Академический Документы

Профессиональный Документы

Культура Документы

Truss Design NS Negi

Загружено:

Sushmit Sharma100%(1)100% нашли этот документ полезным (1 голос)

519 просмотров23 страницыDesign Example

Авторское право

© © All Rights Reserved

Доступные форматы

XLS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документDesign Example

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

100%(1)100% нашли этот документ полезным (1 голос)

519 просмотров23 страницыTruss Design NS Negi

Загружено:

Sushmit SharmaDesign Example

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 23

DESIGN OF STEEL TRUSS

Width of Bldg. = 8 m c/c

Length of Bldg.= 16.5 m

Height of eaves= 7.4 m

Number of bayes = 4

Angle of trust (Alfa) = 30 Deg.

Spacing of truss(assumption) = 4.05 m

Height of truss = 2.309 m

Incline length = 4.619 m

Each incline length = 1.540 m

Horizontal length = 1.333 m

Impose loads:

Imposed load = 0.35 KN/m

2

350.00

For purlin = 0.40 KN/m

2

(horizontal area) 402.50

For truss members = 0.27 KN/m

2

(horizontal area) 268.33

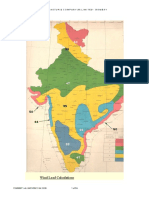

Wind loads:

Take basic wind speed(Vb) = 50 cum (Assume)

F = (Cpe - Cpi) X A X P

z

Cpe & Cpi = Force coefficient for exterior & interrior of building. (Ref: Table B7 and Table B9 ;( " BOOK = Design of steel structure, second edition, LS Negi", pg:309 & 311)

A = Effective area of the structure.

P

z

= Design wind pressure.= 0.6Vz^2

Where,

Design wind speed , Vz = Vb x K1 x K2 x K3

Accroading to the IS:875(part3);

Risk factor, K1 = 1.08 ref; Table B-11, Risk Coefficient K1;( " BOOK = Design of steel structure, second edition, LS Negi", pg:312)

Height and size factor, K2 = 0.91 ref; Table B-12, K2 factor;( " BOOK = Design of steel structure, second edition, LS Negi", pg:312)

Topography factor, K3 = 1 K3 = 1 for upward slope < 3; K3 = 1 to 1.36 for upwind slope > 3

Therefore, Vz = 49.14 m/sec.

Design wind pressure (P

z

) = 1448.84 N/m2

Now,

Height of bldg., h = 9.709 m

Width of bldg., w = 8 m

Length of bldg., L = 16.5 m

h/w = 1.21

L/w = 2.06

0.2

Cpi = 0.2

Wind ward Cpe = -0.3

Lee ward Cpe = -0.4

Wind parallel to ridge

Wind ward Cpe = -0.8

Lee ward Cpe = -0.6

Max.wind load for design = 869.31 N/m2 (downward)

Max.wind load for design = -1448.84 N/m2 (Uplift)

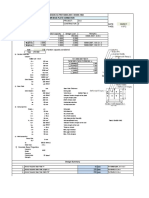

Design of purlins

Spacing of purlins = 1.540 m c/c

Weigth of 20gauge CGI sheets = 112.7 N/m2 (Assume)

Size of CGI sheet= 1.8*0.9 m*m

Load on purlins per meter length :

Weight of sheeting = 173.513 N/m

Weight of purlin (Assuming) = 10 kgf/m

100 N/m

Total dead load = 273.513 N/m

Impose load = 536.667 N/m

Wind load = -2230.641 N/m

-724.422

-869.306

-1159.075

-1448.844

Internal air pressure coefficient for normal permeability, Cpi =

Total pressure =(Cpe -Cpi) x Pd

Downward

Wind normal to ridge :

Dead load + impose load = 810.180 N/m

Dead load + wind load = -1957.128 N/m

When wind load is consider permissible stress is increased by 33.33%,

Therefore, dead load + wind load may be considered 33.33% less effective;

Design wind load = -1471.525 N/m; combination of dead & wind load is critical

Maximum bending moment in the purlin = 2413.668 Nm

Yield stress(f

y

) = 250 N/mm

2

Permissible bending stress = 165 N/mm

2

14628.294 mm

3

14.63 Cm

3

Required tubular purlin (as per common steel sections):

