Академический Документы

Профессиональный Документы

Культура Документы

C 1002 - 00 Qzewmditmda

Загружено:

Humberto Gutierrez0 оценок0% нашли этот документ полезным (0 голосов)

157 просмотров4 страницыThis standard covers Steel Self-Piercing Tapping Screws for use in fastening gypsum panel products and Metal Plaster Bases to cold-formed Steel Studs less than 0.033 in. (0. Mm) in thickness and wood members. This standard has been approved for use by agencies of the department of defense.

Исходное описание:

Оригинальное название

c 1002 – 00 ;Qzewmditmda

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis standard covers Steel Self-Piercing Tapping Screws for use in fastening gypsum panel products and Metal Plaster Bases to cold-formed Steel Studs less than 0.033 in. (0. Mm) in thickness and wood members. This standard has been approved for use by agencies of the department of defense.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

157 просмотров4 страницыC 1002 - 00 Qzewmditmda

Загружено:

Humberto GutierrezThis standard covers Steel Self-Piercing Tapping Screws for use in fastening gypsum panel products and Metal Plaster Bases to cold-formed Steel Studs less than 0.033 in. (0. Mm) in thickness and wood members. This standard has been approved for use by agencies of the department of defense.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

Designation: C 1002 00

Standard Specication for

Steel Self-Piercing Tapping Screws for the Application of

Gypsum Panel Products or Metal Plaster Bases to Wood

Studs or Steel Studs

1

This standard is issued under the xed designation C 1002; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope *

1.1 This specication covers steel self-piercing tapping

screws for use in fastening gypsum panel products and metal

plaster bases to cold-formed steel studs less than 0.033 in.

(0.84 mm) in thickness and wood members and for fastening

gypsum panel products to gypsum board.

1.2 This specication also covers test methods for determin-

ing performance requirements and physical properties.

1.3 The values stated in inch-pound units are to be regarded

as the standard. The SI (metric) values given in parentheses are

approximate and are for information only.

1.4 The following safety hazards caveat pertains only to the

test methods described in this specication: This standard does

not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2.1 ASTM Standards:

A 548 Specication for Steel Wire, Carbon, Cold-Heading

Quality for Tapping or Sheet Metal Screws

2

C 11 Terminology Relating to Gypsum and Related Build-

ing Materials and Products

3

C 36 Specication for Gypsum Wallboard

3

C 645 Specication for Nonstructural Steel Framing Mem-

bers

3

C 847 Specication for Metal Lath

3

3. Terminology

3.1 Denitions: For denitions relating to gypsum and

related building materials and systems, see Terminology C 11.

3.2 Denitions of Terms Specic to This Standard:

3.2.1 self-piercing, vthe ability to penetrate without ben-

et of a pre-drilled hole with sharp-point angles of not more

than 30.

3.2.2 spin-out, vfor a screw, the continued rotation of a

screw without further penetration into the substrate.

4. Classication

4.1 Steel screws covered by this specication are of four

types of thread congurations:

4.1.1 Type G, course-pitch high-thread self-piercing screws

for fastening gypsum board to gypsum board.

4.1.2 Type S, ne-thread screw for fastening gypsum board

to cold formed steel members.

4.1.3 Type W, course-thread screw for fastening gypsum

board to wood members.

4.1.4 Type A, course-pitch tapping screw thread for fasten-

ing metal plaster bases to wood or cold-formed steel.

5. Materials

5.1 Steel Wire, for manufacturing screws, Specication

A 548, Grades 1013 to 1022.

6. Physical Properties

6.1 Hardness:

6.1.1 The surface of Type S, Type W, and Type A screws

shall be case hardened to a depth of not less than 0.002 in.

(0.05 mm) with case hardness not less than 45 HRC.

6.1.2 The surface of Type G screws is not required to be

case hardened.

6.2 DuctilityThe screws shall have sufficient ductility to

be able to withstand a 15 bend without visible signs of fracture

when tested as specied in 12.6.6.

7. Performance Requirements

7.1 Type G Screws:

7.1.1 Screws shall be able to self-pierce and drive into

gypsum panel products.

7.1.2 Screw threads shall be adequate to pull the head of the

screw below the surface of the gypsum panel product when

tested as specied in 12.6.2.

