Академический Документы

Профессиональный Документы

Культура Документы

Table of Content

Загружено:

Thanit ThanadirekАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Table of Content

Загружено:

Thanit ThanadirekАвторское право:

Доступные форматы

TABLE OF CONTENT

1. INTRODUCTION

1.1. Feature and general principal

1.2. Application

1.2.1. Building structure

1.2.1.1. Total precast concrete system

1.2.1.2. Precast concrete cladding

1.2.2. Parking structure

1.3. Production process Production process Production process Production process

1.3.1. Structural Components versus Architectural Components

1.3.2. Long-Line, Multi-Piece Forms versus Single-Piece Forms

1.3.3. Prestressed Components versus Non-Prestressed

Components

1.3.4. Pretensioned Components versus Post-Tensioned

Components

1.3.5. Production Limitations

2. NOTATION

3. TOLERANCES FOR PRECAST CONCRETE

3.1. Introduction

3.1.1. Product tolerance

3.1.2. Erection tolerance

3.1.3. Interfacing tolerance

3.2. Product tolerance

3.2.1. Product tolerance listing

3.2.1.1. Architectural wall panel

3.2.1.2. Structural wall panel

3.2.1.3. Hollow core wall panel

3.2.1.4. Columns

3.2.1.5. Beam and spandrel beam

3.2.1.6. Hollow core slab

3.2.1.7. Stair unit

3.2.1.8. Modular unit

3.3. Erection tolerance

3.3.1. Erection tolerance listing

3.3.1.1. Beam erection tolerance

3.3.1.2. Floor and roof member erection tolerance

3.3.1.3. Column erection tolerance

3.3.1.4. Structural wall erection tolerance

3.3.1.5. Architectural wall erection tolerance

3.3.1.6. Room module erection tolerance

3.3.1.7. Stair unit erection tolerance

3.4. Interfacing tolerance

4. COMPONENT HANDLING AND ERECTION BRACING

4.1. Preconstruction planning

4.2. Practice and procedure

4.2.1. Transportation & Unloading

4.2.2. Erection Handling

4.2.3. Erection Bracing

4.2.4. Striping

4.2.5. Rigging Configurations

4.2.6. Guying and bracing

4.2.7. Spreader Beams

4.2.8. Handling Devices

4.2.8.1. Aircraft-Cable Loops

4.2.8.2. Prestressing-Strand Loops

4.2.8.3. Threaded Inserts

4.3. Installation

4.3.1. General

4.3.2. Load bearing member

4.3.2.1. Column

4.3.2.2. Beam

4.3.2.3. Wall panels

4.3.3. Floor or roof member

4.3.3.1. Hollow core slab

4.3.3.2. Stemmed member

4.3.3.3. Flat slab

4.3.4. Cladding

4.3.4.1. Wall panel

4.3.4.2. Sprandel

4.3.4.3. Column cover

4.3.5. Bracing Equipment and Materials

4.4. Equipment

4.4.1. General

4.4.2. Selection of handling equipment

4.4.3. Safety devices

4.4.4. Cranes

4.4.5. Operating equipment

4.4.6. Personnel access equipment

4.5. Yarding and Storage

4.5.1. Lateral Stability

4.5.2. Storage

4.6. Erection safety

4.6.1. Erection safety plan

4.6.2. Cranes

4.6.3. Equipment

4.6.4. Rigging

4.6.5. Tools

4.6.6. Unloading

4.6.7. Lifting

4.6.8. Fall protection

4.6.9. Setting/connecting/releasing

4.6.10. Safety inspection/ Safety program

5. PRECAST CONCRETE MATERIALS

5.1. Introduction

5.2. Concrete

5.2.1. Cement

5.2.2. Aggregates

5.2.3. Chemical Admixtures

5.2.4. Pigments

5.2.5. Physical properties

5.2.6. Finishes

5.3. Grout, Mortar, Drypack

5.3.1. Sand-cement mixture

5.3.2. Non-shrink grout

5.3.3. Epoxy grout

5.4. Connection material

5.4.1. Steel sections

5.4.2. Bearing pads

5.4.3. Structural bolts/Anchor bolts

5.5. Reinforcement

5.5.1. Prestressing tendons

5.5.2. Prestress bars

5.5.3. Deformed reinforcing bars

5.5.4. Structural welded-wire reinforcement

5.5.5. Carbon-fibre mesh

5.5.6. Protection of reinforcement

