Академический Документы

Профессиональный Документы

Культура Документы

Efficiency of Boiler

Загружено:

Ruban Kumar0 оценок0% нашли этот документ полезным (0 голосов)

29 просмотров12 страницBoiler efficiency

Оригинальное название

Efficiency of boiler

Авторское право

© © All Rights Reserved

Доступные форматы

ODP, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документBoiler efficiency

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате ODP, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

29 просмотров12 страницEfficiency of Boiler

Загружено:

Ruban KumarBoiler efficiency

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате ODP, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 12

Efficiency: The ratio of the effective or useful

output to the total input in any system.

Instrumentation:Instruments for a specific

purpose.

Boiler

there are two methods for boiler efficiency

calculation namely:

1.input output method

2.heat loss method

Input-Output ethod

The Input-Output efficiency measurement

method is based on the ratio of the output-

to-input of the boiler.

It is calculated by

dividin! the boiler output "in BT#s$ by the

boiler input "in BT#s$ and multiplyin! by 1%%.

The actual input and output of the boiler are

determined thou!h instrumentation and the

data is used in calculations that result in the

fuel-to-steam efficiency.

&eat 'oss ethod

&eat loss method is the method that is used to

calculate the percenta!e amount of heat which is

not useful. This method is very effective used in an

attempt to find potential savin!s of boiler with heat

balance.

There are several factors act as the source of heat

loss combustion. These factors will be used to

calculate boiler efficiency based on heat loss

method. The source of heat loss can be seen as

followin! below:

a. &eat loss due to dry flue !as

&eat loss due to dry flue !as is the heat loss

which is contained in dry flue !as such as (O2)

O2 and *2. These !ases are one of causes of

heat loss in combustion process. The hi!h

temperature of flue !as comin! out from boiler

affect amount of heat loss.

The wei!ht and heat loss of dry flue !as of

combustion of coal can be calculated as followin!

formula:

+df! , m(O2 - m.O2 - mO2 - m*2

Eloss df! , +df! / (p / "To - Ts$

+here:

+df! , wei!ht of dry flue !as "0!10! coal$

Eloss df! , heat loss in dry flue !as "0210!$

To , temperature of dry flue !as comin!

out from boiler

Ts , temperature of surroundin! air

b. &eat loss due to steam in flue !as

There are two sources of steam contained in flue

!as. It is steam from burnin! &2 and steam from

fuel moisture coupled with steam present in

combustion air.

- The calculation formula of heat due to

steam from burnin! &2 is:

+&2O , 3 / &2

Eloss &2 , +&2O / "h! - hf$

+here:

+&2O , wei!ht of water content "0!10! coal$

Eloss-&2O , amount of heat loss due to steam

from burnin! process of hydro!en "0210!$

&! , enthalpy of steam at the temperature of flue

!as comin! out from boiler

hf , enthalpy of water at surroundin! air

temperature.

.team from fuel moisture and combustion air

(alculation of heat loss due to steam from fuel

moisture and combustion air: can be seen in the

followin! formula:

Eloss-&2O , "+&2O-coal - +&2O-air$ / "&! - &f$

+here:

Eloss-&2O , amount of heat loss due to steam

from fuel moisture and combustion air

&eat loss due to unburned carbon

The calculation is assumed level of e/cess air is

provided about more 2%4 and combustion that

occurs only produces unburned carbon about 14

of carbon content in fuel. (alculation of heat loss

due to unburned carbon can be seen as followin!

formula:

Eloss-#( , +#( / &&5carbon

+here:

+#( , wei!ht of unburned carbon "0!10!$

&&5carbon , hi!hest heatin! value "0210!$

Eloss-#( , amount of heat loss due to unburned

carbon

&eat loss due to radiation

The amount of heat loss due to radiation depends

on the rate of heat which is released in

combustion furnace. Based on the 6B6 chart

"6merican Boiler anufacturers 6ssociation$) at

bi! heat release rate) the amount of heat loss due

to radiation tends to constant. The heat radiation

that occurs is estimated %.24 calorific value of

fuel.

