Академический Документы

Профессиональный Документы

Культура Документы

Re95320 2006-06

Загружено:

namduong368Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Re95320 2006-06

Загружено:

namduong368Авторское право:

Доступные форматы

Linear Motion and

Assembly Technologies Service Pneumatics Hydraulics

Electric Drives

and Controls

DRC Travel Drive Control

Application Software

Electronic travel drive control for

travel management of hydraulic drives

RE 95 320/06.06

replaces: 02.04

Features

The electronic travel drive control is an application-specic,

adaptable software package for travel management of hydrau-

lic drives. With its integrated reversing functions and hydro-

static braking, it allows soft start-up, acceleration and reversing

operations.

Variants DRCD and DRCE also include functions for speed

limiting, diesel-engine overheating protection (via CAN), diesel-

engine overspeed protection, automotive travel, load limiting

control, CAN-bus interface (SAE-J 1939) and three parameter-

izable travel modes which can be selected by the driver.

The integrated, adjustable inch function enables innite limiting

of the pump control.

Variants A, B and C:

Travel drives with simple pump control in combination with

xed displacement motors

Variants D and E:

Complex travel drives with pump and motor control

The DRC travel drive control is designed for

operation with Rexroth pumps A4VG and A10VG with electric

control (proportional solenoid).

The software can be parameterized by the user.

Diagnostics and parameterization are possible with the BO-

DEM PC software.

The control offers diagnostic capabilities via the CAN bus.

Contents

Ordering code 2

Variant overview 3

Variants DRCA through DRCC 4

Functional description 4

Parameterization and diagnostics 6

DRCA connection diagram 7

DRCB connection diagram 8

DRCC connection diagram 9

Required components 10

Variants DRCD and DRCE 11

Functional description 12

Parameterization and diagnostics 15

DRCD connection diagrams 16

DRCE connection diagrams 18

Required components 20

Safety instructions 20

Technical data sheet

2/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

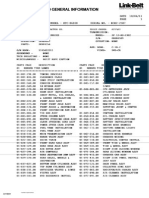

Ordering information

The AS/DRC application software may only be operated with controllers RC2-2/20 (DRCA to DRCC) or RC4-4 (DRCD and

DRCE) and other additional components (see pages 11 and 20). When placing an order, the hardware and software ordering

codes are to be linked by a "+".

Examples:

RC2-2/20+AS/DRCA10

RC4-4/20+AS/DRCD10

Ordering code

AS/ DRC 1x

Type

Application software AS/

Software

Travel drive control DRC

Variant A

Control of an EP variable pump via joystick A

Variant B

Control of an EP variable pump via acceleration pedal with direction switch B

Variant C

Control of an EP variable pump via external voltage

with direction switch C

Variant D

Control of a DE/EV variable pump and

an EP variable motor (load-dependent travel behavior) D

Variant E

Control of an EP variable pump and

an EP variable motor (load-independent travel behavior) E

Version

The version number indicates the development state of the software. 1x

Bosch Rexroth AG RE 95 320/06.06 DRC Travel Drive Control 3/20

Variant overview

The fundamental differences between the various variants are summarized in the following tables:

Variants A B C

See page 4

Installed on controller RC2-2

Control of variable pump Electro-proportional EP (with feedback)

Possible variable pumps A4VGEP, A10VGEP

Possible xed / variable

motors

Fixed displacement motor, e.g. A2FM

Pilot control devices Joystick Acceleration

pedal and direction

switches

External control

voltage (e.g. from

PLC) and direction

switches

Automotive travel No

Load limiting control No

Number of variants of

the acceleration behavior

which are parameterizable

and which can be select-

ed by the driver

3

Additional functions No

CAN-bus interface

(SAE-J 1939)

No

Field of application Pavers, rollers Industrial

applications

Variants D I

See page 11

Installed on controller RC4-4

Control of variable pump Electric, direct-controlled DE

or EV (without feedback)

Electro-proportional EP

(with feedback)

Possible variable pumps A4VGDE/EV, A10VG.DE A4VGEP, A10VGEP

Possible xed / variable

motors

Up to 2 variable motors A6VMEP;

xed displacement motor, e.g. A2FM

Pilot control devices Acceleration pedal or CAN

Inch pedal

Travel direction switch

Poti for speed limiting

Selector switch for travel modes

Automotive travel Yes

Load limiting control Yes

Number of travel modes

which can be parameter-

ized and selected by the

driver

3

Additional functions Speed limiting

Overheating protection (via CAN)

Diesel overspeed protection

CAN-bus interface

(SAE-J 1939)

Yes

Field of application Wheeled vehicles with load-

dependent travel behavior

(wheel loaders, fork lift trucks,

telehandlers, special vehicles)

Wheeled vehicles with load-

independent travel behavior

(special vehicles)

4/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

Variants DRCA, DRCB and

DRCC

The electronic drive control is designed to actuate a variable

pump in a closed hydraulic circuit.

Control is based on the following hydraulic concept:

An A4VG or A10VG variable pump with electro-proportional

EP control combined with one or more A2FM, A2FE, A4FM

or A10FM xed displacement motors.

The following diesel engine conguration can be used:

Diesel engine with or without CAN-bus interface

The travel drive control receives the actual speed value via a

speed sensor.

Functional description

The software is used for the realization of easily reversible

hydraulic drives. Figure 1 shows a typical conguration for the

travel drive control.

Setpoint specication

The desired vehicle speed and travel direction are specied

via the setpoint specication. This can be performed in three

different ways:

Figure 1: Typical configuration for the DRC travel drive control, variants A-C (DRCA to DRCC)

Variant A: Joystick

If the drive is controlled via a joystick, the setpoint and travel

direction are specied via this lever. The potentiometer of the

joystick is monitored for wire break and short circuit.

Variant B: Acceleration pedal

If the drive is controlled via an acceleration pedal, two

direction switches (for forwards/backwards travel) must also

be connected. The setpoint is specied via the pedal, the

travel direction via the direction switches. The potentiometer

connected to the acceleration pedal is monitored for wire

break and short circuit.

Variant C: External control voltage

If the drive is controlled via an external voltage, for example

via a PLC, two direction switches (for forwards/backwards

travel direction ) can also be connected. The setpoint is

specied via the external control voltage, the travel direction

via a control signal or the direction switches.

Where setpoint specication occurs via an external control

voltage, no monitoring is carried out by the travel drive

control. Undened states at the inputs can cause the drive to

start unintentionally.

Safety monitoring must be guaranteed by the connected

signal source (e.g. PLC).