Zx = 14.4 Cm

3

Outside Diameter = 76.1 mm

Nominal Bore = 65 mm

Class = Medium

Thickness = 3.65 mm

Weight = 6.53 kg/m

Area of X-section = 8.31 Cm

2

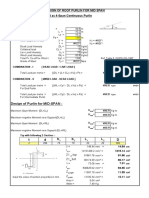

Design Load for roof truss

Loads:

1) Dead loads:

Length along the sloping roof = 4.619 m

Self weight of the truss = 100 N/m2 (Assume @100 N/m2 horizontally)

Gauge of CGI sheet = 20

weight of roofing material = 112.7 N/m2

No. of purling = 8

Weight of purling = 65.3 N/m2

Therefore;

Load due to :

Self weight of truss = 3240.00 N

Roofing material (CGI sheet) = 4216.37 N

Purlins = 2115.72 N

Total = 9572.086 N

No. of panels = 6

Load acting on intermediate panel point = 1595.35 N

Dead load acting on node = 1595.35 N

Dead load acting on shoe = 797.67 N

2) Imposed loads:

Miscellaneouse load (Live loads) = 0.2 N/m2 (Assume)

Total live load = 8724.48 N

Load acting on intermediat panel point = 1454.08 N

Live load acting 0n node = 1454.08 N

Live load acting on shoe = 727.04 N

3) Wind loads:

Total wind load = 1448.84

Wind load acting on one intermediat panel = 9034.10 N

Wind load acting on shoe = 4517.05 N

Therefore, section modulus (Zx) =

N/m

2

N/m

2

N/m

2

Force coefficient for exterior & interrior of building. (Ref: Table B7 and Table B9 ;( " BOOK = Design of steel structure, second edition, LS Negi", pg:309 & 311)

ref; Table B-11, Risk Coefficient K1;( " BOOK = Design of steel structure, second edition, LS Negi", pg:312)

ref; Table B-12, K2 factor;( " BOOK = Design of steel structure, second edition, LS Negi", pg:312)

K3 = 1 for upward slope < 3; K3 = 1 to 1.36 for upwind slope > 3

Cpi = -0.2

-579.538

Total pressure =(Cpe -Cpi) x Pd

-144.884

-289.769

Uplift

-869.306

N/m; combination of dead & wind load is critical

Load Combinations:

Angle of trust, = 30 Deg.

Angle of trust, = 49.11 Deg.

Angle of trust, = 60.00 Deg.

Dead load acting on node = 1.595 kN

Dead load acting on shoe = 0.798 kN

1.45 kN

Wind load acting on one intermediat panel = 9.03 kN

Wind load acting on shoe = 4.52 kN

Sign convention (Compression -ve, tension +ve)

Imposed load Wind load Maximum Minimum

(b) (c ) (a+b) (a+c) / 1.33 KN KN

Principal LoU1 -7.27 39.12 -15.25 23.42

Rafter U1U2 -7.27 44.33 -15.25 27.34

Rafter U2U3 -5.82 39.12 -12.20 24.61

Main tie L0L1 6.30 -31.62 13.20 -18.58

Main tie L1L2 5.04 -22.59 10.56 -12.83

Main tie L2L3 3.78 -13.55 7.92 -7.07

Main sling U3L2 2.52 -18.07 5.28 -11.51 5.28 -11.51

Main strut U2L2 -2.18 15.65 -4.57 9.97 9.97 -4.57

Minor sling U2L1 1.92 -13.80 4.03 -8.79 4.03 -8.79

Minor strut U1L1 -1.45 10.43 -3.05 6.64 6.64 -3.05 -1.60

Design load

27.34 -15.25

13.20 -18.58 5.53

4.14

2.76

-2.39

-7.98

-7.98

-6.38

6.91

2.11

1) Dead loads:

2) Imposed loads:

3) Wind loads:

Member

Forece (KN) due to

Load combination

Dead laod

(a)

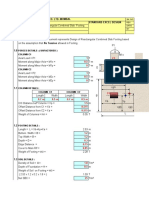

Design of truss member

1) Rafter (L0-U3 & U3-L5):

