Академический Документы

Профессиональный Документы

Культура Документы

2007 Engineering Studies Assessment Task

Загружено:

Suman SahaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2007 Engineering Studies Assessment Task

Загружено:

Suman SahaАвторское право:

Доступные форматы

HSC ENGINEERING STUDIES

ASSESSMENT TASK 1

CIVIL STRUCTURES

ANDREW HARVEY

CONTENTS

CONTENTS............................................................................................................................... 2

REPORT BODY......................................................................................................................... 3

Truss Design: ......................................................................................................................... 3

Analysis of Forces in all Members: ........................................................................................ 3

Breaking Stress in First Member to Fail:................................................................................ 3

Comparative Ratio: ................................................................................................................ 4

Conclusion: ............................................................................................................................ 4

Recommendations: ................................................................................................................ 4

APPENDIX A............................................................................................................................. 6

Design 1 (Warren Truss):....................................................................................................... 6

APPENDIX B........................................................................................................................... 10

Design 2 (Warren Truss):..................................................................................................... 10

APPENDIX C JOINTS.......................................................................................................... 12

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 2 of 14

REPORT BODY

Truss Design:

We used the first truss design, (See Appendix A & B). We chose this one because it had the

lowest maximum force in any member, and therefore would take more load than design

number two.

Analysis of Forces in all Members:

F

gb

3

F

gh bh gb fg ef de ae ad = = = = = = = =

3 2

F

dc ch = =

3

2F

cf =

Breaking Stress in First Member to Fail:

The member with the most force in it is cf. So we predicted that it would fail first.

The actual weight that caused it to fail was 35kg. So the tensile strength of 6mm square balsa

is 396N. However this would not be true if the first member to fail was in compression, or if

the truss failed first at a joint.

The first member to fail was unclear. Many members broke, and we couldnt see which

members failed first. The position of breakages is shown below.

F

2

ad

dc

de

ae

F

2

cf

bh

fg

gh

ef

ch

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 3 of 14

In total the truss failed in 8 different places. However many of these breakages resulted from

one member initially failing. I suspect from the analysis of forces that the first member to

break was the one in red.

Stress in the member that is thought to have broke first.

MPa 00 . 11

000036 . 0

06 . 396

Area

Force

Stress = = =

Comparative Ratio:

Comparative Ratio 28 . 1452

0241 . 0

35

(kg) mass

(kg) load

= = =

Conclusion:

Member

Force at

point of

failure (N)

Nature

ad 198.03 Compression

ae 198.03 Compression

de 198.03 Tension

ef 198.03 Compression

fg 198.03 Compression

gb 198.03 Compression

bh 198.03 Compression

gh 198.03 Tension

ch 99.02 Tension

dc 99.02 Tension

cf 396.06 Tension

cf was the first member to break. It was in tension and it had a force of 396.06N acting on it.

This stress in this member was 11.00GPa.

Recommendations:

Although it is not likely that the break at joint BGH was the first breakage, that joint could have

been manufactured better. This was the only break that was directly at the joint, as all the

other breakages were either in the middle of a member or just outside where the gusset was

attached. The gusset at joint BGH was the first one made, and it was not as good as the rest.

This gusset didnt optimise the surface area available for gluing.

Also we could have applied more glue to the joints to make them stronger, and in places such

as is shown in the figure below.

We could have added

glue here, extending no

further than the gusset.

To strengthen the joint.

However this may not

have been allowed.

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 4 of 14

Alternate Height:

We also considered changing the height of the truss. By use of method of section the lower

middle member had a force of 132.8N.

35 kg

171.5N

A

M

As shown by the section line, we ignore the parts on the left.

By taking moments about point A, we have 3 external forces acting on the truss. With only

one unknown of the cental lower member, M.

( ) (

( ) Tension 8 . 132

30 . 387 5 . 171 300 0 M

=

+ = =

+

N M

M

A

)

This is a less force compared with our actual design having 396.06N.

There was no height limit, so we could have made the truss higher, this would mean that it

could have held a greater load before failure.

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 5 of 14

APPENDIX A

Design 1 (Warren Truss):

Free Body Diagram:

60

60

60

60 60

60

60

60

60

60

60

60 60 60 60

R

L

and R

R

can be calculated now. By looking at it you can see that R

L

=

2

F

and R

R

=

2

F

.

However for the sake of accuracy, these forces can be calculated, as shown below.

