Академический Документы

Профессиональный Документы

Культура Документы

Experimental Work: Chapter No.3

Загружено:

saabiaanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Experimental Work: Chapter No.3

Загружено:

saabiaanАвторское право:

Доступные форматы

Chapter No.

3

EXPERIMENTAL WORK

PDF created with pdfFactory Pro trial version www.pdffactory.com

MATERIALS AND METHODS

The study was divided into two parts.

(A) Production of glucose oxidase from Aspergillus niger.

(B) Commercial application of glucose oxidase.

3.1 (A) Production of glucose oxidase from Aspergillus niger

Glucose oxidase was produced from Aspergillus niger by the submerged fermentation

following the methods of Fidurek and Gromada (1996) with some changes. The study of

this part includes following aspects:

3.1.1 Screening of sources for the microbial strain producing highest GOX activity

along with optimizing pH and carbon source.

3.1.2 Optimization of other fermentation conditions for improved GOX production like

fermentation period, MgSO

4

, KH

2

PO

4

, and urea.

3.1.3 Enzyme kinetics

3.1.4 Enhanced GOX production by UV mutation

3.1.5 Purification of GOX.

3.1.1 Screening for the fungal strain producing the highest GOX activity along

with optimizing carbon source and pH

For commercial production of enzyme first step is the screening of different native strains

for the optimal enzyme production.

So in this section different strains of A. niger were examined along with optimization of

two growth conditions pH and carbon source, (i.e. glucose concentration) for the optimal

production of glucose oxidase. This will help the commercial production of glucose

oxidase in Pakistan.

3.1.1.1 Microorganism

The strains of A. niger were isolated from five different sources (bread, potato, grapes,

pickle, sugar beet) identified from the fungal culture bank (FCB) at Punjab University

Lahore. They were grown on malt extract agar medium at pH 5.5 and with following

composition (gl

-1

).

PDF created with pdfFactory Pro trial version www.pdffactory.com

1. Malt extract 20 g

2. Peptone 2.5 g

3. Agar 10 g.

The medium was prepared by weighing accurately 1-3 and dissolving them in 500 ml of

distilled water. The medium was boiled, with constant stirring for 15 minutes and was

poured into clean test tubes. The tubes were plugged with sterilized cotton and autoclaved

at 20 lbs PSI at 100C for 15 minutes. After autoclaving the tubes were placed in slanting

position for 24 hours. Transfer of strains on fresh medium continued after every two

weeks. These pure and identified colonies were kept in the refrigerator at 4C for storage.

3.1.1.2 Substrate (carbon source)

Glucose obtained from biochemistry Lab. Chemistry Department, GC University Lahore

was used as carbon source for the growth and production of glucose oxidase.

3.1.1.3 Fermentation

The enzyme was produced by submerged fermentation of A. niger in 250 ml shake flask.

The fermentation medium with the following composition was used.

Table 3.1 Composition of fermentation medium.

No. Compounds Amount g/100 ml

1. NaNO

3

12.5

2. Urea 0.2

3. MgSO

4

.7H

2

O 1.25

4. FeSO

4

.7H

2

O 0.025

5. KH

2

PO

4

2.5

6. CaCO

3

1.75/25 ml H

2

O

(Petruccioli and Federici, 1993) with some amendments i.e. urea used instead peptone

and no KCl was added in the medium.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Table 3.2 Composition of components used in the 250 ml flask.

No. Ingredients Amounts

1. CaCO

3

1.75 g/25 ml

2. NaNO

3

2 ml

3. Urea 2 ml

4. MgSO

4

.7H

2

O 2 ml

5. FeSO

4

.7H

2

O 2 ml

6. KH

2

PO

4

2 ml

7. Glucose 10 ml

8. Spore suspension 5 ml

(i) Substrate level (carbon source):

The required glucose amount (4.0, 5.0, 6.0, 7.0, 8.0, 9.0, 10.0, 11.0, 12.0 and 13.0%(w/v)

was dissolved in 100 ml water. After sterilization, 10 ml of above different

concentrations of glucose solution was added to the flasks containing 35 ml of the sterile

fermentation medium containing the compounds mention in table 3.2 (2ml each) and

were inoculated with 5 ml spore suspension (10

7

10

8

spore/ml) (Collins et al; 1984).

Now the flask contained sterilized growth media of about 50 ml (shown in table 3.2)

which was already autoclaved at 20 lbs. PSI at 100C for 15 minutes.

(ii) pH of media

The required pH of the medium (4.0, 4.5, 5.0, 5.5, 6.0, 6.5, 7.0, 7.5 and 8.0) was adjusted

by 1M HCl and 1M NaOH. These flasks were then incubated in shaking incubator at 100

rpm and 30C for 48 hours (Willis, 1966). The fungal spores were also counted by

Thoma Counting Chamber (Collins et al; 1984). All the experiments were carried out in

triplicate.

3.1.1.4 Enzyme extraction and partial purification

After 48 hours of incubation in shaking incubator at 30C, the mycelia were collected by

filtration and washed with distilled water. The mycelia collected were weighed. The

washed mycelia were crushed in sodium citrate buffer (0.1 M pH = 5) In Mortar and

Pestle for 30 minutes and centrifuged at 10,000 rpm for 10 minutes mycelium debris was

PDF created with pdfFactory Pro trial version www.pdffactory.com

separated and kept for dry mass estimation. The filtrate was precipitated with (NH

4

)

2

SO

4

and kept at 4C overnight. The precipitate was collected by centrifugation at 10,000 rpm

for 10 minutes. Each sample were dissolved in 2 ml of distilled water and refrigerated.

3.1.1.5 Assay of GOX

The glucose oxidase activity was determined by the fast spectrophotometric method by

following the enzymatic reduction of benzoquinone to hydroquinone at 290 nm using

glucose as substrate (Ciucu and Patroescu, 1984, Dr. Abdul Hameed and Khawar)

One unit (u) of enzyme activity was defined as the amount of enzyme producing one

micromole of hydrogen peroxide per minute at 30C.

It was also defined as the amount of enzyme catalyzing the decomposition of one

micromole of hydrogen-peroxide per minute at 30C or One unit catalysis the oxidation

of 1 mole glucose to gluconic acid per minute at 25C pH 5 coupled with peroxide and

1-4 benzoquinone. Glucose oxidase oxidize glucose to gluconic acid and H

2

O

2

produced

in above reaction reduces benzoquinone to hydroquinone. Both spectrometer cell (A and

B) were filled up with 2 ml of 1 M glucose solution which was prepared a day before at

room temperature so that and anomers formed at equilibrium.

In cell A, 1.0 ml of 0.1% benzoquinone solution (0.01 g in 10 ml distilled water) and 1.0

ml of buffer solution (sodium citrate buffer of 0.1 M, pH = 5) were added. This cell was

taken as standard. In cell B, 1.0 ml of 0.1% benzoquinone solution and 0.9 ml of sodium

citrate buffer were added. The mixtures of both cell (A and B) were allowed to

equilibrate at 25C for 5 minutes.

In cell B, at time zero 0.05 ml of glucose oxidase solution was added and mixture was

stirred. An increase in absorbance at 290 nm was recorded for 1 2 minutes.

PDF created with pdfFactory Pro trial version www.pdffactory.com

(UV-Cecil CE 7200 Spectrophotometer)

This rate was used to calculate the enzyme activity as follows:

Enzyme activity at 25C =

mM

290

A V

I A u

V

moles HQ/min/ml

Where

V = 4.0 ml, volume of reaction mixture

= 0.05 ml, GOX solution

A

290

mM

= 2.31, molecular absorption co-efficient of HQ

(hydroquinone) at ) = 290 nm

I = 2 cm, length of cell.

*A = the actual absorbance of sample after

sub starting the control.

Above equation become.