5.6. Waterproofing

5.6.1. Coating for horizontal deck surface

5.6.2. Clear Surface Sealers for Architectural Precast Concrete

Panels

5.6.3. Surface Coatings for Architectural Precast Concrete

5.6.4. Joint Sealants

6. ARCHITECTURAL PRECAST CONCRETE

6.1. ---

7. QUALITY CONTROL FOR PLANT AND PRODUCTION OF

STRUCTURAL PRECAST

7.1. ---

8. DRAFTING

8.1. Introduction

8.2. Erection drawing

8.2.1. Key plan and general notes

8.2.2. Elevation

8.2.3. Plan

8.2.4. Section

8.2.5. Connection detail

8.3. Production drawing

8.3.1. Piece detail

8.3.2. Handling detail

8.3.3. Hardware detail

Вам также может понравиться

- HUB Contractors and Suppliers for UNC WilmingtonДокумент76 страницHUB Contractors and Suppliers for UNC Wilmingtonsati67% (6)

- Structural Masonry Special InspectionДокумент132 страницыStructural Masonry Special InspectionFrancisco Bonilla100% (1)

- Ray P. Prasad (Auth.) - Surface Mount Technology - Principles and Practice-Springer Netherlands (1989)Документ616 страницRay P. Prasad (Auth.) - Surface Mount Technology - Principles and Practice-Springer Netherlands (1989)Muhammad Fatiyan RizkilahОценок пока нет

- Precast Concrete Frames GuideДокумент58 страницPrecast Concrete Frames GuideibrahimrobertОценок пока нет

- Ray Prasad, Surface Mount Technology (SMT) 2-Nd Edition (Технология поверхностного монтажа)Документ791 страницаRay Prasad, Surface Mount Technology (SMT) 2-Nd Edition (Технология поверхностного монтажа)Михаил100% (1)

- UFGS Metal Building SystemsДокумент45 страницUFGS Metal Building SystemsMayyouОценок пока нет

- BOP Shear Pressure Calculations Rev 1 PDFДокумент3 страницыBOP Shear Pressure Calculations Rev 1 PDFflasher_for_nokiaОценок пока нет

- Construction Manual California PDFДокумент956 страницConstruction Manual California PDFAlexander Ponce VelardeОценок пока нет

- API STD 1104Документ45 страницAPI STD 1104Andreia MenesesОценок пока нет

- Dubai Engineering StanderДокумент193 страницыDubai Engineering Standermzafarnawaz80% (5)

- Technical Data Handbook of TK CorporationДокумент172 страницыTechnical Data Handbook of TK CorporationGerard Adrian Bautista AnonuevoОценок пока нет

- Working Guide to Drilling Equipment and OperationsОт EverandWorking Guide to Drilling Equipment and OperationsРейтинг: 5 из 5 звезд5/5 (9)

- Government of Andhra Pradesh Water Resources Department Technical Specifications for PSVGP Tunnel ConstructionДокумент203 страницыGovernment of Andhra Pradesh Water Resources Department Technical Specifications for PSVGP Tunnel ConstructionNaveen Nagisetti100% (1)

- STM Paper PDFДокумент73 страницыSTM Paper PDFAlrack sinner75% (4)

- Composite StructuresДокумент184 страницыComposite StructuresAbhinav50% (2)

- Finite Element Analysis in GeotechnicalEngineering Application by David M. Potts and Lidija ZdravkovДокумент226 страницFinite Element Analysis in GeotechnicalEngineering Application by David M. Potts and Lidija ZdravkovJesus Gonzalez100% (13)

- FRP Lamella ACI User ManualДокумент0 страницFRP Lamella ACI User ManualThanit ThanadirekОценок пока нет

- Tech. Specification Volume (IIB) Canals-MasterДокумент231 страницаTech. Specification Volume (IIB) Canals-MasterAshajyothi PalavaliОценок пока нет

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesОт EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesРейтинг: 5 из 5 звезд5/5 (5)

- Standards ISO For Oil and Gas PDFДокумент1 страницаStandards ISO For Oil and Gas PDFsugiantobarusОценок пока нет