( ) ( )

( ) ( )

=

= =

=

=

+ = =

+

+

2

R

3 . 0 R 6 . 0 0 M

2 6 . 0

3 . 0

R

3 . 0 R 6 . 0 0 M

L

L

R

R

R

R

R

L

F

F

F F

F

The internal stresses can also be calculated.

ADC:

Close up of Joint ADC The R

L

force is known in both magnitude and

direction, so it is drawn in first. The forces in

members ad and dc are known in direction but not

magnitude or sense. However, the sense can be

ad

dc

F

2

F

2

ad

30

dc

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 6 of 14

obtained from the above force diagram, along with

the magnitudes.

3

30 cos

2 F F

ad =

=

60

= =

3 2

30 tan

2

F F

dc

ADE:

We know the forces in member ad, so the forces in members de and ae can be calculated.

Close up of Joint ADE The forces in member ad are known in both magnitude and

direction, so it is drawn in first. The forces in members de

and ae are known in direction but not magnitude or sense.

However, the sense can be obtained from the above force

diagram, along with the magnitudes.

de and ae are easily resolved. It is an equilateral triangle because all the internal angles are

60, so ad = de = ae.

de

ae

So far the forces in the truss are as follows:

CDEF:

There are 4 members at joint CDEF. two of which are unresolved.

F

F

2

ad

dc

de

ae

F

2

ad

ae

de

ad

de

ae

60

60

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 7 of 14

Close up of Joint CDEF. The forces in members dc and de are known in both

magnitude and direction, so they is drawn in first. The forces

in members ef and cf are known in direction but not

magnitude or sense. However, the sense can be obtained

from the above force diagram, along with the magnitudes.

To resolve cf and ef, I have split this quadrilateral into two triangles. One of them is shown

below.

de

de

cf =

= 2

60 cos

It can be seen that as the polygon is symmetrical ef = de.

So now the forces in the truss are as follows:

Final Analysis

As the truss is symmetrical, and the force is applied centrally, then we can assume the same

forces for the other side of the truss.

(All triangles are equilateral (60 angles), and all members are 200mm.)

Where: (as previously calculated) (magnitudes only)

F

F

2

ad

dc

de

ae

F

2

cf

ef

ch

gb

fg

gh

bh

F

F

2

ad

dc

de

ae

F

2

cf

ef

dc

ef

cf

de

120

cf

120

60 60

ef

de

dc

cf

30 60

de

n

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 8 of 14

3

F

gh bh gb fg ef de ae ad = = = = = = = =

3 2

F

dc ch = =

3

2F

cf =

So with these results, I know which members are in tension and which are in compression

(from the above diagram), and I can also work out the forces in each member given different

masses applied at force F.

Now I could see how the truss would behave. I tested it with a 50kg mass applied centrally at

the top. The forces I calculated are shown on the diagram below.

(50kg) 490N

282.9N 282.9 N

As there are 11 members, each being 0.2m long. The total amount of balsa used in this

design is 2.2m. 3m of balsa weights 100g, so the 2.2m that was used in our truss design

weighed 75g.

(25kg) 245N

122.5 N

70.7 N 282.9 N 70.7 N

141.5 N

122.5 N

141.5 N

141.5 N

141.5 N

141.5 N

141.5 N

141.5 N

141.5 N

(100kg) 980N

282.9 N 1131.6 N 282.9 N

565.8N 565.8 N

565.8 N

565.8 N

565.8 N

565.8 N

565.8 N

565.8 N

490N 490 N

245N

141.5 N 565.8 N 141.5 N

282.9 N

282.9 N

282.9 N

282.9 N

282.9 N 282.9 N

245N

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 9 of 14

APPENDIX B

Design 2 (Warren Truss):

A

F

B

D F H

E G

J

I

L

K

Where all triangles are equilateral.

F

2

120

C

F

2

The forces in members ad, dc, ae, de, ef and cf have been calculated in design 1, and they

are the same for this truss design. So the following forces are known.

F

AEFG

There are 4 members at joint AEFG. two of which are unresolved.

Free Body Diagram Force Diagram

Close up of Joint AEFG.

ef fg =

3

2F

ag =

CFGH

There are 4 members at joint CFGH. two of which are unresolved.

ae

ag

fg ef

120

120

60 60

ag

ef

fg

ae

F

2

ae

dc cf

de ad

ef

F

2

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 10 of 14

Free Body Diagram Force Diagram

3

3F

ch

fg gh

=

=

As the truss is symmetrical I can fill in the rest of it.

