Академический Документы

Профессиональный Документы

Культура Документы

Civil and Structural

Загружено:

Hitendra PanchalАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Civil and Structural

Загружено:

Hitendra PanchalАвторское право:

Доступные форматы

Page1of3

J OB PROCEDURE FOR SOI L I NVESTI GATI ON

(PROCEDURE NO: 6724-700-50-47-J P-001)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL SEL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of3

(PROCEDURE NUMBER: 6724-700-50-47-J P-001)

J OB PROCEDURE FOR SOIL INVESTIGATION

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. PROCEDURE

5. INSPECTIONS & RECORDS

Page3of3

PROCEDURE NO.6724-700-50-47-J P-001

J OB PROCEDURE FOR SOIL INVESTIGATION

1.0 PURPOSE

The purpose of this procedure is for testing of soil and to ensure that proper quality control and system

is exercised at site for design of compressor /other foundations as per codes / standards.

2.0 SCOPE

This procedure covers supervision and method of testing & record keeping for soil investigation.

3.0 REFERENCE

As per contract specifications

IS Codes / Standards

4.0 PROCEDURE:

Area where soil testing to be done will be barricaded and ensured that no encumbrances are there

Marking of testing location at site and same will be verified whether it is as per drawing or not

Rig with mortar pump to be erected on testing points.

Required water connection to be made,

Drilling shall be started,

Required level, required test, Samples can be collected and tested.

Required test (SPT) Record to be maintained,

Log book of boring to be maintained by SEL & periodic checking to be done by EIL/GAIL if required,

Boring shall be done up to required depth as per contract / soil conditions

All collected samples and test shall be carried out in approved lab and report generated,

Finally all soil report shall be prepared. and submitted to EIL / GAIL

5.0 RECORDS:

Site inspection notes / Reports of site test as per ITP No: 6724-700-50-47-ITP-001

Review test & inspection documents.

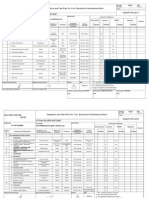

INSPECTION & TEST PLAN FOR SOIL INVESTIGATION

DOC.NO.6724-700-50-47-ITP-001

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR ,

RATNAGIRI

SR NO ACTIVITY SEL EIL

RECORDS TO

BE

SUBMITTED/

FORMAT NO

Remarks

1 POSITION OF TEST LOCATION WC S YES

2 A) REVIEW OF CALIBRATION CERTIFICATES

OF INSTRUMENTS / TESTING EQUIPMENTS

B) FIELD CALIBRATION, IF ANY

WC

WC

HP

W

YES

YES

Calibration

Certificate to

be submitted

3 BORING & SAMPLING WC W YES

4

IN SITU TESTING (SPY, CPT, PILE LOAD

TEST, ETC)

WC S YES

5 LAB TESTING (AS APPLICABLE) WC RW YES

Test report to

be submitted

6 MONITORING OF WATER LEVEL WC S

INSPECTION & TEST DOCUMENTS

REVIEW TEST & INSPECTION DOCUMENTS

WC RW YES

Prepared by Reviewed by Checked by Approved by

SEL SEL SEL EIL

Page1of4

J OB PROCEDURE FOR EXCAVATI ON

(PROCEDURE NO: 6724-700-50-47-J P-002)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL SEL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of4

(PROCEDURE NUMBER: 6724-700-50-47-J P-002 )

J OB PROCEDURE FOR EXCAVATION

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. PROCEDURE

5. INSPECTIONS & RECORDS

Page3of4

J OB PROCEDURE FOR EXCAVATION

1. PURPOSE

The purpose of this procedure is for supervision of all excavation works and to ensure that proper quality

control is exercised at site.

2. SCOPE

This procedure covers supervision of excavation work and method of record keeping for all earth work in

soil, soft rock and hard rock.

3. REFERENCE

All works relating to excavation work will be confirmed to contract document.

special condition

design basis

4. PROCEDURE

SURVEY WORK

Initial survey to be done and locate the location of earth work as per approved drawings

Survey to be done with reference to the existing plant foundation and reference drawing.

With reference drawing centre line co ordinate to be marked at site (pegging)

Excavation boundary line with margin to be marked.

Initial joint level to be recorded and joint record to be maintained by SEL

EXCAVATION

Initial excavation permission to be taken from plant in charge.

Required barricading to be done.

Location of existing underground system to be marked / if required manual trial pit will be done

Earth work will be done by manually / mechanically as per the site condition.

During the earth work required shoring & strutting will be done to hold the collapsed earth or foundation.

Page4of4

Required lighting arrangement will be done and other suitable measures for protection against accident due

to open excavation.

Making of dewatering arrangement so that excavation area to be dry.

For hard rock, breaker to be made available with all safety measures and required permission.

For any underground system across the excavation, necessary clearance to be obtained from Engineer - in

charge.

Excavation to be done in slope / steps as per the site condition.

Final dressing to be done as per the drawing.

Excavated earth will be stored at designated location without affecting plant operation and brought back for

back filling if found good.

5. INSPECTION AND DOCUMENTATION

All the excavation area shall be inspected for firm bed sides, leaks, location as given in the drawings.

All excavation will be inspected by Engineer or the contractor.

All inspection to be done as per approved ITP.

Initial joint level record to be maintained by SEL

Excavation bed level to be jointly recorded by SEL

Measurement of shoring to be recorded.

Soft rock / hard rock initial level and measurement to be recorded jointly and record to be submitted for

information only to consultant

Record to be submitted as per ITP NO : 6724-700-50-ITP-002

Page 1 of 2

INSPECTION & TEST PLAN FOR EXCAVATION

DOC.NO. : 6724-700-50-47-ITP-002

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

SR

NO

ACTIVITY SEL EIL

RECORDS TO BE

SUBMITTED/

FORMAT NO

Remarks

1 a. Calibration certificate of measuring &

testing / Instruments

b. Field calibration, if any

W

W

HP

S

YES

YES

2 Layout checking

W S

YES As per

Drawing

3 Taking initial levels W S YES Level Record

4 Slope of excavation, benching, overburden,

shoring & Strutting (In case of deep

excavation)

W S

5 Check for sub soil water, dewatering

requirements As per specifications.

W S

6 Check for bottom level of excavation

W S

7 Stacking of different types of soils separately

W S

8 List of obstacle encountered (Cables, pipes,

conduits Etc.)

W S

YES Make as built

Drawing

Page 1 of 2

9 Barricading of excavated pits for safety and

Protection from rain.

W S

FOR HARD ROCK

1 Obtaining license from district authorities for

Undertaking blasting operation.

W RW

YES Permission

Letter

2 Storing of explosive materials as per

explosive Rules.

W S

3 Prominent display of red flags around the

area To be blasted.

W S

4 Check the dimensions of bore holes. W S

5 Stacking of hard rock for useable/ non-

useable

W S

INSPECTION & TEST DOCUMENTS

Completeness of inspection and test records W RW YES (As Per ITP)

Prepared by Reviewed by Checked by Approved by

SEL SEL SEL EIL

Page1of3

J OB PROCEDURE FOR BACKFILLING

(PROCEDURE NO: 6724-700-50-47-J P-003)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL SEL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of3

(PROCEDURE NUMBER: 6724-700-50-47-J P-003 )

J OB PROCEDURE FOR BACKFILLING

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. MATERIAL

5. PROCEDURE

6. INSPECTIONS & RECORDS

Page3of3

J OB PROCEDURE FOR BACKFILLING

1.0 PURPOSE

The purpose of this procedure is for supervision of all backfilling works and to ensure that proper quality

control is exercised at site.

2.0 SCOPE

This procedure covers supervision of job and method of record keeping for all backfilling work.

3.0 REFERENCE

All works relating to backfilling work will confirm to contract document.

4.0 MATERIAL

Backfilling soil to be approved by Engineer in charge.

Required soil testing prior to backfilling to be done.

5.0 PROCEDURE

Before backfilling area to be cleaned and backfilling permission to be obtained from EIL.

Backfilling around foundation shall be with suitable soil

Backfilling shall be done in layer as specified in specification and compacted till 95 % of max. Dry density is

achieved with watering, rolling and ramming by manually / mechanically by compactor up to the level

shown in drawing.

Required test of compaction shall be carried out layer by layer and recorded jointly.

