Академический Документы

Профессиональный Документы

Культура Документы

Parker - Energy Saving

Загружено:

matealoredana80150 оценок0% нашли этот документ полезным (0 голосов)

35 просмотров12 страницParker Hannifin has more than 40 years experience in the design and manufacturing of drives, controls, motors and mechanical products. Parker draws on industry-leading technological leadership and experience from engineering teams in Europe, North America and Asia. Parker's manufacturing teams seek continuous improvement through the implementation of lean manufacturing methods throughout the process.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документParker Hannifin has more than 40 years experience in the design and manufacturing of drives, controls, motors and mechanical products. Parker draws on industry-leading technological leadership and experience from engineering teams in Europe, North America and Asia. Parker's manufacturing teams seek continuous improvement through the implementation of lean manufacturing methods throughout the process.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

35 просмотров12 страницParker - Energy Saving

Загружено:

matealoredana8015Parker Hannifin has more than 40 years experience in the design and manufacturing of drives, controls, motors and mechanical products. Parker draws on industry-leading technological leadership and experience from engineering teams in Europe, North America and Asia. Parker's manufacturing teams seek continuous improvement through the implementation of lean manufacturing methods throughout the process.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 12

Energy Saving Technologies

for Motor-Driven Systems

Variable Speed Drive Solutions

2 23

Global Product Design

Parker Hannifin has more than 40

years experience in the design and

manufacturing of drives, controls,

motors and mechanical products.

With dedicated global product

development teams, Parker draws

on industry-leading technological

leadership and experience from

engineering teams in Europe, North

America and Asia.

Local Application Expertise

Parker has local engineering

resources committed to adapting

and applying our current products

and technologies to best fit our

customers needs.

Manufacturing to Meet

Our Customers Needs

Parker is committed to meeting the

increasing service demands that

our customers require to succeed

in the global industrial market.

Parkers manufacturing teams

seek continuous improvement

through the implementation of lean

manufacturing methods throughout

the process. We measure ourselves

on meeting our customers

expectations of quality and delivery,

not just our own. In order to meet

these expectations, Parker operates

and continues to invest in our

manufacturing facilities in Europe,

North America and Asia.

Manufacturing

Parker Sales Ofces

Distributors

Worldwide

Manufacturing Locations

Europe

Littlehampton, United Kingdom

Dijon, France

Offenburg, Germany

Milan, Italy

Asia

Shanghai, China

Chennai, India

North America

Rohnert Park, California

Irwin, Pennsylvania

Wadsworth, Ohio

Port Washington, New York

New Ulm, Minnesota

Local Manufacturing

and Support in Europe

Parker provides sales assistance

and local technical support through

a network of dedicated sales

teams and authorized technical

distributors throughout Europe.

For contact information, please

refer to the Sales Offices on the

back cover of this document or visit

www.parker.com

Parker Hannin - the global leader

in motion and control technologies

A world class player on a local stage

23

Together, we can reduce your

energy usage and save you money

Reduce your energy consumption with Parker SSDs variable

speed drive solutions

With over thirty years experience

in the design and manufacture of

drive modules and systems, Parker

has the expertise to work with

you to identify areas of potential

energy saving and to propose

individual solutions to help you

match your energy consumption

to the actual needs of your process

and business.

In addition to the high quality and

reliability of its products, Parker

SSD also ofers a range of value-

added services such as energy

audits, commissioning and

maintenance contracts. When

it comes to improving energy

efciency, Parker SSDs proven

track record gained across a

wide range of industries speaks

volumes.

Whether youre looking for a fully

engineered turn-key solution, or

help with a specifc aspect of your

energy usage, Parker SSD has

the necessary competencies to

compliment and assist your own

team throughout all stages of your

projects, from the initial energy

audit to startup and throughout its

operating life.

S Sectional process

lines :

Savings up to

35%

Hoisting and

conveying :

Savings up to

35%

Extruders,

mixers, crushers :

Savings up to

20%

Pumps and

sfans :

Savings up to

50%

4 45

Te detailed energy audit enables

our engineers to gather data

relating to:

- Phase current

- Phase voltage

- Energy consumption (kW)

- Power factor

Using portable measuring and

recording equipment, our highly

qualifed and experienced

applications engineers conduct

a comprehensive energy audit of

your installations without having

to interrupt their operation.

Energy monitoring and individually

tailored solutions

Evaluating the period for return on

investment (ROI)

With the aid of sophisticated

tools and the work of our highly

qualifed engineers, Parker SSD is

able to provide the answer to the

often posed question: How long

will it take to deliver a return on

my investment?