Final Analysis

ch

F

cj bi ag cf

F

cl dc

F

bk bl kl jk ij hi gh fg ef de ae ad

F

=

= = = =

= =

= = = = = = = = = = = =

3

3

3

2

3 2

3

Case 1 (25kg)

141N

71N

283N

424N

cf

gh

ch

fg

120

ch

120

60 60

gh

fg

cf

F

F

2

dc cf

ae

de

ef

ad

F

2

fg gh hi

ij

jk

kl

bl

bk bi ag

ch cj cl

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 11 of 14

APPENDIX C JOINTS

The joints are shown here. When we decided upon the joints we took into account whether

the members were in tension or compression. We gave members in tension the greater

surface area of gluing.

ADC

CDEF

CFGH

ad

dc

de ef

dc fc

fg gh

fc hc

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 12 of 14

CHB

BGH

AEFGB

hb

ch

bg

bh

gh

ae bg

ef

fg

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 13 of 14

ADE

de

ae

ad

__________________________________________________________________________

HSC Engineering Studies Assessment Task 1 14 of 14

Вам также может понравиться

- Post-Tension Flat Slab Design ExampleДокумент17 страницPost-Tension Flat Slab Design ExampleAwni Alkhteeb92% (12)

- ShapingStructures Statics 2006 Prof W ZalewskiДокумент34 страницыShapingStructures Statics 2006 Prof W ZalewskiRodrigo Lameiras100% (3)

- Force in A Statically Determinate Cantilever TrussДокумент12 страницForce in A Statically Determinate Cantilever TrussIkhwan Z.86% (7)

- Wagon Tippler DesignДокумент34 страницыWagon Tippler DesignAnku Pandey71% (7)

- Lab 5-Force in A Statically Determinate Cantilever Truss UTHMДокумент15 страницLab 5-Force in A Statically Determinate Cantilever Truss UTHMMoly Muliyani75% (8)

- Static Analysis of A Simple Cardan JointДокумент6 страницStatic Analysis of A Simple Cardan Jointazkar01Оценок пока нет

- ME2114E Combined Bending & Torsion - LabДокумент13 страницME2114E Combined Bending & Torsion - LabCinderella0212100% (2)

- Direct Rubber Shear Test PDFДокумент9 страницDirect Rubber Shear Test PDFMohammad ShehabОценок пока нет

- Shearing Forces in BeamsДокумент9 страницShearing Forces in BeamsKheshav JhundooОценок пока нет

- Experiment Shearing ForcesДокумент17 страницExperiment Shearing ForcesAnushaBheenuck73% (11)

- Spaghetti Bridge Construction HintsДокумент23 страницыSpaghetti Bridge Construction HintsRonny Antonio Quispe SuniОценок пока нет

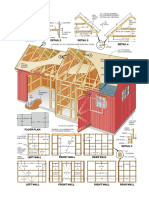

- APB Pole Barns Building GuideДокумент32 страницыAPB Pole Barns Building GuideWilliam Tilson75% (4)

- MiTeK Gable End and BracingДокумент4 страницыMiTeK Gable End and BracingSam LeungОценок пока нет

- ENSC 3008 Lecture Notes 2016Документ316 страницENSC 3008 Lecture Notes 2016richard4handokoОценок пока нет

- Lab8 BoundaryElementExerciseДокумент9 страницLab8 BoundaryElementExerciseansariОценок пока нет

- Lesson 1 and 2 PDFДокумент18 страницLesson 1 and 2 PDFDenver NieverasОценок пока нет

- Reading 1Документ20 страницReading 1Hwee Peng YeoОценок пока нет

- Manual Mechanics of Deformable Bodies 3Документ48 страницManual Mechanics of Deformable Bodies 3Miyamura IzumiОценок пока нет

- Project StrucДокумент19 страницProject StrucSelesteОценок пока нет

- Shear Force in A BeamДокумент12 страницShear Force in A BeamAzri Arif Zainal Arif100% (1)

- Shear Force in A BeamДокумент16 страницShear Force in A BeamIkhwan Z.100% (7)

- Finite Element AnalysisДокумент29 страницFinite Element AnalysisShams Abbas NaqviОценок пока нет