Enzyme activity = 17.316 x *A

= moles HQ/min/ml

Specific activity =

17.316 A

mgprotein/ml

V

= mole HQ/min/mg Protein.

3.1.1.6 Protein estimation

Proteins were estimated according to the method described by Moss and Bond (1957).

3.1.1.6.1 Reagents

Solution A = 40 gm sodium carbonate in 500 ml distilled water.

Solution B = 0.38 gm CuSO

4

.5H

2

O and 0.6 gm potassium-sodium tartarate

in 500 ml distilled water.

Solution C = 1 part Folin reagent (Folin ciocaltems phenol reagent BDH) and 2

parts of H

2

O (prepared just before use)

Solution D = 1N NaOH.

3.1.1.6.2 Standard bovine serum albumin solution (500 g ml

-1

)

5.0 mg of Bovine Serum Albumin (BSA) was dissolved in 10 ml of distilled water. The

serum albumin dissolved very slowly. The standard was made two days before use and

kept at 4C.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.1.1.6.3 Procedure

0.5 ml NaOH 1N (sol. D) was added in each tube containing protein sample (250-750 g)

and were shaken in water bath (37C) for 30 minutes. After cooling 2.6 ml of solution A

and 2.5 ml of solution B was added in each sample as well as in standard tube. The

solution in each tube was thoroughly mixed and incubated at 37C for 30 minutes. Then

0.5 ml of solution C was added, mixed well and kept for 20 minutes at room temperature.

BSA (0.05 1.5 ml) was simultaneously used in experiment. The optical density was

measured at 661nm on spectrophotometer (UV-Cecil CE 7200) and a standard calibration

curve was drawn and with its help the proteins were estimated.

0.00

0.10

0.20

0.30

0.40

0.50

0.60

0.70

0.00 0.05 0.10 0.15 0.20 0.25 0.30

Concentrations (mg/mL)

A

b

s

o

r

b

a

n

c

e

(

O

D

)

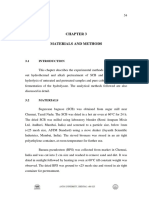

Fig-3.1 Standard curve for bovine serum albumin for protein estimation

3.1.2 Optimization of fermentation conditions for max. GOX

production

The conditions for glucose oxidase production by A. niger were also optimized other than

substrate level (carbon source i.e. glucose) and pH optimization was carried out along

with screening of fungal strains in the previous section (3.1).

PDF created with pdfFactory Pro trial version www.pdffactory.com

The medium containing glucose was cultured with A. niger isolated from potato

(screened in previous section) for different incubation periods with varying

concentrations of urea, CaCO

3

, MgSO

4

.7H

2

O and KH

2

PO

4

at 30C in shake flask.

3.1.2.1 Submerged fermentation

Triplicate flasks of 250 ml containing 50 ml of sterilized growth media along with 5 ml

of spore suspension were incubated at 30 on shaking incubator (100 rpm) for each

condition to be optimized.

3.1.2.2 Sample preparation

After 48 hours incubation experimental flasks (in each experimental process) were

harvested. The process of enzyme extraction is described in section 3.1.

3.1.2.3 Glucose oxidase assay

GOX activity was measured by method of which was Ciucu and Patroescu (1984),

described in section 3.1.

3.1.2.4 Fermentation period (incubation time)

The growth media containing 10% (w/v) glucose as substrate at pH = 5.5 (both

conditions optimized in previous section) contained in 10 flasks were sterilized,

inoculated and were incubated at 30C under continuous shaking condition (100 rpm).

Triplicate growth media were incubated for 12, 24, 36, 48 and 60 hours.

3.1.2.5 CaCO

3

The effect of different concentrations of CaCO

3

(i.e. 1.5, 2.5, 3.5 and 4.5%) in the

medium were studied for maximum production of GOX.

3.1.2.6 Nitrogen source (urea)

The concentrations of urea (nitrogen source i.e. 0.1, 0.2, 0.3, 0.4 and 0.5%) have a

considerable influence on GOX production. Different concentrations of urea were added

into the fermentation medium having 10% glucose at pH 5.5.

3.1.2.7 KH

2

PO

4

The effect of different concentrations of KH

2

PO

4

(i.e. 0.2, 0.4, 0.6, 0.8 and 1.0%) were

studied on GOX production in the medium containing optimum concentration of glucose

(10%), Urea (0.2%), and CaCO

3

(3.5%) at pH 5.5.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.1.2.8 MgSO

4

.7H

2

O

Different concentrations of MgSO

4

.7H

2

O i.e. 0.01, 0.02, 0.03 and 0.04%were examined

for GOX activity in pre-optimized culture medium with 10% glucose, 0.4% KH

2

PO

4

,

0.2% Urea, 3.5% CaCO

3

at pH 5.5 and 30C.

3.1.3 Enzyme kinetics

The effect of temperature on the enzyme activity was also investigated. Effect of aeration

on GOX production in shake flask (oxygen supply) was also investigated.

The effect of aeration rate on GOX production by A. niger (source potato) was studied by

changing the shaking speed as well as the volume of the medium in the flasks. Different

volumes of the medium in 250 ml conical flasks (such as 20, 30, 40, 50, 60 and 80 ml)

and different speeds of the shaker such as (50, 100 and 150 rpm) were tested (Table

4.17).

3.1.4 Enhanced GOX production by UV mutation

A mutation is a permanent change in the DNA sequence of gene. Mutation is a genes

DNA sequence can alter the amino acid sequence of the protein encoded by the gene.

How does this happen? The DNA sequence of each gene determines the amino acid

sequence for the protein it encodes. The DNA sequence is interpreted in groups of three

nucleotide bases, called codons. Each codon specifies a single amino acid in the

polypeptide chain.

3.1.4.1 Microorganism

The fungal strain of A. niger was isolated from potato source and identified from FCB.

Punjab University Lahore and was grown on malt extract agar medium at pH 5.5 as

described earlier in the section (3.1.1.1). The cultures were stored in the refrigerator at

4C for further studies.

3.1.4.2 Preparation for mutagenesis

One ml of prepared conidial inoculums was transferred to 100 ml of sterilized water. This

conidial suspension was further diluted up to 10-30 by serial dilution method.

3.1.4.3 Ultraviolet treatment

Diluted conidial suspension (10 ml) was transferred in the sterilized petri plates. The Petri

plates were placed under the UV lamp (emitting the energy of 2.6 x106 J/m2/S) in the

laminar flow for 5- 60 minutes. After different time intervals 0.5 ml of the irradiated

PDF created with pdfFactory Pro trial version www.pdffactory.com

conidial suspension was transferred to the petri plates containing malt extract agar with 2-

Deoxy D- glucose medium. The Petri plates were then placed in the incubator at 30

o

C for

3-4 days. The young colonies of Aspergillus niger on the petri plates were picked up and

transferred to the malt extract slants

3.1.4.4 Fermentation technique

Submerged fermentation technique was employed process is same as described in

previous section (3.1.1.3).

3.1.4.5 Enzyme extraction:

The enzyme extraction was carried out using the method explained in previous section

(3.1.1.4)

3.1.4.6 Enzyme assay

The process details have been described in previous section (3.1.1.5).

3.1.5 Purification of glucose oxidase

Following steps are involved for the purification of glucose oxidase from A. niger.

Filtration

(NH

4

)

2

SO

4

Precipitation

Dialysis

Gel filtration using Sephadex G-75

3.1.5.1 Filtration

After 48 hours of incubation at 30

o

C and 120 rmp the culture medium was filtered

through nylon gauze to remove the mycelia. The mycelia were washed with distilled

water and the whole solution then filtered through filter paper. The pH of filtrate was

adjusted at 5.0 by using citrate buffer and NaOH and filtrate was placed at 4

o

C for 60

minutes and enzyme activity was calculated.