Power

supply Ignition lock

RC2-2

controller with

DRC software

Diagnostics

socket

CAN-bus

interface

Speed limiting

Start release

signal

for starter

HG joystick valve

Two optional

direction switches

Two optional

switches for

acceleration

behavior

Optional

speed sensor

Engine Variable pump

A4VG...EP or

A10VG...EP

Fixed displacement motor

A2FM or

A2FE or

A4FM or

A10FM

BODEM

PC

software

RS232

Bosch Rexroth AG RE 95 320/06.06 DRC Travel Drive Control 5/20

Inch function

A second potentiometer can be connected for innitely variable

setpoint limitation.

For variants A and B, the inching potentiometer is monitored

for wire break and short circuit.

For variant C, the values at the input for the inching potentiom-

eter are specied by an external control voltage. In this case

safety must be guaranteed by the connected signal source.

Travel behavior

Travel behavior is controlled by three variables.

The setpoint is specied via the joystick, the acceleration

pedal or the external control voltage (depending on the vari-

ant).

The control of the PWM output for the specied setpoint is

dened in the travel behavior characteristic.

The acceleration behavior selected by the position of the

time ramp switch determines how quickly the control at the

PWM output changes.

Figure 2 shows the method of operation of the travel drive con-

trol. The following is a description of travel behavior for variant

A. The principles are the same for variants B and C:

The joystick is in the neutral position when it is positioned

within a user-denable range around the zero position (dead

band).

If the joystick is in the neutral position, the PWM outputs for

the forwards and backwards directions that control the propor-

tional solenoids of the pump are switched off.

If the joystick is moved to a position outside the dead band,

the current at the relevant PWM output (for forwards or

backwards travel) increases according to the position of the

joystick and the set characteristic. The corresponding pro-

portional solenoid is actuated. In addition, the acceleration

behavior can be selected via the time ramp switch. Three dif-

ferent travel modes can be parameterized ("soft", "medium",

"hard").

Start release

Start release is used to prevent the drive from starting uninten-

tionally.

For start release, a digital switched output is used. Its signal

must be integrated into the start control of the diesel engine.

The output is switched on if the joystick is in the neutral posi-

tion.

After the controller is switched on (ignition switch turned on),

the joystick must be in the neutral position in order for the start

release to be issued and the drive started

Speed monitoring

With speed monitoring, stalling of the diesel engine can be

prevented. This requires an additional speed sensor. With this

sensor, a speed threshold can be set. This threshold must be

exceeded before the drive can be started.

Special function

The special function can be used for different purposes and in

different modes:

In "error lamp" mode, a signaling device such as an error

lamp can be connected in order to display various error

warnings through different ashing frequencies.

In "backwards travel" mode, the special function is con-

nected as soon as backwards travel is selected. This can be

used for a warning signal or reversing light, for example.

In "operating threshold" mode, a special function is connect-

ed when an operating threshold is reached. This could be a

vibration drive on a roller, for example. The threshold can be

set separately for forwards and backwards travel.

Figure 2: Method of operation of the DRC travel drive control, variants A-C (DRCA to DRCC)

Joystick

Inching

Evaluation

of inching

joystick

Characteristics Time ramps

Ramp selection

("soft", "medium", "hard")

Evaluation

of direction

Evaluation

of special

switching

functions,

error lamp

Pump

control

(electr. current)

Special

switching

functions

0V/12V(24V)

6/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

Parameterization and diagnostics

The parameters which need to be set in order to commission

the DRC travel drive control can be easily changed using the

BODEM PC software.

You can congure BODEM to display the most important pro-

cess data and the error messages for diagnostics and trouble-

shooting purposes.

Important features

Three different possibilities for setpoint specication are

available through the variants

Integrated inch function

Three different acceleration and delay behaviors can be

selected externally

Integrated backwards travel warning possible

Integrated safety functions for start release and speed moni-

toring

Joystick, acceleration pedal and inching potentiometer are

monitored for wire break and short circuit.

The inputs and outputs of the controller are monitored (for

cable break, short circuit).

Divers errors can be displayed by means of a ashing code

on one of the connected error lamps.

All errors can be output via the CAN-bus interface.

Important error events are stored in the controller and can

also be read later in plain text form using BODEM.

Bosch Rexroth AG RE 95 320/06.06 DRC Travel Drive Control 7/20

Figure 3: Inputs and outputs on controller for DRC, variant A (DRCA)

DRCA connection diagram

2

)

2

)

41

1

42

2

33

32

3?

48

28

A

B

31

30

1

)

51

50

1?

40

52

39

TxD

PS232 PxD

CAN H

CAN L

C

D

B

E

A

G

F

H

+5v

1 A

3

)

0 v

8 A

2?

10

11

34

45

4?

46

49

36

35

38

2

)

2

)

A

B

29

15

44

43

6)

+5v

6)

+24v

+12v/

Ignition lock with

starter non-repeat unit

Supply voltage

of the electronics

Power

input

Supply of the

power outputs

P

r

o

p

o

r

t

i

o

n

a

l

o

u

t

p

u

t

s

S

w

i

t

c

h

e

d

o

u

t

p

u

t

s

F

r

e

q

u

e

n

c

y

i

n

p

u

t

s

S

e

n

s

o

r

s

u

p

p

l

y

v

o

l

t

a

g

e

V

o

l

t

a

g

e

i

n

p

u

t

s

C

u

r

r

e

n

t

i

n

p

u

t

s

S

w

i

t

c

h

e

d

i

n

p

u

t

s

Ground

Speed sensor 1

Joystick

potentiometer 1

(1 to 5k)

Inching

potentiometer 2

(1 to 5k)

Pump forwards

Pump backwards

Start release

Special function

Travel behavior 1

Travel behavior 2

Diagnostics plug

for BODEM

CAN bus

4

)

Ground

connection for

case

Reserved

1)

Short, low-resistance connection from a housing screw to the unit or vehicle ground

2)

Separate ground connection from solenoid return lead to battery (chassis also possible)

3)

Separate fuses recommended for switches, sensors and electronics

4)

CAN-bus: 120 terminating resistor recommended (see installation instructions in RDE 90 300-01)

5)

Separate ground connection possible from current source to battery, controller GND (pin 38/49)

6)

Stabilized voltage source

7)

Observe maximum current consumption where proportional solenoids and switched outputs are controlled simultaneously

8/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

Figure 4: Inputs and outputs on controller for DRC, variant B (DRCB)

DRCB connection diagram

2

)

2

)

41

1

42

2

33

32

3?

48

28

A

B

31

30

1

)

51

50

1?

40

52

39

TxD

PS232 PxD

CAN H

CAN L

C

D

B

E

A

G

F

H

+5v

1 A

3

)

0 v

8 A

2?

10

11

34

45

4?