27.34 KN; Tension

15.25 KN; Compression

Effective length, l = 1077.72 mm; since rafter is continuous over panel points

Maximum bending moment = 3175.11 Nm

19243.11 mm

3

19.24 Cm

3

Section type = Medium

Nominal bore, d = 160 mm

Outer diameter, D = 165.1 mm

Weight per meter, w1 = 19.2 kgf/m

Radius of gyration, r = 56.7 mm

Yield stress of steel, fy = 250 N/mm2

Ratio, (l/r) = 19.01

Permissible stress in axial compression,

ac

= 148.92 N/mm2

Permissible direct stress in axial tension,

at

= 150 N/mm2

Actual compression stress,

ac,cal

= 11.71 N/mm2; Safe in compression

Actual compression stress,

ac,cal

= 20.99 N/mm2; Safe in tension

2) Main ties (Lo-L5):

13.20 KN; Tension

18.58 KN; Compression

Effective length, l = 933.33 mm

Maximum bending moment = 1618.52 Nm

9809.19 mm

3

9.81 Cm

3

Section type = Medium

Nominal bore, d = 90 mm

Outer diameter, D = 101.6 mm

Weight per meter, w1 = 9.75 kgf/m

Radius of gyration, r = 34.5 mm

Ratio, (l/r) = 27.05

Permissible stress in axial compression,

ac

= 146.61 N/mm2

Permissible direct stress in axial tension,

at

= 150 N/mm2

Actual compression stress,

ac,cal

= 14.27 N/mm2; Safe in compression

Actual compression stress,

ac,cal

= 10.14 N/mm2; Safe in tension

3) Main sling (U3L2 & U3L3):

5.28 KN; Tension

11.51 KN; Compression

Effective length, l = 2266.67 mm; since ends of copression section partially restrained for lateral bending

Maximum bending moment = 5912.30 Nm

35832.09 mm

3

35.83 Cm

3

Section type = Medium

Nominal bore, d = 90 mm

Outer diameter, D = 101.6 mm

Weight per meter, w1 = 9.75 kgf/m

Radius of gyration, r = 34.5 mm

Ratio, (l/r) = 65.70

Permissible stress in axial compression,

ac

= 116.48 N/mm2

Permissible direct stress in axial tension,

at

= 150 N/mm2

Actual compression stress,

ac,cal

= 8.84 N/mm2; Safe in compression

Section adopted for rolled steel beam

Section adopted for rolled steel beam

Section adopted for rolled steel beam

Design load =

Therefore, section modulus (Zx) =

Design load =

Therefore, section modulus (Zx) =

Design load =

Therefore, section modulus (Zx) =

Actual compression stress,

ac,cal

= 4.06 N/mm2; Safe in tension

mm; since ends of copression section partially restrained for lateral bending

U3

U

1

U

4

U

1

U

5

fig: Truss components

L4 L3 L5 Lo L1 L2

1

.5

4

m

1

.5

4

m

1

.5

4

m

1

.5

4

m

1

.5

4

m

1

.5

4

m

= 30 = 49 = 60

1.333 m

fig: Truss

1.333 m 1.333 m 1.333 m 1.333 m 1.333 m

fig: Wind load

9

.0

3

4

K

N

9

.0

3

4

K

N

1.595 KN

1.595 KN 1.595 KN

1.595 KN

fig: Dead load

23.471 KN 23.471 KN

4

.5

1

7

K

N

4.786 KN

9

.0

3

4

K

N

4

.5

1

7

K

N

9

.0

3

4

K

N

4

.5

1

7

K

N

1.595 KN

4.786 KN

4

.5

1

7

K

N

0.798 KN 0.798 KN

3.912 KN

fig: Wind load components

2.259 KN 2.259 KN

4.517 KN

3.912 KN

4.517 KN 4.517 KN

4.517 KN

7.824 KN

7.824 KN

7.824 KN

7.824 KN

7.824 KN

4.517 KN

Вам также может понравиться

- Truss 6 V - Plate Connection DesignДокумент9 страницTruss 6 V - Plate Connection DesignSiddharth Tiwari100% (1)

- Design of Welded Plate GirderДокумент25 страницDesign of Welded Plate GirderJinshad UppukodenОценок пока нет