On the basis of the physical data

recorded during the energy audit,

Parker SSD is able to evaluate your

actual potential for energy saving,

allowing the payback period and

therefore ROI to be calculated

based on your actual operating

cycles.

Installation, service and training

As well as delivering efective,

efcient solutions adapted to

your specifc needs, we are keen

to ensure that the performance

of our products continue to meet

your expectations throughout

their life.

To this end, we have a 24/7,

365 day telephone support

line manned by a team of

experienced application

engineers providing

comprehensive help and

assistance with all aspects of

maintaining the performance of

your drive systems.

Parker SSD also ofers a whole

host of on-site services and

maintenance contracts, designed

to ensure the maximum possible

lifespan of your installations is

achieved.

For maximum efectiveness,

Parker SSD can also train your

teams to enable them to maintain

and support your installed

products. Training programs and

courses are run throughout the

year at our training facilities and

can be adapted to the specifc

requirements of your business, or

even delivered on-site.

Parker, your partner on the road

towards energy efciency

45

Parker, your partner on the road

towards energy efciency

Enhanced Capital Allowance Scheme

(ECA) for energy saving technologies

Financial help in making the change

to energy saving technologies

Enhanced capital allowance scheme for energy saving

technologies

You may think that making the

change to more energy-efcient

products is likely to be expensive.

Te reality is that although these

technologies may have a higher

upfront investment cost than

other less-efcient technologies,

they will start delivering energy

savings from day one. Payback

times of less than 18 months are

not uncommon and in some cases

this has been reduced to under 6

months.

If that in itself is not compelling

enough to convince you to make

the change to more energy-

efcient technologies, there are

a number of added incentives

provided the Carbon Trust to

encourage you to switch.

Set up in 2001 as an independant

company by Government, the

Carbon Trust is leading the drive

towards a low carbon economy

with advice and initiatives aimed

at removing obstacles to adopting

energy-efcient technologies.

Te ECA scheme encourages

businesses to invest in energy

saving plant or equipment by

allowing them to write of 100%

of the capital cost of equipment

against taxable profts in the year of

purchase.

Energy Technologies List (ETL)

Te ETL contains a wide-

range of difering energy

saving technologies that have

been assessed and meet the

requirements of the energy

technology criteria list. Tis

ensures that listed items meet the

requirements of the ECA scheme

and businesses may claim 100%

frst-year capital allowance.

As a licensed manufacturer of

energy saving technologies, Parker

SSD Drives has the right to display

the ETL symbol in connection

with its ETL listed products. Tis

demonstrates our continued

commitment to our customers

and to meeting the challenges of

meeting climate change through

energy-efciency.

6 67

Energy saving solutions for

pumps and fans

Speed control =

Savings

Up to 50% energy savings

Improved power factor

Reduced maintenance

Quieter operation

Increased service life

Reduced carbon footprint

Pumps and fans are widely used

throughout industry. Estimates

are that many of these are as

much as 20% oversized for the

application they are used for.

When operated at a constant

speed, a signifcant amount

of the power consumed is

wasted, costing your company

considerable amounts of money.

Matching process demands by

controlling the speed of pumps

and fans means that the motor

will always operate at the optimal

speed to deliver just the right

amount of air or fuid. Terefore

the energy consumption is

reduced. Savings of up to 50% can

be achieved with payback in less

than 18 months in many cases.

Pumps and fans that operate at

maximum speed continously will

inevitably have shortler life spans

and be subject to unnecessary

wear and tear. Variable speed

drives can help to prevent this

while also reducing energy

consumption and improving the

power factor of your installations.

In addition to the increased

lifespan of your system, youll

also see signifcant savings with

maintenance and repair bills and

a noticeable reduction in noise

pollution.

Control by ow regulation - motor

run at maximum speed

Control by Parker variable speed

drive

Gate valve

Constant speed

Motor

Electricity supply

(400VAC - 50Hz)

DOL, Star-Delta or

electronic starter

Electricity supply

(400VAC - 50Hz)

Variable speed

Motor

Pump

Motor

Electricity supply

(400VAC - 50Hz)

A

B

C

D

E

G

F

More efcient

Less efcient

Constant speed

Power consumption

higher than needed

Poor power factor

Higher energy costs

15,418 / Yr

= 22kW x 8760h x 0.08/kWh

Motor

Electricity supply

(400VAC - 50Hz)