3.1.5.2 (NH

4

)

2

SO

4

Precipitation

Ammonium sulphate precipitation (salting out) is a technique used to precipitate proteins

from solution by increasing the ionic strength of the solution. The technique is reliant on

the hydrophobic nature of proteins, since they contain hydrophilic and hydrophobic

groups. When the proteins are dissolved, water is forced into contact with the proteins

hydrophobic groups and in the process becomes ordered around the proteins. Increasing

PDF created with pdfFactory Pro trial version www.pdffactory.com

the concentration of salt ions by the addition of ammonium sulphate causes the water to

be removed from around the protein exposing the hydrophobic portions of the proteins.

Precipitation of the proteins will then occur due to the aggregation of proteins via the

exposed hydrophobic portions. This technique is used to fractionate the proteins from

solution since proteins with larger or more hydrophobic portions will aggregate and

precipitate before those with smaller or fewer proteins of hydrophobic groups.

Procedure

Solid ammonium sulphate is added to 100ml of solution of glucose oxidase at the

concentration of 30% (w/v). The suspension was stirred for half an hour at 4

o

C. After

sufficient shaking the precipitates were collected by centrifugation at 10,000 rpm for 30

minutes. Enzyme activity was determined for each concentration and precipitates were

collected for further purification. Enzyme solution was then treated with 40, 50, 60, 70

and finally 80% (w/v) (NH

4

)

2

SO

4

.

3.1.5.3 Dialysis

The precipitates obtained after ammonium sulphate precipitation procedure, were

suspended in small volume of Citrate buffer (pH 5) and dialyzed by using 12,000 d

molecular weight cut off dialysis bag , which was placed in 2 liters of Citrate buffer (pH

5) for 24 hours at 4

o

C against three changes. GOX activity of the dialyzed material was

determined (section 3.1.1.5).

3.1.5.4 Gel filtration using Sephadex G-75

The principle of gel filtration is based on elution of proteins on the basis of size and

shape of the molecules. Molecules of smaller size pass through the beads of gel and the

remaining larger sized pass through spaces between the gel beads. Larger molecules are

eluted earlier and smaller which travel inside the gel beads eluted later.

Reagents

0.1 M Citrate buffer (pH 5.0)

Dextrin blue (molecular weight 2x10

6

) solution (0.5% w/v)

Sephadex-G-75

PDF created with pdfFactory Pro trial version www.pdffactory.com

Procedure

Sephadex-G-75 was soaked in 500 ml of 0.1 M citrate buffer (pH 5.0) containing 0.1 g of

sodium azide and incubated at room temperature for 24 hours. After soaking, the gel was

deaerated by direct drive rotary vacuum pump and then poured in a 0.9 x 60 cm column.

The packed column was washed with 0.1 M citrate buffer (pH5.0). Dextran blue (0.5%

w/v) was used for the determination of its void volume. Dialyzed enzyme extract was

applied on the column and fractions each of 3 ml were collected. Each fraction was then

assayed for enzyme activity and the amount of the protein present. Fractions containing

enzyme activity were pooled and lyophilized (Jakoby 1971).

3.2 Commercial applications of glucose oxidase

In the present research projects two commercial applications of GOX were investigated;

3.2.1 Estimation of glucose by standardization of conditions using GOX.

3.2.2 The production of calcium gluconate, gluconic acid and its derivatives using

glucose oxidase.

3.2.1 Estimation of glucose by standardization of conditions using GOX

The disease involved in the elevation of blood glucose level is known as diabetes

mellitus. It is a very common disease now a days. It is a metabolic problem and is

prevalent in many parts of the world. One fundamental aspect of diabetes is an

abnormality of glucose metabolism due to in sufficient action of insulin, owing either to

its absence or to resist in action (Murray et al 2001). Blood glucose level in diabetes

becomes so elevated that the glucose spills over into urine, providing a convenient

diagnostic test for the disease (Voct et al 1999).

In the process of determination of glucose level there are involved three enzymes i.e.

mutarotase, glucose oxidase and peroxidase. The overall reaction mechanism is as

follows:

-D-glucose

Mutarotase

-D-glucose

-D-glucose

Glucose Oxidase

!-D-gluconolactone + H

2

O

2

2H

2

O

2

Peroxidase

2H

2

O + O

2

.

PDF created with pdfFactory Pro trial version www.pdffactory.com

The enzymes and their kits for glucose estimation are being imported at high cost and a

lot of foreign exchange is required. Economy of our country can not afford such high cost

kits so there is a need to optimize the conditions for such methods. So this part of the

project was designed to develop the technology to optimize the conditions for glucose

estimation using these 3 enzymes and to prepare low priced local kits as compared to

imported kits.

The three enzymes glucose oxidase, mutarotase and peroxidase were produced/extracted

and purified for the preparation and optimization of glucose estimation kit.

3.2.1.1 Glucose oxidase

Glucose Oxidase was produced by submerged fermentation using glucose as substrate

and Aspergillus niger (source potato) as the fermentative organism. GOX extraction,

purification and assays were described earlier in the section (3.1)

3.2.1.2 Mutarotase

Bovine kidney cortex was used to extract the enzyme mutarotase. It was purified by

ammonium sulfate precipitation, dialysis and gel filtration chromatography.

3.1.2.2.1 Enzyme extraction

The method of Bentley (1962) and (Zia M. A.) was applied to prepare extracts. A bovine

kidney cortex of about 100g was mixed with 100 ml of 0.1M phosphate buffer of pH 5.8

and 50 ml of chloroform and was homogenized in a blender for 2 minutes. This extract

was centrifuged at 8,000 rpm for 15 minutes and the supernatants were dialyzed for 2

hours against 0.1 M phosphate buffer (pH 5.8) with continuous stirring.

3.2.1.2.2 Enzyme assay

The activity of mutarotase was determined by following the procedure of Calzyme

Laboratory Manual (1998).

i) Determination of spontaneous mutarotation

At time zero, 100 mg -D-glucose was dissolved in 10 ml of 5mM sodium EDTA and

transferred to polarimeter. Rotation was recorded at 1 minute intervals for the first 10

minutes. After 10 minutes rotation was recorded every 5 minutes intervals. After 30

minutes the rotation was noted at 15 minutes intervals. Until the rotation become

constant.

PDF created with pdfFactory Pro trial version www.pdffactory.com

ii) Graph rotation vs time

The Initial rotation corresponds to an -D-glucose concentration of 555 mole. The data

obtained were extra plotted to zero to obtain the initial rotation.

iii) Blank rotation graph

Graph rotation was determined against time in 1 minute intervals, up to 5 minutes.

iv) Standard curve

Graph rotation Vs mole of -D-glucose using data from spontaneous mutarotation was

plotted. It was between 555 mole (initial and 195 mole (Final rotation).

v) Determination of test rotation

At time zero, 0.1 ml of enzyme sample was added to 9.9 ml of 5 mM sodium EDTA

solution and dissolved in 100 mg -D-glucose. The rotation was determined at 30 second

intervals for 10 minutes.

vi) Calculation

a = Initial rotation from spontaneous rotation graph.

b = Rotation for 5 minutes from graph (ii)

c = Blank rotation for 5 minutes (c = a-b)

d = Conversion of c to moles of -D glucose from standard curve

graph.

e = 555 mole -D glucose at initial rotation.

f = Spontaneous rate in micromoles/minute (f = e-d/5 minutes)

g = Test rotation per 5 minutes from test graph.

h = Test rotation after 5 minutes (h = a-g)

i = Conversion of h to micromole from standard curve.

j = Test rate in mole/minute i.e. [j = (e-i)/5 min f].

Units/mg protein = j/mg protein/10.0 ml reaction mixture.

