Академический Документы

Профессиональный Документы

Культура Документы

Brochure Tiedemann Dynamometers

Загружено:

Darmanto Suwarni MunirИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Brochure Tiedemann Dynamometers

Загружено:

Darmanto Suwarni MunirАвторское право:

Доступные форматы

Dynamometers

Force Measurements

in a Small Space

1

Ring Dynamometers

Measurement of Tensile and Compressive Forces

Tiedemann dynamometers, manufactured for more than 60 years, offers high

precision instruments for mechanical force measurements for tensile and

compressive forces. The measurement range of the ring dynamometers go from

50 N to 200 kN.

Applications

The Tiedemann dynamometers are always used where measurements may allow

only minimal length changes. They are applied in the measurement of cable

tension on overhead wires, as an extension would lead to an increase of slack

span. Other applications include high-precision measurements in mechanical

engineering and vehicle manufacturing e.g. in test stands for brakes, in

machinery and transport equipment, as well as in measurements where only

little room for the measuring instrument is available.

Universal Dynamometer with standard scale, max. 2 kN

2

Execution of the Dynamometer

The ring dynamometer consists of a special shaped elastic steel ring attached

with two facing drawbar eyes and pressure seats. A load on the ring leads to a

slight deformation, which is measured with a precise dial gauge.

Measured Value and Maximal Load

The measured deformation is converted through a

calibration table into tensile or compressive forces.

The mechanical analogue dial indicator shows a

change in diameter of the ring of 5 microns per

division. The ring will deform less than 1.5 mm. The

error on accuracy is less than 0.3%.

On Tiedemann dynamometers, the indicator can be

set in such a way that it displays the maximum force

in one measuring run. This is of advantage for fast

processes and during experiments where reading of

scale is difficult or not possible, as may be the case in

determining the drag resistance of gliders, towed

trailers and boats or an operation force at a

inapproachable place.

Choice of Measuring Range

The ring dynamometers are available with various methods in execution.

Depending on the design the measurement range last from 50 N up to 200 kN.

The universal dynamometers are combination instruments for tensile or

compressive forces. Drawbar eyes carry the tensile force whereas pressure seats

take the compressive force. Alternative both forces can be connected via screw

bolts. Other pure tensile and compression dynamometers are available as well.

The dynamometers are designed for specific ranges that may not be exceeded,

not even temporarily by shock. Thus, if the measured force is not exactly known

or you are not sure that the force is free of shocks, then the next strongest ring

has to be chosen. For continuous loads (1 hour or longer) or permanent changing

charges, only a maximum of 80 % of the measuring range may be used.

Special Designs and Protectors

Because of the diversity of measuring

challenges that have to solved, Tiedemann

welcomes your input along the way.

We also offer a splash protective rubber

cover on some of our instruments, rotating

drawbar eyes or dynamometers with

modified seats for compressive forces.

Lever for maximum load

Protective jacket

3

Calibration

The calibration of the dynamometers with a maximum load up to 10 kN is done

with force measuring equipment at Tiedemann. The accuracy of our calibration

device is certified periodically by the measurement office of material testing. It is

classified into the grade of quality 0.5 (highest possible accuracy) according to

DIN 51220. Instruments with a higher load are calibrated by the measurement

office for material testing for the engineering industry at the University of

Munich. Therefore, it is traceable in all cases to the official comparison standard

according to ISO 9000ff.

Calibration Table

The determination of the calibration

values (10 steady steps from zero to the

maximum load) occurs according to the

internal testing method following DIN

51301 (increasing and decreasing load

and for indication for maximum load).

The values are determined separately for

each device, estimated on 1/10 scale and

slightly corrected according to a

compensation curve of minimal

quadratic divergence (polynomial of

degree 3). By this, incorrect values or

irregularities in the dial indicator can be

recognized before delivery. The

calibration curve through the 10 given

values is almost straight for tensile

forces but slightly curved for

compressive force.

Dynamometer with

Drawn Scale

Dynamometers with a drawn scale

are first calibrated according to

the same method.

Then a drawn scale with

interpolated force values will

replace the standard scale for one

arbitrary rotation of the dial

gauge. The measurement range

then becomes smaller.

4

Important Instructions

The calibrated dynamometers must not be modified after delivery. If the drawbar

eyes for tensile forces or the seats for compressive forces are turned or removed,

the rigidity of the whole device will be changed. The calibration table and the

maximum load are no longer valid.

