Академический Документы

Профессиональный Документы

Культура Документы

2 Supplier Registration Form For Direct Material Only

Загружено:

Smitesh Vangalwar0 оценок0% нашли этот документ полезным (0 голосов)

213 просмотров11 страницedhvsha

Оригинальное название

2 Supplier Registration Form for Direct Material Only

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документedhvsha

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

213 просмотров11 страниц2 Supplier Registration Form For Direct Material Only

Загружено:

Smitesh Vangalwaredhvsha

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 11

Format Number.

SCMF/01/03 Annexure - 1 Page 1 of 10

KIRLOSKAR OIL ENGINES LIMITED

SUPPLIER REGISTRATION FORM FOR DIRECT MATERIAL ONLY

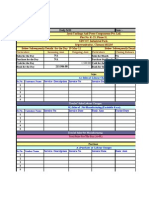

Part I Date:

Business Information:

1 Supplier Name: HEMANT ENGINEERING WORKS (ANIL P BUREWAR)

Address :SVNO-188/1

MUKATA PARK

CHAKRAPANI

VASAHAT BHOSARI

PUNE-39

Office : GAT No-765

PAWAR VASTI

KUDALWADI CHIKALI

PUNE-412114

Factory: HEMANT

ENGGINEERING WORKS;

GAT No-765

PAWAR VASTI

KUDALWADI CHIKALI

PUNE-412114

City: PUNE-412114

State: MAHARASHTRA

Pin Code: 412114

Telephone: 020-64108030

Fax: -

Telex: -

Mobile: 9372456037/ 9371804139

E-Mail: hemant.eng@rediffmail.co

m

2 Ownership Pattern ()

Public Limited Partnership

Private Limited Proprietary

Year of Establishment : 1995

3 Industrial License No : -

Central Sales Tax Registration No. :C27690341542C

VAT TIN No.:V27690341542

Central Excise Regulations License No. :ABCPB7463KEM001

MSME - Yes/ No if yes Registration no:270251112355

PAN base Service Tax number: w..e..f. date:

RTGS form for E-payments with certification form Bank COPY ATTACHED

( Please attach Xerox copies of all Registration certificates with self-certification)

Format Number. SCMF/01/03 Annexure - 1 Page 2 of 10

Name & Address of Bankers-

(Attach RTGS form submit with banker seal)

Name: ORIENTAL BANK OF COMMERCE

Address: PIMPRI, PUNE-411018 phone:7422625

Type of Service:

Material: PERFORATION BY SHEET

Subcon /Labour Charges: SUBCON

Service provider: NIL

Material, Labour Charges & Service provider: RAW MATERIAL SUPPLY

Contact details of Finance person- SELF

Name: ANIL P BUREWAR

Designation:PROPRIETOR

Telephone no & Cell No.:020-6410803 ; 9372456037

E-mail id: hemant.eng@rediffmail.com

4

5

Sales & PBIT for last three years

FY FY FY CURRENT FY

SALES 10-11 11-12 12-13 13-14

PBIT 3589953=00 3298145=00 3576752=00 7000000=00

INVESTMENT

QUALITY

CAPACITY 120 ton 240 ton 260 ton 290 ton

TECHNOLOGY SPM

Working Hours

No. of shifts : ()