- Shear and Moment Diagram - Wikipedia, The Free EncyclopediaДокумент9 страницShear and Moment Diagram - Wikipedia, The Free EncyclopediazidaaanОценок пока нет

- Sample - Force in RedundantДокумент44 страницыSample - Force in RedundantSammi YongОценок пока нет

- Analysis of TrussДокумент22 страницыAnalysis of TrussSalem AlbarkiОценок пока нет

- Force Table 1Документ4 страницыForce Table 1cikbonОценок пока нет

- Fea Lab ReportДокумент11 страницFea Lab Reportkhan fiveerОценок пока нет

- SWK211 2023 Vibration PracticalДокумент5 страницSWK211 2023 Vibration PracticalAyur RampersadhОценок пока нет

- Shear and Moment Diagram - Wikipedia, The Free EncyclopediaДокумент10 страницShear and Moment Diagram - Wikipedia, The Free EncyclopediaPrabhat MishraОценок пока нет

- Balancing of Rotating MassesДокумент17 страницBalancing of Rotating MassesHasan AL-BahraniОценок пока нет

- Force in Statically Determinate Truss ReportДокумент15 страницForce in Statically Determinate Truss ReportHidayah Rahman88% (8)

- Understanding Fatigue in Metal: Intergraph CASДокумент10 страницUnderstanding Fatigue in Metal: Intergraph CASRoyster CabralОценок пока нет

- Lecture 2 Stress ApplicationsДокумент9 страницLecture 2 Stress ApplicationsHussein AssamОценок пока нет

- ForceДокумент45 страницForcefastidious_5Оценок пока нет

- 1-1 Stress Analysis and DesignДокумент25 страниц1-1 Stress Analysis and Design陈韦权Оценок пока нет

- Engineering Council Certificate Level: Mechanical and Structural Engineering C105Документ0 страницEngineering Council Certificate Level: Mechanical and Structural Engineering C105darkyrose27Оценок пока нет

- 1 Normal StressДокумент40 страниц1 Normal StressTerise SangalangОценок пока нет

- How To Draw Your Own Column InteractionДокумент23 страницыHow To Draw Your Own Column InteractionErwin ObenzaОценок пока нет

- Shear and Moment DiagramДокумент8 страницShear and Moment DiagrambubbaОценок пока нет

- LECTURE 5 Part 2: Analysis of Statically Determinate Trusses: Method of SectionДокумент11 страницLECTURE 5 Part 2: Analysis of Statically Determinate Trusses: Method of SectionAnthony LoñezОценок пока нет

- Engineering MechanicsДокумент80 страницEngineering MechanicsVv4H100% (1)

- Internal Forces Internal Forces Internal Forces Internal ForcesДокумент54 страницыInternal Forces Internal Forces Internal Forces Internal Forcesiwhy_0% (1)

- HES5320 Solid Mechanics, Semester 2, 2011, Practical Lab On Thick-Walled Cylinder by Stephen BongДокумент17 страницHES5320 Solid Mechanics, Semester 2, 2011, Practical Lab On Thick-Walled Cylinder by Stephen BongStephenPYBong100% (5)

- AMOS Note - Week 10-11 (Mod-IV)Документ105 страницAMOS Note - Week 10-11 (Mod-IV)Arupananda PrustyОценок пока нет

- Beam Analysis: Chapter - FOURДокумент14 страницBeam Analysis: Chapter - FOUR胡宇晟Оценок пока нет

- Lecture 2 - Tension Members - Part 1Документ10 страницLecture 2 - Tension Members - Part 1Dad MeОценок пока нет

- Me 354 Lab #4: Discussion of The Torsion TestДокумент13 страницMe 354 Lab #4: Discussion of The Torsion TestKHairil AdZharОценок пока нет

- S TN Mat 001Документ18 страницS TN Mat 001Hafiz DoyoxОценок пока нет

- EAS 326-03 M E: Ave 98/150, S.D. 21Документ7 страницEAS 326-03 M E: Ave 98/150, S.D. 21arief_7Оценок пока нет

- Statically Determinate Truss ReportДокумент14 страницStatically Determinate Truss ReportMuhammad IbrahimОценок пока нет

- Pech Lourdes ADA5Документ36 страницPech Lourdes ADA5Lourdes Elena Pech CruzОценок пока нет

- Laboratorio de Sólidos CerchaДокумент11 страницLaboratorio de Sólidos CerchaJoseth FerneyОценок пока нет