46

49

36

35

38

2

)

2

)

A

B

29

15

44

43

6)

+5v

6)

+24v

+12v/

Direction switch, forwards

Direction switch, backwards

Ignition lock with

starter non-repeat unit

Supply voltage

of the electronics

Power

input

Supply of the

power outputs

P

r

o

p

o

r

t

i

o

n

a

l

o

u

t

p

u

t

s

S

w

i

t

c

h

e

d

o

u

t

p

u

t

s

F

r

e

q

u

e

n

c

y

i

n

p

u

t

s

S

e

n

s

o

r

s

u

p

p

l

y

v

o

l

t

a

g

e

V

o

l

t

a

g

e

i

n

p

u

t

s

C

u

r

r

e

n

t

i

n

p

u

t

s

S

w

i

t

c

h

e

d

i

n

p

u

t

s

Ground

Speed sensor 1

Acceleration

pedal

potentiometer 1

(1 to 5k)

Inching

potentiometer 2

(1 to 5k)

Pump forwards

Pump backwards

Start release

Special function

Travel behavior 1

Travel behavior 2

Diagnostics plug

for BODEM

CAN bus

4

)

Ground

connection for

case

Reserved

1)

Short, low-resistance connection from a housing screw to the unit or vehicle ground

2)

Separate ground connection from solenoid return lead to battery (chassis also possible)

3)

Separate fuses recommended for switches, sensors and electronics

4)

CAN-bus: 120 terminating resistor recommended (see installation instructions in RDE 90 300-01)

5)

Separate ground connection possible from current source to battery, controller GND (pin 38/49)

6)

Stabilized voltage source

7)

Observe maximum current consumption where proportional solenoids and switched outputs are controlled simultaneously

Bosch Rexroth AG RE 95 320/06.06 DRC Travel Drive Control 9/20

Figure 5: Inputs and outputs on controller for DRC, variant C (DRCC)

DRCC connection diagram

2

)

2

)

41

1

42

2

33

32

3?

48

28

A

B

31

30

1

)

51

50

1?

40

52

39

TxD

PS232 PxD

CAN H

CAN L

C

D

B

E

A

G

F

H

+5v

1 A

3

)

0 v

8 A

2?

10

11

34

45

4?

46

49

36

35

38

2

)

2

)

A

B

29

15

44

43

6)

+5v

6)

+24v

+12v/

E

x

t

.

s

e

t

p

o

i

n

t

s

p

e

c

i

c

a

t

i

o

n

E

x

t

.

s

e

t

p

o

i

n

t

s

p

e

c

i

c

a

t

i

o

n

Direction switch, forwards

Direction switch, backwards

Ignition lock with

starter non-repeat unit

Supply voltage

of the electronics

Power

input

Supply of the

power outputs

P

r

o

p

o

r

t

i

o

n

a

l

o

u

t

p

u

t

s

S

w

i

t

c

h

e

d

o

u

t

p

u

t

s

F

r

e

q

u

e

n

c

y

i

n

p

u

t

s

S

e

n

s

o

r

s

u

p

p

l

y

v

o

l

t

a

g

e

V

o

l

t

a

g

e

i

n

p

u

t

s

C

u

r

r

e

n

t

i

n

p

u

t

s

S

w

i

t

c

h

e

d

i

n

p

u

t

s

Ground

Speed sensor 1

Pump forwards

Pump backwards

Start release

Special function

Travel behavior 1

Travel behavior 2

Diagnostics plug

for BODEM

CAN bus

4

)

Ground

connection for

case

Reserved

1)

Short, low-resistance connection from a housing screw to the unit or vehicle ground

2)

Separate ground connection from solenoid return lead to battery (chassis also possible)

3)

Separate fuses recommended for switches, sensors and electronics

4)

CAN-bus: 120 terminating resistor recommended (see installation instructions in RDE 90 300-01)

5)

Separate ground connection possible from current source to battery, controller GND (pin 38/49)

6)

Stabilized voltage source

7)

Observe maximum current consumption where proportional solenoids and switched outputs are controlled simultaneously

10/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

Required components

The following electronic components are required:

RC2-2/20 controller with 52-pin mating connector

(RE 95200)

Software AS/DRCA, AS/DRCB or AS/DRCC

HG104 joystick (RE 95041)

Optional: IDR speed sensor (RE 95130) with mating con-

nector

Optional: acceleration and inch pedals

Optional: time-ramp switch for the acceleration behavior

Optional: direction switch

The following hydraulic components are required:

Variable pump with electro-proportional control

A4VGEP (RE 92003) or

A10VGEP (RE 92750)

Fixed displacement motor

A2FM (RE 91001) or

A2FE (RE 91008) or

A4FM (RE 91120) or

A10FM (RE 91172)

The following items are required for commissioning and ser-

vice:

Diagnostics socket (RE 95085)

BODEM PC software with BODEM connecting cable

(RE 95085)

Bosch Rexroth AG RE 95 320/06.06 DRC Travel Drive Control 11/20

Variants DRCD and DRCE

Hydraulic system

The electronic travel drive control is designed to actuate a

variable pump in a closed hydraulic circuit with electric, direct-

controlled DE / EV control (DRCD) or electric, proportional EP

control (DRCE) and a variable motor with electric, proportional

EP control.

The following Rexroth hydraulic pumps are supported:

DRCD:

A4VG.DE, A4VG.EV (see catalog RE 92003)

A10VG.DE (see catalog RE 92750)

DRCE:

A4VG.EP (see catalog RE 92003)

A10VG.EP (see catalog RE 92750)

In combination with the variable pump, multiple xed or up to

two variable motors can be used.

The following Rexroth xed displacement motors are sup-

ported:

A2FM (see catalog RE 91001)

A2FE (see catalog RE 91008)

A4FM (see catalog RE 91120)

A10FM (see catalog RE 91172)

The following Rexroth variable motor is supported:

A6VM.EP (see catalog RE 91 604)

The electronic travel drive control can be used with a diesel

engine with or without a CAN bus interface.

Interfaces

Comprehensive information on interfaces and technical data

for the RC4-4 controller can be found in the catalog entitled

"Controller RC" (RE 95 200). The most important interfaces

for the DRCD and DRCE electronic travel drive control are:

Analog input signals (from potentiometers or angle sensors)

Analog voltages in the range from 0 - 5 V are received as

input signals by the DRCD and DRCE.

Digital input signals (from switches)

DRCD and DRCE receive digital input signals from the

travel direction switch, from the switch for determining the

travel mode, from the seat switch and, if applicable, from the

switch contacts on the acceleration and inch pedals.

The "teach function" input can be used to activate calibration

of the potentiometers and the plotting of the teach curve

without BODEM.