#ncountable heat loss

There are several sources that can cause heat

loss in combustion) where the value is too

complicated to be calculated certainly. This heat

loss is called as uncountable heat loss. The

amount of uncountable heat loss is about %.74 of

calorific value of fuel.

Eloss total , Eloss-df! - Eloss-&2 - Eloss-&2O -

Eloss-#( - Eradiation - Euncountable

Вам также может понравиться

- Boiler Mountings and AccesoriesДокумент2 страницыBoiler Mountings and AccesoriesRuban KumarОценок пока нет

- Safe Working in Confined SpaceДокумент27 страницSafe Working in Confined SpaceRuban KumarОценок пока нет

- CEA India Load Generation Balance Report 2014 - 2015 PDFДокумент125 страницCEA India Load Generation Balance Report 2014 - 2015 PDFRuban KumarОценок пока нет

- Turbo Generator Cooling SystemДокумент18 страницTurbo Generator Cooling SystemRuban Kumar100% (3)

- Steam Turbine BasicsДокумент4 страницыSteam Turbine BasicsRuban KumarОценок пока нет

- Safety Valve in BoilerДокумент4 страницыSafety Valve in BoilerRuban KumarОценок пока нет

- Fully Water Cooled Turbo Generator (Stator and Rotor)Документ7 страницFully Water Cooled Turbo Generator (Stator and Rotor)Ruban Kumar100% (1)

- TurbineДокумент7 страницTurbineRuban KumarОценок пока нет

- ESP Electrostatic PrecipitatorДокумент18 страницESP Electrostatic PrecipitatorRuban KumarОценок пока нет

- Ash Handling SystemДокумент11 страницAsh Handling SystemRuban KumarОценок пока нет

- Drum in BoilerДокумент18 страницDrum in BoilerRuban Kumar100% (1)

- Auxiliary Power Consumption in Thermal Power PlantДокумент10 страницAuxiliary Power Consumption in Thermal Power PlantRuban Kumar0% (1)

- Boiler Interview Questions Part 1Документ6 страницBoiler Interview Questions Part 1Ruban KumarОценок пока нет

- Generator Excitation SystemДокумент16 страницGenerator Excitation SystemRuban Kumar100% (1)

- Turbine Oil SystemДокумент15 страницTurbine Oil SystemRuban KumarОценок пока нет

- Plant Operational Data of NTPC Power Stations, IndiaДокумент44 страницыPlant Operational Data of NTPC Power Stations, IndiaRuban KumarОценок пока нет

- Coal To ElectricityДокумент4 страницыCoal To ElectricityRuban KumarОценок пока нет

- TransformerДокумент57 страницTransformerRuban KumarОценок пока нет

- Cooling TowerДокумент6 страницCooling TowerRuban KumarОценок пока нет

- Fuel Firing System Power PlantДокумент12 страницFuel Firing System Power PlantRuban Kumar100% (1)

- CADCAMДокумент50 страницCADCAMPrem Chander100% (5)

- Power Generation From CoalДокумент114 страницPower Generation From CoalOral KarahanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Power Plant EngineeringДокумент3 страницыPower Plant EngineeringSree MurthyОценок пока нет

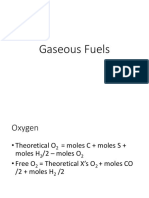

- Gaseous FuelДокумент12 страницGaseous FuelChrister John UyОценок пока нет

- High-Scoring IELTS Writing Model AnswersДокумент22 страницыHigh-Scoring IELTS Writing Model Answershojatollah100% (2)

- Nantambi Business ModelsДокумент30 страницNantambi Business Modelssishu21Оценок пока нет

- Renewable Energy ResourcesДокумент3 страницыRenewable Energy ResourcesSandeep SunnyОценок пока нет

- Effect of Supercharging On Engine PerformanceДокумент13 страницEffect of Supercharging On Engine PerformanceanshurathoreОценок пока нет