General Shift : AM/PM TO AM/PM

1

st

Shift 7 AM TO 3PM

2

nd

Shift 3 PM TO 11 PM

3

rd

Shift If required AM/PM TO AM

6

Directors / Executives of the Company

Name & Designation Address & Phone Qualification &

Experience

1

ANIL P BUREWAR

MUKATA PARK

CHAKRAPANI

VASAHAT BHOSARI

9371804139

DME-15yrs

2

PANDURANG T

BUREWAR

9371804139 DEE-20 yrs

Format Number. SCMF/01/03 Annexure - 1 Page 3 of 10

3

ANIL HANDE

BHOSARI-9860713251 BCom-5 yrs

4

SANDEP AMBUDKAR

BHOSARI-9922887815

DME-5 yrs

7

Associated Undertaking N/A

Name & Address Business Level of Participation by holding

company

1

2

3

8

Products Supplied

Perforation Sheet

Mfg. Capacity Rejection In

PPM

INSTAL

LED

UTILIZ

ED

Custom

er End

In-

house

Customer

Name

1 Perforated Sheet

9 ton 8 ton Nil 2500 RV Exhaust

2 Perforated Sheet 8 ton 7 ton Nil 1500 Consultec Pvt Ltd

3

Perforated Sheet

5 ton 5 Ton Nil 1400 Sky Line

4 Perforated Sheet 2 ton 2 Ton Nil 1200 Venky Group Pvt.

Ltd

5

9

Manufacturing facilities

Description of

Machine /

Model / Make /

Size

No.

Machines

Year of

Manufacture

Year of

Purchase

OEE (Overall

Equipment

Effectiveness)

1 P Shearing

10 M Sheet

1 2008 2008 85%

2 Perforation

Machine

1 2008 2008 85%

3 Drill Machine 1 2005 2008 85%

Format Number. SCMF/01/03 Annexure - 1 Page 4 of 10

4 Shearing

machine

1 2008 2008 85%

10 Power Supply (KVA)

Required Load 30 HP

Electricity board 40HP

Generator Set N/A

Stand by Generators

N/A

11 Manpower

S.No

.

Description No. Of Persons

1 Proprietor/Proprietary/Directors 1

2 Executive/Manager 1

3 Skilled 2

4 Semi-Skilled 1

5 Unskilled 1

6 Helper 1

7 Clerk -

8 Accountant 1

9 Inspector 1

10 Contract -

12

(a)

(b)

(c )

(d )

Material Handling & Storage

Equipments / Facilities :- Crane Service (Out Source)

Communication System / Software Details :-

1 Land Line

2. Cell Phone

3. Email Id

Method of Preservation, Protection & Packing of finished goods

As per Customer requirement Packing

For Protection Sheet Stacking Rack

Format Number. SCMF/01/03 Annexure - 1 Page 5 of 10

13 Instruments & Gauges

Description Make Year of

Manufacture

Frequency of

Calibration

1 Vernier Calibre mitutoyo 2012 One year

2 Micro Miter Mitutoyo 2011 One Year

3 Scale - 2013 Replacement in One

Month

4 Steel Measuring

Tape

- 2013 Replacement in One

Month

5

6

7

14

Metallurgical / Endurance Equipments N/A

Description Make Range Year of

Manufacture

1

2

3

4

5

6

Format Number. SCMF/01/03 Annexure - 1 Page 6 of 10

7

15

Future Plans

ISO 9000 / QS 9000 / TS16949

Product Certification :- (ISI / DGS&D / CQA / NTPC / NPCL / Other)

We are in process ISO 9000

16

Future Plans :-

Growth :

To increase sales graph as up as possible

Technology :

SPM of Perforation

Investment :

To Purchase Machinery

Systems etc.:

QS 9000

Enclose one set of each of the following:

1) Income Tax clearance certificate (Please attach a Photostat copy) N/A

2) Balance Sheet (Last 2 years copy to be attached)

3) Product catalogue

Format Number. SCMF/01/03 Annexure - 1 Page 7 of 10

4) Price List

5) Brochure

6) Consent to operate from Pollution Control board. N/A

7) MSDS incase of hazardous chemical suppliers. N/A

8) Any statutory cases pending ( If any please mention) N/A

9) Banker & working capital limits.

10) Company / Firm Registrations Certificates.

11) Duly filled & certified RTGS form.