3.2.1.2.3 Protein estimation

Protein were estimated according to the method of Moss and Bond (1957) as mentioned

earlier in section (3.1). The optical density was measured at 661 nm wavelength and a

standard curve was plotted between concentration (mg/ml) and absorbance. Total protein

concentrations were estimated from that curve.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.1.2.4 Partial purification of mutarotase by (NH

4

)

2

SO

4

precipitation

technique

The enzyme extract was precipitated by ammonium sulfate for partial purification as

described by the method of Bentley (1962). Solid ammonium sulphate was added to 100

ml of solution of glucose oxidase at the concentration of 30% (w/v). The suspension was

stirred for half an hour at 4

o

C. After sufficient shaking the precipitates were collected by

centrifugation at 10,000 rmp for 30 minutes. Enzyme activity was determined for each

concentration and precipitates were collected for further purification. Enzyme solution

was then treated with 40, 50, 60, 70 and finally 80% (w/v) (NH

4

)

2

SO

4

.

3.2.1.2.5 Dialysis

The precipitates obtained by ammonium sulphate precipitation were measured in 0.1 m

phosphate (pH 5.8) buffer and dialyzed in dialysis bag with constant stirring for 2 hours

and then were subjected to enzyme assay (3.2.1.2.2) and protein estimation (3.2.1.2.3).

3.2.1.2.6 Gel filtration using sephadex G-75

Reagents

0.1 M Phosphate (pH 5.8)

Dextran blue (molecular weight 2x10

6

) solution (0.5% w/v)

Sephadex-G-75

Procedure

Sephadex-G-75 was soaked in 500 ml of 0.1 M phosphate (pH 5.8) containing 0.1 g of

sodium azide and incubated at room temperature for 24 hours. After soaking the gel was

deaerated by direct drive rotary vacuum pump and then poured in a 0.9 x 60 cm column.

The packed column was washed with 0.1 M phosphate (pH 5.8). Dextrin blue (0.5% w/v)

was used for the determination of its void volume. Dialyzed enzyme extract was applied

on the column and fractions each of 3 ml were collected. Each fraction was then assayed

for enzyme activity and the amount of the protein present (Jakoby 1971).

3.2.1.3 Peroxidase

Peroxidase isolated from horse Radish was purified by ammonium sulfate precipitation

technique, Dialysis and gel filtration chromatography for utilization in glucose estimation

kit.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.1.3.1 Enzyme extracts preparation

About 100g horse Radish, was thoroughly washed with water, cut into small pieces and

homogenized in a blender with 500 ml distilled water. It was centrifuged at 10,000 rpm

for 15 minutes at 4C and filtered (Civello et al 1995) and (Zia M.A.).

The filtrate was heated in water bath at 65C for 3 minute to inactivate catalase and

cooled quickly in ice cold water. Enzyme assays were performed and protein was

estimated as explained in section (3.2.1.2.3).

3.2.1.3.2 Enzyme assay

The activity of peroxidase enzyme was determined by the method as described by Civello

et al (1995).

Buffered substrate solution was prepared as follow:

Phosphate buffer (pH 6.5) = 46.6 ml

H

2

O

2

(30%) = 0.32 ml

Guaiacol = 1.00 ml

The reagents were mixed in agitator and completely covered till the whole day. In the

blank solution preparation, H

2

O

2

was not added only Guaiacol (1 ml) and phosphate

buffer (46.6 ml) were mixed in agitator and used as blank spectrophotometer was set to

zero at 470 nm wavelengths after in setting blank solution in it. Then in UV cell 1 ml of

buffered substrate solution was taken along with 0.02 ml of enzyme extract and kept in

spectrophotometer and absorbance was recorded after 3 minutes which is directly

proportional to the enzyme activity.

3.2.1.3.3 Partial Purification of Peroxidase by (NH

4

)

2

SO

4

precipitation

techniques

The enzyme extract was precipitated by ammonium sulfate for partial purification as

described by the method of Bentley (1962). Solid ammonium sulphate was added to 100

ml of solution of glucose oxidase at the concentration of 30% (w/v). The suspension was

stirred for half an hour at 4

o

C. After sufficient shaking the precipitates were collected by

centrifugation at 10,000 rpm for 30minutes. Enzyme activity was determined for each

concentration and precipitates were collected for further purification. Enzyme solution

was then treated with 40, 50, 60, 70 and finally 80% (w/v) (NH

4

)

2

SO

4

.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.1.3.4 Dialysis

The precipitate obtained by (NH

4

)

2

SO

4

were dialyzed in the dialysis bag with 0.2 M

phosphate buffer (pH 6.5) with constant stirring for 2 hours and then the sample was

subjected to enzyme assay (3.2.1.3.2) and protein estimation (3.2.1.2.3).

3.2.1.3.5 Gel filtration using Sephadex G-75

Reagents

0.2 M Phosphate (pH 6.5)

Dextran blue (molecular weight 2x10

6

) solution (0.5% w/v)

Sephadex-G-75

Procedure

Sephadex-G-75 was soaked in 500 ml of 0.2 M phosphate (pH 6.5) containing 0.1 g of

sodium azide and incubated at room temperature for 24 hours. After soaking the gel was

deaerated by direct drive rotary vacuum pump and then poured in a 0.9 x 60 cm column.

The packed column was washed with 0.2 M phosphate (pH 6.5). Dextrin blue (0.5% w/v)

was used for the determination of its void volume. Dialyzed enzyme extract was applied

on the column and fractions of three ml were collected. Each fraction was then assayed

for enzyme activity and the amount of the protein present (Jakoby 1971).

3.2.1.4 Optimization of conditions for glucose estimation

Glucose oxidase, mutarotase and peroxidase enzymes were used to estimate glucose

level. The conditions of these partially purified enzymes were optimized. The standard

solution of -D-glucose 100 mg dL

-1

was prepared in distilled water. 2 ml of this solution

was used in all the parameters to be optimized and the three enzymes added at the same

time. Following parameters were optimized.

3.2.1.4.1 Guaiacol time

Timing for the addition of Guaiacol as chromogen was before adding peroxidase.

3.2.1.4.2 Enzyme concentrations

Different concentrations were optimized for three sets of the enzymes as follow:

Set A Mutarotase (5 L) + GOX (15L) + Peroxidase (10L)

Set B Mutarotase (10 L) + GOX (30L) + Peroxidase (20L)

Set C Mutarotase (20 L) + GOX (60L) + Peroxidase (40L)

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.1.4.3 Wavelength

Different wavelengths were optimized at spectrophotometer i.e.

i) 470 nm wavelength

ii) 290 nm wavelength

iii) 546 nm wavelength

3.2.1.4.4 Incubation period

Two different incubation periods were investigated at 37C for best results i.e.

i) 10 minutes

ii) 20 minutes

3.2.1.4.5 Sensitivity of glucose estimation kit

Different concentration of glucose was used to determine the sensitivity of glucose

estimation kit. The different concentration were used as: 200, 170, 140, 110, 80 and , 50

mg dL

-1

and their absorbance were calculated with the help of standard curve and the

sensitivity was measured as shown in Table 4.39 and Fig. 4.67.

3.2.1.4.6 Comparison with standard kit

All the optimized conditions (mentioned above) were used for preparation of glucose

estimation kit and then this kit was compared with standard estimation kit. The blood

samples of seven diabetic patients were investigated with both kits and comparison was

made as shown in Table 4.38 and Fig. 4.66

3.2.2 Production of calcium gluconate, gluconic acid and its

derivatives by GOX method

In the present research project gluconic acid, and its derivatives (metal salts) such as

sodium, magnesium, copper, nickel and cobalt gluconates were synthesized from calcium

gluconate which were earlier obtained by A. niger.

3.2.2.1 Production of calcium gluconate

Calcium gluconate was produced by submerged fermentation.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.2.1.1 Microorganism

Aspergillus niger strain (source potato) was obtained and identified from fungal Cultural

Bank Punjab University Lahore, Pakistan and was used in the present study. The fungal

culture was grown on malt extract agar medium at pH 5.5 as described in previous

section in (3.1).