- CHE112P Lecture 4Документ13 страницCHE112P Lecture 4Paolo Gochingco100% (1)

- Institute of Aeronautical EngineeringДокумент11 страницInstitute of Aeronautical EngineeringrkОценок пока нет

- Renewable Energy Poster PDFДокумент1 страницаRenewable Energy Poster PDFAngelie LapeОценок пока нет

- Petroleum Product: BY: Mohamed Shihab, Tayeb Hishyar Mustafa Khalid, Haval Abdi, Kawa SalimДокумент14 страницPetroleum Product: BY: Mohamed Shihab, Tayeb Hishyar Mustafa Khalid, Haval Abdi, Kawa SalimMohamed Shihab BerwariОценок пока нет

- Textbook 3 Cementproduction v31Документ8 страницTextbook 3 Cementproduction v31Mohammad Awais NazirОценок пока нет

- Hydrogen BombДокумент3 страницыHydrogen BombirfuuОценок пока нет

- Unesco - Eolss Sample Chapters: Power Plant TechnologyДокумент9 страницUnesco - Eolss Sample Chapters: Power Plant TechnologyMaryОценок пока нет

- 100 Top Most Power Plant Engineering - Electrical Engineering Objective Type Questions and AnswersДокумент10 страниц100 Top Most Power Plant Engineering - Electrical Engineering Objective Type Questions and AnswersEj ParañalОценок пока нет

- 4 Inresol Introduction and ProductsДокумент22 страницы4 Inresol Introduction and ProductsFahidlhvОценок пока нет

- Power Plant Simulator For OperatorsДокумент2 страницыPower Plant Simulator For Operatorsalbert100% (1)

- Advanced Jet Fuels - JP-4 Through JP-8 and BeyondДокумент10 страницAdvanced Jet Fuels - JP-4 Through JP-8 and BeyondMASOUDОценок пока нет

- Applied Thermal Engineering: Research PaperДокумент8 страницApplied Thermal Engineering: Research PaperCristhian MoralesОценок пока нет

- University of The East: Review of Related LiteratureДокумент10 страницUniversity of The East: Review of Related LiteratureJoshua RodriguezОценок пока нет

- Biomass EnergyДокумент13 страницBiomass EnergyMarie Oviel DolorosaОценок пока нет

- IACS Ur-M59Документ4 страницыIACS Ur-M59Seong Ju KangОценок пока нет

- Jolly, Vijay K. 1997. From Mind To Market Cap 1Документ53 страницыJolly, Vijay K. 1997. From Mind To Market Cap 1Marcos B. TecОценок пока нет

- Brent Civic Centre BuildingДокумент7 страницBrent Civic Centre BuildingAgnes Cheverloo CastilloОценок пока нет

- Liability Insurance 24 Maret 2019 - 24 Maret 2020.2Документ16 страницLiability Insurance 24 Maret 2019 - 24 Maret 2020.2ruhul bayanОценок пока нет

- Algae Article Fong 1503324Документ63 страницыAlgae Article Fong 1503324Alejandra AragónОценок пока нет

- Reactive Systems Chapter 13Документ47 страницReactive Systems Chapter 13brayan100% (1)

- CCCCCCCCCCCCCCCCCCCCCCCC CCCCCCC: C C C CДокумент9 страницCCCCCCCCCCCCCCCCCCCCCCCC CCCCCCC: C C C CSwati KhannaОценок пока нет

- LUYỆN VIẾT ĐOẠN VĂN TIẾNG ANH - ON GLOBAL WARMINGДокумент3 страницыLUYỆN VIẾT ĐOẠN VĂN TIẾNG ANH - ON GLOBAL WARMINGVũ TuấnОценок пока нет

- Glossary. API The American Petroleum Institute, A Trade Association.Документ22 страницыGlossary. API The American Petroleum Institute, A Trade Association.edwingtt@gmailОценок пока нет

- Gas Turbines Siemens InteractiveДокумент22 страницыGas Turbines Siemens InteractiveBony DiazgОценок пока нет