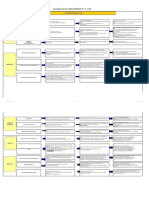

PART II

Quality System Information

A. Systems Yes No

1 Separate quality control function / department in the organization

2 Quality policy and procedure manual in use and up to date

3 Written procedure defining quality related functions

4 Existence of system for customer complaint and rejections

5 Existence of Quality cost reporting system

6 Existence of a formal system of approval of new machinery

7 Existence of quality and inspection records maintained

8 Usage of problem solving techniques to solve / eliminate problems

9 Formal Quality improvement program exists

10 The procedure for notifying your customer of process or material

changes prior to the change exists

11 First part inspection/ approval required prior to beginning a production

run

12 Product recall procedure exists

B.

Process Control

1 Implementation of process capability studies

2 Implementation of S P C by operator at his work station

3 Written procedures displayed at the work station

4 Implementation of control charts to reduce process variation

5 Procedure exists to prevent the shipment of non confirming material

from a process.

6 Existence of procedures in place to control processes where statistical

methods are not appropriate

7 Usage statistical techniques for problem solving

C. Quality Control Procedures.

1. Incoming material inspected or statistically certified by the Supplier

2. Inspection instructions written for all incoming material

3. Material certification required for incoming material on some product.

4. Documentation of in process inspection plans / procedures and results

Format Number. SCMF/01/03 Annexure - 1 Page 8 of 10

5. Identification of rejected incoming material

6. Existence of a formal corrective action procedure (Internal and External)

7. Agency approvals such as UL,CSA, etc. obtained on material as

required

8. Controls in place to prevent non-conforming material from getting back

into production

9. Reworked material submitted to Inspection for re inspection

D.

Drawing Control

1. Are controls in place to assure that the latest drawing is being used by

Production

2. Does the quality function review drawings, related documents and

specifications for new products for acceptance?

3. Do you request yearly updates on customer drawings and specifications

E.

Gauges and Test Equipment.

1. Are all test and measurement equipment permanently marked for ease

of identification

2. Existence of documented calibration control

3. Are all gauges and test equipment marked with and or identified as to

calibration due date

4. The gauges calibration and maintenance on a regular basis

5. Calibration of gauges to the same standard as company gauges

6. Documentation of procedure to notify the customer of suspect material

when a gauge(s) found to be out of calibration (defective)

7. Traceability of calibration standards to the National Institute of Science

and Technology or other National Regulatory agency

F.

Technical Capability

1. Existence of reliability testing on products produced

2. Is production maintained on a scheduled basis

3. Will Supplier maintain the tooling and replace worn out tooling at their

expense

4. Capability of design and or building of own tooling

5. Spare production capacity to supply product at required production rates

6. Participation in pursuing ISO 9000/ QS 9000 / TS 16949 certification: If

so, expected completion.

7. Can you clean and apply rust inhibitor to finished good per ES81 159.

G.

Finished Product Verification.

1. Documented procedures / evidence of finished product final audit

2. Documentation of audit finding

3. Adaptation of test procedures or inspection instructions based on

customer requirements

Format Number. SCMF/01/03 Annexure - 1 Page 9 of 10

4. Deviation procedure exists

5. Deviation procedure require customer approval prior to shipment

6. Verification of the correct part number marked on the containers

7. Existence of bar coding capability.

8. Measurement of outgoing Quality Levels

9. Please list your outgoing Quality Level for the last 6 months in PPM.

H. List all major in-house process capabilities such as: Die-casting, de-burring, welding,

molding stamping, rust Inhibiting, washing etc.

Please List the quality awards you have received

Please list those companies for which you are quality certified supplier

Authorized Signatory

Name:

Designation:

Company Seal:

Format Number. SCMF/01/03 Annexure - 1 Page 10 of 10

FOR OFFICE USE ONLY

Special Advantage in introducing this new supplier:

Nature- Capital/ Revenue

Site name/ BU

Payment Terms:

Delivery terms: Ex. Supplier Ex. KOEL

Freight terms: By Supplier By KOEL Specify if Other

Octroi paid by- By Supplier By KOEL

Specify Others:-

Existing source:

Recommendation for Further Evaluation

YES NO

Basis of Recommendation for Evaluation :-

Documents to be checked &confirmed by sourcing at the time of submission andfinance

department at the time ofreleasing new Supplier code are:

1) All the enclosures mentioned in the form are attached Yes No

2) Audit results of all five typesof auditsconducted at supplier. Yes No

3) Supplier Quality Agreement signed off by the supplier. Yes No

4) Supplier Category: ProprietaryNon- Proprietary

Comments (if any) _________________________________________________________

Signed By:-

Commodity Leader Sourcing Leader

(Sourcing) (Sourcing Department)

Format Number. SCMF/01/03 Annexure - 1 Page 11 of 10

Departmental Head Sourcing Head

Supplier Quality Improvement (Sourcing Department)

Finance Manager. Manager SCM (QMS)

Вам также может понравиться

- IQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartДокумент33 страницыIQA Report Summary Sheet - Bolt & Zest Front Strut: 1 Mounting of PartJetesh DevgunОценок пока нет

- SQ Mark & 100ppm ChecklistДокумент14 страницSQ Mark & 100ppm Checklistkarpags100% (2)

- MW Wiretec PVT - LTD.: Quality Assurance Plan Section C' Process Flow Chart-MIG Wire ISO 9001:2015Документ7 страницMW Wiretec PVT - LTD.: Quality Assurance Plan Section C' Process Flow Chart-MIG Wire ISO 9001:2015Våïbhäv Çhåühåñ100% (1)

- Qatar Fasteners commercial registration detailsДокумент357 страницQatar Fasteners commercial registration detailsSangram PatilОценок пока нет

- Sperry Sun - LWD and LWD ServicesДокумент8 страницSperry Sun - LWD and LWD ServicesBAS100% (1)

- Free Space Optical Communication PDFДокумент233 страницыFree Space Optical Communication PDFIgor Novid100% (1)

- TVS Bolt PricelistДокумент32 страницыTVS Bolt PricelistDhanus Kodi0% (1)

- Garment MAnpower ConsultantsДокумент5 страницGarment MAnpower ConsultantskeshavaswamydkОценок пока нет

- SopДокумент18 страницSopNitta MallikОценок пока нет

- Catalog GRP 2019Документ86 страницCatalog GRP 2019MadhaneОценок пока нет

- Master List of Machines - COMBINED-20-01-20Документ8 страницMaster List of Machines - COMBINED-20-01-20Ankita AgrawalОценок пока нет

- Form - 3A - Notice of Change of ManagerДокумент1 страницаForm - 3A - Notice of Change of Managerhdpanchal86Оценок пока нет

- SPC ArticleДокумент3 страницыSPC ArticleThanapoom BoonipatОценок пока нет

- Compliances Under GST & Income Tax Act-KinexinДокумент3 страницыCompliances Under GST & Income Tax Act-KinexinDeepak ChauhanОценок пока нет

- Belal 151128152242 Lva1 App6892Документ203 страницыBelal 151128152242 Lva1 App6892দীপ্তি হুমাইরাОценок пока нет

- List of MachineДокумент16 страницList of MachineKaran MalhiОценок пока нет

- The Tamil Nadu Factories Rules FORM 25-B: Service CardДокумент1 страницаThe Tamil Nadu Factories Rules FORM 25-B: Service CardVijay Baskar SОценок пока нет

- Tool Preventive Maintenance Plan Year - 2018Документ3 страницыTool Preventive Maintenance Plan Year - 2018Saurabh100% (1)

- Wire RoadДокумент16 страницWire Road02081987Оценок пока нет

- Bosch Power Tools India Price List February 2012Документ6 страницBosch Power Tools India Price List February 2012Waleed Mohammed FekryОценок пока нет

- MRM PPT - HR 13.08.2022Документ14 страницMRM PPT - HR 13.08.2022HA PLОценок пока нет

- VD2019 01.07.2019 Rev.6Документ223 страницыVD2019 01.07.2019 Rev.6qc deОценок пока нет