Frequency inputs (from the speed sensor)

The DRCD and DRCE can receive frequency signals from

speed sensors for the purpose of monitoring the speed of

the diesel engine and of the hydraulic motor.

Proportional outputs (PWM currents)

The DRCD and DRCE supply regulated pulse-width

modulated currents for direct control of proportional

solenoids. The dither frequency optimizes these outputs for

accuracy and minimum hysteresis for the electrical control of

pumps and hydraulic motors.

Switched outputs

The DRCD and DRCE supply digital output signals for

direct control of on/off solenoids. These outputs control

the directional valve of the pump for travel direction pre-

selection.

The DRCD and DRCE supply a digital output signal for

connecting an error lamp.

CAN-bus interface

The CAN-bus interface CAN1 is available for transmitting the

speed and the temperature of the diesel engine. In addition,

the position of the acceleration pedal can be determined by

the diesel engine. Diagnostic messages can be transmitted

on CAN2 by the RC controller.

Diagnostics interface

To communicate with the parameterization and diagnostic

tools, the tool in question must be connected to the

controller via a special diagnostics socket.

This diagnostics socket needs to be part of the cable

harness. This enables the connection of a laptop with the

BODEM PC software (RE 95 085).

BODEM can be used for communicating with a variety of

controllers available in the Rexroth line.

12/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

Functional description

Automotive travel

The hydrostatic drive with travel drive control facilitates com-

fortable driving, such as that experienced in an automobile. The

variable pump is controlled by the deection of the acceleration

pedal. The variable motor follows after the pump is fully swiv-

eled out.

DRCD

The travel behavior of the DRCD drive control is load de-

pendent, as with all cars or trucks. With increasing load, the

vehicle slows or becomes sluggish. Examples here include be-

ginning to climb after traveling on a at stretch or the difference

between a loaded and an empty vehicle. The load dependence

has the advantage that the driver has a better feel for the driv-

ing status and conditions.

DRCE

The travel behavior of the DRCE drive control is load indepen-

dent if sufcient drive power is present. It is therefore particu-

larly well suited for applications in which it is important that

xed speeds be maintained.

Inch function

A potentiometer can be used to innitely limit the pump and,

therefore, the ow from the pump. Thus, the vehicle speed can

be decoupled from the diesel engine speed.

As a result, the vehicle can be driven slowly while at the same

time maintaining maximum diesel speed to provide maximum

ow for the working hydraulics.

The inch function can be activated or deactivated via param-

eters.

Power

supply

Ignition lock

RC4-4 controller

with DRCD and DRCE

software

BODEM

PC software

R

S

2

3

2

D

i

a

g

n

o

s

t

i

c

s

s

o

c

k

e

t

S

p

e

e

d

l

i

m

i

t

i

n

g

A

c

c

e

l

.

p

e

d

a

l

T

e

m

p

e

r

a

t

u

r

e

o

f

d

i

e

s

e

l

e

n

g

i

n

e

v

i

a

C

A

N

D

i

e

s

e

l

e

n

g

i

n

e

s

p

e

e

d

v

i

a

s

p

e

e

d

s

e

n

s

o

r

o

r

v

i

a

C

A

N

Engine Variable pump A4VG...DE/EV/EP

or A10VG...DE/EP

Variable motor A6VM...EP or

xed displacement motor A2FM

or A2FE, or A4FM

or A10FM

S

p

e

e

d

s

e

n

s

o

r

I

n

c

h

p

e

d

a

l

S

p

e

e

d

l

i

m

i

t

i

n

g

I

n

c

h

p

e

d

a

l

T

r

a

v

e

l

d

i

r

e

c

t

i

o

n

T

e

a

c

h

f

u

n

c

t

i

o

n

S

p

e

c

i

a

l

f

u

n

c

t

i

o

n

S

e

a

t

s

w

i

t

c

h

S

p

e

c

i

a

l

f

u

n

c

t

i

o

n

Figure 6: Typical configuration for the DRC travel drive control, variants D-E (DRCD and DRCE)

Bosch Rexroth AG RE 95 320/06.06 DRC Travel Drive Control 13/20

Evaluation

Direction

switch

Control of

variable pump

Accel. pedal

Inch pedal

Control of

variable motors

Time ramps Travel behavior

Pre-position Time ramps

Diesel engine speed

Diesel temperature

Output speed

Load limiting control

Overheating pro-

tection

Diesel protection

Speed limiting

Travel behavior

("soft", "medium", "hard")

Evaluation

Teach curve

Inch function

Figure 7: Method of operation of the DRC travel drive control, variants D-E (DRCD and DRCE)

Travel behavior

Travel behavior is controlled by the following variables.

The travel mode ("soft", "medium", "hard") is dened with

one switch and two digital inputs. This determines, among

other properties, how quickly the control of the proportional

outputs is changed.

The setpoint value for the pump and motor is specied by

the acceleration pedal and the teach curve. The direction is

specied by the direction switch.

The control of the variable pump for the specied diesel-

engine-speed setpoint value is dened in the travel behavior

characteristic.

A separate characteristic with the corresponding ramps can

be parameterized for each travel mode ("soft", "medium",

"hard").

The output speed at the hydraulic motor and the acceleration

pedal dene the behavior of the variable motors.

If the acceleration pedal is pressed:

If a xed displacement motor is connected (only the

variable pump is controlled), the current value of the pump

control increases.

The current value increases with increasing deection of the

acceleration pedal. The pump swivels out further and the

vehicle speed increases.

The xed displacement motor reaches its maximum speed at

maximum pump ow.

If a variable motor is connected (both variable pump as

well as variable motors are controlled):

With increasing deection of the acceleration pedal,

the swivel angle of the pump is initially increased. If the

pump is completely swiveled out, the swivel angle of the

variable motor is also reduced and, as a result, so too is the

displacement. The variable motor is guided by the measured

output speed (hydraulic-motor speed-guided behavior). The

output speed continues to increase.

With the acceleration pedal fully pushed down, the pump

control is at a maximum and the motor is swiveled back to

a minimum displacement V

g min

determined by the hydraulic

travel drive control. The variable motor has reached the

maximum output speed.

The travel behavior is dened via two switched inputs. The

selected travel mode determines:

The characteristic for the travel behavior

The characteristic for the pre-position

The reaction behavior during reversing

14/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

Reversing operation

Travel direction change (reversing) is performed via the direc-

tion switch. The vehicle is decelerated and then reaccelerated

in the opposite direction. The reaction behavior can be speci-

ed in parameters.

Load limiting control

The integrated load limiting control reduces the accepted hy-

draulic power in the event of overloading of the diesel engine. It

can be activated or deactivated via parameters.