6.0 INSPECTION & DOCUMENTATION

Each & every layer to be inspected by Engineer as per ITP No : 6724-700-50-47-ITP-003

Required compaction test to be taken with the consultation of Engineer in charge and lab test

conducted

Compaction record to be maintained as per ITP

INSPECTION & TEST PLAN FOR BACKFILLING

DOC. NO. - 6724-700-50-47-ITP-003

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR ,

RATNAGIRI

SR

NO

ACTIVITY SEL EIL

RECORDS TO BE

SUBMITTED/

FORMAT NO

Remarks

1 Checking of Materials i.e. Earth WC S Yes

2

Adequate slope, benching in excavation for

safety

WC S

3

Calibration certificate of measuring & testing

Field calibration, if any.

WC

WC

HP

S

Yes

Yes

4 Layout, line & level. WC S

5

Ensure proper laying & joining, grouting at

Manholes/ chambers prior to back filling

WC S

6

Check for supports / firm bed / sub soil

water level.

WC S

7 Testing for leakages by blocking pipe ends. WC W

8

Hydrostatic testing and other tests, removal

of Blockages, cleaning & flushing of system

WC HP Yes

9 Back filling in layers consolidating & watering WC S Yes

10 Compaction Test WC RM Yes

11

Check for MS rungs in proper position, inlet /

Outlet pipe levels in manholes.

WC S

12 Soil Treatment , if any WC RM

13 Preparation of As built drawings WC RW Yes

INSPECTION & TEST DOCUMENTS

Completeness of inspection and test records WC RW Yes

Prepared by Reviewed by Checked By Approved by

SEL SEL SEL EIL

Page1of4

J OB PROCEDURE FOR BLACK TOPPI NG(PREMI X CARPETI NG)

(PROCEDURE NO: 6724-700-50-47-J P-004)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL EIL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of4

(PROCEDURE NUMBER: 6724-700-50-47-J P-004)

J OB PROCEDURE FOR BLACK TOPPING (PREMIX CARPETING)

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. PROCEDURE

5. INSPECTIONS & RECORDS

Page3of4

J OB PROCEDURE FOR BLACK TOPPI NG (PREMI X CARPETI NG)

1. PURPOSE

The purpose of this procedure is for supervision of Black Topping for road work and to insure that proper

quality control is exercised at site

2. SCOPE

This procedure covers supervision of Black Topping for road work and method of record keeping for all

Black Topping at site.

3. REFERENCE

All work related to Black Topping will be conformed to EIL contract document

IS codes

Design Basis

4. MATERIAL

Required material for Black Topping shall be as per EIL specifications

5. PROCEDURE

Material approval to be done

Review of calibration of plant

Review of calibration of instrument/ testing of equipment

WBM top surface to be properly clean , and joint around aggregate to be clean properly

Checking of road camber / level

Tack coat to be applied as per specification

Required thickness of premix carpeting after rolling to be spread

During the spreading of premix carpet, bitumen temperature and its consumption to be check

Take the premix sample for check test (as applicable)

Seal coat to be spread over the premix carpet

Page4of4

Finally compacted thickness of black topping to be checked and it should be as per drawing / specified

in specification.

Prepared the berm by sites of road in specified width

Remove all surplus earth from the road sites & dumped designated area

Final inspection of black topping will done jointly and any defect found to be repaired immediately.

6. INSPECTION AND TEST DOCUMENT

Review of test and inspection reports as per ITP NO 6724-700-50-47-ITP-004

INSPECTION & TEST PLAN FOR BLACK TOPPING

DOC. NO. - 6724-700-50-47-ITP-004

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

Sr.

No.

Activities SEL EIL Record to

submitted

Remarks

1 Approval of source of materials WC Rw

2

Review of calibration certificates of instruments / testing

equipments

Field calibration if any

WC

WC

HP

W

3 Surface preparation & check for camber / level WC S

4 Checking/ testing of material wherever required WC W

5 Tack coat application WC S

6

Premix carpeting(including thickness of carpeting) and

rolling

WC S

7 Seal coat (Including thickness of seal coat) WC S

8 Check for camber and levels WC S

9 Check for bitumen temperature and consumption WC S

10 Premix sample check test (as applicable) WC W

11 Removal of surplus earth WC S

12 Berm preparation WC S

13 Final inspection WC HP

INSPECTION AND TEST DOCUMENTS

Review test and inspection documents

WC

Rw

PREPARED BY REVIEWED BY CHECKED BY APPROVED BY

SEL SEL SEL EIL

Page1of4

J OB PROCEDURE FOR CONCRETING WORK

(PROCEDURE NO: 6724-700-50-47-J P-005)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL EIL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of4

(PROCEDURE NUMBER: 6724-700-50-47-J P-005)

J OB PROCEDURE FOR CONCRETING WORK

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. MATERIAL

5. PROCEDURE

6. INSPECTIONS & DOCUMENTATION

Page3of4

J OB PROCEDURE FOR CONCRETI NG WORK

1.0 PURPOSE

The purpose of this procedure is for supervision of concreting works and ensures that proper quality

control is exercised at site.

2.0 SCOPE

The procedure covers supervision of concreting works and method of record keeping for concreting

work at site.

3.0 REFERENCE

All plain and reinforced concrete work will comply with the requirements mentioned in EIL specification

Design Basis

4.0 MATERIAL

All material required for the concreting / RCC work shall be as per EIL specification

5.0 PROCEDURE

For PCC / RCC approval of design mix

Required grade concrete to be approved by mix design / RMC

Trial cubes will be taken at batching plant / at site as per the design mix of specified grade of contract

as per design

Testing will be done at 3 days, 7 days, and 28 days.

If results are found acceptable then design mix / RMC will be approved.

Bed level of excavation shall be checked jointly by contractor and consultant and permission may be

obtained to do the PCC work.

Required shuttering to be done as per the drawing with proper supports and height.

Reinforcement steel bars which are bending earlier as per the approved bar bending schedule are to be

placed as per drawings and bindings as per specified wires.

Required laps, chairs, spacer bars to be provided.

Page4of4

Required bolts, inserts, plates, openings / pockets to be fixed as per drawings.

Top level of concrete to be marked on shuttering.

Pre pour checking by our Engineer and consultant to be done and obtained the clearance for

concreting the next day.

Concreting will be done by mixer m/c / RMC which is required to meet quality standards

Concreting will be done in layer and compaction of concrete will be done by vibrator machines in

layers.

Finally top of concrete will be finished as required in spec. drawings and shall match exact foundation

top

Required testing cubes will be taken for testing of desired strength at 7 days, & 28 days in approved

lab.

From next day onward cubes will be puts under the water filled tank/sump.

Shuttering will be removed after 24 hours and surfaces to be observed and seen that concrete will be

ok or not.

Compressor foundation to be done in single pour only (monolithic)

6.0 INSPECTION & DOCUMENTATION

Vibrating & compaction of concreting to be inspected during concrete.

Cubes to be taken and its to be numbers, with date of casting grade, fdn. no,

Location etc

Final finishing to be observed.

Pre pour cards to be filled up before concreting.

Pour concrete to be filled up after concreting.

Records of material / RMC to be submitted.

Others will be as per ITP No : 6724-700-50-47-J P-005A, 6724-700-50-47-J P-005B, 6724-700-50-47-J P-

005C, 6724-700-50-47-J P-005D

INSPECTION & TEST PLAN FOR PLAIN CEMENT CONCRETE (PCC)

DOC.NO.- 6724-700-50-47-J P-ITP-005A

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

SR

NO

ACTIVITY SEL EIL

RECORDS TO

BE

SUBMITTED/

FORMAT NO

Remarks

1

a. Review of calibration certificates of

instruments / testing Equipments.

b. Field calibration, if any.

WC

WC

HP

W

2

Checking of layout and materials,

compaction of sub grade

WC S

3 Mix proportion. WC S

4 Check for shuttering, dewatering if any WC S

5 Concreting with proper compaction. WC S

6 Checking of top level of PCC. WC S YES

7 Curing. WC S

INSPECTION & TEST DOCUMENTS

Review test and inspection documents. WC RW

Prepared By Reviewer by Checked By Approved by

SEL SEL SEL EIL

INSPECTION & TEST PLAN FOR RCC ( SUB STRUCTURE)

DOC.NO.- 6724-700-50-47-J P-ITP-005B

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR ,

RATNAGIRI

SR

NO

ACTIVITY SEL EIL

RECORDS TO

BE

SUBMITTED/

FORMAT NO

Remarks

1 Approval of source of materials. WC RW YES

2

Approval of agency for providing Ready

Mix concrete (RMC)

WC W YES

APPROVED

VENDOR

3

a) Calibration certificate of measuring

& testing Equipments / instruments

of RMC plant

b) Field calibration, if any

WC

WC

HP

W

YES

YES

4

Checking of layout & condition of PCC /

Leveling course.

