLERANCES

AND FITS

Terms Related to Metric Limits and Fits.

(Reprinted from ASME B4.2-1978, by permission of The American Society of Mechanical Engineers. All rights reserved.)

23

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

GEOMETRIC

DIMENSIONING

AND

TOLERANCING

Geometric tolerances state the maximum allowable

variations of a form or its position from the perfect

geometry implied on the drawing. The term geometric

refers to various forms, such as a plane, a cylinder, a

cone, a square, or a hexagon.

24

Technical Drawing with Engineering Graphics, 14/e

Giesecke, Hill, Spencer, Dygdon, Novak, Lockhart, Goodman

2012, 2009, 2003, Pearson Higher Education,

Upper Saddle River, NJ 07458. All Rights Reserved.

Tolerances and CAD 3D models

Tolerances can be added directly to a 3D model so that it can be used as the

digital product definition. (Reprinted from ASME Y14.41-2003, by permission of

The American Society of Mechanical Engineers. All rights reserved.)

SolidWorks software makes

it easy to select surface

finish symbols. (Courtesy of

Solidworks Corporation.)

Вам также может понравиться

- Game Theory and OligopolyДокумент45 страницGame Theory and OligopolyBolWolОценок пока нет

- EfficiencyДокумент43 страницыEfficiencyBolWolОценок пока нет

- ExternalitiesДокумент42 страницыExternalitiesBolWolОценок пока нет

- The Labor Market QuizДокумент6 страницThe Labor Market QuizBolWolОценок пока нет

- Efficiency QuizДокумент7 страницEfficiency QuizBolWolОценок пока нет

- Externalities QuizДокумент8 страницExternalities QuizBolWolОценок пока нет

- The marginal social benefit from making it 1st degree cooler is $5 + $4 + $3 = $12Документ41 страницаThe marginal social benefit from making it 1st degree cooler is $5 + $4 + $3 = $12BolWolОценок пока нет

- The Labor MarketДокумент43 страницыThe Labor MarketBolWolОценок пока нет

- Risk and Time PreferenceДокумент40 страницRisk and Time PreferenceBolWolОценок пока нет

- MonopolyДокумент42 страницыMonopolyBolWolОценок пока нет

- Risk and Time Preference QuizДокумент6 страницRisk and Time Preference QuizBolWolОценок пока нет

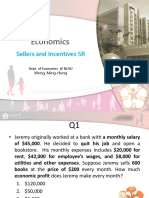

- Economics: Sellers and IncentivesДокумент42 страницыEconomics: Sellers and IncentivesBolWolОценок пока нет

- Game Theory and Oligopoly QuizДокумент7 страницGame Theory and Oligopoly QuizBolWolОценок пока нет

- Common-Pool Resources and Public Goods QuizДокумент6 страницCommon-Pool Resources and Public Goods QuizBolWolОценок пока нет

- Economics Monopoly MR MC Deadweight LossДокумент7 страницEconomics Monopoly MR MC Deadweight LossBolWolОценок пока нет

- Elasticity QuizДокумент7 страницElasticity QuizBolWolОценок пока нет

- Economics: Sellers and Incentives SRДокумент7 страницEconomics: Sellers and Incentives SRBolWolОценок пока нет

- ElasticityДокумент38 страницElasticityBolWolОценок пока нет

- Market Equilibrium A2Документ32 страницыMarket Equilibrium A2BolWolОценок пока нет

- ConsumersДокумент43 страницыConsumersBolWolОценок пока нет

- Market Equilibrium BДокумент38 страницMarket Equilibrium BBolWolОценок пока нет

- Sellers AДокумент44 страницыSellers ABolWolОценок пока нет

- Economics: Sellers and IncentivesДокумент7 страницEconomics: Sellers and IncentivesBolWolОценок пока нет

- TradeДокумент35 страницTradeBolWolОценок пока нет

- Market Equilibrium A QuizbДокумент4 страницыMarket Equilibrium A QuizbBolWolОценок пока нет

- Consumers QuizДокумент7 страницConsumers QuizBolWolОценок пока нет

- Market Equilibrium and Inferior GoodsДокумент6 страницMarket Equilibrium and Inferior GoodsBolWolОценок пока нет

- Economic PrinciplesДокумент34 страницыEconomic PrinciplesBolWolОценок пока нет

- Trade EconomicsДокумент7 страницTrade EconomicsBolWolОценок пока нет

- Torsion PDFДокумент66 страницTorsion PDFBolWolОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Win Top Prizes in Investizo's SuperTrader ContestДокумент3 страницыWin Top Prizes in Investizo's SuperTrader ContestJafrid NassifОценок пока нет

- Essential Guide VLSI Aspirants FAQ Physical DesignДокумент3 страницыEssential Guide VLSI Aspirants FAQ Physical DesignRohith RajОценок пока нет