7.2 Type S Screws:

7.2.1 GeneralScrews shall be able to self-pierce and drive

1

This specication is under the jurisdiction of ASTM Committee C11 on

Gypsum and Related Building Materials and Systems and is the direct responsibility

of Subcommittee C11.02 on Specications and Test Methods for Accessories and

Related Products.

Current edition approved July 10, 2000. Published October 2000. Originally

published as C 1002 83. Last previous edition C 1002 98.

2

Discontinued; see 1990 Annual Book of ASTM Standards, Vol 01.03.

3

Annual Book of ASTM Standards, Vol 04.01.

1

*A Summary of Changes section appears at the end of this standard.

Copyright ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

into cold-formed steel members in less than 2 s, when tested as

specied in 12.6.3.1.

7.2.2 Screws for Fastening Gypsum Panel ProductsScrew

threads shall be adequate to pull the head of the screw below

the surface of the gypsum panel product, without spin-out,

when tested as specied in 12.6.3.1.

7.3 Type W Screws:

7.3.1 GeneralScrew threads shall be able to self-pierce

and drive into wood members.

7.3.2 Screws for Fastening Gypsum Panel ProductsScrew

threads shall be adequate to pull the head of the screw below

the surface of the gypsum panel product, without spin-out

when tested as specied in 12.6.4.1.

7.4 Type A Screws:

7.4.1 GeneralScrew shall be able to pierce and drive into

wood or cold-formed steel members.

7.4.2 Screws for Fastening Metal Plaster BasesScrew

threads shall be adequate to pull a metal plaster base tightly

enough against the face of a wood or steel stud, without

spin-out, so that when subjected to a steady pull, the plaster

base will tear before slipping out from under the screw head,

when tested in accordance with 12.6.5.1 or 12.6.5.2.

8. Dimensions and Permissible Variations

8.1 Head Diameter:

8.1.1 GeneralHeads shall be permitted to be out of round

not more than 0.02 in. (0.51 mm).

8.1.2 Screws for Fastening Gypsum BoardNot less than

0.315 in. (8 mm).

8.1.3 Screws for Fastening Metal Plaster BasesNot less

than 0.437 in. (11.1 mm).

8.2 Head Contour:

8.2.1 Screws for Fastening Gypsum Panel ProductsThe

top of the head shall be at. The outer ange thickness shall be

0.025 6 0.005 in. (0.64 6 0.13 mm). The contour beneath the

ange head shall be such that the screw head shall be able to

be driven so that the head of the screw rests immediately below

the surface of the gypsum panel product.

8.2.2 Screws for Fastening Metal Plaster BasesThe top of

the screw shall be either at or contoured. The underside of the

head shall be at or near at. The threads shall extend to the

underside of the head.

8.3 Driving Recess:

8.3.1 Screws for Fastening Gypsum BoardNo. 2 Phil-

lips design, depth of recess, not less than 0.104 in. (2.64 mm).

8.3.2 Screws for Fastening Metal Plaster BasesNo. 2

Phillips design, depth of recess, not less than 0.077 in. (1.95

mm).

8.3.3 Determine depth of recess with a Phillips penetration

depth gage.

8.3.4 Other types of screw-driving recesses having perfor-

mance values equal to those of the recesses specied are

acceptable.

8.4 Shank DiameterNot less than No. 6, with major

diameter not less than 0.136 in. (3.45 mm).

8.5 Length:

8.5.1 Nominal LengthThe nominal length shall be the

minimum length.

8.5.2 Type W and Type A screws shall be long enough to

penetrate wood members not less than

5

8 in. (15.9 mm).

8.6 ThreadsEither single or multiple thread design.

8.7 PointsSelf-piercing design.

9. Finish and Appearance

9.1 FormThe form shall be straight and neatly formed.

9.2 ThreadsThe threads shall be clean and smooth.

9.3 FinishScrews shall have a corrosion-resistant treat-

ment. The treatment shall not inhibit adhesion to nishing

compounds nor bleed through eld-applied decoration.

10. Sampling

10.1 Obtain not less than one specimen of each type of

screw to be tested from each of ve containers, with not less

than ve screws per 16 000 screws, to constitute a lot for

testing.

11. Number of Tests and Retests

11.1 If any of the rst lot fails the test, test 25 more screws.

11.2 If two or more screws of the second lot fail the second

test, then the represented lot fails to meet the specied

requirements.