- BasfДокумент8 страницBasfThanit ThanadirekОценок пока нет

- VITSOE Dieter Rams SpeechДокумент4 страницыVITSOE Dieter Rams SpeechThanit ThanadirekОценок пока нет

- VITSOE Dieter Rams SpeechДокумент4 страницыVITSOE Dieter Rams SpeechThanit ThanadirekОценок пока нет

- Dry Van ManualДокумент234 страницыDry Van ManualMichael Yoanito Oliviano100% (1)

- Amerapex PresentationДокумент21 страницаAmerapex Presentationzaga312Оценок пока нет

- National Structural Concrete SpecificationДокумент77 страницNational Structural Concrete SpecificationNana IbrahimОценок пока нет

- Plugs Connectors Receptacles Powertite AppletonДокумент29 страницPlugs Connectors Receptacles Powertite AppletonJuan Pablo Villazon RichterОценок пока нет

- API 5L GR.B SteelДокумент2 страницыAPI 5L GR.B SteelYosua Rielys PОценок пока нет

- Finite Element Analysis in Geotechnical Engineering-Vol2Документ448 страницFinite Element Analysis in Geotechnical Engineering-Vol2Harish Lambadi77% (13)

- Noi Bai International Airport Terminal 2 ConstructionДокумент2 страницыNoi Bai International Airport Terminal 2 ConstructionManh TuОценок пока нет

- GRE Pipe InstallationДокумент32 страницыGRE Pipe Installationelkhatri100% (3)

- 2019 Exam With ExplanationДокумент100 страниц2019 Exam With ExplanationMarlatif SakandalОценок пока нет

- Project Work Break Down System - GeneralДокумент6 страницProject Work Break Down System - GeneralAnthony Agner100% (2)

- En 1992-1 PDFДокумент225 страницEn 1992-1 PDFTemur LomidzeОценок пока нет

- UFGS 04 20 00 Unit MasonryДокумент70 страницUFGS 04 20 00 Unit MasonryPetrit AhmetiОценок пока нет

- Unedited Version 193 RlsДокумент167 страницUnedited Version 193 RlsDavid LeОценок пока нет

- H Proc Notices Notices 055 K Notice Doc 53267 931085311Документ128 страницH Proc Notices Notices 055 K Notice Doc 53267 931085311Heris DoggaОценок пока нет

- Ufgs 03 31 29 PDFДокумент70 страницUfgs 03 31 29 PDFgrahambrasicОценок пока нет

- Ufgs 03 30 00 PDFДокумент91 страницаUfgs 03 30 00 PDFsadiОценок пока нет

- Ufgs 08 44 00Документ63 страницыUfgs 08 44 00moudshahineОценок пока нет

- Ufgs 03 30 00Документ91 страницаUfgs 03 30 00bhhernandezОценок пока нет

- Table of Contents of An Industrial Training ReportДокумент2 страницыTable of Contents of An Industrial Training ReportKanishka WijesekaraОценок пока нет

- Section 03 45 00 Precast Architectural ConcreteДокумент40 страницSection 03 45 00 Precast Architectural ConcreteKyla OfiladaОценок пока нет

- Marine Concrete UFGS 03-31-29Документ67 страницMarine Concrete UFGS 03-31-29Hasan al MahmudОценок пока нет

- T Proc Notices Notices 040 K Notice Doc 35291 396040301Документ135 страницT Proc Notices Notices 040 K Notice Doc 35291 396040301Engr Nissar KakarОценок пока нет

- Ufgs 32 13 13.06Документ36 страницUfgs 32 13 13.06Ausberto Arnez CamposОценок пока нет

- Ufgs 03 30 00.00 10Документ54 страницыUfgs 03 30 00.00 10Jorge Yitzhak PachasОценок пока нет

- Malaysian Communications and Multimedia CommissionДокумент27 страницMalaysian Communications and Multimedia CommissionjhchooiОценок пока нет

- En-1992 (Design of Concrete Structures 1st Draft)Документ212 страницEn-1992 (Design of Concrete Structures 1st Draft)nicole moralesОценок пока нет

- Ufgs 09 97 13.27Документ43 страницыUfgs 09 97 13.27Amir KhakzadОценок пока нет

- Notation: Pci Bridge Design ManualДокумент104 страницыNotation: Pci Bridge Design Manualjrobert123321Оценок пока нет