- M - Procd For MRMДокумент2 страницыM - Procd For MRMravikpandeyОценок пока нет

- UP security workforce minimum wagesДокумент2 страницыUP security workforce minimum wagesVivek SinghОценок пока нет

- Galaxy Metal CastДокумент12 страницGalaxy Metal CastayhamОценок пока нет

- Sop On Sewn Button Snap Fastener Safety PDFДокумент58 страницSop On Sewn Button Snap Fastener Safety PDFAri RamadhanОценок пока нет

- HRM - All Unit SlidesДокумент206 страницHRM - All Unit SlidesHanny Khn007Оценок пока нет

- Format No - Qf-As-02 - Daily Production Log BookДокумент2 страницыFormat No - Qf-As-02 - Daily Production Log BookDisha ShahОценок пока нет

- AutomotiveIndustry ListДокумент10 страницAutomotiveIndustry ListVikash KumarОценок пока нет

- Customer List For Ped, w0, Ped QMS, Ce Approval & Asme Jobs With Other Inspection ServicesДокумент34 страницыCustomer List For Ped, w0, Ped QMS, Ce Approval & Asme Jobs With Other Inspection Servicesapi-3703379100% (3)

- 4M Change RecordДокумент6 страниц4M Change RecordRAHUL SINGHОценок пока нет

- QAP-KGN-CIAL-001, Rev00Документ2 страницыQAP-KGN-CIAL-001, Rev00iftekhar ahmedОценок пока нет

- Factories Rules TNДокумент30 страницFactories Rules TNvignesh100% (1)

- Allena Auto Industries Pvt. LTD.: Critical ProblemsДокумент2 страницыAllena Auto Industries Pvt. LTD.: Critical ProblemsAnkur DhirОценок пока нет

- ABC Engineering Production RecordsДокумент12 страницABC Engineering Production RecordsNnandkishoreОценок пока нет

- Register of DeductionsДокумент1 страницаRegister of Deductionsadm developersОценок пока нет

- Master List of Instruments & EquipmentsДокумент7 страницMaster List of Instruments & EquipmentsBalkishan DyavanapellyОценок пока нет

- PLANTДокумент33 страницыPLANTGaurav KapoorОценок пока нет

- PROJECT:0.654.0303.00-CMR162-3 DATE: February/2015 APPROVED BY: Leman Özgüler/Quality Manager Revision: 0 Total Page: 1/1Документ1 страницаPROJECT:0.654.0303.00-CMR162-3 DATE: February/2015 APPROVED BY: Leman Özgüler/Quality Manager Revision: 0 Total Page: 1/1Metin DemirciogluОценок пока нет

- Business Plan Format for PVC Pipe ManufacturingДокумент10 страницBusiness Plan Format for PVC Pipe ManufacturingPriyanshu ChokhaniОценок пока нет

- FAQs On SBOДокумент52 страницыFAQs On SBOAbhinay KumarОценок пока нет

- RELIABLE TECHNICAL SERVICES CERTIFICATIONДокумент2 страницыRELIABLE TECHNICAL SERVICES CERTIFICATIONMangesh Mohite0% (1)

- Critical Spares ListДокумент3 страницыCritical Spares ListAnurag JhaОценок пока нет

- Source: A Handbook On Labour Laws of IndiaДокумент96 страницSource: A Handbook On Labour Laws of IndiagayathriОценок пока нет

- The Tamil Nadu Shops and Establishments ActДокумент14 страницThe Tamil Nadu Shops and Establishments ActwhadahegОценок пока нет

- SKF Industrial Shaft Seals (5300 EN) - CATALOGUE PDFДокумент379 страницSKF Industrial Shaft Seals (5300 EN) - CATALOGUE PDFLily VyОценок пока нет

- Sampling Plan PDFДокумент2 страницыSampling Plan PDFprabhakarmetОценок пока нет