The most important feature of the travel drive control is the

measurement of the set and actual speeds of the diesel en-

gine.

The set speed of the diesel engine is measured via the accel-

eration pedal position (via analog input or via CAN bus).

The actual speed is measured via a speed sensor (via fre-

quency input or CAN bus).

Through the comparison of the set and actual speeds, it is pos-

sible to detect an overload of the diesel engine. In the event of

a potential overload, the electronics reduce the power input of

the hydraulic pump and of the variable motor:

The load limiting control calculates the current speed drop of

the diesel engine from the set and actual speed values.

The current speed drop is compared to the parameterizable

limit values. Different limit values can be parameterized for

different set speeds.

As long as the accepted hydraulic power does not exceed

the installed diesel power, the speed drop will not exceed

the parameterized limit values. The load limiting control does

not engage.

If the speed drop of the diesel engine exceeds the limit

values, the load limiting control engages:

The pump power is reduced (the swivel angle is reduced).

If a variable motor is used, the motor power is also re-

duced

(the swivel angle is increased).

The controller calculates the available pump power or motor

power. The control behavior can be set on the basis of the

factors of the individual controller elements. You can set the

P, I and D factors separately for the closed loop control of the

pump power and the motor power.

The software contains default values for the parameters of the

closed loop control. To achieve optimal behavior, these param-

eters must be individually tuned to the respective machine.

Overheating protection

Requirement for this function is a diesel engine with a CAN-

bus interface and an available temperature signal. The tempera-

ture of the diesel engine is transmitted via the CAN bus. It is

compared to a parameterizable limit value. As soon as the limit

value is exceeded, overheating protection engages:

The pump power is reduced. If a variable motor is used, the

motor power is reduced as well.

The accepted hydraulic power is limited until the diesel tem-

perature is 5 C below the parameterized maximum tempera-

ture.

Overheating protection can be activated or deactivated via

parameters.

Diesel protection

When traveling downhill, the machine supports itself on the

diesel engine ("engine brake"). To protect the diesel engine

from overspeeding, the hydraulic transmission ratio is in-

creased. The requirement for this function is the use of variable

motors.

The diesel engine speed is compared to a parameterizable

limit value.

As soon as the diesel engine speed exceeds the limit value,

diesel protection engages:

The motor power of the variable motor is increased.

Diesel protection can be activated or deactivated via

parameters.

Speed limiting

In order to adhere to country-specic regulations, the maximum

speed of the vehicle is dened. It is stored in a parameter

during commissioning. The requirement for this function is a

connected speed sensor on the hydraulic motor.

In addition, a potentiometer can be used to limit the vehicle

speed during operation. For example, to simplify driving and

working with attachments such as brushes.

The speed sensor on the hydraulic motor delivers the actual

value and the set maximum speed serves as the setpoint value

for a PI controller. Speed limiting can be activated or deacti-

vated via parameters.

Seat switch

A seat-switch input can be parameterized as a safety function.

Travel is possible only when the seat switch is closed.

Special function

The special function directly outputs the digital signal from the

"special function" input to the "special function" output.

Note that when in the open state, the switch must be connect-

ed to ground; when in the closed state, it must be connected

to battery voltage.

Bosch Rexroth AG RE 95 320/06.06 DRC Travel Drive Control 15/20

Important features

Automotive travel

Selectable travel modes

Integrated load limiting control

Reversing operation

Integrated inch function

Three different acceleration and delay behaviors can be

selected externally

Parameterizable speed limiting

Integrated overheating protection of the diesel engine

Integrated safety functions for start release

Analog inputs and proportional outputs are monitored for

wire break and short circuit.

Divers errors can be displayed by means of a ashing code

on one of the connected error lamps.

All errors can be output via the CAN-bus interface.

Important error events are stored in the controller and can

also be read later in plain text form using BODEM.

Parameterization and diagnostics

The parameters which need to be set in order to commission

the DRC travel drive control can be easily changed using the

BODEM PC software.

You can congure BODEM to display the most important pro-

cess data and the error messages for diagnostics and trouble-

shooting purposes.

16/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

Figure 8: Inputs and outputs on the controller for DRCD, control via potentiometers

DRCD connection diagram

Control via potentiometers

22

7

51

50

24

40

39

26

25

TxD

RS232 RxD

CAN H1

CAN L1

CAN H2

CAN L2

C

D

B

E

A

1

2

3

1

3

5

15A

1A

3)

27

42

41

2

1

28

+12 V/+24 V

0 V

1A

37

48

10

11

23

14

12

33

32

44

43

18

17

H

52

G

F

1

2

3

31

30

4

16

1

4

4

29

15

5

6

OE

35

36

38

47

46

49

8

20

19

+5V

5)

+5V

5)

45

34

9

21

1)

2)

2

2)

2)

2)

2)

2)

2)

3

INH

6) 13

Ignition lock with

starter non-repeat

unit

Emergency off

Outputs

on

Ground

Diesel engine speed

Hydraulic motor speed

Seat switch

Acceleration

pedal

(1 - 5 k)

Inch pedal

(1 - 5 k)

Speed limiting

(1 - 5 k)

Special function

Teach function

Supply voltage

of the electronics

Supply of the

power outputs

P

r

o

p

o

r

t

i

o

n

a

l

o

u

t

p

u

t

s

S

w

i

t

c

h

e

d

o

u

t

p

u

t

s

F

r

e

q

u

e

n

c

y

i

n

p

u

t

s

V

o

l

t

a

g

e

i

n

p

u

t

s

C

u

r

r

e

n

t

i

n

p

u

t

s

S

w

i

t

c

h

e

d

i

n

p

u

t

s

C

o

n

s

t

a

n

t

v

o

l

t

a

g

e

s

o

u

r

c

e

5

V

/

2

x

1

0

0

m

A

CAN-bus

diesel engine

4)

Diagnostics plug

for BODEM

Pump forwards

Pump backwards

Special function

Error lamp

Hydraulic motor 1

DRE valve of the pump

Hydraulic motor 2

1)

Short, low-resistance connection from a housing screw to the device ground or vehicle ground

2)

Separate ground connection from solenoid return line to battery (chassis also possible)

3)

Separate fuses recommended for switches, sensors and electronics

4)

CAN bus: 120

terminating resistor recommended (see installation instructions RDE 90 300-01)

5)

Outputs 5V / ground can be used alternatively as sensor supply

6)

Level >3V release output stages (proportional and switched outputs)

Travel behavior 1

Travel behavior 2

Travel direction switch,

forwards

Travel direction switch,

backwards

Switch contact for accel-

eration pedal (optional)