- Ufgs 09 97 13.15Документ43 страницыUfgs 09 97 13.15Tim KearneyОценок пока нет

- sf7df8f) + Dxfgu/kflnsf: (Multiple Choice)Документ7 страницsf7df8f) + Dxfgu/kflnsf: (Multiple Choice)Prashant McFc AdhikaryОценок пока нет

- Design of Steel Structures TocДокумент6 страницDesign of Steel Structures TocalbsteinporОценок пока нет

- Ufgs 03 30 00.00 10 PDFДокумент54 страницыUfgs 03 30 00.00 10 PDFjackcan501Оценок пока нет

- MortarlessDM BS56282005 Part 1 Section 1 100410Документ16 страницMortarlessDM BS56282005 Part 1 Section 1 100410andriessebastia9395Оценок пока нет

- 1Документ2 страницы1airtelОценок пока нет

- Fib Bulletin 65 ContentsДокумент7 страницFib Bulletin 65 ContentsMarko ĆećezОценок пока нет

- ED-E-MS-500 Rev 01 (Method Statement Solid Blockwork, 26-10-16)Документ7 страницED-E-MS-500 Rev 01 (Method Statement Solid Blockwork, 26-10-16)Nalin SenadeeraОценок пока нет

- Ufgs 07 61 15.00 20Документ27 страницUfgs 07 61 15.00 20sharethefilesОценок пока нет

- Ehe EngДокумент551 страницаEhe EngMohamed OumlkhirОценок пока нет

- Code On Structural Concrete (EHE-08) : Articles and AnnexesДокумент31 страницаCode On Structural Concrete (EHE-08) : Articles and AnnexesSimoo AkrОценок пока нет

- Ufgs 13 34 19Документ45 страницUfgs 13 34 19sharandeep1112Оценок пока нет

- UFGS 13 34 19 Metal Building SystemДокумент46 страницUFGS 13 34 19 Metal Building SystemsharethefilesОценок пока нет

- CT4860 Structural Design OF PavementsДокумент110 страницCT4860 Structural Design OF PavementsMinn KhantОценок пока нет

- UFGS 31 00 00Документ47 страницUFGS 31 00 00marco miguelОценок пока нет

- ETAG 001-Part1 PDFДокумент53 страницыETAG 001-Part1 PDFMoisés MachadoОценок пока нет

- 20072Документ218 страниц20072KekekLagosОценок пока нет

- Fundamentals of Materials Engineering - A Basic GuideОт EverandFundamentals of Materials Engineering - A Basic GuideОценок пока нет

- Testing PlanДокумент1 страницаTesting PlanThanit ThanadirekОценок пока нет

- First Fix and Second Fix - Wikipedia, The Free EncyclopediaДокумент2 страницыFirst Fix and Second Fix - Wikipedia, The Free EncyclopediaThanit ThanadirekОценок пока нет

- Rebar Bending - GEM38Документ2 страницыRebar Bending - GEM38Thanit ThanadirekОценок пока нет

- Table of Contents for Project Report on IDEO Wutthakat (S11Документ2 страницыTable of Contents for Project Report on IDEO Wutthakat (S11Thanit ThanadirekОценок пока нет

- Cal Colum StrengtheningДокумент5 страницCal Colum StrengtheningThanit ThanadirekОценок пока нет

- How Do I Get To..Документ1 страницаHow Do I Get To..Thanit ThanadirekОценок пока нет

- S Structural Work: S1 Substructure S11 PilingДокумент12 страницS Structural Work: S1 Substructure S11 PilingThanit ThanadirekОценок пока нет

- CoverДокумент2 страницыCoverThanit ThanadirekОценок пока нет

- Wall B2Документ10 страницWall B2Thanit ThanadirekОценок пока нет

- Building Inspection ManualДокумент162 страницыBuilding Inspection ManualPipim PogiОценок пока нет

- Manual For Precast Concrete Construction: by Ananda DevelopmentДокумент1 страницаManual For Precast Concrete Construction: by Ananda DevelopmentThanit ThanadirekОценок пока нет