- Billet Cutting Process Quality Control SheetДокумент1 страницаBillet Cutting Process Quality Control SheetBalram JiОценок пока нет

- EV Product Catalogue PDFДокумент174 страницыEV Product Catalogue PDFAkОценок пока нет

- Raw Material Inspection ReportДокумент4 страницыRaw Material Inspection ReportVinayОценок пока нет

- Kirloskar Oil Engines LTD (Bearing)Документ2 страницыKirloskar Oil Engines LTD (Bearing)mayur_jamgaonkarОценок пока нет

- Metal Press Machine Preventive Maintenance RecordДокумент1 страницаMetal Press Machine Preventive Maintenance RecordVirendra KumarОценок пока нет

- Qa-R-01 List of Measuring Equipment and Calib. DueДокумент1 страницаQa-R-01 List of Measuring Equipment and Calib. DuevinothОценок пока нет

- MIS ReportДокумент88 страницMIS ReportRambo070586Оценок пока нет

- Supplier Assessment FormДокумент5 страницSupplier Assessment FormTerence279Оценок пока нет

- Hariom Work OrderДокумент2 страницыHariom Work OrderAman DubeyОценок пока нет

- Month Wise Compliance ChecklistДокумент2 страницыMonth Wise Compliance ChecklistDevrupam SHОценок пока нет

- Responsibility and Authority - QMSДокумент47 страницResponsibility and Authority - QMSDisha Shah50% (2)

- RFP SampleДокумент43 страницыRFP SampleNishant NeogyОценок пока нет

- Sitas - NDTДокумент4 страницыSitas - NDTAnonymous oWDHhP100% (1)

- Ppap Spacer TubeДокумент37 страницPpap Spacer TubeSeenivasagam SeenuОценок пока нет

- Capacity VerificationДокумент5 страницCapacity VerificationHarsha MP100% (2)

- LenovoДокумент1 страницаLenovoSmitesh VangalwarОценок пока нет

- Pelton Wheel CharacteristicsДокумент10 страницPelton Wheel Characteristicsতানভীর ইবনে গিয়াসОценок пока нет

- Claim Form FRM LIC Gratuity Office 2nd FileДокумент1 страницаClaim Form FRM LIC Gratuity Office 2nd FileSmitesh VangalwarОценок пока нет

- NiceДокумент1 страницаNiceSmitesh VangalwarОценок пока нет

- GI Sheet Perforation Quotation from Hemant Engineering WorksДокумент1 страницаGI Sheet Perforation Quotation from Hemant Engineering WorksSmitesh VangalwarОценок пока нет

- 0606 Supplier Evaluation FormДокумент4 страницы0606 Supplier Evaluation FormSmitesh VangalwarОценок пока нет

- Hemant Engineering Works: Pawar Wasti, Gat No-765, Chikhli Kudalwadi Pune Mob - 9372456037Документ2 страницыHemant Engineering Works: Pawar Wasti, Gat No-765, Chikhli Kudalwadi Pune Mob - 9372456037Smitesh VangalwarОценок пока нет

- DDDДокумент1 страницаDDDSmitesh VangalwarОценок пока нет

- Chapter 8Документ55 страницChapter 8Smitesh VangalwarОценок пока нет

- University of Mumbai: AC 6/6/2012 Item No. 4.76Документ47 страницUniversity of Mumbai: AC 6/6/2012 Item No. 4.76Dikshit JainОценок пока нет

- Read MeДокумент7 страницRead MeSmitesh VangalwarОценок пока нет

- K1 RootingДокумент20 страницK1 RootingHassan BallouzОценок пока нет

- Acopos User's ManualДокумент171 страницаAcopos User's ManualKonstantin Gavrilov100% (1)

- ZMD402AT-CT Technical DataДокумент7 страницZMD402AT-CT Technical DataCarlos SandersОценок пока нет

- Lightning Protection SystemДокумент5 страницLightning Protection SystemRifki FathurrahmanОценок пока нет