12. Test Methods

12.1 The following test methods set forth procedures used

to determine the ability of the screws to self-pierce through

gypsum panel and metal plaster base and into the backup

material without spin-out.

12.1.1 The test methods can also be used to determine

whether or not alternate screw driving recesses will have

performance values equal to those of the Phillips recess

specied.

12.2 Signicance and UseThe test methods provide pro-

cedures for evaluating the physical properties and performance

requirements of steel self-piercing screws. The degree of

correlation between these tests and service performance has not

been determined.

12.3 Apparatus:

12.3.1 Screw GunStandard manufacture electric screw

gun, turning at a minimum of 2500 r/min having a bit suitable

for the driving recess of the screw being tested.

12.3.2 Timing DeviceStandard stopwatch, calibrated

in

1

10 s.

12.3.3 ViceStandard machinists vice, not less than 3 in.

(76 mm).

12.3.4 ClampLocking pliers (Vice-Grip), 6 in. (152

mm).

12.4 Materials:

12.4.1 Gypsum WallboardSpecication C 36, Type

X,

5

8 in. (16 mm) thick.

12.4.2 Metal LathAs in Specication C 847, diamond

mesh, weight 2.5 lb/yd

2

(1.4 kg/m

2

).

12.4.3 Steel StudAs in Specication C 645, 0.0179 in.

(0.455 mm) thick, hardness not less than 52 HRB, size 3

5

8 in.

(92.1 mm).

12.4.4 Wood StudDouglas r, construction grade, 2 by 4

or 2 by 6, nominal, containing not less than 16 % nor more than

19 % free moisture as determined by a suitable moisture meter.

12.4.5 Kraft Paper0.01 in. (0.25 mm) thick, 2 in. (51

mm) square.

C 1002

2

12.5 Specimen Preparation:

12.5.1 Cut 6-in. (152-mm) square specimens from a sheet of

gypsum wallboard not less than 12 in. (305 mm) away from the

edge or end.

12.5.1.1 Weigh the specimens to within 1 g, and then

condition at a temperature of 85 6 15F (29.5 6 5.5C) in an

atmosphere having a relative humidity of 50 6 2 %. Individu-

ally test the specimens after constant weight is reached.

12.5.2 Cut 6 in. (152 mm) square specimens from a sheet of

metal lath not less than 4 in. (102 mm) away from the edge or

end.

12.5.3 Cut 12 in. (305 mm) long specimens from a length of

a steel stud.

12.5.4 Cut 12 in. (305 mm) long specimens from a length of

wood stud.

12.6 Procedure:

12.6.1 General:

12.6.1.1 When driving Type G screw specimens, the total

pressure shall be not more than 20 lbf (89.0 N).

12.6.1.2 When driving Types S and W screw specimens, the

total pressure shall be 25 lbf (111 N).

12.6.1.3 Drive the screws not closer than

5

8 in. (9.5 mm)

from the edges of the gypsum wallboard and not closer than 2

in. (50 mm) from the edges of metal lath.

12.6.2 Type G Screw TestRigidly support the two speci-

mens of gypsum wallboard sandwiched together. With a screw

gun, drive the screw specimen into the gypsum boards, so that

the head of the screw is below the surface of the wallboard.

12.6.3 Type S Screw Test:

12.6.3.1 Screws for Fastening Gypsum BoardRigidly

support a specimen of gypsum wallboard over a steel stud

specimen. With a screw gun, drive the screw specimen through

four layers of Kraft paper, through the wallboard and into the

steel stud. Observe the length of time it takes to drive the screw

to the depth required to meet the performance requirements

specied in 7.2.1 and observe if there was spin-out.

12.6.4 Type W Screw Test:

12.6.4.1 Screws for Fastening Gypsum BoardRigidly

support a specimen of gypsum wallboard over a wood stud

specimen. With a screw gun, drive the screw specimen through

four layers of Kraft paper, through the wallboard and into the

wood stud.

12.6.5 Type A Screw Test:

12.6.5.1 Screws for Fastening Metal LathRigidly support

a specimen of metal lath over a wood stud specimen. With a

screw gun, drive the screw specimen through the metal lath and

into the wood stud. Grasp the metal lath with the locking pliers

and pull steadily in a direction parallel to the plane of the lath.

Observe whether the lath tears before it slips out from under

the screw head.