- Compressive strength aluminum truss anglesДокумент109 страницCompressive strength aluminum truss anglesSamia H. Bhuiyan100% (2)

- Design of Through Type Plate GirderДокумент9 страницDesign of Through Type Plate GirderAnju Kl0% (1)

- Truss load calculation spreadsheetДокумент40 страницTruss load calculation spreadsheetk varalakshmiОценок пока нет

- Steel Roof Truss1Документ121 страницаSteel Roof Truss1Nikhil100% (1)

- Load - Calculation For Dead LoadДокумент6 страницLoad - Calculation For Dead LoadSandesh PrajapatiОценок пока нет

- Calculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLДокумент3 страницыCalculation Sheet: 71197 Design For Pile Cap - Two Piles PP DJM MVLV.m. RajanОценок пока нет

- Steel Section Design as per IS 800:2007Документ12 страницSteel Section Design as per IS 800:2007vishalnalwar100% (1)

- b03 - LRFD - Girt, Purlin - To VendorДокумент52 страницыb03 - LRFD - Girt, Purlin - To VendorSaleem KhaderОценок пока нет

- Pile Cap Design For 4 PILEДокумент4 страницыPile Cap Design For 4 PILEParth DaxiniОценок пока нет

- Design Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992Документ2 страницыDesign Data: CONNECTION DESIGN AS PER IS800-2007, IS4000-1992OmPrakashОценок пока нет

- ROOF PURLIN DESIGN FOR MID BAYДокумент3 страницыROOF PURLIN DESIGN FOR MID BAYUtkarsh BhardwajОценок пока нет

- Wind As Per 875-2015Документ33 страницыWind As Per 875-2015V.m. RajanОценок пока нет

- Design of gantry girder STAAD inputДокумент5 страницDesign of gantry girder STAAD inputDarsHan MoHanОценок пока нет

- Project by Location: Girting Design AДокумент10 страницProject by Location: Girting Design AJurie_sk3608Оценок пока нет

- Design of Steel Truss Bridge (Live Load Reaction)Документ35 страницDesign of Steel Truss Bridge (Live Load Reaction)Chandra Prakash Jyoti100% (1)

- LOAD CALCULATIONS FOR MAIN FRAME-1Документ1 страницаLOAD CALCULATIONS FOR MAIN FRAME-1Adarsh SinghОценок пока нет

- Load Calc3Документ43 страницыLoad Calc3Saravanan SilambanОценок пока нет

- Analysis Report Tensile Canopy - HOCKEY STADIUM - R0 - AДокумент23 страницыAnalysis Report Tensile Canopy - HOCKEY STADIUM - R0 - ANeeraj KumarОценок пока нет

- Design of Trestle "TF1" and Beams AboveДокумент8 страницDesign of Trestle "TF1" and Beams AbovePartha Gangopadhyay100% (3)

- Design Composite Girder.Документ42 страницыDesign Composite Girder.arabindaОценок пока нет

- Depth of Fixity & Pile DesignДокумент2 страницыDepth of Fixity & Pile DesignSoumya BandyopadhyayОценок пока нет

- PURLIN - DESIGN - AS - PER - IS - CODE LatestДокумент22 страницыPURLIN - DESIGN - AS - PER - IS - CODE Latestnitin chaudharyОценок пока нет

- Metal Sheet Calculations for 44-195 ProfileДокумент29 страницMetal Sheet Calculations for 44-195 ProfileAnonymous HkX2aE9FxОценок пока нет

- Summary of Loads-Left Bank Abutment: Sukhaura River Motorable Bridge, Makwanpur Abutment Design IDD, ChitwanДокумент26 страницSummary of Loads-Left Bank Abutment: Sukhaura River Motorable Bridge, Makwanpur Abutment Design IDD, ChitwanPoshan DhunganaОценок пока нет

- Pile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterДокумент22 страницыPile Cap - Pedestal - Beam Design - Add-On Ammonia ConverterShuvam SarkarОценок пока нет

- RaftДокумент48 страницRaftHariom KhungarОценок пока нет

- Combine Footing FinallДокумент227 страницCombine Footing FinallKhalid BanafaОценок пока нет