WC S

YES

5 Checking / testing of materials. WC S YES

6 Design Mix Approval WC HP YES Design mix doc

7

Check for line & level of shuttering including

Its condition, quality and rigidity.

WC S

8

Check for sub-soil water & dewatering

arrangement, if any

WC S YES

9

Placing of reinforcement & covers to

reinforcement.

WC W

10

Check for inserts, Anchor bolts and pipe

sleeves, pockets etc.

WC S YES

11 Pour card. WC HP

6724-700-

50-47-IR-

001 & 002

12

Quality records of RMC like delivery ticket

information.

WC RW YES

13

Check for obstacles encountered ( Electrical

conduits, Pipe lines etc.)

WC S YES

14 Concreting, testing, compaction, & finishing. WC RM YES

15 Casting of cubes. WC RM

16 Curing WC S

17

Testing of cubes 7 Days ---

-- 28 Days

WC

WC

RM

W

6724-700-

50-47-IR-

003

18 Removal of shuttering. WC S

19 Check for water tightness, renderings, if any. WC S

20 Preparation of As built drawings WC RW YES

INSPECTION & TEST DOCUMENTS

Completeness of inspection and test records WC RW YES

Prepared by Reviewed by Checked by Approved by

SEL SEL SEL EIL

INSPECTION & TEST PLAN FOR RCC ( SUPER STRUCTURE)

DOC.NO.- 6724-700-50-47-J P-ITP-005C

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

SR

NO

ACTIVITY SEL EIL

RECORDS TO BE

SUBMITTED/

FORMAT NO

Remarks

1 Approval of source of materials. WC RW

2

Approval of agency for providing Ready Mix

concrete (RMC)

WC W YES

3

a) Calibration certificate of measuring &

testing Equipments / instruments of RMC

Plant

b) Field calibration, if any

WC

WC

HP

W

YES

YES

4 Checking of layouts WC S YES

5 Checking / testing of materials. WC RW YES

6 Design Mix Approval WC HP YES

7

Check for line & level of shuttering and

scaffolding / Vertical bracing including

hoisting arrangement.

WC S

8

Placing of reinforcement & covers to

reinforcement

WC W

9

Check for inserts, bolts, pipe sleeves, MS

rungs, concealed Electrical conduits, fan

hooks, dowel, welding etc. if any.

WC S YES

10 Check for pockets / openings WC S

11 Check for expansion joints, if any WC S

12

Check for water stoppers, slopes, stoppers, if

any

WC S

13 Pour Card WC HP

6724-700-50-

47-IR-001 &

002

14

Quality records of RMC like Delivery Ticket

information

WC RW YES

15 Concreting, testing, compaction, & finishing. WC RM YES

16 Casting of cubes. WC RM

17 Curing. WC S

18

Testing of cubes --- 7 Days

--- 28 Days

WC

WC

RM

W

6724-700-50-

47-IR-003

19 Removal of formwork / staging WC S

20

Verification of dimension viz. AFC drawings

and tolerances

WC S

21 Check for water tightness, renderings, if any WC S

22 Preparation of As built drawings WC S YES

INSPECTION & TEST DOCUMENTS

Completeness of inspection and test records WC RW YES

Prepared by Reviewer by Checked by Approved by

SEL SEL SEL EIL

INSPECTION & TEST PLAN FOR RCC (CRITICAL STRUCTURE)

DOC.NO.- 6724-700-50-47-J P-ITP-005D

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR ,

RATNAGIRI

SR

NO

ACTIVITY SEL EIL

RECORDS TO BE

SUBMITTED/

FORMAT NO

Remarks

1 Approval of source of materials. WC RW YES

2

Approval of agency for providing Ready

Mixed Concrete (RMC)

WC RW YES

3

Calibration certificate of measuring & testing

equipments / instruments

WC RW YES

4 Checking of layout. WC S YES

5 Checking / testing of materials. WC W YES

6 Soil strata below PCC WC S

7 Design of Mix. WC HP YES

8

Check for line & level of shuttering and

scaffolding / vertical bracing Including

hoisting arrangements, shoring and strutting.

WC S

9

Placing of reinforcement & coverts to

reinforcement

WC S

10

Check for inserts, Anchor bolts, pipe sleeves,

MS rungs, concealed electrical Conduits, fan

hooks, dowel, etc. including welding if any

WC W YES

11 Check or pockets / openings WC W

12

Detailed work plan including equipment,

manpower & other sources

WC RW YES

13 Pour Card. WC HP

6724-700-50-

47-IR-001 &

002

14

Quality records of RMC like delivery ticket

Information

WC RW YES

15 Concreting, testing, Compaction & finishing. WC W YES

16 Casting of Cubes WC RW

17 Curing. WC S

18

Testing of cubes. 7 Days

28 Days

WC

WC

RW

W

6724-700-50-

47-IR-003

19 Removal if formwork / staging WC

20

Verification of dimension viz. AFC drawings

and tolerances

WC

S YES

21 Check for water tightness, rendering, if any. WC S

22 Preparation of As built drawings. WC RW YES

INSPECTI ON & TEST OCUMENTS

Completeness of inspection and test records WC RW YES

Note: Compressor Foundation shall be done by Single pour only

Prepared By Reviewed by Checked By Approved by

SEL SEL SEL EIL

Page 1 of 2

POUR CARD I (PROGRAMME OF CONCRETING)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDI TI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

CLIENT : M/s RGPPL, RATNAGIRI FORMAT NO: 6724-700-50-47-IR-001 REV.NO. - 0

PMC : M/s EIL REPORT NO :

DATE :

1. Reference document :

2. Type of Structure :

3. Levels From : To :

4. Grade of Concrete / Approved Design Mix

5. Brand Name, Grade and consignment no. cement

6. Estimated volume of concrete :

7. Quantity of cement required :

8. Reinforcement checking details :

No. Dia. Length

a) Laps

b) Separators

c) Chairs

d) Any other

Remarks

9. Pre pour inspection details Checked NA

a) Survey / Layout.

b) Sub soil compaction.

c) Completion of underground works.

d) Cleanliness.

e) Cover to reinforcement.

f) Anchor bolt.

g) Sleeves / pockets.

h) Water stopper.

i) Formwork.

j) Slopes.

k) Construction / Expansion joints.

l) Admixtures.

m) Any other.

Remarks

10.

Clearance for Electrical / Mechanical

Works required / not required

Electrical Mechanical

11.

The above structures finally inspected on at AM/PM and found / not found satisfaction for

concreting.

Remarks, if any

M/s SAVAIR ENERGY LIMITED M/s GAIL/EIL

NAME

SIGN

DATE

Page 2 of 2

Page 1 of 2

POUR CARD II (OBSERVATIONS DURING CONCRETING)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDI TI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

CLIENT : M/s RGPPL, RATNAGIRI FORMAT NO: 6724-700-50-47-IR-002 REV.NO. - 0

PMC : M/s EIL REPORT NO :

DATE :

1. a) Quality of course aggregates

Satisfactory Not to Satisfactory

b) Quality of fine aggregates

Satisfactory Not to Satisfactory

c) Bulk of sand taken into account

Yes No

2. Quality of Water

Satisfactory Not Satisfactory

3. Machinery mobilization

a) Mixture machine

b) Ready mix concrete dumpers

c) Vibrators

d) Pumps

e) Hoists

4. Pour start time AM/PM : Date :

5. Slump

6. W/C Ratio

7. Type Of Weather

Normal Abnormal

Detail of abnormality :

(Precautions taken for < 5 C and > 40 C, rainy season)

Page 2 of 2

8. Number of cubes taken :

9. Quantity of concrete poured :

10. Pour completion time : AM/PM : Date :

11. Curing Method

Traditional Curing compound

Blankets / foils / gunny bags Others ( specify)

12. Period for removal of form work.

13. Any defect (s) observed during concreting :

M/s SAVAIR ENERGY LIMITED M/s GAIL/EIL

NAME

SIGN

DATE

Name of work :

Reference : Type of Cement :

W / C Ratio : Max. size of Aggregate :

Page 1 of 2

CRUSHING STRENGTH RESULTS OF CONCRETE CUBES

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR , RATNAGIRI

CLIENT : M/s RGPPL, RATNAGIRI FORMAT NO: 6724-700-50-47-IR-003 REV.NO. - 0

PMC : M/s EIL REPORT NO :

DATE :

Cube

No.

Id.

Mark

On

Cube

Type &

Location

of

Structure

Date of Age

(days)

Dimensions of Cube Vol.

of

Cube

(m)

Wt.

of

Cube

(kg)

Unit WT.