3.2.2.1.2 Preparation of growth media

The growth medium for A. niger was prepared by mixing the following quantities of

ingredients in each 250 ml Erlenmeyer flask.

Table 3.3 Composition of growth medium

INGREDIENTS AMOUNT (gl

-1

)

MgSO

4

.7H

2

O 0.5

FeSO

4

.7H

2

O 0.01

KH

2

PO

4

1.0

Glucose 100.0

Urea 0.2

NaNO

3

5

Table 3.4 Composition of each 250 ml flask

Ingredients Amounts

CaCO

3

1.75 g/25 ml

KH

2

PO

4

2 ml

NaNO

3

2 ml

MgSO

4

.7H

2

O 2 ml

FeSO

4

.7H

2

O 2 ml

Urea 2 ml

Glucose 10 ml

Spore suspension

5 ml

(10

7

10

8

spores/ml)

The above quantities were mixed in the flasks except CaCO

3

and spore suspension,

autoclaved at 121C for 15 minutes and 15 PSI. CaCO

3

was autoclaved separately and

mixed with the media under sterile condition, the flasks were then plugged after the

PDF created with pdfFactory Pro trial version www.pdffactory.com

addition of inoculums (5 ml).The pH of medium was adjusted at 6.0 by using 1M NaOH

or 1M HCl.

3.2.2.1.3 Fermentation technique

The flasks containing 50 ml of fermentation medium were placed on a shaker for

incubation at 30C with speed of 100 rpm for 48 hours. All experiments were carried out

in triplicates. The samples were drawn at the end of fermentation and the contents of

flasks were filtered and filtrate was centrifuged at 5000 rpm for 5 minutes. The

supernatant was used for the estimation of calcium gluconate and glucose. The dry cell

mass was obtained by drying the wet mycelial mass in oven at 105C for 24 hours

according to method of Haq and Daud (1995).

3.2.2.1.4 Assay methods

(i) Estimation of glucose

Glucose was estimated by DNS method. (Tasun et al 1970) DNS solution was prepared

as:

Distilled water = 1500 ml

NaOH = 20 g

3,5 dinitrosalicyclic acid = 10 g

Above ingredients were dissolved in water and heated in water bath at 80C until clear

solution was obtained. The following chemicals were than added.

Rochelle salt = 300 g

Sod. metabisulphate = 10 g

Phenol (melted at 60C) = 5 ml

The solution was filtered and stored at room temperature.

Standard curve of glucose

One gram of glucose was dissolved in small quantity of distilled water and the volume

was raised to 100 ml this stock solution of glucose contained 10 mg/ml glucose. Five

dilutions (0.2 1.2 mg ml

-1

) were made. From the stock solution 2 ml of each dilution

and 2 ml of DNS solution was transferred in each test tube. Blank was also run in parallel

with 2 ml DNS and 2 ml of distilled water. Test tubes were placed in boiling water for 5

PDF created with pdfFactory Pro trial version www.pdffactory.com

minutes and cooled at room temperature and finally diluted with distilled water upto 20

ml. The absorbance was measured at 546 nm by U.V. spectrophotometer. The standard

curve was made by using each absorbance at respective range of glucose concentration

0

0.1

0.2

0.3

0.4

0.5

0.6

1 2 3 4 5

Concentration

A

b

s

o

r

b

a

n

c

e

Fig. 3.2 Standard curve of glucose

To determine glucose concentration (mg ml

-1

) the optical density was measured at 546nm

on spectrophotometer.

(ii) Calcium gluconate estimation

The analysis of calcium gluconate was made by the method of Pharmacopoeia (1990)

UK.

In 1.0 ml of sample, 2.0 ml of 1M HCl was added and water was added upto 200 ml

while stirring. Approximately 20 ml of 0.05M EDTA was added from burette. Then 20

ml of 1M NaOH and 300 mg of Hydroxy naphthol blue indicator was added upto blue

end point. Each ml of 0.05 M EDTA is equivalent to 2.004 mg of calcium gluconate.

1 ml of 0.05 M EDTA = 2.004 mg of calcium gluconate

AND

Percentage yield of calcium gluconate =

Ca. gluconate Produced

x 100

Glucose added

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.2.1.5 Optimization of conditions to enhance calcium gluconate production

The following parameters were studied:

(i) Effect of Incubation period on calcium gluconate production

The effect of incubation period on calcium gluconate production was studied at an

interval of every 12 hours upto 96 hours.

(ii) Effect of different pH on calcium gluconate production

The effect of pH on ca. gluconate production was studied within the range of 4.0 7.0

pH. The pH was adjusted by 1M HCl or 1M NaOH.

(iii) Effect of glucose concentration on calcium gluconate production

To examine the effect of glucose concentration, different concentrations of glucose were

added to fermentation medium (6-22%).

(iv) Effect of different types of carbonates and CaCO

3

concentration

Submerged fermentation was carried out using different metal carbonate such as MgCO

3

,

CaCO

3

, ZnCO

3

and FeCO

3

in the medium. The various levels of CaCO

3

(0 7 %) were

further optimized.

(v) Effect of different nitrogen sources and urea concentration

Different nitrogen sources were used at a level of 2-5 gl

-1

in the medium for improving

the expression of calcium gluconate. Different sources are peptone, Urea, NH

4

NO

3

,

NH

4

Cl and NaNO

3

. The various levels of urea (0.1-0.4 gl

-1

) were further optimized.

(vi) Effect of different PO

4

source

To study the effect of different phosphates like K

2

HPO

4

and KH

2

PO

4

on Ca. gluconate

production, different concentration of respective phosphates in fermentation medium i.e.

0.15, 0.20, 0.25, 0.30 were added.

(vii) The effect of temperature

Effect of temperature on calcium gluconate production was also evaluated. The influence

of temperature was studied over the range of 15 to 50C.

3.2.2.2 Preparation of gluconic acid from calcium gluconate

Gluconic acid was prepared from calcium gluconate. Following methods were employed

for its preparation (Prescott and Dunn 1959) and (M. Iqbal and Maqbool).

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.2.2.1 Oxalic acid

Exactly 43.0 gm calcium gluconate was dissolved in 180 ml boiling water. 12.6 gm

crystallized oxalic acid was dissolved in minimum quantity of water. Both the solutions

were mixed at 60C with constant stirring. It was filtered to remove calcium oxalate.

Gluconic acid was crystallized under vacuum at 30 - 40C on a rotary evaporator.

Reaction

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Ca

+

COOH

COOH

COOH

(CHOH)

4

CH

2

OH

+

COO

COO

Ca

.

2

H

2

O 2

+

2H

2

O

Calcium gluconate Oxalic acid Gluconic acid Calcium oxalate

3.2.2.2.2 Sulphuric acid method

Sulphuric acid was employed in place of oxalic acid to remove calcium as calcium

sulphate and thus releasing the gluconic acid.

215.0 gm calcium gluconate was dissolved in 900 ml boiling water. This solution was

placed in an ice bath and 33.4 ml 30 N sulphuric acid was added to it drop wise. It was

stirred constantly for about five minutes and was filtered through a Buckner funnel to

remove precipitated calcium sulphate. Gluconic acid solution was obtained as filtrate.

This solution was used for subsequent preparations of gluconates.

Reaction:

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Ca

+

COOH

(CHOH)

4

CH

2

OH

+

CaSO

4

H

2

SO

4

2

Calcium gluconate Sulphuric acid Gluconic acid Calcium sulphate

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.2.2.3 Identification of gluconic acid

About 5 ml of a warm aqueous solution of gluconic acid (9.03%) were added to 1 ml of

freshly distilled phenylhydrazine. The mixture was taken in a test tube and heated on a

water bath for 30 minutes. After cooling, the inner surface of the tube was scratched with

a glass rod. Crystals of gluconic acid phenylhydrazide were formed (Eric and Cook,

1956).