- CribДокумент1 страницаCribskumarsrОценок пока нет

- Design of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnДокумент2 страницыDesign of Pedestal For Seismological Stations: Slenderness Ratio of The ColumnAdarsh Kumar SОценок пока нет

- Rectangular Combined FootingДокумент38 страницRectangular Combined FootingINNOVATIVE ENGINEERОценок пока нет

- Deck SheetДокумент2 страницыDeck SheetmaheshbandhamОценок пока нет

- Rect. RCC Col. Design As Per IS 456 by K. N. ShethДокумент10 страницRect. RCC Col. Design As Per IS 456 by K. N. ShethKanaiyalal N. ShethОценок пока нет

- Purlins & GirtsДокумент10 страницPurlins & GirtsRaviKiranОценок пока нет

- Base Plate+WIND LOADДокумент15 страницBase Plate+WIND LOADShuvam PyakurelОценок пока нет

- LC PurlinДокумент9 страницLC PurlinRachelle QuilalaОценок пока нет

- Circular Column Design Excel SheetДокумент7 страницCircular Column Design Excel SheetDhananjay ShindeОценок пока нет

- Design of Base PlateДокумент3 страницыDesign of Base Plateravi4paperОценок пока нет

- Design of Abutment PDFДокумент4 страницыDesign of Abutment PDFChManikumarОценок пока нет

- Design of Steel BeamДокумент1 страницаDesign of Steel Beamgaurav sharmaОценок пока нет

- Isolated Footing UniaxialДокумент8 страницIsolated Footing Uniaxialrvshankar143Оценок пока нет

- 1 - Wind Load CalculationsДокумент54 страницы1 - Wind Load CalculationsMASOOD MIYANОценок пока нет

- BASE PLATE DESIGNДокумент4 страницыBASE PLATE DESIGNvinujohnpanickerОценок пока нет

- 1.0bolted Truss ConnectionДокумент7 страниц1.0bolted Truss ConnectionklynchelleОценок пока нет

- JSW Severfield Structure Ltd. composite column design EC4Документ3 страницыJSW Severfield Structure Ltd. composite column design EC4RonakShahОценок пока нет

- Truss DesignДокумент5 страницTruss DesignanbugobiОценок пока нет

- Base Plate INDIA CODEДокумент4 страницыBase Plate INDIA CODEbama sankari100% (1)

- DMIC Design-Work ShopДокумент15 страницDMIC Design-Work ShopMaitrayee AdityaОценок пока нет

- Car ShelterДокумент29 страницCar ShelterMochammad Shokeh100% (1)

- Design Calculation of Gantry GirderДокумент7 страницDesign Calculation of Gantry GirderKushal ChhetriОценок пока нет

- Connection Design SteelДокумент19 страницConnection Design Steelबिजेन्द्र प्रधानОценок пока нет

- Wind Load CalculationДокумент16 страницWind Load CalculationRaju SainiОценок пока нет

- Design of PurlinsДокумент7 страницDesign of Purlinsjiyad100% (1)

- Purlin For 2 Bays RNDДокумент64 страницыPurlin For 2 Bays RNDStephen JamesОценок пока нет

- Truss Design NS NegiДокумент1 страницаTruss Design NS NegiSushmit SharmaОценок пока нет

- Box CulvertДокумент9 страницBox CulvertVarun TyagiОценок пока нет

- 30m 24sq.m SQ 100kpaДокумент20 страниц30m 24sq.m SQ 100kpamanohargudОценок пока нет

- Design of Pile FoundationДокумент16 страницDesign of Pile FoundationD SRINIVASОценок пока нет

- Mechanical Design For Sieve Plate ColumnДокумент14 страницMechanical Design For Sieve Plate ColumnIan Zuhair II100% (1)

- SchneiderElectric 111711 PDFДокумент17 страницSchneiderElectric 111711 PDFShiva Naga KumarОценок пока нет

- Section-1 Es enДокумент75 страницSection-1 Es enSushmit SharmaОценок пока нет

- Action Verbs For ResumesДокумент2 страницыAction Verbs For Resumesapi-2627751040% (1)

- Decision Support For Maintenance and Refurbishment Planning of Hydropower PlantsДокумент10 страницDecision Support For Maintenance and Refurbishment Planning of Hydropower PlantsSushmit SharmaОценок пока нет