(kg/m)

Surface

Area

(cm)

Crushing

Load (kg)

Crushing

Strength

(kg/cm)

Remarks

Casting Testing L

(Cm)

B

(Cm)

H

(Cm)

M/s SAVAIR ENERGY LIMITED M/s GAIL/EIL

NAME

SIGN

DATE

Page 2 of 2

Page1of3

J OB PROCEDURE FOR MI CRO GRADING

(PROCEDURE NO: 6724-700-50-47-J P-006)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL SEL EIL

SIGNATURE

NAME Ganesh K. Rakesh P. Milind D.

DATE

Page2of3

(PROCEDURE NUMBER: 6724-700-50-47-J P-006 )

J OB PROCEDURE FOR MICRO GRADING

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. PROCEDURE

5. INSPECTIONS & RECORDS

Page3of3

J OB PROCEDURE FOR MICRO GRADING

1. PURPOSE

The purpose of this procedure is for supervision of micro grading work and to insure that proper quality

control is exercised at site

2. SCOPE

This procedure covers supervision of micro grading and method of record keeping for micro grading work

at site.

3. REFERENCE

All work related to micro grading shall be as per specification

4. PROCEDURE

Review the calibrating certificate of instrument

Take the initial level of micro grading area

Remove the extra soil , debris, where level is higher than the required and back fill the soil where level

is lower

Area to be graded in gradient so that water can easily flow in drain

Finish the area with small roller or with hand compactor

Take final level & record it

Final inspection will be made jointly

5. INSPECTION AND TEST DOCUMENT

Review test and inspection reports with level records as per ITP No 6724-700-50-47-ITP-006

INSPECTION & TEST PLAN FOR MICRO GRADING

DOC.NO. - 6724-700-50-47-J P-006

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR ,

RATNAGIRI

Sr

no

Activities SEL EIL

Record to

be

submitted

Remarks

1

a) Review of calibration certificates of instruments /

testing equipments

b) Field calibration if any

WC

WC

Rw

W

YES

YES

2 Taking initial level WC S YES

3

Clearing/Removal of extra soil, debris, etc from site by

transportation

WC

S

4

Taking final level WC S YES

5 Verification of gradient of ground WC S

6

Finishing of ground surface by hand compactor/roller (As

applicable)

WC

S

7 Final inspection WC HP

INSPECTION AND TEST DOCUMENTS

Review test and inspection document

WC Rw

PREPARED BY REVIEWED BY CHECKED BY APPROVED BY

SEL SEL SEL EIL

Page1of4

J OB PROCEDURE FOR STRUCTURAL STEEL WORK

(PROCEDURE NO: 6724-700-50-47-J P-007)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL SEL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of4

(PROCEDURE NUMBER: 6724-700-50-47-J P-007 )

J OB PROCEDURE FOR STRUCTURAL STEEL WORK

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. MATERIAL

5. PROCEDURE

6. INSPECTIONS & DOCUMENTATION

Page3of4

J OB PROCEDURE FOR STRUCTURAL STEEL WORK

1.0 PURPOSE

The purpose of this procedure is for supervision of structural steel works and to ensure that proper

quality control is exercised at site.

2.0 SCOPE

The procedure covers supervision and method of record keeping for structural steel work at site.

3.0 REFERENCE

All structural steel work will comply with the requirements mentioned in EIL specification and shop /

field painting as per EIL specification and respective IS, BIS, SP codes and specification.

IS Codes

Design Basis

4.0 MATERIAL

All material shall be confirm to their respective specifications given in EIL specification and IS codes,

BIS, SP codes.

5.0 PROCEDURE

Material to be procured from standard / approved vendors only with all MTC reports. If MTC are not

available / co related with materials will be tested with approved lab taking samples from received

material at site.

Qualified welder to be qualified / approved before taking up the welding job.

Shop fabrication will be made before starting of actual fabrication at site and approved on the basis of

design drawings.

On the basis of shop fabrication drawing, actual fabrication of structural steel shall start.

Periodical checking / inspection will be done by our Engineer & necessary approval may be obtained.

Fit up checking / alignment checking will be done by Engineer & required clearance will be obtained.

After complete fabrication completed final checking / clearance will be done by us / consultant as per

ITP

Page4of4

Fabricated material will be shifted to shot blasting shed and surface will be prepared by shot blasting

(Sa 2.5) and primer painting as per EIL Specification, shall be done. Inspection will be by Engineer /

EIL as per ITPs

Material will be transported to site from fabrication shop after primer painting

Foundation top to be chipped off properly to binding grouting material Nuts / bolt be grease level

plates to be ground.

Required capacity crane to be arranged and erection of structural will be done; proper nuts with lock

nuts tighten.

After alignments of main structural balance component to be fixed and final alignment to be done and

approval to be taken from consultant.

Welding work shall start as per EIL specification and on final welding completed necessary clearance

will be obtained.

No compromise shall be made on moment connections and weld length for structural steel in bracing

& to which shall be as per standards & IS

After completion of all final welding, weld joints shall be cleaned & painting to be done as per EIL

specification

Finally handing to be done and document to be submitted,

All above work shall be done with all safety precaution

6. INSPECTION & DOCUMENTATION

Periodically inspection will be got it to EIL.

Final alignment report to be prepared.

All fit up; weld visual, etc. record to be submitted.

Handing over report to be submitted.

All test reports of material to be submitted.

Record to be submitted as per ITP NO : 6724-700-50-47-ITP-007

INSPECTION & TEST PLAN FOR STRUCTURAL STEEL WORK

DOC.NO. 6724-700-50-47-ITP-007

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR ,

RATNAGIRI

Sr.

No

Activity SEL EIL

Records To Be

Submitted/

Format No

Remarks

A PRE FABRICATION ACTIVITI ES

1

a) Reviews\ of calibration certificates of

instruments / testing.

b) b) Field calibration, if any.

WC

HP

W

YES

2

Checking of structural steel materials supplied by

the contractor / Manufacturers test certificate /

testing (as applicable).

WC RW YES

3

Welding Filler material approval / qualification.

a) Manufacturing test certificates / documents.

b) Testing, if any.

WC RW

4 WPS / PQR WC W YES

5 Welders performance qualification. WC W YES

6 Layout checking. WC S

7 Welding equipment and accessories. WC S

8 Preparation and approval of fabrication drawings. WC RW YES

B FABRICATION ACTIVITI ES

1 Materials as per design drawing WC RW

2 Check straightness and non-warping of members. WC S

3 Dimensional and fit-up checks including provision WC S YES

of slopes for Deflection whenever required.

4 Visual check for welding. WC S YES

5

Grinding including surface preparation for painting

and application of primer.

WC RW YES

6 Checking paint as per specs., shelf-life etc. (MTC) WC S YES

7

Application of specified paint, painting thickness,

etc. (DFT)

WC

WC

RW YES

C FIELD ERECTION ACTIVITIES WC

1

Lifting arrangements including test certificates of

lifting tackles

WC

S/RW YES

2 Correctness of location.

WC

S

3 Orientation of bracing, lugs. WC S

4 Alignment & levels. WC S

5 Field welding (if any). RW YES

6 Grouting. WC S

7 Finishing coat of paint, thickness of paint etc. WC W YES

8 Preparation of As-built drawings. WC RW

INSPECTION & TEST DOCUMENTS

Review test and Inspection documents. WC RW

Prepared By Reviewed by Checked By Approved by

SEL SEL By EIL

Name of Work :

Reference No. : Location / co-ordinates / grids :

Layout clearance obtained : Yes / No

SL.

No.

Item

No.

Material &

Dimensional

clearance

Shop Fit up Shop

Welding

Cleaning &

Primer

Painting

Erection

Fit Up

Alignment

& Leveling

Field

Welding

Grouting

clearance

Final

Painting &

thickness

Remarks

SEL EIL SEL. EIL SEL EIL SEL EIL SEL EIL SEL EIL SEL. EIL SEL EIL

Page 1 of 2

STRUCTURE FABRICATION AND ERECTION REPORT

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR , RATNAGIRI

CLIENT : M/s RGPPL, RATNAGIRI FORMAT NO: 6724-700-50-47-IR-004 REV.NO. - 0

PMC : M/s EIL REPORT NO :

DATE :

M/s SAVAIR ENERGY LIMITED M/s GAIL/EIL

NAME

SIGN

DATE

Page 2 of 2

Name of work: ______________________________ Location/coordinates/grids:

Reference no : _______________________________ Layout clearance obtained: yes/not

Sr No Item No Material and

dimensional

clearance

Plumb reading on

North/ south face

Plumb reading on

West/ east face

Alignment &

level ok/not

Sign of

SEL

Sign

Of

EIL/owner

Remarks

A B A B ALIGN LEVEL

Page 1 of 2

STRUCTURAL COLUMN VERTICALITY CHECKING REPORT

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR , RATNAGIRI

CLIENT : M/s RGPPL, RATNAGIRI FORMAT NO: 6724-700-50-47-IR-005 REV.NO. - 0

PMC : M/s EIL REPORT NO :

DATE :

M/s SAVAIR ENERGY LIMITED M/s GAIL/EIL

NAME

SIGN

DATE

Page 2 of 2

Page1of4

J OB PROCEDURE FOR SHEETING WORK

(PROCEDURE NO: 6724-700-50-47-J P-008)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL SEL EIL

SIGNATURE

NAME Ganesh K. Rakesh P. Milind D.