12.6.5.2 Screws for Fastening Metal LathRigidly support

a specimen of metal lath over a steel stud specimen. With a

screw gun, drive the screw specimen through the metal lath and

into the steel stud. Observe if there was spinout. Grasp the

metal lath with the locking pliers and pull steadily in a plane

parallel to the plane of the lath. Observe whether the lath tears

before it slips out from under the screw head.

12.6.6 Ductility TestHold one end of a screw specimen in

a vice. Hold the other end with the locking pliers and bend the

screw to an angle of 15. Observe for signs of fracture in the

screw shank.

12.7 Precision and BiasNo estimate of the precision or

bias of these methods is available at this time.

13. Inspection

13.1 Inspection of the screws shall be agreed upon between

the purchaser and the producer or the supplier as part of the

purchase agreement.

14. Rejection

14.1 Rejection of screws that fail to conform to the require-

ments of this specication shall be reported to the producer or

supplier promptly and in writing. The notice of rejection shall

contain a statement documenting how the screws have failed to

conform to the specication requirements.

15. Certication

15.1 When specied in the purchase agreement, a produc-

ers or suppliers report shall be furnished at the time of

shipment, certifying that the screws are in compliance with this

specication.

16. Packaging and Marking

16.1 Packaging:

16.1.1 Screws shall be packaged in substantial commercial

shipping containers, constructed so as to preserve the contents

in good condition and to ensure acceptance and safe delivery

by common or other carriers, to the point of delivery.

16.1.2 Individual packages shall be so constructed that the

contents shall be able to be partially removed without destroy-

ing the containers ability to serve as a receptacle for the

remainder of the contents.

16.2 MarkingIndividual packages and shipping contain-

ers shall be marked with the type, size, use, and quantity of

screws contained therein, the name, brand, or trademark of the

producer or supplier, and the ASTM designation.

17. Keywords

17.1 drill screw; gypsum board; lath; metal plaster base;

self-pierce; self-piercing screw

C 1002

3

SUMMARY OF CHANGES

Committee C11 has identied the location of selected changes to this standard since the last issue

(C 1002 98) that may impact the use of this standard.

(1) Revised title and scope.

(2) Revised Title of C 645 in Section 2.

(3) Revised 3.2.2.

(4) Revised Section 4 to include Type A screws.

(5) Revised 6.1.1.

(6) Revised 7.1.1.

(7) Revised 7.2.1.

(8) Revised 7.2.3 as new paragraph 7.4.2.

(9) Revised 7.3.1.

(10) Added new paragraphs 7.4-7.4.2.

(11) Revised 8.7.

(12) Revised 12.1.

(13) Revised 12.2.

(14) Revised 12.3.1.

(15) Revised 12.5.1.

(16) Revised 12.6.2.

(17) Revised 12.6.3.1.

(18) Revised 12.6.4.1.

(19) Added new paragraph 12.6.5.

(20) Renumbered and revised paragraphs 12.6.4.2 and 12.6.3.2

as new paragraphs 12.6.5.1 and 12.6.5.2.

(21) Revised 12.6.3.2.

(22) Revised 16.1.1.

(23) Revised Keywords section.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at

610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org).

C 1002

4

Вам также может понравиться

- Senior Inspector of Fire Alarm Boxes: Passbooks Study GuideОт EverandSenior Inspector of Fire Alarm Boxes: Passbooks Study GuideРейтинг: 5 из 5 звезд5/5 (1)

- Astm C954Документ3 страницыAstm C954Cj Elamparo100% (1)

- A 954 - 96 QTK1NC05NGДокумент4 страницыA 954 - 96 QTK1NC05NGsachinguptachdОценок пока нет

- Astm e 935-00 985-00Документ29 страницAstm e 935-00 985-00zoranmiskovicОценок пока нет

- A 872 - 91 R02 Qtg3mi05mviwmgДокумент3 страницыA 872 - 91 R02 Qtg3mi05mviwmgsachinguptachdОценок пока нет

- ASTM E 303.14603 British PendulumДокумент6 страницASTM E 303.14603 British PendulumKongsak AkkharawongwhatthanaОценок пока нет

- Agencies Engaged in The Testing And/or Inspection of Materials Used in ConstructionДокумент9 страницAgencies Engaged in The Testing And/or Inspection of Materials Used in ConstructionFredyОценок пока нет