3.2.2.3 Preparation of gluconic acid derivatives

The derivatives of gluconic acid such as magnesium gluconate, sodium gluconate, etc

were prepared either from the calcium gluconate or directly from the gluconic acid.

Calcium gluconate on treatment with the metal sulphate under suitable conditions gave

the desired gluconate. Metal carbonates while treated with gluconic acid gave the metal

gluconate with the evolution of carbon dioxide (Baronnet R. 1948). The appropriate

conditions and detailed procedures are given as follows:

3.2.2.3.1 Sodium gluconate

(i) Double decomposition method

Sodium gluconate was prepared by the double decomposition of sodium sulphate and

calcium gluconate as given below:

PDF created with pdfFactory Pro trial version www.pdffactory.com

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Ca

+

CH

2

OH

(CHOH)

4

COONa

+

Na

2

SO

4

COONa

(CHOH)

4

CH

2

OH

+

CaSO

4

Calcium gluconate Sodium sulphate Sodium gluconate Calcium sulphate

The 68.8 gm of calcium gluconate was added to 250 ml boiling water and stirred to

dissolve it. The solution of calcium gluconate was treated with sodium sulphate (51.52

gm). This solution was heated to boiling. The precipitate of calcium sulphate was

removed by filtration while hot. Sodium gluconate solution was concentrated under

vacuum at 30C on a rotary vacuum evaporator. Ethanol was added to crystallize sodium

gluconate. It was filtered and the crystals were dried in a desicator over anhydrous

calcium chloride.

(ii) Gluconic acid method

Sodium gluconate was prepared by the interaction of sodium carbonate and gluconic

acid. The reaction is given by the following equation:

COOH

2(CHOH)

4

CH

2

OH

+

COONa

(CHOH)

4

CH

2

OH

+

Na

2

CO

3

+

H

2

O CO

2

2

Gluconic acid Sodium Sodium Carbon Water

carbonate gluconate dioxide

Sodium carbonate (21.2 gm) was added to 50% gluconic acid (156.8 ml corresponding to

78.5 gm). The solution was heated to expel carbon dioxide. Sodium gluconate solution

was concentrated under vacuum at 30C. Ethanol was added to precipitate the salt. It was

recrystallized from water solution and the crystals were dried in a desicator over

anhydrous calcium chloride.

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.2.3.2 Magnesium gluconate

(i) Procedure

Calcium gluconate (86.0 g) was dissolved in minimum quantity of boiling water.

Magnesium sulphate (49.2 g) was added to the gluconate solution and it was boiled,

filtered, while hot, to remove calcium sulphate. Magnesium gluconate solution was

concentrated at 40 - 50C and the salt was precipitated from the concentrated solution

with alcohol.

Reaction

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Ca

+

MgSO

4

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Mg

+

CaSO

4

Calcium gluconate Magnesium Magnesium Calcium

sulphate gluconate sulphate

(ii) Procedure

Magnesium carbonate (84.0 g) was added to 50% gluconic acid solution (784.0 ml

corresponding to 392.0 g). The solution was heated to expel carbon dioxide and

concentrated under vacuum. Magnesium gluconate was precipitated with ethanol.

Reaction

COOH

2(CHOH)

4

CH

2

OH

+

MgCO

3

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Mg

+

CO

2 +

H

2

O

Gluconic Acid Magnesium Magnesium Carbon Water

gluconate gluconate dioxide

PDF created with pdfFactory Pro trial version www.pdffactory.com

3.2.2.3.3 Copper gluconate

(i) Procedure:

Solution of calcium gluconate (86.0 g) was made in minimum quantity of boiling water.

This solution while boiling was treated with copper sulphate (49.8g) and filtered to

separate calcium sulphate. Copper gluconate solution was concentrated to crystallization

and the crystals were dried in a desicator over anhydrous calcium chloride.

Reaction

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Cu

+

CaSO

4

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Ca

+

CuSO

4

Calcium gluconate Copper sulphate Copper gluconate Calcium sulphate

(ii) Procedure

A 50% Gluconic acid solution (78.4 ml equivalent to 39.2 g) was treated with cuprous

carbonate (22.1 g). Carbon dioxide was removed by heating and the resulting cuprous

gluconate solution was concentrated under vacuum. Cuprous gluconate was precipitated

with alcohol.

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Cu

+

CO

2

COOH

2(CHOH)

4

CH

2

OH

+

CuCO

3

+

H

2

O

Gluconic acid Copper carbonate Copper gluconate Carbon dioxide Water

3.2.2.3.4 Nickel gluconate

56.2 g Nickel sulphate was treated with 86.0 g calcium gluconate previously dissolved in

minimum quantity of water. The solution was heated, filtered to remove calcium

PDF created with pdfFactory Pro trial version www.pdffactory.com

sulphate. Nickel gluconate solution was concentrated and precipitated with alcohol. The

precipitate of nickel gluconate was dried by placing it in a desicator.

Reaction

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Ni

+

CaSO

4

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Ca

+

NiSO

4

Calcium gluconate Nickel sulphate Nickel gluconate Calcium sulphate

(ii) Procedure

The 12.6 g of nickel carbonate was reacted with 78.4 ml (equivalent to 39.2 g) 50%

gluconic acid solution. It was heated to release carbon dioxide and concentrated. Nickel

gluconate was crystallized from the concentrated solution with ethanol.

Reaction

CH

2

OH

(CHOH)

4

COO

COO

(CHOH)

4

CH

2

OH

Ni

+

CO

2

COOH

2(CHOH)

4

CH

2

OH

+

NiCO

3

+

H

2

O

Gluconic acid Nickel carbonate Nickel gluconate Carbon Water

dioxide.

Percentage Yield

Formula used

Actualyield x 100

%ageYield =

Theoretical Yield

These salts of gluconic acid have been prepared and used in view of their comparatively

high water solubility.

PDF created with pdfFactory Pro trial version www.pdffactory.com

Вам также может понравиться

- Physiological and Microbiological Studies On Production of Alkaline Protease From Locally Isolated Bacillus SubtilisДокумент11 страницPhysiological and Microbiological Studies On Production of Alkaline Protease From Locally Isolated Bacillus SubtilisLaorenciaОценок пока нет

- Fermentation and Recovery of L-Glutamic - Acid - FromДокумент8 страницFermentation and Recovery of L-Glutamic - Acid - FromPrachi BhoirОценок пока нет

- Factors Regulating Production of Glucose Oxidase by Aspergillus NigerДокумент5 страницFactors Regulating Production of Glucose Oxidase by Aspergillus NigerI. Murali KrishnaОценок пока нет

- Materials and Methods SummaryДокумент35 страницMaterials and Methods SummaryVijayakumarОценок пока нет

- Isolation and Characterization of A Thermostable - Amylase FromДокумент5 страницIsolation and Characterization of A Thermostable - Amylase FromDương Nguyễn Thùy DungОценок пока нет

- Cellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateДокумент5 страницCellulase Enzyme Production by Streptomyces SP Using Fruit Waste As SubstrateHamka NurkayaОценок пока нет

- Asada 2012 PDFДокумент5 страницAsada 2012 PDFMuztika Andriana RahmawatiОценок пока нет

- Biosynthesis of Protease From Lactobacillus Paracasei: Kinetic Analysis of Fermentation ParametersДокумент5 страницBiosynthesis of Protease From Lactobacillus Paracasei: Kinetic Analysis of Fermentation ParametersGovGovsОценок пока нет

- Hojo 1999Документ11 страницHojo 1999Berk YüzerОценок пока нет

- Isolation and Purification of CellulaseДокумент6 страницIsolation and Purification of CellulaseMeshal NoorОценок пока нет

- Optimization of Alkaline Protease Productivity by ATCC 21415Документ5 страницOptimization of Alkaline Protease Productivity by ATCC 21415David SantiagoОценок пока нет