DATE

Page2of4

(PROCEDURE NUMBER: 6724-700-50-47-J P-008 )

J OB PROCEDURE FOR SHEETING WORK

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. PROCEDURE

5. INSPECTIONS & RECORDS

Page3of4

J OB PROCEDURE FOR SHEETING WORK

1. PURPOSE

The purpose of this procedure is for supervision of sheeting work and to insure that proper quality control is

exercised at site

2. SCOPE

This procedure covers supervision of sheeting work and method of record keeping for all sheeting work at site.

3. REFERENCE

Sheeting work will be conformed to EIL contract document

Contract manual

Standards

Material

Sheeting shall be conformed to EIL contract document

IS codes

Design Basis

Special condition

4. PROCEDURE

Shed roof structure to be completed in all respect like truss, purling, rigid ,welding, alignment, level etc

Take all safety requirement before erection of sheet on roof structure

Check the sufficient quantity material received at site or not

Erect the sheet with proper overlapping each other by crane / rope and pulley

Put the J bolt with , nut, washer, bitumen washer etc & tight properly with purling & sheet

Put the wind strip as per AFC drawing

Erect the ridged , drain etc as per drawing & specification

Cladding to be done as per AFC drawing

Page4of4

Complete the entire work in all respect

Final inspection to be done & hand over to GAIL / EIL

5. INSPECTION AND TEST DOCUMENT

Site inspection reports as per ITP No : 6724-700-50-47-ITP-008

Test report of all materials

INSPECTION & TEST PLAN FOR SHEETING

DOC. NO. - 6724-700-50-47-ITP-008

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

Sr.

No

Activities SEL EIL

Record to be

submitted

Remarks

1

Material test reports

WC

Rw

Yes

2 Completion of structure WC W

-

3 Fixing of sheets , Ridges, Corner, Gutter etc WC Rw

-

4

Checking of J bolt fixing wind Tie & bitumen

washer

WC W Yes

5 Final Inspection

WC

W

Yes

INSPECTION & TESTING DOCUMENTS

Site Inspection Report

WC

Rw

Yes

PREPARED BY REVIEWED BY CHECKED BY APPROVED BY

SEL SEL SEL EIL

Page1of4

J OB PROCEDURE FOR WBM ROAD

(PROCEDURE NO: 6724-700-50-47-J P-009)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL EIL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of4

(PROCEDURE NUMBER: 6724-700-50-47-J P-009)

J OB PROCEDURE FOR WBM ROAD

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. PROCEDURE

5. INSPECTIONS & RECORDS

Page3of4

J OB PROCEDURE FOR WBM ROAD

1. PURPOSE

The purpose of this procedure is for supervising of WBM Road and to insure that proper quality control is

exercised at site

2. SCOPE

This procedure covers supervision of WBM Road and method of record keeping for WBM Road works at

site.

3. REFERENCE

All work related to WBM Road will be conformed to EIL contract document

Special condition

AFC Drawings

IS codes

Design Basis

4. MATERIAL

Required material for WBM road shall be as per respective EIL specifications

5. PROCEDURE

Review of calibrating certification of instruments / testing equipments

Approval of source and checking / testing of material

Layout of road and road crossing to be check

Initial level to be taken

Filling of approved good soil for embankment in specified layers

Rolling the same and compacted till to achieve 95 % dry density

Checking of level

Spreading the metal to required thickness in line & level for base course

Page4of4

Dry rolling will be done

Spreading the murum and rolling

Spread the water and rolled till the proper binding of metal

Check the thickness after compaction

If the thickness found less , rectification will be done

Spread the second layer with murum and rolled and sequence layer to be spread as per AFC drawing

Total thickness of wbm is as per the AFC drawing

6. INSPECTION AND TEST DOCUMENT

Review of test reports and site inspection documents as per ITP No: 6724-700-50-47-ITP-009

INSPECTION & TEST PLAN FOR WBM ROAD

DOC.NO. - 6724-700-50-47-ITP-009

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR ,

RATNAGIRI

Sr.

No

Activities SEL EIL

Record to be

submitted

1

Review of calibration Certificates of instruments & testing

equipments

Field calibration , if any

WC

WC

HP

W

YES

YES

2

Layout checking including road crossing and taking initial

level

WC S

3

Approval of source & checking & testing of material

(wherever required)

WC HP YES

4

Filling (if any) compaction, providing camber in sub-

base including levels

WC S

5

Spreading metal to required thickness, line & level,dry

rolling including spreading of screening material

WC

S

6 Check for camber and levels over metalling WC S YES

7 Spreading murum / sand, watering and rolling WC S

8

Checking thickness after each layer and rectification

thereof (if any)

WC W

YES

9

Checking Quantity of aggregate by excavation of trial

pits as per IRC Code

WC W

YES

INSPECTION AND TEST DOCUMENT

Review test and inspection document WC Rw

PREPARED BY REVIEWED BY CHECKED BY APPROVED BY

SEL SEL SEL EIL

Page1of4

J OB PROCEDURE FOR FI RE PROOFING

(PROCEDURE NO: 6724-700-50-47-J P-010)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL SEL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of4

(PROCEDURE NUMBER: 6724-700-50-47-J P-010)

J OB PROCEDURE FOR FI RE PROOFING

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. PROCEDURE

5. INSPECTIONS & RECORDS

Page3of4

PROCEDURE NO. 6724-700-50-47-J P-010

J OB PROCEDURE FOR FI RE PROOFING

1. PURPOSE

The purpose of this procedure is for supervising of Fire proofing work and to insure that proper quality

control is exercised at site

2. SCOPE

This procedure covers supervision of Fire proofing work and method of record keeping for Fire proofing

work at site.

3. REFERENCE

Work related to fire proofing will be conformed to EIL specification

Special condition

IS codes and standards

Design basis

4. MATERIAL

Material required for Fire proofing shall be as per respective EIL specification

As per IS codes

5. PROCEDURE

Required material will be procured from standard / approved vendor only with MTC report. If MTC

report not available then take the material received sample and send to approved lab for testing with

respective IS code

Approved the required grade of concrete , with its trial cubes testing result

Locate the structure where fire proofing to be done

Weld the squared nuts on structure at 400 mm distance all around

Patch up the weld portion with specified primer, paint

Put the specified welded wire mesh on structure and tied up properly with 16 gauge binding wire

Page4of4

Put the shuttering as per the specified thickness of fire proofing and standard

Rigid the shuttering with clams, supports

Pour the approved grade of concrete, required testing cube to be taken

Finally finishing will be done with 1:2 cement mortar , if required

Put the final coat of approved shed snowcem paint

6. INSPECTION AND TEST DOCUMENT

Review of test reports & Inspection reports as per ITP NO 6724-700-50-47-ITP-010

INSPECTION & TEST PLAN FOR FOR FIRE PROOFING

DOC.NO. 6724-700-50-47-ITP-010

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

Sr.

No

Activities SEL EIL

Record to be

submitted

Remarks

1 Approval of source of material WC Rw

2

Instrument , Testing equipment, calibrating

certificate

WC

HP

Yes

3

Field calibration if any WC W Yes

4 Checking/ testing of material WC W/Rw Yes

5 Design mix approval WC HP Yes

6 Checking of weld mesh fixing , nut fixing etc WC W

7 Checking of shuttering and scaffolding etc WC S

8 Pour card WC HP

6724-700-50-

47-IR-001&002

9 Concreting , testing , finishing WC W YES

10 Casting of cubes WC W

11

Testing of cubes

7 days

28 days

WC

WC

W

W

YES

YES

6724-700-50-

47-IR-003

12 Removal of form work / staging WC S

13 Curing WC S

14

Surface painting WC S

INSPECTION & TESTING DOCUMENTS

Review test & site Inspection report

WC Rw YES

PREPARED BY REVIEWED BY CHECKED BY APPROVED BY

SEL SEL SEL EIL

Page 1 of 2

POUR CARD I (PROGRAMME OF CONCRETING)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDI TI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

CLIENT : M/s RGPPL, RATNAGIRI FORMAT NO: 6724-700-50-47-IR-001 REV.NO. - 0

PMC : M/s EIL REPORT NO :

DATE :

1. Reference document :

2. Type of Structure :

3. Levels From : To :

4. Grade of Concrete / Approved Design Mix

5. Brand Name, Grade and consignment no. cement

6. Estimated volume of concrete :

7. Quantity of cement required :

8. Reinforcement checking details :

No. Dia. Length

a) Laps

b) Separators

c) Chairs

d) Any other

Remarks

9. Pre pour inspection details Checked NA

a) Survey / Layout.

b) Sub soil compaction.

c) Completion of underground works.

d) Cleanliness.

e) Cover to reinforcement.

f) Anchor bolt.

g) Sleeves / pockets.

h) Water stopper.

i) Formwork.

j) Slopes.

k) Construction / Expansion joints.

l) Admixtures.

m) Any other.