- C 1330 - 02 - QzezmzaДокумент2 страницыC 1330 - 02 - Qzezmzamercab15Оценок пока нет

- Jeremias INSTALL DS-GOV PDFДокумент28 страницJeremias INSTALL DS-GOV PDFjudi sierОценок пока нет

- Hot-Formed Welded and Seamless Carbon Steel Structural TubingДокумент6 страницHot-Formed Welded and Seamless Carbon Steel Structural TubingVenreplast PueblaОценок пока нет

- D4945 - 17 4.08 High-Strain Dynamic Testing of Piles (PDA Test)Документ10 страницD4945 - 17 4.08 High-Strain Dynamic Testing of Piles (PDA Test)JemersonMSОценок пока нет

- Astm A588-A588m-05Документ3 страницыAstm A588-A588m-05Hoang Kien100% (1)

- Standard Specification For Lightweight Aggregates For Insulating Concrete PDFДокумент3 страницыStandard Specification For Lightweight Aggregates For Insulating Concrete PDFAndy OliveraОценок пока нет

- C1032 - 06Документ2 страницыC1032 - 06Black GokuОценок пока нет

- Fiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceДокумент3 страницыFiberglass Reinforced Styrene-Butadiene-Styrene (SBS) Modified Bituminous Sheets With A Factory Applied Metal SurfaceKevin Josue100% (1)

- Astm A875m-Zinc 5 % Alum-13Документ8 страницAstm A875m-Zinc 5 % Alum-13Ahmed SalehОценок пока нет

- C22-C22M - 00 (Reapproved 2010)Документ2 страницыC22-C22M - 00 (Reapproved 2010)Black Goku0% (1)

- Astm C955-09Документ4 страницыAstm C955-09rodrigoОценок пока нет

- D 6054 - 97 - Rdywntq - PDFДокумент3 страницыD 6054 - 97 - Rdywntq - PDFwilliamОценок пока нет

- C 1047 - 99 QzewndcДокумент3 страницыC 1047 - 99 QzewndcGarcia ManuelОценок пока нет

- Astm A82 1979Документ6 страницAstm A82 1979yoki_triwahyudiОценок пока нет

- C924MДокумент3 страницыC924MRufo Casco0% (1)

- North American Standard For Cold-Formed Steel Framing - GeneralДокумент49 страницNorth American Standard For Cold-Formed Steel Framing - GeneralNishan GajurelОценок пока нет

- Astm2241 09 PDFДокумент9 страницAstm2241 09 PDFPaola MenaОценок пока нет

- Astm A 779 A779m-12Документ4 страницыAstm A 779 A779m-12Mohammed AliОценок пока нет

- D4748 Determining Bound Pavement Layers by Short Pulse RadarДокумент7 страницD4748 Determining Bound Pavement Layers by Short Pulse Radarvliew18Оценок пока нет

- Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using Glass Fiber ReinforcementsДокумент3 страницыStyrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using Glass Fiber ReinforcementsLuigi HernándezОценок пока нет

- Esr 1308Документ21 страницаEsr 1308dkimОценок пока нет

- A805A805M-09 Standard Specification For Steel, Flat Wire, Carbon, Cold-RolledДокумент12 страницA805A805M-09 Standard Specification For Steel, Flat Wire, Carbon, Cold-Rolledtjt4779Оценок пока нет

- Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsДокумент7 страницAbuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement PanelsAlejandroОценок пока нет

- A126-04 (2014) Gray Iron Castings For Valves, Flanges, and Pipe FittingsДокумент3 страницыA126-04 (2014) Gray Iron Castings For Valves, Flanges, and Pipe FittingsJosh HansenОценок пока нет

- Molded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForДокумент2 страницыMolded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForJesús Luis Arce Guillermo100% (1)

- D409-Standard Test Method For Grindability of Coal by The Hardgrove-Machine Method PDFДокумент9 страницD409-Standard Test Method For Grindability of Coal by The Hardgrove-Machine Method PDFGuntanОценок пока нет

- 2010CaliforniaEnergyCode Gov - Ca.bsc.2010.06Документ126 страниц2010CaliforniaEnergyCode Gov - Ca.bsc.2010.06Laisattrooklai PhisitОценок пока нет

- Nema PB1Документ36 страницNema PB1avikrisadОценок пока нет

- ASTM F363 Gaskets Corrosion TestingДокумент3 страницыASTM F363 Gaskets Corrosion TestingDieguitoOmarMoralesОценок пока нет