- Open Ended - Cantilever TrussДокумент13 страницOpen Ended - Cantilever TrussIkhwan Z.100% (1)

- Manufacturing Remaining Stresses in Truck Frame Rail's Fatigue Life PredictionДокумент10 страницManufacturing Remaining Stresses in Truck Frame Rail's Fatigue Life Predictionklomps_jrОценок пока нет

- LAB2 ChristopherДокумент11 страницLAB2 ChristopherChristopher MorganОценок пока нет

- Mult Cuts Pre PrintДокумент18 страницMult Cuts Pre PrintHarun HodžićОценок пока нет

- Column Buckling Test Experiment 4: EMA 3702L - Mechanics and Materials Science LabДокумент15 страницColumn Buckling Test Experiment 4: EMA 3702L - Mechanics and Materials Science LabRamon OrgeОценок пока нет

- Standard-Slope Integration: A New Approach to Numerical IntegrationОт EverandStandard-Slope Integration: A New Approach to Numerical IntegrationОценок пока нет

- Mathematical Analysis 1: theory and solved exercisesОт EverandMathematical Analysis 1: theory and solved exercisesРейтинг: 5 из 5 звезд5/5 (1)

- GCNSДокумент10 страницGCNSSuman SahaОценок пока нет

- Qut EN50 27746 Dom Cms UnitДокумент3 страницыQut EN50 27746 Dom Cms UnitSuman SahaОценок пока нет

- Class Routine (30 & 31 August 2014) : AdviceДокумент1 страницаClass Routine (30 & 31 August 2014) : AdviceSuman SahaОценок пока нет

- Engineering Science #16 Handout - 2013 Sem 1Документ8 страницEngineering Science #16 Handout - 2013 Sem 1Suman SahaОценок пока нет

- Class Routine (12, 13, 14 & 15 Aug 2014) : AdviceДокумент1 страницаClass Routine (12, 13, 14 & 15 Aug 2014) : AdviceSuman SahaОценок пока нет

- 2014-15 Postgraduate Tuition Fees For School of The Built Environment ProgrammesДокумент6 страниц2014-15 Postgraduate Tuition Fees For School of The Built Environment ProgrammesSuman SahaОценок пока нет

- Class Routine (19, 20, 21 & 22 Aug 2014) : AdviceДокумент1 страницаClass Routine (19, 20, 21 & 22 Aug 2014) : AdviceSuman SahaОценок пока нет

- Class Routine (29, 30, 31 July & 01 Aug 2014) : AdviceДокумент1 страницаClass Routine (29, 30, 31 July & 01 Aug 2014) : AdviceSuman SahaОценок пока нет

- Class Routine (16 & 17 August 2014) : AdviceДокумент1 страницаClass Routine (16 & 17 August 2014) : AdviceSuman SahaОценок пока нет

- Class Routine (02 & 03 August 2014) : AdviceДокумент1 страницаClass Routine (02 & 03 August 2014) : AdviceSuman SahaОценок пока нет

- Class Routine (02 & 03 August 2014) : AdviceДокумент1 страницаClass Routine (02 & 03 August 2014) : AdviceSuman SahaОценок пока нет

- Revit Structure 2012 FundamentalsДокумент11 страницRevit Structure 2012 FundamentalsSuman SahaОценок пока нет

- Faq Sts and SterДокумент7 страницFaq Sts and SterSuman SahaОценок пока нет

- Application For A Student VisaДокумент27 страницApplication For A Student VisaSuman SahaОценок пока нет

- LAB 1: Steps For Analysis & Design of Beam in SAP2000Документ16 страницLAB 1: Steps For Analysis & Design of Beam in SAP2000Suman SahaОценок пока нет

- 1499 Bridge NReqДокумент12 страниц1499 Bridge NReqSuman SahaОценок пока нет

- Design of Steel Structures TocДокумент6 страницDesign of Steel Structures TocSuman Saha0% (1)

- Civ1501 Engineering Statics Semester 2, 2002: Solution To Assignment 2Документ2 страницыCiv1501 Engineering Statics Semester 2, 2002: Solution To Assignment 2Suman SahaОценок пока нет

- Publications Order Form TEMPLATEДокумент1 страницаPublications Order Form TEMPLATESuman SahaОценок пока нет

- 2004 Engineering Studies Notes OhmzДокумент6 страниц2004 Engineering Studies Notes OhmzSuman SahaОценок пока нет