Remarks

10.

Clearance for Electrical / Mechanical

Works required / not required

Electrical Mechanical

11.

The above structures finally inspected on at AM/PM and found / not found satisfaction for

concreting.

Remarks, if any

M/s SAVAIR ENERGY LIMITED M/s GAIL/EIL

NAME

SIGN

DATE

Page 2 of 2

Page 1 of 2

POUR CARD II (OBSERVATIONS DURING CONCRETING)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDI TI ONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR , RATNAGIRI

CLIENT : M/s RGPPL, RATNAGIRI FORMAT NO: 6724-700-50-47-IR-002 REV.NO. - 0

PMC : M/s EIL REPORT NO :

DATE :

1. a) Quality of course aggregates

Satisfactory Not to Satisfactory

b) Quality of fine aggregates

Satisfactory Not to Satisfactory

c) Bulk of sand taken into account

Yes No

2. Quality of Water

Satisfactory Not Satisfactory

3. Machinery mobilization

a) Mixture machine

b) Ready mix concrete dumpers

c) Vibrators

d) Pumps

e) Hoists

4. Pour start time AM/PM : Date :

5. Slump

6. W/C Ratio

7. Type Of Weather

Normal Abnormal

Detail of abnormality :

(Precautions taken for < 5 C and > 40 C, rainy season)

Page 2 of 2

8. Number of cubes taken :

9. Quantity of concrete poured :

10. Pour completion time : AM/PM : Date :

11. Curing Method

Traditional Curing compound

Blankets / foils / gunny bags Others ( specify)

12. Period for removal of form work.

13. Any defect (s) observed during concreting :

M/s SAVAIR ENERGY LIMITED M/s GAIL/EIL

NAME

SIGN

DATE

Name of work :

Reference : Type of Cement :

W / C Ratio : Max. size of Aggregate :

Page 1 of 2

CRUSHING STRENGTH RESULTS OF CONCRETE CUBES

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITI ONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR , RATNAGIRI

CLIENT : M/s RGPPL, RATNAGIRI FORMAT NO: 6724-700-50-47-IR-003 REV.NO. - 0

PMC : M/s EIL REPORT NO :

DATE :

Cube

No.

Id.

Mark

On

Cube

Type &

Location

of

Structure

Date of Age

(days)

Dimensions of Cube Vol.

of

Cube

(m)

Wt.

of

Cube

(kg)

Unit WT.

(kg/m)

Surface

Area

(cm)

Crushing

Load (kg)

Crushing

Strength

(kg/cm)

Remarks

Casting Testing L

(Cm)

B

(Cm)

H

(Cm)

M/s SAVAIR ENERGY LIMITED M/s GAIL/EIL

NAME

SIGN

DATE

Page 2 of 2

Page1of4

J OB PROCEDURE FOR UNDERGROUND PI PI NG

(PROCEDURE NO: 6724-700-50-47-J P-012)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL SEL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of4

(PROCEDURE NUMBER: 6724-700-50-47-J P-012)

J OB PROCEDURE FOR UNDERGROUND PIPING

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. PROCEDURE

5. INSPECTIONS & RECORDS

Page3of4

J OB PROCEDURE FOR UNDERGROUND PIPING

1. PURPOSE

The purpose of this procedure is for supervising of under ground piping work (RCC/ CI) to insure that

proper quality control is exercised at site

2. SCOPE

This procedure covers supervision of under ground piping (RCC/ CI) and method of record keeping for

underground work at site.

3. REFERENCE

WORK RELATED TO UNDER ground piping (RCC/CI) work will be conformed to EIL contract document

Special condition

IS codes

Design Basis

Approved drawing for construction

4. MATERIAL

Required material for underground piping work (RCC/CI) shall be as per respective EIL specifications

5. PROCEDURE

Material to be procured from standard / approved vendor only , with all MTC report

If MTC report not available / co related with material will be tested in approved lab , by sending of

sample from received material at site

Review of calibration certification of instrument / testing equipment

Field calibration will be done if required

Layout for piping , manhole to be done at site as per AFC drawing

Before excavating the trench or manhole, underground obstruction will be checked. If found anything

necessary precaution will be taken to protect it.

Page4of4

J oint level to be taken if required

After excavated trench for piping and for manhole/ chamber bed level to be checked and recorded

Lay the pipe line as per AFC drawing and jointing will be done

Make the manhole / chamber as per AFC drawing and grouting with pipe line

All joints will be curved

Before hydro test all joints, bed , supports etc will be visually checked

Hydro test will be done by filling of water in line & manhole chambers for leaking of joints

Record to be maintained

Removal of any blockages , cleaning and flushing of the system

Back filling will be done in specified layers and complexion test will be carried out

Checking of MS rings in manhole chambers , proper grouting with pipes for inlet / outlet pipes, and

level of inlet / outlet and manhole to be checked

Finally as built drawing will be prepared and hand over the system to EIL / GAIL

6. INSPECTION AND TEST DOCUMENTS as per ITP No: 6724-700-50-47-ITP-012

REVIEW TEST AND INSPECTION DOCUMENTS

INSPECTION & TEST PLAN FOR UNDERGROUND PIPING

DOC.NO. - 6724-700-50-47-ITP-012

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER COMPRESSOR ,

RATNAGIRI

Sr.

No

Activities Contractor EIL

Record to be

submitted

Remarks

1 Checking of material WC W YES

2

Adequate slope, benching in excavation for safety

purposes if required

a) review of calibration certificates of

instruments / testing equipments

b) Field calibration, if any

WC

WC

S

HP

YES

YES

3 Layout Line & level WC W

4 Laying & joining, grouting at manhole/chambers WC S

5 Check for supports/firm bed / sub soil water level WC S YES

6 Testing for leakages by blocking pipe ends WC S YES

7

Hydro-testing and other test, Removal of

blockages, Cleaning & flushing of system

WC

W

YES

8 Back filling in layers WC HP

9

Check for MS rungs in proper position, inlet/outlet

pipe levels in manholes

WC

S

10 Preparation of As Built Drawings WC S YES

INSPECTION & TESTING DOCUMENTS

Review test & Inspection Document

WC Rw

PREPARED BY REVIEWED BY CHECKED BY APPROVED BY

SEL SEL SEL EIL

Page1of3

J OB PROCEDURE FOR DI SMANTLI NG OF RCC (EXI STI NG)

(PROCEDURE NO: 6724-700-50-47-J P-013)

PROJ ECT : PROCUREMENT AND INSTALLATION OF ADDITIONAL BOIL OFF GAS (BOG) BOOSTER

COMPRESSOR, RATNAGIRI

CLIENT : M/s RATNAGIRI GAS AND POWER PRIVATE LIMITED

. (Promoters: M/S NTPC Limited & GAIL (INDIA) Limited)

CONSULTANT : M/s ENGINEERS INDIA LIMITED

CONTRACTOR : M/s SAVAIR ENERGY LIMITED

PREPARED BY CHECKED BY REVIEWED BY APPROVED BY

ORGANIZATION SEL SEL SEL EIL

SIGNATURE

NAME GANESH K. RAKESH P. MILIND D.

DATE

Page2of3

(PROCEDURE NUMBER: 6724-700-50-47-J P-013 )

J OB PROCEDURE FOR DISMANTLING OF RCC (EXISTING)

CONTENTS

1. PURPOSE

2. SCOPE

3. REFERENCE

4. PROCEDURE

5. INSPECTIONS & RECORDS

Page3of3

J OB PROCEDURE FOR DISMANTLING OF RCC (EXISTING)

1. PURPOSE

The purpose of this procedure is for supervising of dismantling of RCC (Existing) and to insure that proper

safety and other damages could not be at site

2. SCOPE

This procedure covers supervision of dismantling of RCC (Existing) and record keeping for dismantling of

RCC work at site.