- Aspergillus niger Oxalic Acid Production OptimizationДокумент7 страницAspergillus niger Oxalic Acid Production OptimizationAndrew FaguhОценок пока нет

- Purification and Characterization of Cellulase From The Wild-Type and Two Improved Mutants ofДокумент7 страницPurification and Characterization of Cellulase From The Wild-Type and Two Improved Mutants ofAlonso PomaОценок пока нет

- Production of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Recombinant Escherichia Coli With A Highly Concentrated Whey SolutionДокумент4 страницыProduction of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Recombinant Escherichia Coli With A Highly Concentrated Whey Solutionapi-3743140Оценок пока нет

- Cellulase Production by Thermophilic Bacillus Sp. SMIA-2 and Its Detergent CompatibilityДокумент10 страницCellulase Production by Thermophilic Bacillus Sp. SMIA-2 and Its Detergent CompatibilitydadjОценок пока нет

- App// D: O., Microbiology BiotechnologyДокумент4 страницыApp// D: O., Microbiology BiotechnologyRoger FernandezОценок пока нет

- Paper Iccheas 2021 - Cek 15 Sept (Revisi 20 Sept)Документ9 страницPaper Iccheas 2021 - Cek 15 Sept (Revisi 20 Sept)Agfri Satriyo Huda WaskithoОценок пока нет

- Silver Recovery From Waste Photographic Films by AnДокумент2 страницыSilver Recovery From Waste Photographic Films by AnMuhammad Adnan LaghariОценок пока нет

- Published ProceedingsДокумент8 страницPublished ProceedingsmagribisnisОценок пока нет

- Comparative Study of Biosurfactants Production Bybacillus Licheniformis and CandidaДокумент7 страницComparative Study of Biosurfactants Production Bybacillus Licheniformis and CandidaCatalinaManjarresОценок пока нет

- Article 3. Production of Acetone Butanol Ethanol From Corn Mash and Molasses in Bath FermentationДокумент8 страницArticle 3. Production of Acetone Butanol Ethanol From Corn Mash and Molasses in Bath Fermentationnicolas vergaraОценок пока нет

- Some Changes in Postharvest Physiology and ActivitiesДокумент4 страницыSome Changes in Postharvest Physiology and ActivitiesShailendra RajanОценок пока нет

- Production of α-amylase using new strain of Bacillus polymyxa isolated from sweet potatoДокумент7 страницProduction of α-amylase using new strain of Bacillus polymyxa isolated from sweet potatoInternational Organization of Scientific Research (IOSR)Оценок пока нет

- Purification and Characterization of Alkaline Xylanase Secreted From Paenibacillus MacquariensisДокумент10 страницPurification and Characterization of Alkaline Xylanase Secreted From Paenibacillus MacquariensisDhani94Оценок пока нет

- Thermostable β-Galactosidase from Bacillus coagulansДокумент6 страницThermostable β-Galactosidase from Bacillus coagulansguiervicalОценок пока нет

- β-galactosidase from Bacillus coagulans RCS3: Production and characterization of a thermostableДокумент6 страницβ-galactosidase from Bacillus coagulans RCS3: Production and characterization of a thermostablemoogambigai smОценок пока нет

- Article1380180775 - Oyeleke and OduwoleДокумент4 страницыArticle1380180775 - Oyeleke and Oduwoleaditi_joshee419Оценок пока нет

- Full Report Carbs On 161.1Документ23 страницыFull Report Carbs On 161.1Kim Leonard BolandosОценок пока нет

- Im 2009Документ8 страницIm 2009Jesus C. MendozaОценок пока нет

- Research Journal of Pharmaceutical, Biological and Chemical SciencesДокумент7 страницResearch Journal of Pharmaceutical, Biological and Chemical SciencesMaslakhatun NisakdiyahОценок пока нет

- Growth Kinetics of Diazotrophic Bacillus Sphaericus UPMB10 Cultured Using Different Types and Concentrations of Carbon and Nitrogen SourcesДокумент11 страницGrowth Kinetics of Diazotrophic Bacillus Sphaericus UPMB10 Cultured Using Different Types and Concentrations of Carbon and Nitrogen SourcesTejas DoshiОценок пока нет

- Yeast in Batch Culture - Expt - 4 - Shake Flask - Part 1 - 4th EdДокумент7 страницYeast in Batch Culture - Expt - 4 - Shake Flask - Part 1 - 4th EdRachel HechanovaОценок пока нет

- Production of Ethanol From MolassesДокумент5 страницProduction of Ethanol From MolassesKrishna PotluriОценок пока нет

- Jurnal Tugas TFДокумент5 страницJurnal Tugas TFDhian ZhahirahОценок пока нет

- Lipase optimization Staphylococcus oil millДокумент5 страницLipase optimization Staphylococcus oil millShankar AcharОценок пока нет

- Biochemical Characterization of K-Amylase From The Yeast Cryptococcus AvusДокумент5 страницBiochemical Characterization of K-Amylase From The Yeast Cryptococcus AvusVirginia Elena Jimenez JimenezОценок пока нет

- Chapter - Vii: Moringa Oleifera Seed PowderДокумент18 страницChapter - Vii: Moringa Oleifera Seed PowderDrVishwanatha HNОценок пока нет

- Kinetics of Cyclosporin A Production by Tolypocladium inflatumДокумент7 страницKinetics of Cyclosporin A Production by Tolypocladium inflatumKarla Andrea Hernández GilОценок пока нет

- Potential of Taiwan Sorghum Spirits Lees For The Production of BioethanolДокумент21 страницаPotential of Taiwan Sorghum Spirits Lees For The Production of Bioethanolrichardson sitohangОценок пока нет

- 14 Chapter 3Документ50 страниц14 Chapter 3Shahid pin100% (1)

- Effect of Bacterial Density Yield Coefficients: and Substrate ConcentrationДокумент5 страницEffect of Bacterial Density Yield Coefficients: and Substrate ConcentrationJamie SamuelОценок пока нет

- Aspergillus Niger Was Used For Cellulase Production in Submerged (SMF) and Solid State Fermentation (SSF)Документ9 страницAspergillus Niger Was Used For Cellulase Production in Submerged (SMF) and Solid State Fermentation (SSF)M Syafiq SamadОценок пока нет

- J. Bacteriol.-1957-Duff-597-601 PDFДокумент5 страницJ. Bacteriol.-1957-Duff-597-601 PDFnein mein100% (1)

- 2.2.1. Sample Collection: BT Isolation Was Done by Using Two Different Methods Based On The Sample Type. The ShakenДокумент4 страницы2.2.1. Sample Collection: BT Isolation Was Done by Using Two Different Methods Based On The Sample Type. The ShakenLeong HlОценок пока нет

- Ethanol CalculationДокумент14 страницEthanol CalculationMuhammad Azim Khan NiaziОценок пока нет

- A New Method For Producing A Non Heated Jam Sample The Use of Freeze Concentration and High Pressure SterilizationДокумент3 страницыA New Method For Producing A Non Heated Jam Sample The Use of Freeze Concentration and High Pressure SterilizationNhật Nguyễn SĩОценок пока нет

- Optimisation of Media and Cultivation Condition L. CaseiДокумент5 страницOptimisation of Media and Cultivation Condition L. CaseiMathilda PasaribuОценок пока нет

- 09 Chapter3Документ13 страниц09 Chapter3AnuradhaОценок пока нет

- A Novel Facile Two-Step Method For Producing Glucose From CelluloseДокумент24 страницыA Novel Facile Two-Step Method For Producing Glucose From Celluloseza vaОценок пока нет

- 1293 FullДокумент6 страниц1293 FullAndréRochaОценок пока нет

- Purification and Characterization of A Monoacylglycerol Lipase From The Moderately Thermophilic Bacillus Sp. H-257Документ7 страницPurification and Characterization of A Monoacylglycerol Lipase From The Moderately Thermophilic Bacillus Sp. H-257ayauОценок пока нет