- Wall BДокумент10 страницWall BThanit ThanadirekОценок пока нет

- FRPДокумент5 страницFRPThanit ThanadirekОценок пока нет

- TC1Документ13 страницTC1Thanit ThanadirekОценок пока нет

- Wall B2Документ10 страницWall B2Thanit ThanadirekОценок пока нет

- VG Extension PDFДокумент1 страницаVG Extension PDFThanit ThanadirekОценок пока нет

- HDA-P Example #10Документ5 страницHDA-P Example #10Thanit ThanadirekОценок пока нет

- Slab Deflections 2Документ3 страницыSlab Deflections 2Thanit ThanadirekОценок пока нет

- Building AccessementДокумент12 страницBuilding AccessementThanit ThanadirekОценок пока нет

- JANUARY 2014: Sunday Monday Tuesday Wednesday Thursday Friday Saturday 1 2 3 4Документ4 страницыJANUARY 2014: Sunday Monday Tuesday Wednesday Thursday Friday Saturday 1 2 3 4Thanit ThanadirekОценок пока нет

- Queenax The Bridge X5 Gym in Vallentuna SwedenДокумент1 страницаQueenax The Bridge X5 Gym in Vallentuna SwedenThanit ThanadirekОценок пока нет

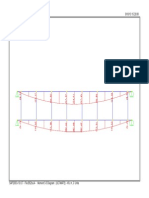

- Beam - BS2toJ4 PDFДокумент1 страницаBeam - BS2toJ4 PDFThanit ThanadirekОценок пока нет

- RAPT Installation Manual AmendmentДокумент16 страницRAPT Installation Manual AmendmentbbwhaleОценок пока нет

- Tes 55Документ1 страницаTes 55Thanit ThanadirekОценок пока нет

- Concentric Swage NippleДокумент3 страницыConcentric Swage NippleLuis Fernando Manjarrez AriasОценок пока нет

- DVS2205Документ26 страницDVS2205Earl Jerico TamaresОценок пока нет

- Cement Testing: Setting Time & Le Chatelier's Soundness TestДокумент34 страницыCement Testing: Setting Time & Le Chatelier's Soundness TestAshuОценок пока нет

- MARQUEZ Kenneth Whel F. Quiz 3Документ20 страницMARQUEZ Kenneth Whel F. Quiz 3joseph ibuyanОценок пока нет

- 0.1 Introduction PDFДокумент14 страниц0.1 Introduction PDFB VarunОценок пока нет

- Concrete Dams on Rock Foundations AnalysisДокумент5 страницConcrete Dams on Rock Foundations AnalysisÖzgür DoğanОценок пока нет

- Concrete Beam Design ACI 318Документ7 страницConcrete Beam Design ACI 318Kutty MansoorОценок пока нет

- MF 200 MekanikДокумент72 страницыMF 200 MekanikNoor Sa'adahОценок пока нет

- Mohammadinia2017 PDFДокумент29 страницMohammadinia2017 PDFAndrew PiОценок пока нет

- Jointing Tech - MV Joints & TermsДокумент48 страницJointing Tech - MV Joints & TermsMichael Hamudikuwanda100% (1)

- Standard U-Bolt PDFДокумент2 страницыStandard U-Bolt PDFjurieskОценок пока нет

- Flux Cored Arc Welding Wire SpecsДокумент4 страницыFlux Cored Arc Welding Wire SpecsAdam LimОценок пока нет

- New Microsoft Word DocumentДокумент6 страницNew Microsoft Word Documentsanchit2203Оценок пока нет

- CasestudyДокумент1 страницаCasestudyAltaf PalwalaОценок пока нет

- Formina Sanitary Ware Bathtub Shower Tray Sauna Jacuzzi FreestandingДокумент156 страницFormina Sanitary Ware Bathtub Shower Tray Sauna Jacuzzi FreestandingmahertexОценок пока нет

- CN30-8 (Classification Notes - Strength Analysis of Hull Structures in H...Документ25 страницCN30-8 (Classification Notes - Strength Analysis of Hull Structures in H...Công TuấnОценок пока нет

- House of C. Julius Polybius - AD79eruptionДокумент6 страницHouse of C. Julius Polybius - AD79eruptiond cornsОценок пока нет

- FKT NiehII Statik GRP StressДокумент98 страницFKT NiehII Statik GRP StressSakshi AgrawalОценок пока нет

- Country Presentation: MalaysiaДокумент12 страницCountry Presentation: MalaysiaADBI Events100% (1)