3. REFERENCE

Work related to dismantling of RCC (Existing) will be conformed to EIL specification

4. PROCEDURE

Mark the structure to be dismantled

Disconnect all the services like power gas supply , water etc

Barricading the area where dismantling work place

Verify & ensure the all workers should used appropriate PPE

Keep the fire fighting arrangement

Check the gas cutter , J ack hammer, Air compressor condition

Mark or decide the where initial debris of dismantling to be stored

Make the disposal arrangement from the mark or decided area to designated area

Take all the precautions so that neighboring structure could not be damage

Ensured the First Aid arrangement at site

Finally finished the area after complete dismantling

Вам также может понравиться

- ITP For Civil and StructuralДокумент60 страницITP For Civil and StructuralMohan Babu100% (1)

- Itp Civil WorkДокумент9 страницItp Civil WorkChristian Albert Sinaga RumajarОценок пока нет

- G05.4 - Civil WorksДокумент107 страницG05.4 - Civil WorksLandon Mitchell100% (1)

- ITPДокумент11 страницITPMohammad Hadoumi Saldan100% (1)

- M.S & R.S For Soil Investigation WorksДокумент14 страницM.S & R.S For Soil Investigation WorksAL BASTAKI CONTRACTING L.L.C.100% (1)

- B-QAC-PLN-210-39157 SARPI ITP For Site Preparation and Earth WorksДокумент26 страницB-QAC-PLN-210-39157 SARPI ITP For Site Preparation and Earth WorksZaidi100% (1)

- ITP - Concrete WorksДокумент17 страницITP - Concrete WorksVasilica BArbarasa100% (2)

- Itp BuildingДокумент42 страницыItp BuildingHaekal RamadhanОценок пока нет

- 026-Itp For Structural Steel PDFДокумент18 страниц026-Itp For Structural Steel PDFKöksal Patan100% (11)

- Method Statement For Fabrication Works Structural SteelДокумент13 страницMethod Statement For Fabrication Works Structural SteelRohit SharmaОценок пока нет

- Field ITP Civil Rev-8after Lump-Sump.Документ17 страницField ITP Civil Rev-8after Lump-Sump.Echik Kici100% (3)

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Документ37 страницIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedОценок пока нет

- ITP For Steel StructureДокумент3 страницыITP For Steel Structuretrey100% (4)

- Inspection and Test Plan Piling: 1. Document ReviewДокумент3 страницыInspection and Test Plan Piling: 1. Document ReviewZara BhaiОценок пока нет

- ITP - Civil WorkДокумент5 страницITP - Civil WorkShabeer Shaarim Abdul JabbarОценок пока нет

- Itp For Painting WorksДокумент28 страницItp For Painting WorksAhmed saberОценок пока нет

- Dgs-Civil WorksДокумент18 страницDgs-Civil WorksMuhammad NazamОценок пока нет

- 20.104 Construction of SteelworkДокумент52 страницы20.104 Construction of SteelworkWilliam Chong100% (2)

- Civil ItpДокумент60 страницCivil ItpBiswas100% (1)

- CON 311 V00 Method Statement For Structural Steel and Pipe Support Fabrication PDFДокумент22 страницыCON 311 V00 Method Statement For Structural Steel and Pipe Support Fabrication PDFfurkanОценок пока нет

- Inspection and Test Plan - StructureДокумент15 страницInspection and Test Plan - StructureFerdie OSОценок пока нет

- Preparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction OperationsДокумент5 страницPreparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction Operationssateeshsingh100% (2)

- Method Statement For Steel Pipe Pile Fabrication CorrectedДокумент43 страницыMethod Statement For Steel Pipe Pile Fabrication CorrectedOlugbemiga James OlalekanОценок пока нет

- Inspection and Test PlanДокумент6 страницInspection and Test PlanMadison ChanОценок пока нет

- ITP Piling WorksДокумент4 страницыITP Piling WorksMohammad Hadoumi Saldan100% (1)

- Civil Engineering ExaminationДокумент4 страницыCivil Engineering Examinationshardultagalpallewar100% (2)

- 6-15-0006 Rev 4Документ7 страниц6-15-0006 Rev 4cynideОценок пока нет

- 7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingДокумент9 страниц7T04-CS-00-PC-011 R13 Consruction Procedure For Alloy Steel PipingMoustafa FaresОценок пока нет

- B-QAC-PLN-210-39154 SARPI ITP For Structural Steel Erection WorksДокумент19 страницB-QAC-PLN-210-39154 SARPI ITP For Structural Steel Erection WorksZaidi50% (2)

- Technical Specifications For Piling WorksДокумент10 страницTechnical Specifications For Piling WorksArzath SajeerОценок пока нет

- Material Approval Request: North-South Commuter Railway Extension ProjectДокумент2 страницыMaterial Approval Request: North-South Commuter Railway Extension ProjectResearcherОценок пока нет

- INS-P-006-Procedure For Inspection of PlatesДокумент4 страницыINS-P-006-Procedure For Inspection of PlatesDeepak100% (1)

- Simple Drilling MethodsДокумент4 страницыSimple Drilling MethodsGreen Action Sustainable Technology GroupОценок пока нет

- QA-000-AA-5016 ITP For Stone Colume Rev. 0 (Approved)Документ15 страницQA-000-AA-5016 ITP For Stone Colume Rev. 0 (Approved)AbrahamAbraciaОценок пока нет

- Excavation Trenching & BackfillДокумент12 страницExcavation Trenching & BackfillphilipyapОценок пока нет

- ITP AllДокумент1 страницаITP AllMuhammadIqbalMughalОценок пока нет

- ITP-CI-026a-02 (Building Finishing Works)Документ4 страницыITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyОценок пока нет

- Steel Structure ErectionДокумент33 страницыSteel Structure ErectionAhmed ImranОценок пока нет

- Method Statement - Non-Metallic Pipeline Instalation & Pull Through To HDDДокумент8 страницMethod Statement - Non-Metallic Pipeline Instalation & Pull Through To HDDMuhammad IrsyadiОценок пока нет

- Method Statement - PilingДокумент65 страницMethod Statement - PilingNaseer IsmailОценок пока нет

- ITP C 005 (Structural Concrete)Документ4 страницыITP C 005 (Structural Concrete)segun ajibolaОценок пока нет

- Inspection and Test Plan - StructureДокумент14 страницInspection and Test Plan - StructureFerdie OSОценок пока нет

- Project Internal Audit Procedure: Name Position Signature Date Prepared byДокумент7 страницProject Internal Audit Procedure: Name Position Signature Date Prepared byTwin Bulls100% (1)

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Документ4 страницыFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- Elding Rocedure Pecification: 7200-HDPE Butt WeldДокумент2 страницыElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifОценок пока нет

- MOS-CVL-11 Concrete Repair MOSДокумент2 страницыMOS-CVL-11 Concrete Repair MOSWaqar Ahmad MalikОценок пока нет

- ITP For Steel Structure1Документ3 страницыITP For Steel Structure1吴兴泊Оценок пока нет

- ITP For Pile Splicing Work & Miscellaneous WorkДокумент3 страницыITP For Pile Splicing Work & Miscellaneous WorkMuthu Barathi ParamasivamОценок пока нет

- Excavation Work ProcedureДокумент11 страницExcavation Work ProcedureResearcher100% (1)

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Документ17 страницIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedОценок пока нет

- Concrete Work: (Please Provide Detail of Repair Activities E.G)Документ2 страницыConcrete Work: (Please Provide Detail of Repair Activities E.G)Eze NonsoОценок пока нет

- Excavation and Backfill: Method StatementДокумент6 страницExcavation and Backfill: Method Statementtrealdi suryoОценок пока нет

- ITP FW For Civil Building WorksДокумент17 страницITP FW For Civil Building WorksAjit Singh RathoreОценок пока нет

- JMC Office Building Construction Inspection and Testing PlanДокумент41 страницаJMC Office Building Construction Inspection and Testing Planmurtada kamilОценок пока нет

- Itp Lime StabilizationДокумент2 страницыItp Lime StabilizationMikiRoniWijayaОценок пока нет

- NDT Structural SteelДокумент35 страницNDT Structural Steeltinz_3100% (2)

- ITP-FW For Civil & Building WorksДокумент17 страницITP-FW For Civil & Building WorksRajnath Rajbhar Pancham86% (7)

- BH-04, Final ReportДокумент16 страницBH-04, Final ReportcivilceejiОценок пока нет