Switch contact for inch

pedal (optional)

CAN-bus diagnos-

tic messages

4)

Bosch Rexroth AG RE 95 320/06.06 DRC Travel Drive Control 17/20

Figure 9: Inputs and outputs on the controller for DRCD, control via angle sensors

22

7

51

50

24

40

39

26

25

TxD

RS232 RxD

CAN H1

CAN L1

CAN H2

CAN L2

C

D

B

E

A

1

2

3

15A

1A

3)

27

42

41

2

1

28

+12 V/+24 V

0 V

1A

37

48

10

11

23

3

13

14

12

33

32

44

43

18

17

H

52

G

F

1

2

3

31

30

4

16

1

2

4

4

29

15

5

6

OE

1

35

36

38

47

46

49

8

20

19

+5V

5)

+5V

5)

45

34

9

21

1)

2)

2)

2)

2)

2)

2)

2)

5

4

6

1

5

5

4

6

WS 1

WS 1

+

+

INH

6)

Ignition lock with

starter non-repeat

unit

Emergency off

Outputs

on

Ground

Diesel engine speed

Hydraulic motor speed

Seat switch

Special function

Teach function

Supply voltage

of the electronics

Supply of the

power outputs

P

r

o

p

o

r

t

i

o

n

a

l

o

u

t

p

u

t

s

S

w

i

t

c

h

e

d

o

u

t

p

u

t

s

F

r

e

q

u

e

n

c

y

i

n

p

u

t

s

V

o

l

t

a

g

e

i

n

p

u

t

s

C

u

r

r

e

n

t

i

n

p

u

t

s

S

w

i

t

c

h

e

d

i

n

p

u

t

s

C

o

n

s

t

a

n

t

v

o

l

t

a

g

e

s

o

u

r

c

e

5

V

/

2

x

1

0

0

m

A

CAN-bus

diesel engine

4)

Diagnostics plug

for BODEM

Pump forwards

Pump backwards

Special function

Error lamp

Hydraulic motor 1

DRE valve of the pump

Hydraulic motor 2

1)

Short, low-resistance connection from a housing screw to the device ground or vehicle ground

2)

Separate ground connection from solenoid return line to battery (chassis also possible)

3)

Separate fuses recommended for switches, sensors and electronics

4)

CAN bus: 120 terminating resistor recommended (see installation instructions RDE 90 300-01)

5)

Outputs 5V / ground can be used alternatively as sensor supply

6)

Level >3V release output stages (proportional and switched outputs)

Travel behavior 1

Travel behavior 2

Travel direction

switch, forwards

Travel direction switch,

backwards

Accel. pedal

Inch pedal

Speed limiting

(1 - 5 k)

CAN-bus diagnos-

tic messages

4)

DRCD connection diagram

Control via angle sensors

18/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

Figure 10: Inputs and outputs on the controller for DRCE, control via potentiometers

22

7

51

50

24

40

39

26

25

TxD

RS232 RxD

CAN H1

CAN L1

CAN H2

CAN L2

C

D

B

E

A

1

2

3

1

3

5

15A

1A

3)

27

42

41

2

1

28

+12 V/+24 V

0 V

1A

37

48

10

11

23

14

12

33

32

44

43

18

17

H

52

G

F

1

2

3

31

30

4

16

1

4

4

29

15

5

6

OE

35

36

38

47

46

49

8

20

19

+5V

5)

+5V

5)

45

34

9

21

1)

2)

2)

2)

2)

2)

2)

3

INH

6) 13

Ignition lock with

starter non-repeat

unit

Emergency off

Outputs

on

Ground

Diesel engine speed

Hydraulic motor speed

Seat switch

Acceleration pedal

(1 - 5 k)

Inch pedal

(1 - 5 k)

Speed limiting

(1 - 5 k)

Special function

Teach function

Supply voltage

of the electronics

Supply of the

power outputs

P

r

o

p

o

r

t

i

o

n

a

l

o

u

t

p

u

t

s

S

w

i

t

c

h

e

d

o

u

t

p

u

t

s

F

r

e

q

u

e

n

c

y

i

n

p

u

t

s

V

o

l

t

a

g

e

i

n

p

u

t

s

C

u

r

r

e

n

t

i

n

p

u

t

s

S

w

i

t

c

h

e

d

i

n

p

u

t

s

C

o

n

s

t

a

n

t

v

o

l

t

a

g

e

s

o

u

r

c

e

5

V

/

2

x

1

0

0

m

A

CAN-bus

diesel engine

4)

Diagnostics plug

for BODEM

Special function

Hydraulic motor 2

Error lamp

Pump backwards

Pump forwards

Hydraulic motor 1

1)

Short, low-resistance connection from a housing screw to the device ground or vehicle ground

2)

Separate ground connection from solenoid return line to battery (chassis also possible)

3)

Separate fuses recommended for switches, sensors and electronics

4)

CAN bus: 120

terminating resistor recommended (see installation instructions RDE 90 300-01)

5)

Outputs 5V / ground can be used alternatively as sensor supply

6)

Level >3V release output stages (proportional and switched outputs)

Travel behavior 1

Travel behavior 2

Travel direction switch,

forwards

Travel direction switch,

backwards

Switch contact for accel-

eration pedal (optional)

Switch contact for inch

pedal (optional)

CAN-bus diagnos-

tic messages

4)

DRCE connection diagram

Control via potentiometers

Bosch Rexroth AG RE 95 320/06.06 DRC Travel Drive Control 19/20

Figure 11: Inputs and outputs on the controller for DRCE, control via angle sensors

22

7

51

50

24

40

39

26

25

TxD

RS232 RxD

CAN H1

CAN L1

CAN H2

CAN L2

C

D

B

E

A

1

2

3

15A

1A

3)

27

42

41

2

1

28

+12 V/+24 V

0 V

1A

37

48

10

11

23

3

13

14

12

33

32

44

43

18

17

H

52

G

F

1

2

3

31

30

4

16

1

4

4

29

15

5

6

OE

1

35

36

38

47

46

49

8

20

19

+5V

5)

+5V

5)

45

34

9

21

1)

2)

2)

2)

2)

2)

2)

5

4

6

1

5

5

4

6

WS 1

WS 1

+

+

INH

6)

Ignition lock with

starter non-repeat

unit

Emergency off

Outputs

on

Ground

Diesel engine speed

Hydraulic motor speed

Seat switch

Special function

Teach function

Supply voltage

of the electronics

Supply of the

power outputs

P

r

o

p

o

r

t

i

o

n

a

l

o

u

t

p

u

t

s

S

w

i

t

c

h

e

d

o

u

t

p

u

t

s

F

r

e

q

u

e

n

c

y

i

n

p

u

t

s

V

o

l

t

a

g

e

i

n

p

u

t

s

C

u

r

r

e

n

t

i

n

p

u

t

s

S

w

i

t

c

h

e

d

i

n

p

u

t

s

C

o

n

s

t

a

n

t

v

o

l

t

a

g

e

s

o

u

r

c

e

5

V

/

2

x

1

0

0

m

A

CAN-bus

diesel engine

4)