- On-Line Monitoring Systems For Water AnalysisДокумент14 страницOn-Line Monitoring Systems For Water AnalysisMickeyYS LongОценок пока нет

- ASTM E119 - 12aДокумент34 страницыASTM E119 - 12aOmer Taj-eldinОценок пока нет

- E53-07 (Reapproved 2013) PDFДокумент4 страницыE53-07 (Reapproved 2013) PDFearth metallurgical services pvt.ltd.Оценок пока нет

- Astm A185 A185m-07Документ6 страницAstm A185 A185m-07HelisОценок пока нет

- Effect of Moisture and Temperature On Adhesive Bonds: Standard Practice ForДокумент2 страницыEffect of Moisture and Temperature On Adhesive Bonds: Standard Practice Formohammad1361Оценок пока нет

- A994Документ8 страницA994saleemut3Оценок пока нет

- C811-98 (Reapproved 03)Документ3 страницыC811-98 (Reapproved 03)diego echagarayОценок пока нет

- Lime Putty For Structural PurposesДокумент2 страницыLime Putty For Structural Purposesasemamaw damtieОценок пока нет

- D 2661 - 97 - Rdi2njetotdbrte - PDFДокумент9 страницD 2661 - 97 - Rdi2njetotdbrte - PDFAndre CasteloОценок пока нет

- C24Документ5 страницC24maria tОценок пока нет

- Epoxy-Resin-Base Bonding Systems For ConcreteДокумент6 страницEpoxy-Resin-Base Bonding Systems For ConcreteDataniel RosarioОценок пока нет

- Concrete Construction Article PDF - Brick and Block Get Together in New Code PDFДокумент4 страницыConcrete Construction Article PDF - Brick and Block Get Together in New Code PDFQuang Tan TruongОценок пока нет

- Deformed and Plain Carbon-Steel Bars For Concrete ReinforcementДокумент8 страницDeformed and Plain Carbon-Steel Bars For Concrete ReinforcementmameniqОценок пока нет

- ASTM E2347 - Indentation Softening Temperature by Thermomechanical Analisys PDFДокумент5 страницASTM E2347 - Indentation Softening Temperature by Thermomechanical Analisys PDFAugusto ManuelОценок пока нет

- ASTM D897.20934 Propiedades Ténsiles en Uniones AdhesivasДокумент3 страницыASTM D897.20934 Propiedades Ténsiles en Uniones Adhesivasamgoyesv17Оценок пока нет

- Astm D3262-96Документ8 страницAstm D3262-96anish_am2005Оценок пока нет

- D450Документ2 страницыD450saifullah629Оценок пока нет

- Roofing and Waterproofing: Standard Terminology Relating ToДокумент9 страницRoofing and Waterproofing: Standard Terminology Relating ToRONALD MUELLERОценок пока нет

- Astm 2466-15 PDFДокумент6 страницAstm 2466-15 PDFDeisabel CrespoОценок пока нет

- Application of Gypsum Veneer Plaster: Standard Specification ForДокумент5 страницApplication of Gypsum Veneer Plaster: Standard Specification ForINARQ1979Оценок пока нет

- A 941 - 04 QTK0MQДокумент7 страницA 941 - 04 QTK0MQTrầnHữuHòaОценок пока нет

- Flow of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForДокумент3 страницыFlow of Freshly Mixed Hydraulic-Cement Concrete: Standard Test Method ForEvert RiveraОценок пока нет

- Ufgs 13 34 19Документ45 страницUfgs 13 34 19sharandeep1112Оценок пока нет

- C 954 Â " 98 QZK1NC1SRUQДокумент4 страницыC 954 Â " 98 QZK1NC1SRUQSebastián RodríguezОценок пока нет

- F 438 - 99 Rjqzoc05oqДокумент5 страницF 438 - 99 Rjqzoc05oqHumberto GutierrezОценок пока нет

- D 2680 - 95 Rdi2odatotvbДокумент8 страницD 2680 - 95 Rdi2odatotvbHumberto GutierrezОценок пока нет

- Jesús Rubí M.: Fórmulas de Cálculo Diferencial e IntegralДокумент0 страницJesús Rubí M.: Fórmulas de Cálculo Diferencial e IntegralSergio1218Оценок пока нет