- 5779-004-Pvc-W-Specs - 002 - R0Документ33 страницы5779-004-Pvc-W-Specs - 002 - R0bansalhimanshu07Оценок пока нет

- Bridge No 40Документ24 страницыBridge No 40Toushik Ahamed MollaОценок пока нет

- Execut I Ve Post GR Aduat e PR Ogr Amme I N Management: For Wor Ki NG PR of Essi Onal S Bat CH - 14 Admi SSI ON - 2021Документ17 страницExecut I Ve Post GR Aduat e PR Ogr Amme I N Management: For Wor Ki NG PR of Essi Onal S Bat CH - 14 Admi SSI ON - 2021Hitendra PanchalОценок пока нет

- CP SCM IITbombay 090921Документ19 страницCP SCM IITbombay 090921Hitendra PanchalОценок пока нет

- Alexandr - Trade For A LifeДокумент312 страницAlexandr - Trade For A LifeHitendra PanchalОценок пока нет

- Execut I Ve Post GR Aduat e PR Ogr Amme I N Management: For Wor Ki NG PR of Essi Onal S Bat CH - 14 Admi SSI ON - 2021Документ17 страницExecut I Ve Post GR Aduat e PR Ogr Amme I N Management: For Wor Ki NG PR of Essi Onal S Bat CH - 14 Admi SSI ON - 2021Hitendra PanchalОценок пока нет

- Seven Secrets To Crude Oil Futures Trading SuccessДокумент16 страницSeven Secrets To Crude Oil Futures Trading SuccessSatish KumarОценок пока нет

- Terms and Condition of Zomato Offer: DefinitionsДокумент2 страницыTerms and Condition of Zomato Offer: DefinitionsHitendra PanchalОценок пока нет

- Male ReproduksiДокумент11 страницMale ReproduksiEri Sarmantua SitinjakОценок пока нет

- Alexandr - Trade For A LifeДокумент312 страницAlexandr - Trade For A LifeHitendra PanchalОценок пока нет

- Sunil Parameswaran Futures Markets Made Easy With 250 QuestionsДокумент341 страницаSunil Parameswaran Futures Markets Made Easy With 250 QuestionsHitendra PanchalОценок пока нет

- FAME Booklet - FIDD Central Office PDFДокумент40 страницFAME Booklet - FIDD Central Office PDFHitendra PanchalОценок пока нет

- The Five Minute Investor PDFДокумент75 страницThe Five Minute Investor PDFatilio2Оценок пока нет

- Fundamental Analysis For InvestorsДокумент213 страницFundamental Analysis For InvestorsTheVagabond Harshal100% (19)

- Trading in The Buff E-BookДокумент42 страницыTrading in The Buff E-Bookking5459Оценок пока нет

- Dabur Buy ICICIDirect 20200731 PDFДокумент9 страницDabur Buy ICICIDirect 20200731 PDFHitendra PanchalОценок пока нет

- FAME Booklet - FIDD Central Office PDFДокумент40 страницFAME Booklet - FIDD Central Office PDFHitendra PanchalОценок пока нет

- FT Letter PDFДокумент1 страницаFT Letter PDFHitendra PanchalОценок пока нет

- A Report On The Indian Exchange Traded Funds (ETF) IndustryДокумент26 страницA Report On The Indian Exchange Traded Funds (ETF) IndustryHitendra PanchalОценок пока нет

- Decoupling Between Equities & EconomyДокумент10 страницDecoupling Between Equities & EconomyHitendra PanchalОценок пока нет

- Robert Fox PresentationДокумент27 страницRobert Fox PresentationKapil SharmaОценок пока нет

- Weekly: Join in Our Telegram Channel - T.Me/Equity99Документ6 страницWeekly: Join in Our Telegram Channel - T.Me/Equity99Hitendra PanchalОценок пока нет

- Weekly: Join in Our Telegram Channel - T.Me/Equity99Документ6 страницWeekly: Join in Our Telegram Channel - T.Me/Equity99Hitendra PanchalОценок пока нет

- Tiered Campuses ListДокумент8 страницTiered Campuses ListHitendra PanchalОценок пока нет

- Dabur Buy ICICIDirect 20200731 PDFДокумент9 страницDabur Buy ICICIDirect 20200731 PDFHitendra PanchalОценок пока нет

- Firms Not Falling in Any of Above Categories May BeДокумент3 страницыFirms Not Falling in Any of Above Categories May BeHitendra PanchalОценок пока нет

- Comp Off Approved Policy PDFДокумент2 страницыComp Off Approved Policy PDFHitendra PanchalОценок пока нет

- COncrete Design MixДокумент1 страницаCOncrete Design MixHitendra PanchalОценок пока нет

- Savair Energy LTD: Issued For Approval Issued For ApprovalДокумент29 страницSavair Energy LTD: Issued For Approval Issued For ApprovalHitendra PanchalОценок пока нет

- 6 Quality ProcedureДокумент74 страницы6 Quality ProcedureHitendra PanchalОценок пока нет

- 2) Rotery Compressor Datasheet Rev CДокумент9 страниц2) Rotery Compressor Datasheet Rev CHitendra PanchalОценок пока нет

- Fluid Flow Hydraulics Sizing and Selection Rev WebДокумент58 страницFluid Flow Hydraulics Sizing and Selection Rev WebHitendra Panchal100% (1)

- Sample Tender Evaluation Report Annex 20Документ4 страницыSample Tender Evaluation Report Annex 20Tan Min Wee100% (2)

- Apply Quality ControlДокумент24 страницыApply Quality Controlrame100% (1)

- SOP For Development of An Investigator Brochure or IMP DossierДокумент7 страницSOP For Development of An Investigator Brochure or IMP DossierMondo BijaineОценок пока нет

- CMT 0034Документ5 страницCMT 0034mpedraza-1Оценок пока нет

- Alarm Systems: Design, Management and Procurement: Suggested Checklist For An Alarm Management Philosophy DocumentДокумент2 страницыAlarm Systems: Design, Management and Procurement: Suggested Checklist For An Alarm Management Philosophy DocumentOleksii FilipovОценок пока нет

- Report en PDFДокумент111 страницReport en PDFJo K ErОценок пока нет

- HCML Recruitment February 2021Документ4 страницыHCML Recruitment February 2021Fanny ArdiansyahОценок пока нет

- UFC 3-120-10 Interior Design, With Change 1 (06!15!2006)Документ53 страницыUFC 3-120-10 Interior Design, With Change 1 (06!15!2006)Bob VinesОценок пока нет

- Isa 5.4Документ22 страницыIsa 5.4Tiago Santos Silva100% (1)

- Section 09940 METAL PAINTINGДокумент14 страницSection 09940 METAL PAINTINGIm ChinithОценок пока нет

- Teco ManualДокумент227 страницTeco ManualauragniОценок пока нет

- MX200 Design en R01Документ116 страницMX200 Design en R01אנדרי שניידר100% (1)

- Business Consultant JD IGT SolutionsДокумент2 страницыBusiness Consultant JD IGT SolutionsHarneet SinghОценок пока нет

- System Design and ModelingДокумент3 страницыSystem Design and Modelingsbr11Оценок пока нет

- Lembaga Arkitek Malaysia: General Circular No. 2/2017 (Amendment 2017)Документ20 страницLembaga Arkitek Malaysia: General Circular No. 2/2017 (Amendment 2017)Lem TeohОценок пока нет

- AMENDED BIDDING DOCUMENTS GPG-B1-2020-430 BFP-NHQ FIRETRUCKS Part 2 PDFДокумент49 страницAMENDED BIDDING DOCUMENTS GPG-B1-2020-430 BFP-NHQ FIRETRUCKS Part 2 PDFMonkey D LuffyОценок пока нет

- Cargill Sem Manual enДокумент16 страницCargill Sem Manual enAnnisa IchaОценок пока нет

- MS JDB 007 - Annexure 2 - ABE Epidermix 344Документ2 страницыMS JDB 007 - Annexure 2 - ABE Epidermix 344Ben WalkerОценок пока нет

- Exam ManualДокумент48 страницExam ManualNilakshi Barik MandalОценок пока нет

- A Buyers Guide To Mezzanine Floors 2020Документ22 страницыA Buyers Guide To Mezzanine Floors 2020Llonsson50% (2)

- KSEB Technical SPec PDFДокумент279 страницKSEB Technical SPec PDFTravis WoodОценок пока нет

- Guideline Book r10 7 JULY 2017 PDFДокумент117 страницGuideline Book r10 7 JULY 2017 PDFHrishikesh RokadeОценок пока нет