- Tivizen Iplug Greek GuideДокумент13 страницTivizen Iplug Greek GuideDenexoОценок пока нет

- Autodesk 2010 Product Key PDFДокумент6 страницAutodesk 2010 Product Key PDFDragon NestОценок пока нет

- Acetylated Castor Oil - Preparation and Thermal DecompositionДокумент7 страницAcetylated Castor Oil - Preparation and Thermal DecompositionPee Hai NingОценок пока нет

- Updated Infra-IIVendor ListДокумент22 страницыUpdated Infra-IIVendor ListabhibaikarОценок пока нет

- Air Sentry Guardian-BreathersДокумент14 страницAir Sentry Guardian-BreathersNelson PeraltaОценок пока нет

- COMEC Modular Storage SolutionsДокумент8 страницCOMEC Modular Storage SolutionsPedro ChapadoОценок пока нет

- KSD301 Series: Technical ParametersДокумент8 страницKSD301 Series: Technical ParametersFelipe J MarreroОценок пока нет

- Reading 03 - Iron Lady The Eiffel TowerДокумент2 страницыReading 03 - Iron Lady The Eiffel TowerFernando Elías Valderrama GómezОценок пока нет

- BV DoshiДокумент29 страницBV DoshiAnkit LuthraОценок пока нет

- Understanding Japanese Management PracticesДокумент16 страницUnderstanding Japanese Management PracticesBusiness Expert Press100% (3)

- Osciloscopio 1006Документ74 страницыOsciloscopio 1006ERNESTO BRAVOОценок пока нет

- University Institute of Information Technology: Ouick Learn - MCQДокумент53 страницыUniversity Institute of Information Technology: Ouick Learn - MCQvimalОценок пока нет

- Assessment 1 - Questioning - Written Assessment: Satisfactory or Not YetsatisfactoryДокумент38 страницAssessment 1 - Questioning - Written Assessment: Satisfactory or Not YetsatisfactoryAbhishek Kumar0% (1)

- Design and Development of Swashplate-Less HelicopterДокумент68 страницDesign and Development of Swashplate-Less HelicopterNsv DineshОценок пока нет

- DirectX 11 Practical ProjectsДокумент64 страницыDirectX 11 Practical Projectszubair ansariОценок пока нет

- Nuclear ReactorsДокумент45 страницNuclear ReactorsAtul100% (3)

- Meshing Methods (ANSYS Meshing) - Everyone Is Number OneДокумент14 страницMeshing Methods (ANSYS Meshing) - Everyone Is Number Oneicemage1991Оценок пока нет

- Aerodrome Controller (ADC) ExamДокумент5 страницAerodrome Controller (ADC) ExamaxnpicturesОценок пока нет

- 1 GPM V1 vacuum dehydrator removes water down to 20 PPMДокумент3 страницы1 GPM V1 vacuum dehydrator removes water down to 20 PPMLuis100% (1)

- Well Control - Fundamental - W2 - Well Control PrincipleДокумент17 страницWell Control - Fundamental - W2 - Well Control PrincipleGilbert SunaryoОценок пока нет

- Article ASI Magazine September 2014 Fumed Silica in Adhesives and Sealants FormulationsДокумент4 страницыArticle ASI Magazine September 2014 Fumed Silica in Adhesives and Sealants FormulationsdombaraОценок пока нет

- BFT 40503 A T E: Ntersection OntrolДокумент12 страницBFT 40503 A T E: Ntersection OntrolghajiniiОценок пока нет

- Monopoly - Indian Railways: - Anand Dube - Darshna Chande - Karan Sobti - Sriaditya Kasula - Vinay ChaudhariДокумент52 страницыMonopoly - Indian Railways: - Anand Dube - Darshna Chande - Karan Sobti - Sriaditya Kasula - Vinay ChaudhariKristamRajuОценок пока нет

- pd1185 Fire CodeДокумент3 страницыpd1185 Fire CodeCamille MangaranОценок пока нет