Diagnostics plug

for BODEM

Special function

Hydraulic motor 2

Error lamp

Pump backwards

Pump forwards

Hydraulic motor 1

1)

Short, low-resistance connection from a housing screw to the device ground or vehicle ground

2)

Separate ground connection from solenoid return line to battery (chassis also possible)

3)

Separate fuses recommended for switches, sensors and electronics

4)

CAN bus: 120 terminating resistor recommended (see installation instructions RDE 90 300-01)

5)

Outputs 5V / ground can be used alternatively as sensor supply

6)

Level >3V release output stages (proportional and switched outputs)

Travel behavior 1

Travel behavior 2

Travel direction

switch, forwards

Travel direction switch,

backwards

Accel. pedal

Inch pedal

Speed limiting

(1 - 5 k)

CAN-bus diagnos-

tic messages

4)

DRCE connection diagram

Control via angle sensors

20/20 Bosch Rexroth AG DRC Travel Drive Control RE 95 320/06.06

This document, as well as the data, specications and other information

set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be

reproduced or given to third parties without its consent.

The data specied above only serve to describe the product. No statements

concerning a certain condition or suitability for a certain application can be

derived from our information. The information given does not release the user

from the obligation of own judgment and verication. It must be remembered that

our products are subject to a natural process of wear and aging.

Subject to change.

Bosch Rexroth AG

Hydraulics

Product Unit Mobile Electronics

Elchingen Plant

Glockeraustrae 4

89275 Elchingen, Germany

Telephone +49 (0) 73 08 82-0

Fax +49 (0) 73 08 72-74

info.brm-me@boschrexroth.de

www.boschrexroth.com/mobile-electronics

Safety instructions

The suggested circuits do not imply any technical liability for

the system on the part of Rexroth.

To switch off the system in emergencies, the power supply

to the electronics must be disconnected by an emergency

off switch. The emergency off switch must be installed in an

easily accessible position for the operator. Safe braking must

be ensured when the emergency off function is activated.

The vehicle must be equipped with sufciently dimensioned,

separate mechanical service brake and parking brake.

Lines to the electronics must not be routed close to other

power conducting lines in the machine or vehicle.

Radio equipment and mobile telephones must not be used

inside the drivers cab without a suitable outside antenna

and nowhere near the control electronics. A sufciently large

distance to radio systems must be maintained.

All connectors must be unplugged from the electronics dur-

ing electrical welding operations.

The electronics may only be tested with the proportional

solenoids connected.

The proportional solenoids must not be connected to spark

suppression diodes.

On/off solenoids at the outputs of the RC electronics do not

need to be connected to spark suppression diodes.

Other inductive consumers that are in the system but not

connected to the RC must be connected to spark suppres-

sion diodes.

In order to preserve the warranty, any installation or replace-

ment of the RC software (ash EPROM) must be performed

by Rexroth staff.

Cables/wires must be sealed individually to prevent water

from entering the unit.

Dangerous malfunctions may result if the control electronics

are opened or modied or the wiring repaired without autho-

rization.

A risk analysis according to IEC 61508 is to be performed

for the travel drive. For classications greater than "SIL a",

please consult Rexroth.

Please observe operating instructions RE 95320-B (DRCA,

DRCB, DRCC), RE 95321-B (DRCD) and RE 95322-B

(DRCE).

Required components

The following electronic components are required:

RC4-4 controller with 52-pin mating connector (RE 95200)

and installed AS/DRCD or DRCE software

Travel direction switch

Selector switch for travel modes

Speed sensor for recording the vehicle speed (can be inte-

grated in the hydraulic motor)

Acceleration pedal with angle sensor and mating connector

(alternately via CAN)

Inch pedal with angle sensor and mating connector

Optional: error lamp

Multi-circuit switch as input for teach function

The following hydraulic components are required:

Variable pump with electro-proportional control

DRCD:

A4VGDE or EV (RE 92003) or

A10VGDE (RE 92750)

DRCE:

A4VGEP (RE 92003) or

A10VGEP (RE 92750)

Fixed displacement motor

A2FM (RE 91001) or

A2FE (RE 91008) or

A4FM (RE 91120) or

A10FM (RD 91172)

The following items are required for commissioning and ser-

vice:

Diagnostics socket (RE 95085)

BODEM PC software with BODEM connecting cable

(RE 95085)

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Manitowoc 11000-1 Parts Manual PDFДокумент1 040 страницManitowoc 11000-1 Parts Manual PDFnamduong368100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- AutoCAD 2014 Tutorial 3DДокумент26 страницAutoCAD 2014 Tutorial 3DseleneletoОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- AutoCAD 2013Документ264 страницыAutoCAD 2013panosscribd100% (1)

- AutoCAD 3D Course ManualДокумент166 страницAutoCAD 3D Course ManualJed Tedor98% (47)

- LTM 1130-5.1 - PN - Technical Specification PDFДокумент18 страницLTM 1130-5.1 - PN - Technical Specification PDFnamduong368Оценок пока нет

- LTM 1130-5.1 - PN - Technical Specification PDFДокумент18 страницLTM 1130-5.1 - PN - Technical Specification PDFnamduong368Оценок пока нет

- LTM 1130-5.1 - PN - Technical Specification PDFДокумент18 страницLTM 1130-5.1 - PN - Technical Specification PDFnamduong368Оценок пока нет

- LTM 1130-5.1 - PN - Technical Specification PDFДокумент18 страницLTM 1130-5.1 - PN - Technical Specification PDFnamduong368Оценок пока нет

- Workshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Документ140 страницWorkshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Courtney French91% (23)

- CBE 25, MN PDFДокумент95 страницCBE 25, MN PDFnamduong368Оценок пока нет

- CBE 25, MN PDFДокумент95 страницCBE 25, MN PDFnamduong368Оценок пока нет

- CBE 25, MN PDFДокумент95 страницCBE 25, MN PDFnamduong368Оценок пока нет

- CBE 25, MN PDFДокумент95 страницCBE 25, MN PDFnamduong368Оценок пока нет

- CBE 25, MN PDFДокумент95 страницCBE 25, MN PDFnamduong368Оценок пока нет

- CBE 25, MN PDFДокумент95 страницCBE 25, MN PDFnamduong368Оценок пока нет

- Manitowoc 4600 S4 Lubrication Guide PDFДокумент40 страницManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- Hypac C766C, C778B - Om PDFДокумент122 страницыHypac C766C, C778B - Om PDFnamduong368100% (2)