Tensile forces must always be fed in with a bolt intended for the size of the device

(dimension d). Thinner bolts will lead to deformation or breakage of the drawbar

eye.

Compressive forces are preferably fed in by steel balls:

Diameter of balls up to 10 kN about 7 mm

up to 100 kN about 15 mm

up to 200 kN about 25 mm

The ring of the dynamometer must not be engraved or it will be in danger of

breakage.

Repair and Calibration Services

According to DIN 51301, the testing certificate is valid for only 24 months.

Therefore, it is recommended to recalibrate the device after this period.

Tiedemann will provide this calibration. The performance of the dynamometer is

examined before calibration. In case the dynamometer is from Tiedemann,

damaged parts are replaced by new ones automatically. After recalibration, our

company will deliver a practically new instrument.

If required Tiedemann would provide a test certificate showing the repair and

calibration for dynamometers with a maximum load of 10 kN (necessary for

quality control according ISO 9000ff.) Additionally and for dynamometers for

higher forces, an official test certificate from the measurement office of material

testing can be provided.

Technical Data

The following pages show all configurations and the technical data for:

- Universal Dynamometers for tensile or compressive force

- Universal Dynamometers with screw joint for tension and compression

- Compressive Force Dynamometers

- Tensile Force Dynamometers

5

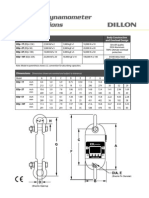

Universal Dynamometers for Tensile or Compressive Force

With these universal dynamometers, either tensile or compressive forces

(according to the direction of mounting) can be measured without any alteration.

Each instrument is calibrated individually. The calibration values (10 determined

values for both tension and compression) are given in a calibration table.

6

Universal-Dynamometers with Screw Joints for

Tensile / Compressive Force

With this model the forces are fed via the

thread bolts for tensile and compressive forces

at the same bolts. Thus, this type is ideal for

alternating loads.

When the device is unloaded, the dial indicates

300 graduation marks. If the forces are tensile,

the indication will rise; if the forces are

compressive, the value will decrease. Therefore,

the indication for maximum load works with

tensile forces only.

7

Compression Force Dynamometers

8

Tensile Force Dynamometers

Tiedemann & Betz GmbH & Co. KG Zur Maximilianshhe 6 82467 Garmisch-Partenkirchen Germany

Phone: +49-8821-3068 or -18917 Fax: +49-8821-3922 Cell Phone: +49-160-97 8443 96 www.Tiedemann-Betz.com

Вам также может понравиться

- Overview and Lessons From More Than A Decade of Feeder Life ManagementДокумент10 страницOverview and Lessons From More Than A Decade of Feeder Life ManagementDarmanto Suwarni MunirОценок пока нет

- ANSYS TutorialДокумент60 страницANSYS TutorialDarmanto Suwarni MunirОценок пока нет

- WDW 200eДокумент2 страницыWDW 200eDarmanto Suwarni MunirОценок пока нет

- Abro, Hamer Laser, Rubber, TMR KompresДокумент3 страницыAbro, Hamer Laser, Rubber, TMR KompresDarmanto Suwarni MunirОценок пока нет

- (Dynamometer) EDjr SpecДокумент2 страницы(Dynamometer) EDjr SpecDarmanto Suwarni MunirОценок пока нет

- Diesel in Line Fuel Injection Pumps PDFДокумент3 страницыDiesel in Line Fuel Injection Pumps PDFDavid Spears100% (3)

- University SustainabilityДокумент4 страницыUniversity SustainabilityDarmanto Suwarni MunirОценок пока нет

- Penuntun Praktikum: Disusun Oleh: Dr. Ir. Agus Haryanto, M.PДокумент5 страницPenuntun Praktikum: Disusun Oleh: Dr. Ir. Agus Haryanto, M.PDarmanto Suwarni MunirОценок пока нет

- Penuntun Praktikum: Disusun Oleh: Dr. Ir. Agus Haryanto, M.PДокумент5 страницPenuntun Praktikum: Disusun Oleh: Dr. Ir. Agus Haryanto, M.PDarmanto Suwarni MunirОценок пока нет