- KJ00003418341Документ14 страницKJ00003418341Atac SonmezОценок пока нет

- Amylase ProjectДокумент2 страницыAmylase Projectmadura cОценок пока нет

- Qureshi Butanol Production Using Clostridium Beijerinckii BA101 Hyper-Butanol Producing Mutant Strain and Recovery by PervaporationButanolprodДокумент12 страницQureshi Butanol Production Using Clostridium Beijerinckii BA101 Hyper-Butanol Producing Mutant Strain and Recovery by PervaporationButanolprodschall0Оценок пока нет

- Supercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYДокумент7 страницSupercritical Fluid Extraction of Byproduct From PECAN (Caryaillinoinensis (Wangenh.) K. Koch) OIL INDUSTRYGuillermo Serralde PaezОценок пока нет

- The Isolation and Improvement of Aspergillus Niger by Radiation For HigherProduction of Citric AcidДокумент6 страницThe Isolation and Improvement of Aspergillus Niger by Radiation For HigherProduction of Citric AcidHakouОценок пока нет

- Countercurrent Extraction of 2,3-Butanediol: Dr. Sadhana VishwakarmaДокумент4 страницыCountercurrent Extraction of 2,3-Butanediol: Dr. Sadhana VishwakarmaAtika SaraswatiОценок пока нет

- Reagents.: Materials and MethodsДокумент6 страницReagents.: Materials and Methodsedal_108Оценок пока нет

- Research SampleДокумент11 страницResearch SamplesuryasanОценок пока нет

- Umts Cell Selection and ReselectionДокумент29 страницUmts Cell Selection and ReselectionNeoRa Ndivo Rams0% (1)

- GSM Handover OptimizationДокумент9 страницGSM Handover OptimizationRoger ParsonsОценок пока нет

- Mall Plaza Report - FinalДокумент30 страницMall Plaza Report - FinalsaabiaanОценок пока нет

- Amr Codec BMДокумент5 страницAmr Codec BMsaabiaanОценок пока нет

- TestДокумент19 страницTestsaabiaanОценок пока нет

- Ajowan JellyДокумент4 страницыAjowan Jellysaabiaan100% (1)

- AMRHR Tests Cegetel v02Документ56 страницAMRHR Tests Cegetel v02saabiaanОценок пока нет

- Cross FeederДокумент1 страницаCross FeedersaabiaanОценок пока нет

- TestДокумент19 страницTestsaabiaanОценок пока нет

- PresentationДокумент30 страницPresentationsaabiaanОценок пока нет

- GSM Functionality and Fine Tuning - A Case StudyДокумент9 страницGSM Functionality and Fine Tuning - A Case StudyEho2011Оценок пока нет

- Minimum ExpenseДокумент2 страницыMinimum ExpensesaabiaanОценок пока нет

- MSC and BSC Parameter DescriptionДокумент25 страницMSC and BSC Parameter DescriptionsaabiaanОценок пока нет

- Urban-Rural Cell Type ChangeДокумент4 страницыUrban-Rural Cell Type ChangesaabiaanОценок пока нет

- Corrosion Control for Petrochemical ProcessesДокумент78 страницCorrosion Control for Petrochemical ProcessesShesharam ChouhanОценок пока нет

- Bioactuators Based On Stimulus-ResponsiveДокумент21 страницаBioactuators Based On Stimulus-ResponsiveSqual59Оценок пока нет

- Measurement of Electrodeposited Metallic Coating Thicknesses by Dropping TestДокумент5 страницMeasurement of Electrodeposited Metallic Coating Thicknesses by Dropping TestTuanbk NguyenОценок пока нет

- Volumetric Analysis: Grade XIIДокумент58 страницVolumetric Analysis: Grade XIIAS gamingОценок пока нет

- Colorfastness Water TestДокумент3 страницыColorfastness Water Testrohit008Оценок пока нет

- Teacher Resource Bank: GCE Chemistry PSA14: A2 Physical Chemistry - Determine An Equilibrium ContstantДокумент8 страницTeacher Resource Bank: GCE Chemistry PSA14: A2 Physical Chemistry - Determine An Equilibrium ContstantDzumani YamikaniОценок пока нет

- Chemical Engineering Journal: Yunfei He, Luxin Zhang, Yuting Liu, Simin Yi, Han Yu, Yujie Zhu, Ruijun SunДокумент12 страницChemical Engineering Journal: Yunfei He, Luxin Zhang, Yuting Liu, Simin Yi, Han Yu, Yujie Zhu, Ruijun Sunbruno barrosОценок пока нет

- Acids and Bases in Everyday LifeДокумент6 страницAcids and Bases in Everyday LifeLothar GraudinsОценок пока нет

- Laboratory Scientific Officer 28 Feb 2021 20Документ15 страницLaboratory Scientific Officer 28 Feb 2021 20Anupam DhawaleОценок пока нет

- 4.8 Carboxylic Acids FactfileДокумент6 страниц4.8 Carboxylic Acids FactfileHerton FotsingОценок пока нет

- TCCA - US3898222 - P - Process For Preparing Trichloroisocyanuric AcidДокумент3 страницыTCCA - US3898222 - P - Process For Preparing Trichloroisocyanuric AcidListya Eka AnggrainiОценок пока нет

- Optimization of Aniline Blue ProcessДокумент6 страницOptimization of Aniline Blue ProcessAditya ShrivastavaОценок пока нет

- Casein PDFДокумент3 страницыCasein PDFEasy ways2017Оценок пока нет

- Coloring MetalsДокумент57 страницColoring Metalscfowen100% (1)

- Marking Scheme P2 Chemistry 2016Документ10 страницMarking Scheme P2 Chemistry 2016Farid SallehОценок пока нет

- Chemical ListДокумент854 страницыChemical ListMichael HarrisonОценок пока нет

- Assignment 1 Organic ChemistryДокумент9 страницAssignment 1 Organic ChemistryAnotidaishe MugadzaОценок пока нет

- Cbjescpu 01Документ11 страницCbjescpu 01Karthy JanaviОценок пока нет

- Magnesium Chloride HexahydrateДокумент2 страницыMagnesium Chloride HexahydratekrutОценок пока нет

- PHYSICAL CHEMISTRY ENERGETICSДокумент104 страницыPHYSICAL CHEMISTRY ENERGETICSmichaela menzelОценок пока нет

- Teaching Chemistry Concepts Through Real-World IssuesДокумент6 страницTeaching Chemistry Concepts Through Real-World IssuesJaren NadongОценок пока нет

- Thermodynamics Calculations and ConceptsДокумент10 страницThermodynamics Calculations and ConceptsJeff Dela Rosa100% (2)

- Ascorbic Acid PDFДокумент7 страницAscorbic Acid PDFM Ahya KОценок пока нет

- Calcium Oxalate Precipitation and SolubilityДокумент2 страницыCalcium Oxalate Precipitation and SolubilityHassan HaiderОценок пока нет

- Titrimetric Analysis BTech-IДокумент100 страницTitrimetric Analysis BTech-IMayankОценок пока нет

- Power Plant Chemistry PDFДокумент175 страницPower Plant Chemistry PDFak_thimiriОценок пока нет

- Addition Reactions at sp2 CarbonsДокумент85 страницAddition Reactions at sp2 CarbonsPrarabdha SharmaОценок пока нет

- Class 10 Chemistry Viva Questions With AnswersДокумент26 страницClass 10 Chemistry Viva Questions With AnswersZeeshan AhmadОценок пока нет

- US20100184952A1Документ13 страницUS20100184952A1Niki MullinsОценок пока нет

- Lubrizol Well Stimulation: Acidizing Additives Application GuideДокумент2 страницыLubrizol Well Stimulation: Acidizing Additives Application GuideLê CôngОценок пока нет