- Singapore FlyerДокумент13 страницSingapore Flyersanusi69100% (1)

- Beam Column Sample LectureДокумент9 страницBeam Column Sample LectureCan RapsОценок пока нет

- Univeristy of Engineering and Technology Peshawar: Steel StructuresДокумент77 страницUniveristy of Engineering and Technology Peshawar: Steel StructuresMuhammad SaqibОценок пока нет

- Holy Spirit University of Kaslik - USEK: GCV401 - Structural AnalysisДокумент13 страницHoly Spirit University of Kaslik - USEK: GCV401 - Structural AnalysisNabihОценок пока нет

- Reinforced Concrete RevisionДокумент21 страницаReinforced Concrete RevisionMikey ZhangОценок пока нет

- Design of Truss BridgeДокумент18 страницDesign of Truss BridgeBCE 2074 B Teacher100% (3)

- CE413 - Steel LacingДокумент38 страницCE413 - Steel LacingSaba MohsinОценок пока нет

- Strut and Tie Design For ConcreteДокумент8 страницStrut and Tie Design For ConcreteElvin Sandajan0% (1)

- Detail 2 Detail 1 Detail 3 Detail 4 3 3: Detail 2 Detail 1 Detail 3 Detail 4Документ1 страницаDetail 2 Detail 1 Detail 3 Detail 4 3 3: Detail 2 Detail 1 Detail 3 Detail 4Victor ParvanОценок пока нет

- Cold Formed Steel Frame DesignДокумент9 страницCold Formed Steel Frame Designnagaraju100% (1)

- Thin-Walled Structures: Wang Xingxing, Wang Wei, Fei HaojieДокумент16 страницThin-Walled Structures: Wang Xingxing, Wang Wei, Fei HaojieSaeed MohebbiОценок пока нет

- Gridshell - Edge Truss Steel Size Legeccd: CC11 CC12 CC13 CC14 CC15 CC16 CC17 CC18 CC19 CC20 CC21 CC22 CC23Документ1 страницаGridshell - Edge Truss Steel Size Legeccd: CC11 CC12 CC13 CC14 CC15 CC16 CC17 CC18 CC19 CC20 CC21 CC22 CC23Faisal MuhammadОценок пока нет

- Fiber Beam-Columns Models With Flexure-Shear Interaction For Nonlinear Analysis of Reinforced Concrete StructuresДокумент146 страницFiber Beam-Columns Models With Flexure-Shear Interaction For Nonlinear Analysis of Reinforced Concrete StructuresMuntasir BillahОценок пока нет

- BT AssignmentДокумент12 страницBT AssignmentRosemarie EscaroОценок пока нет

- CV 7-8-2021 22 Final PrintedДокумент51 страницаCV 7-8-2021 22 Final PrintedPandith AradhyaОценок пока нет

- Shear Wall Modelling Techniques: A ReviewДокумент9 страницShear Wall Modelling Techniques: A ReviewAmanulla MullaОценок пока нет

- 1973v03 PDFДокумент16 страниц1973v03 PDFTugba TekbenОценок пока нет

- ETFE For Space Structures PDFДокумент15 страницETFE For Space Structures PDFOsama KhanОценок пока нет

- STAADPro V8i Verification ManualДокумент562 страницыSTAADPro V8i Verification ManualMarius RizeaОценок пока нет

- PAPER IASS Geodesic Dome Cottonera Sports Hall MaltaДокумент9 страницPAPER IASS Geodesic Dome Cottonera Sports Hall MaltaistructeОценок пока нет

- 3.finite Element Formulation For Truss1Документ75 страниц3.finite Element Formulation For Truss1dawit gashuОценок пока нет

- High-Tech Architecture Kansai Airport by Renzo Piano: Helwan University Faculty of Fine Arts Architecture DepartmentДокумент40 страницHigh-Tech Architecture Kansai Airport by Renzo Piano: Helwan University Faculty of Fine Arts Architecture DepartmentadelelshamyОценок пока нет

- Ee Rev03 - Quiz 1Документ5 страницEe Rev03 - Quiz 1JAMEL C IBRAHIMОценок пока нет

- Design Requirements FootbridgeДокумент5 страницDesign Requirements FootbridgeshalvinОценок пока нет

- CSE5011-B Exam Jan 2021Документ15 страницCSE5011-B Exam Jan 2021Fahad NoumanОценок пока нет