- F 477 - 02 RJQ3NWДокумент4 страницыF 477 - 02 RJQ3NWHumberto GutierrezОценок пока нет

- D 2657 - 03 Rdi2ntcДокумент7 страницD 2657 - 03 Rdi2ntcHumberto GutierrezОценок пока нет

- D 3517 - 03 Rdm1mtctukveДокумент14 страницD 3517 - 03 Rdm1mtctukveHumberto GutierrezОценок пока нет

- D 5319 - 97 R01 RduzmtkДокумент4 страницыD 5319 - 97 R01 RduzmtkHumberto GutierrezОценок пока нет

- F 409 - 99 Rjqwos05oueДокумент16 страницF 409 - 99 Rjqwos05oueHumberto GutierrezОценок пока нет

- D 5926 - 96 Rdu5mjytukveДокумент5 страницD 5926 - 96 Rdu5mjytukveHumberto GutierrezОценок пока нет

- D 3309 - 96a R02 RDMZMDKДокумент11 страницD 3309 - 96a R02 RDMZMDKHumberto GutierrezОценок пока нет

- D 4495 - 98 Rdq0otutukveДокумент7 страницD 4495 - 98 Rdq0otutukveHumberto GutierrezОценок пока нет

- D 2467 - 02 Rdi0njctmdiДокумент8 страницD 2467 - 02 Rdi0njctmdiHumberto GutierrezОценок пока нет

- D 4726 - 02 Rdq3mjyДокумент11 страницD 4726 - 02 Rdq3mjyHumberto GutierrezОценок пока нет

- D 3840 - 99 Rdm4ndatotkДокумент9 страницD 3840 - 99 Rdm4ndatotkHumberto GutierrezОценок пока нет

- D 3035 - 03 RdmwmzutukveДокумент8 страницD 3035 - 03 RdmwmzutukveHumberto GutierrezОценок пока нет

- Type PSM Poly (Vinyl Chloride) (PVC) Sewer Pipe and Fittings: Standard Specification ForДокумент12 страницType PSM Poly (Vinyl Chloride) (PVC) Sewer Pipe and Fittings: Standard Specification ForHumberto GutierrezОценок пока нет

- D 2105 - 01 - RdixmduДокумент6 страницD 2105 - 01 - RdixmduSwapnil CallaОценок пока нет

- D 2729 - 96 Rdi3mjktukveДокумент6 страницD 2729 - 96 Rdi3mjktukveHumberto GutierrezОценок пока нет

- D 1527 - 99 Rde1mjctukveДокумент11 страницD 1527 - 99 Rde1mjctukveHumberto GutierrezОценок пока нет

- D 1694 - 95 R00 Rde2otqДокумент4 страницыD 1694 - 95 R00 Rde2otqHumberto GutierrezОценок пока нет

- D 2235 - 96 RdiymzutukveДокумент7 страницD 2235 - 96 RdiymzutukveHumberto GutierrezОценок пока нет

- D 2444 - 99 Rdi0ndqДокумент8 страницD 2444 - 99 Rdi0ndqHumberto GutierrezОценок пока нет

- D 2122 - 98 RdixmjitotgДокумент5 страницD 2122 - 98 RdixmjitotgHumberto GutierrezОценок пока нет

- D 6246 - 01 RdyyndytmdeДокумент10 страницD 6246 - 01 RdyyndytmdeHumberto GutierrezОценок пока нет

- D 4947 - 00 RDQ5NDCДокумент8 страницD 4947 - 00 RDQ5NDCHumberto GutierrezОценок пока нет

- D 6216 - 03 RdyymtyДокумент32 страницыD 6216 - 03 RdyymtyHumberto GutierrezОценок пока нет

- D 2914 - 01 Rdi5mtqДокумент14 страницD 2914 - 01 Rdi5mtqHumberto GutierrezОценок пока нет

- D 542 - 95 Rdu0mi1sruqДокумент5 страницD 542 - 95 Rdu0mi1sruqHumberto GutierrezОценок пока нет

- D 1608 - 98 R03 Rde2mdgДокумент6 страницD 1608 - 98 R03 Rde2mdgHumberto GutierrezОценок пока нет

- D 6941 - 03 Rdy5ndetukveДокумент5 страницD 6941 - 03 Rdy5ndetukveHumberto GutierrezОценок пока нет