- 3 - Electrical System PDFДокумент39 страниц3 - Electrical System PDFnamduong3680% (1)

- Transformerless H6D2 InverterДокумент47 страницTransformerless H6D2 InverterPinnam MallikarjunaОценок пока нет

- Design of A Power Converter Based On UC3842 For Blade Electric VehicleДокумент6 страницDesign of A Power Converter Based On UC3842 For Blade Electric VehicleHossam SobhyОценок пока нет

- Manitowoc 8500-1 Parts Manual PDFДокумент1 046 страницManitowoc 8500-1 Parts Manual PDFnamduong368100% (1)

- Power Electronics Unit 4Документ89 страницPower Electronics Unit 4Ajju K AjjuОценок пока нет

- Digital Modulation TechniquesДокумент34 страницыDigital Modulation TechniquesAkash ModiОценок пока нет

- Manitowoc 4600 S4 Parts Manual PDFДокумент108 страницManitowoc 4600 S4 Parts Manual PDFnamduong36850% (2)

- Manitowoc 4600 S4 Parts Manual PDFДокумент108 страницManitowoc 4600 S4 Parts Manual PDFnamduong36850% (2)

- Mcv116 Electrovalvula PDFДокумент26 страницMcv116 Electrovalvula PDFRafael Skandon100% (2)

- CBD&CBG 25manual PDFДокумент120 страницCBD&CBG 25manual PDFnamduong368Оценок пока нет

- Energies 10 00666 PDFДокумент46 страницEnergies 10 00666 PDFnamduong368Оценок пока нет

- ZF - 3HP12 For BMW Workshop ManualДокумент36 страницZF - 3HP12 For BMW Workshop Manualnamduong368100% (1)

- TEREX AC1000 - Load Chart PDFДокумент116 страницTEREX AC1000 - Load Chart PDFduongpnОценок пока нет

- SM-751 - 67 To 88 PDFДокумент22 страницыSM-751 - 67 To 88 PDFnamduong368100% (1)

- Link Belt HTC86100 Parts Manual PDFДокумент423 страницыLink Belt HTC86100 Parts Manual PDFnamduong368Оценок пока нет

- Link Belt RTC80130 Parts Manual PDFДокумент453 страницыLink Belt RTC80130 Parts Manual PDFnamduong368100% (1)

- SM-751 - 1 To 22 PDFДокумент22 страницыSM-751 - 1 To 22 PDFnamduong368Оценок пока нет

- Manitowoc SC70 Lubrication Guide PDFДокумент32 страницыManitowoc SC70 Lubrication Guide PDFnamduong368Оценок пока нет

- Holtz 1992 PWMДокумент11 страницHoltz 1992 PWMSamuelPereiraОценок пока нет

- Matlab-Simulink Model Three-Phase Voltage Source InverterДокумент5 страницMatlab-Simulink Model Three-Phase Voltage Source InverterDương Tấn TàiОценок пока нет

- Tap Tempo Lfo (Taplfo v2)Документ3 страницыTap Tempo Lfo (Taplfo v2)withstringsОценок пока нет

- Review of Impedance Source Power Converter For Electrical ApplicationsДокумент25 страницReview of Impedance Source Power Converter For Electrical ApplicationsInternational Journal of Advances in Applied Sciences (IJAAS)Оценок пока нет

- .Power Quality Improvement in Power Distribution System Using D-STATCOMДокумент5 страниц.Power Quality Improvement in Power Distribution System Using D-STATCOMMuhammad AzisОценок пока нет

- Power Quality Improvement in Modified Solid State Transformer System Using StatcomДокумент6 страницPower Quality Improvement in Modified Solid State Transformer System Using StatcomdevchandarОценок пока нет

- Speed Control of Induction Motor Using PI and V/F Scalar Vector ControllersДокумент9 страницSpeed Control of Induction Motor Using PI and V/F Scalar Vector ControllersYesha ShahОценок пока нет

- SG3526Документ12 страницSG3526pionalabzОценок пока нет

- (12.4) Optimized Space Vector Switching Sequences For Multilevel InvertersДокумент8 страниц(12.4) Optimized Space Vector Switching Sequences For Multilevel Invertersenrico piccoОценок пока нет

- M3 TutorialДокумент43 страницыM3 TutorialSamuel FernándezОценок пока нет

- Modeling and Simulation of SVPWM Based ApplicationДокумент10 страницModeling and Simulation of SVPWM Based ApplicationAshish PorwalОценок пока нет

- OpenECU-CCS FaultListДокумент18 страницOpenECU-CCS FaultListsaranakom cheecharoenОценок пока нет

- Variable Frequency Control vs. Eddy Current ControlДокумент3 страницыVariable Frequency Control vs. Eddy Current ControlA.YOGAGURUОценок пока нет

- Digi Xbee3®: Hardware Reference ManualДокумент73 страницыDigi Xbee3®: Hardware Reference ManualVangahОценок пока нет

- Block Diagram (SBD) - Hvac - TiДокумент4 страницыBlock Diagram (SBD) - Hvac - TiPoovendhan ManiОценок пока нет

- AIC Selection GuideДокумент7 страницAIC Selection GuideWerner LouwОценок пока нет

- HM7000 Series Decoders Reference ManualДокумент130 страницHM7000 Series Decoders Reference ManualFernandoОценок пока нет

- Gea s1301Документ19 страницGea s1301PervimОценок пока нет

- General Description Features: High-Current, High-Performance Drmos Power ModuleДокумент18 страницGeneral Description Features: High-Current, High-Performance Drmos Power ModulePablo AllosiaОценок пока нет

- Powtech Pt100 ManualДокумент112 страницPowtech Pt100 ManualNisar AhmedОценок пока нет

- Manual - Driver INDELДокумент12 страницManual - Driver INDELMarcelo Lescano100% (1)

- Vacon NXP Grid Converter Application Manual DPD01599B UKДокумент138 страницVacon NXP Grid Converter Application Manual DPD01599B UKTrung NguyenОценок пока нет

- FireBird V Hardware Manual V1.08 2012-10-12Документ121 страницаFireBird V Hardware Manual V1.08 2012-10-12Oshin Sharel BrittoОценок пока нет

- ATV312HU40N4: Product Data SheetДокумент3 страницыATV312HU40N4: Product Data SheetNur Nazihah Addina NanaОценок пока нет

- QPSKДокумент89 страницQPSKMuthe Murali100% (1)