- OT3 GIS For BeginnersДокумент37 страницOT3 GIS For Beginnersmakmohit6037Оценок пока нет

- What Is New in PMBOK Guide 6th EdДокумент130 страницWhat Is New in PMBOK Guide 6th EdMikiRoniWijaya94% (16)

- Labour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazetteДокумент44 страницыLabour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazettenepalcaОценок пока нет

- PPA ProcedureДокумент5 страницPPA ProcedureSushmit SharmaОценок пока нет

- Electricity Act 2049-EnglishДокумент14 страницElectricity Act 2049-EnglishFariyad AnsariОценок пока нет

- Cement Grouted Rock Bolts PDFДокумент28 страницCement Grouted Rock Bolts PDFSushmit SharmaОценок пока нет

- Labour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazetteДокумент44 страницыLabour Act, 2048 (1992) : It Came Into Force On 2054.7.18 (Nov. 3, 2000) by A Notification Published in The Nepal GazettenepalcaОценок пока нет

- Decision Support For Maintenance and Refurbishment Planning of Hydropower PlantsДокумент10 страницDecision Support For Maintenance and Refurbishment Planning of Hydropower PlantsSushmit SharmaОценок пока нет

- EIA IEE Working Procedure 2073Документ4 страницыEIA IEE Working Procedure 2073Sushmit SharmaОценок пока нет

- Hydropower Development Policy, 2049: 1. BackgroundДокумент5 страницHydropower Development Policy, 2049: 1. BackgroundRajpОценок пока нет

- Christie Burger Henk HattinghДокумент28 страницChristie Burger Henk HattinghSushmit SharmaОценок пока нет

- Asset Management Council 1205 TheAsset0602 PDFДокумент48 страницAsset Management Council 1205 TheAsset0602 PDFSushmit SharmaОценок пока нет

- A Holistic Approach To Asset Management in The NetherlandsДокумент10 страницA Holistic Approach To Asset Management in The NetherlandsSushmit SharmaОценок пока нет

- Crucial Role of Physical Modeling in Developing Intake ConfigurationДокумент20 страницCrucial Role of Physical Modeling in Developing Intake Configurationrelu100% (1)

- 02 Sanchez AM Overview PDFДокумент20 страниц02 Sanchez AM Overview PDFSushmit SharmaОценок пока нет

- Fostering Academic Cooperation and CollaborationДокумент22 страницыFostering Academic Cooperation and CollaborationSushmit SharmaОценок пока нет

- Barreiro-Trigos Octavio PDFДокумент72 страницыBarreiro-Trigos Octavio PDFSushmit SharmaОценок пока нет

- GIS Tutorial 1 Basic WorkbookДокумент417 страницGIS Tutorial 1 Basic WorkbookJuan95% (21)

- Good Governance in The Public SectorДокумент54 страницыGood Governance in The Public Sectorhermione_crisОценок пока нет

- Supply Chain Management Fact SheetДокумент4 страницыSupply Chain Management Fact SheetYong Yang YangОценок пока нет

- 05 Supplier Selection Process PDFДокумент15 страниц05 Supplier Selection Process PDFSushmit SharmaОценок пока нет

- HCF PDFДокумент68 страницHCF PDFSushmit SharmaОценок пока нет

- PMI ManagingSubcontracts March2010Документ25 страницPMI ManagingSubcontracts March2010Sushmit SharmaОценок пока нет

- Multilevel Project Governance Trends and OpportunitiesДокумент18 страницMultilevel Project Governance Trends and OpportunitiesSushmit SharmaОценок пока нет

- Case Template Nuremberg-Ingolstadt FinalДокумент45 страницCase Template Nuremberg-Ingolstadt FinalSushmit SharmaОценок пока нет

- PCI Parking BuildingДокумент125 страницPCI Parking BuildingProfessor Dr. Nabeel Al-Bayati-Consultant EngineerОценок пока нет

- Load Rating of Bridge Gusset PlatesДокумент14 страницLoad Rating of Bridge Gusset PlatesdapinminОценок пока нет

- A Short Study On Launching Techniques: April 2015Документ16 страницA Short Study On Launching Techniques: April 2015raaaaajjjjjОценок пока нет