- DRG ch7 PDFДокумент56 страницDRG ch7 PDFRamim AhmedОценок пока нет

- Furse - Flat Tape SystemДокумент12 страницFurse - Flat Tape SystemnknfiveОценок пока нет

- Turbo ChargersДокумент13 страницTurbo Chargersma.powersourceОценок пока нет

- Rodamientos Lineales NSKДокумент54 страницыRodamientos Lineales NSKAriel Linder Ureña MontenegroОценок пока нет

- BS-919-2-2007-diş Mastar Toleransları PDFДокумент42 страницыBS-919-2-2007-diş Mastar Toleransları PDFalifuat duyguОценок пока нет

- SAE 45 ACME-16 and NPT Ball ValvesДокумент3 страницыSAE 45 ACME-16 and NPT Ball ValvesFloyd PriceОценок пока нет

- 9Документ140 страниц9Dixon Javier Cortes TapiaОценок пока нет

- PC78MR-6 Sebm030601Документ592 страницыPC78MR-6 Sebm030601Augusto Oliveira95% (19)

- Fishing ToolsДокумент4 страницыFishing ToolsalambertОценок пока нет

- Torques FagДокумент52 страницыTorques FagAlain Gonzalo Larama CastroОценок пока нет

- TwinDisc MG5114DC 1022655 - 0506 - CDДокумент266 страницTwinDisc MG5114DC 1022655 - 0506 - CDKacam Rasan100% (3)

- CK700-1F Cke800-1f CK850-2F Shop ManualДокумент554 страницыCK700-1F Cke800-1f CK850-2F Shop ManualPhụ Tùng Cơ Giới100% (1)

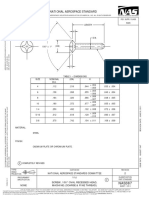

- National Aerospace Standard: Fed. Supply ClassДокумент2 страницыNational Aerospace Standard: Fed. Supply ClassGlenn CHOU100% (1)

- BS 04514-2001Документ18 страницBS 04514-2001Eslam ElsayedОценок пока нет

- Po336 Service ManualДокумент40 страницPo336 Service ManualJohn Alexander Bonilla AngelОценок пока нет

- ME301-Module iV-Design of Mechanical Joints-partI-Power Screws and Threaded JointsДокумент79 страницME301-Module iV-Design of Mechanical Joints-partI-Power Screws and Threaded JointsMohammed AlryaniОценок пока нет

- LandRoverDefender 1984-2006 DigitalДокумент68 страницLandRoverDefender 1984-2006 DigitalMihai AndronieОценок пока нет

- 1 Din HandbookДокумент2 страницы1 Din Handbookoadipphone7031Оценок пока нет

- W26 358 9004Документ29 страницW26 358 9004MROstop.comОценок пока нет

- Thread Identification Chart PDFДокумент1 страницаThread Identification Chart PDFashik asdОценок пока нет

- Astm A733 - 13Документ5 страницAstm A733 - 13Bell SilverОценок пока нет

- Alcoa Aerospace CatalogueДокумент15 страницAlcoa Aerospace CataloguePuneeth KumarОценок пока нет

- C-7003 - Manual Mantenimiento - #M50608-01 PDFДокумент56 страницC-7003 - Manual Mantenimiento - #M50608-01 PDFstefan corjucОценок пока нет

- Page Numbers Represent Printed Catalog PagesДокумент34 страницыPage Numbers Represent Printed Catalog PagesMilos BoricicОценок пока нет

- 0010 kOBELCO SK 179-9 PDFДокумент52 страницы0010 kOBELCO SK 179-9 PDFDaman Huri100% (2)

- Automotive Engines Theory and Servicing: Ninth EditionДокумент33 страницыAutomotive Engines Theory and Servicing: Ninth EditionmhafizanОценок пока нет

- Installation Manual - BM-BE - 1212Документ2 страницыInstallation Manual - BM-BE - 1212Lit Phen TuОценок пока нет

- Metric and Inch (Sae) Fasteners: All ModelsДокумент22 страницыMetric and Inch (Sae) Fasteners: All ModelsMONTACARGAS AVSОценок пока нет

- Machine Design MCQsДокумент30 страницMachine Design MCQsManish Tiwari33% (3)

- Satish Lele: Codes and StandardsДокумент10 страницSatish Lele: Codes and StandardsAamerMAhmadОценок пока нет