- Kitab Al Ghayah Wa Al Taqrib Matan Abi Syuja Asy SyafiiyyahДокумент105 страницKitab Al Ghayah Wa Al Taqrib Matan Abi Syuja Asy SyafiiyyahDarmanto Suwarni MunirОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Ilmu KhotifДокумент28 страницIlmu KhotifAndré Martins78% (27)

- 2.PsychoCrash Social Psy-1Документ62 страницы2.PsychoCrash Social Psy-1Gopika Sureshnv0% (1)

- Acc05 SCG116Документ42 страницыAcc05 SCG116Hilal HazaaОценок пока нет

- Reservoir Rock PropertiesДокумент148 страницReservoir Rock Propertiesiscribdusername100% (7)

- Load ScheduleДокумент8 страницLoad SchedulemerebookОценок пока нет

- Pigging Training Course Mod 7 Rev 1Документ26 страницPigging Training Course Mod 7 Rev 1Suparerk Sirivedin100% (1)

- Parts PrecedentДокумент252 страницыParts PrecedentOscar PinzonОценок пока нет

- Infineon IRFZ44N DataSheet v01 - 01 ENДокумент9 страницInfineon IRFZ44N DataSheet v01 - 01 ENIkram RidhoОценок пока нет

- DysphagiaДокумент4 страницыDysphagiaMicaОценок пока нет

- Origami Undergrad ThesisДокумент63 страницыOrigami Undergrad ThesisEduardo MullerОценок пока нет

- Biology Unit 4Документ44 страницыBiology Unit 4Mohammad KhanОценок пока нет

- Course Specification Course Title: Basic Architectural DraftingДокумент1 страницаCourse Specification Course Title: Basic Architectural DraftingDinah Fe Tabaranza-OlitanОценок пока нет

- Module II Activated Sludge Math ProblemsДокумент5 страницModule II Activated Sludge Math ProblemsArashОценок пока нет

- History of Costa RicaДокумент2 страницыHistory of Costa Ricakrishnan MishraОценок пока нет

- How To Build A GreenhouseДокумент67 страницHow To Build A GreenhouseBolarinwaОценок пока нет

- Neoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaДокумент26 страницNeoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaErwin SuryanaОценок пока нет

- Mold Maintenance StepДокумент0 страницMold Maintenance StepMonica JoynerОценок пока нет

- EASL 2021 Version 4 NewДокумент691 страницаEASL 2021 Version 4 NewGupse Köroğlu AdalıОценок пока нет

- 2020 Landfill Capacity Calculation Work SheetДокумент4 страницы2020 Landfill Capacity Calculation Work SheetLYОценок пока нет

- Gastritis: Department of Gastroenterology General Hospital of Ningxia Medical University Si Cen MDДокумент82 страницыGastritis: Department of Gastroenterology General Hospital of Ningxia Medical University Si Cen MDAvi Themessy100% (1)

- Advanced Logic Synthesis: Multiple Choice QuestionsДокумент16 страницAdvanced Logic Synthesis: Multiple Choice QuestionsmanojkumarОценок пока нет

- Asutphin Client Assessment Matrix Fitt Pros Unit 8Документ4 страницыAsutphin Client Assessment Matrix Fitt Pros Unit 8api-307235123Оценок пока нет

- Chapter 4: Palm Oil and Oleochemical Industries.: Presented By: Lovelyna Eva Nur Aniqah Siti MaryamДокумент15 страницChapter 4: Palm Oil and Oleochemical Industries.: Presented By: Lovelyna Eva Nur Aniqah Siti MaryamdaabgchiОценок пока нет

- 18-039 Eia 07Документ34 страницы18-039 Eia 07sathishОценок пока нет

- Material Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Документ5 страницMaterial Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Thais Roberta CamposОценок пока нет

- Barium Chloride 2h2o LRG MsdsДокумент3 страницыBarium Chloride 2h2o LRG MsdsAnas GiselОценок пока нет

- MPI Report 009 Sub Structure B668Документ1 страницаMPI Report 009 Sub Structure B668John DolanОценок пока нет

- A Review of Linear AlgebraДокумент19 страницA Review of Linear AlgebraOsman Abdul-MuminОценок пока нет

- RocketsДокумент2 страницыRocketsAlin VoicuОценок пока нет

- CST STUDIO SUITE - High Frequency Simulation PDFДокумент128 страницCST STUDIO SUITE - High Frequency Simulation PDFGenik Podunay100% (2)