- (M.tech) - Engine Truss Mount Optimisation-Inspire Case StudyДокумент15 страниц(M.tech) - Engine Truss Mount Optimisation-Inspire Case StudyABHISHEKSОценок пока нет

- Fem Design Verification Checklist For Protastructure 2016 (Summary)Документ25 страницFem Design Verification Checklist For Protastructure 2016 (Summary)OjullaIsaacОценок пока нет

- Architectural Vernacular TermsДокумент43 страницыArchitectural Vernacular TermsNyak nyak100% (1)

- RegulatorsДокумент63 страницыRegulatorsshruti konkaОценок пока нет

- Staad Pro Example 12Документ48 страницStaad Pro Example 12V.m. RajanОценок пока нет

- Xstructures STAAD Fundamentals 2020Документ122 страницыXstructures STAAD Fundamentals 2020jet toledo100% (5)

- Chapter 4Документ20 страницChapter 4Usha GautamОценок пока нет

- Classification of Bridges Ver 0.0Документ24 страницыClassification of Bridges Ver 0.0Kumar VikramОценок пока нет

- Link 180Документ5 страницLink 180Omar NajmОценок пока нет

- Assessment of The Out-Of-plane Imperfections of A Steel Tied Arch BridgeДокумент8 страницAssessment of The Out-Of-plane Imperfections of A Steel Tied Arch BridgeDhimas Surya NegaraОценок пока нет

- Chapter 1 Introduction To Structural Analysis and LoadsДокумент24 страницыChapter 1 Introduction To Structural Analysis and LoadsMarissa BrownОценок пока нет

- IFC Phase 2Документ16 страницIFC Phase 2ipwaikinОценок пока нет

- Truss Brace Splicing Methods: Discover The Cost SavingsДокумент4 страницыTruss Brace Splicing Methods: Discover The Cost Savingszulkhairi lopОценок пока нет

- 1764 Shrutkirti Long SpanДокумент20 страниц1764 Shrutkirti Long SpanShrutkirti SupekarОценок пока нет

- N. Krishna Raju - Design of Bridges - Libgen - LiДокумент97 страницN. Krishna Raju - Design of Bridges - Libgen - LiShreshtha BhargavaОценок пока нет

- APA Introduction To Lateral DesignДокумент20 страницAPA Introduction To Lateral Designbradley.vassauОценок пока нет

- 安泰科柔性支架宣传册 - EnglishДокумент10 страниц安泰科柔性支架宣传册 - EnglishMUHAMAD FIKREE BIN SHAHARUDDINОценок пока нет

- Final Report. Design of Bridge Over Kerunga Khola (T+steel Truss)Документ177 страницFinal Report. Design of Bridge Over Kerunga Khola (T+steel Truss)Anjan LuitelОценок пока нет

- Rce 403 LPДокумент2 страницыRce 403 LPgaurav sharmaОценок пока нет

- Vertical Irregularities From ASCE 7-10-3Документ1 страницаVertical Irregularities From ASCE 7-10-3Bunkun15Оценок пока нет

- Timber in Bridge Structures: A Case StudyДокумент47 страницTimber in Bridge Structures: A Case Studyzefferson100% (1)

- Wide Cable Supported Bridges For Railcumroad TrafficДокумент10 страницWide Cable Supported Bridges For Railcumroad TrafficMushahid RazaОценок пока нет

- Planning and Design of Warehouse: Submitted byДокумент22 страницыPlanning and Design of Warehouse: Submitted byDineshkumar RajaОценок пока нет

- tHEORY mODULEДокумент34 страницыtHEORY mODULEJorge DanielleОценок пока нет

- Bridge 1 Figures CorrectДокумент78 страницBridge 1 Figures Correctusama buttОценок пока нет

- Trac Bridge ProposalДокумент15 страницTrac Bridge Proposalapi-310947092Оценок пока нет

- Thin-Walled Structures: Wang Xingxing, Wang Wei, Fei HaojieДокумент16 страницThin-Walled Structures: Wang Xingxing, Wang Wei, Fei HaojieSaeed MohebbiОценок пока нет

- Topic 1 - Introduction To Steel DesignДокумент48 страницTopic 1 - Introduction To Steel DesignAce De GuzmanОценок пока нет