- Operator Interface SERIES 300 Device Platform EAGLE OS ET-316-TXДокумент6 страницOperator Interface SERIES 300 Device Platform EAGLE OS ET-316-TXDecoОценок пока нет

- Trade ReportДокумент6 страницTrade ReportIKEOKOLIE HOMEPCОценок пока нет

- Modern Machine Shop 262180-MAR 2014Документ228 страницModern Machine Shop 262180-MAR 20141mmahoneyОценок пока нет

- FSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansДокумент23 страницыFSR & FST First Stage Regulator: Maintenance Manual FOR Authorised TechniciansпавелОценок пока нет

- Borrero Nuevo Delaunay Mendez - 2019 - Ethnographical and Historical Accounts For Understanding The Exploration of New Lands The Case PDFДокумент16 страницBorrero Nuevo Delaunay Mendez - 2019 - Ethnographical and Historical Accounts For Understanding The Exploration of New Lands The Case PDFBárbara Olguín MuñozОценок пока нет

- Sae Technical Paper Series 2015-36-0353: Static and Dynamic Analysis of A Chassis of A Prototype CarДокумент12 страницSae Technical Paper Series 2015-36-0353: Static and Dynamic Analysis of A Chassis of A Prototype CarGanesh KCОценок пока нет

- The Crime of Galileo - de Santillana, Giorgio, 1902Документ372 страницыThe Crime of Galileo - de Santillana, Giorgio, 1902Ivo da Costa100% (2)

- What Happens To Load at YieldingДокумент14 страницWhat Happens To Load at YieldingWaqas Anjum100% (2)

- Non-Permanence Risk Report Template (Short Form) : Instructions For Completing TheДокумент5 страницNon-Permanence Risk Report Template (Short Form) : Instructions For Completing Theferrian prabowoОценок пока нет

- As 1463-1988 Polyethylene Pipe Extrusion CompoundsДокумент6 страницAs 1463-1988 Polyethylene Pipe Extrusion CompoundsSAI Global - APACОценок пока нет

- NB-CPR 14-612r7 Issuance of Certificates Under CPRДокумент13 страницNB-CPR 14-612r7 Issuance of Certificates Under CPRÜmit BUCAKОценок пока нет

- Course Material For Module 3Документ11 страницCourse Material For Module 3Noble VargheseОценок пока нет

- Series Portable Oscilloscopes: Keysight DSO1000A/BДокумент15 страницSeries Portable Oscilloscopes: Keysight DSO1000A/BNestor CardenasОценок пока нет

- Intermediate Financial Management 13th Edition Brigham Test BankДокумент25 страницIntermediate Financial Management 13th Edition Brigham Test BankMonicaHoustonwjtgz100% (56)

- Role and Benefits of Sports Psychology For The Improvement of Performance of Sports PersonsДокумент5 страницRole and Benefits of Sports Psychology For The Improvement of Performance of Sports PersonsIJRASETPublicationsОценок пока нет

- Duration of LTMДокумент3 страницыDuration of LTMsamueldaОценок пока нет

- AGITAN Defoamer Technologies PDFДокумент15 страницAGITAN Defoamer Technologies PDFMarco Lopez100% (1)

- SAPA Presentation - 8-31-18Документ34 страницыSAPA Presentation - 8-31-18Roi AlcaideОценок пока нет

- A 18-Page Statistics & Data Science Cheat SheetsДокумент18 страницA 18-Page Statistics & Data Science Cheat SheetsAniket AggarwalОценок пока нет

- SANY HDForklift Brochure-112018Документ14 страницSANY HDForklift Brochure-112018Rossman Mejicanos100% (1)

- Drilling RisersДокумент13 страницDrilling Risersadvantage025Оценок пока нет

- AssignmentДокумент15 страницAssignmentWahab MirzaОценок пока нет

- Eco Schools Action PlanДокумент1 страницаEco Schools Action PlanJohnty GreentoesОценок пока нет

- Flaechendicht k435 de 0216 0 Eng ScreenДокумент2 страницыFlaechendicht k435 de 0216 0 Eng ScreenAlexandru IonescuОценок пока нет

- 9608/21/M/J/15 © Ucles 2015Документ57 страниц9608/21/M/J/15 © Ucles 2015Asilbek AshurovОценок пока нет

- Determination of The Molecular Weight of Polymers From Viscosity MeasurementsДокумент10 страницDetermination of The Molecular Weight of Polymers From Viscosity MeasurementsAbdullah MunawarОценок пока нет

- Mastercam Book 5 Axis Bai 1Документ31 страницаMastercam Book 5 Axis Bai 1tuanvn76100% (3)

- Energy Conservation Opportunities Sugar Industry IДокумент8 страницEnergy Conservation Opportunities Sugar Industry INikhil MohiteОценок пока нет