A

B

C

D

E

G

F

More efcient

11.3kW

Less efcient

Variable speed

Power consumption

is matched to load

Improved power factor

Reduced energy costs

7,919 / Yr

= 11.3kW x 8760h x 0.08/kWh

22kW

Save energy through speed control

Improved power factor and service life

67

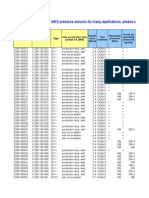

AC650V variable speed drive

Ratings 0.25kW - 110kW

Features

Ready to install Fastpack

solutions available

Communications options

allowing integration in building

management systems

Simple parameter setting and

adjustment

Power rating 0.25kW to 110 kW

Voltage range 220-240Vac 10% single phase

380-460Vac 10% three phase

50-60Hz 5%

Output frequency 0-240Hz

Operating temperature 0-40C

Enclosure Colour RAL7032

IP 54 (IP 55)

Dimensions 300x300x210 or

400x300x210 mm

Natural ventilation

Operator controls Drive or door mounted 4 character

back-lit display. Password protectable.

Te AC650V range of variable

speed drives have been designed

to provide simple no-fuss speed

control of standard three phase

AC induction motors from

0.25kW to 110kW. Tanks to its

sensorless fux vector technology,

the AC650V provides exceptional

control at lower speeds, accurate

speed regulation of variable loads

and high starting torques for high

inertia systems.

With a range of pre-programmed

on-board macros, the AC650V

is extremely quick to setup

and easy to operate in any

application.

With a variety of

communications options and

mounting arrangements, the

AC650V is easily integrated into

any environment. Optional EMC

flters, ftted as standard up to

7.5kW ensure compatability with

current EMC regulations.

Technical specification

Total annual energy saving = 7,499

8 89

Energy saving solutions for extruders

Save energy by removing gearboxes and adopting

a direct-drive solution

Parker torque motors are

permanent magnet brushless

servo motors, specially designed

to replace DC or induction motor

and gearbox combinations in

extruder applications.

Designed to deliver high torque at

low speed without any additional

mechanical transmission

systems, their usage results in

more compact, more efcient,

quieter and virtually maintenance

free drives systems.

Example of energy saving

Removal of the gearbox has an

immediate impact on the overall

installations efciency, resulting

in signifcant energy savings.

Example:

- 100 kW extruder

- 7200 h annual operating period

- Energy cost : 0.08/kWh

= 100kW x 7200h x 0.08/kWh

Overall efciency improvement

due to the installation of a torque

motor: 10%

Annual saving : 5,760

Conventional DC or induction

motor with gearbox

Parker torque motor without

gearbox

Motor

Electricity supply

(400VAC - 50Hz)

A

B

C

D

E

G

F

More efcient

Less efcient

Gearbox required

Signifcant mechanical

losses

Lower power output

0.91 x 0.91 = 0.81

Higher energy usage

71,111 / Yr

= 100kW / 0.81 x 7200h x 0.08/kWh

Motor

Electricity supply

(400VAC - 50Hz)

A

B

C

D

E

G

F

More efcient

111kW

Less efcient

No gearbox needed

No mechanical losses

Higher power output

0.91

Lower energy usage

64,000 / Yr

= 100kW / 0.9 x 7200h x 0.08/kWh

123kW

89

Energy saving solutions for extruders

Torque motors TMW

Technical specification

More than just motors, Parker

torque motors are complete

and ready-to-use direct drive

systems, specially designed with a

number of innovative and indus-

try specifc features to fully and

efectively respond to the exacting

needs of the plastics and rubber

machine builders and end-users.

Delivering torques up to 22,100

N.m, at speeds ranging from 50

to 500 rpm, Parker torque motors

represent the perfect alternative

to gearbox based systems for

extruder applications of powers

up to 320kW.

Torque range 1200 22100 N.m (water-cooled)

Shaft heights 200, 315 or 400 mm

Rated voltage 400 VAC and 480 VAC

Speed 50 500 rpm (size dependant)

- Field weakening operating up to 1.2xn

rated

- Other speeds available on request

Cooling Water jacket as standard

- Natural ventilation with derating

(consult us)

Mounting IMB3

IP rating IP 54

Thermal protection

1 x KTY sensor and 2 x PTC probes

- Temperature alarm as default

Shaft end Hollow shaft with keyway as standard

- Customized interfaces available on request

Thrust bearing SKF 294__E as standard

Feedback sensor EnDat encoder as standard

Hollow shaft direct EnDat encoder (option)

Resolver (option)

Torque range 1,200 to 22,100 Nm

Features

No mechanical transmission

elements

No mechanical losses

Virtually maintenance free

Silent operation

Total annual energy saving = 7,111

10 10 11

Energy saving hydraulic solutions

Improved efciency in hydraulic systems with

electronic control technologies

In any variable industrial process

such as one involving a hydraulic

pump, an unregulated motor

running at maximum speed is

wasting energy.

Reducing the motor speed during

low demand times can achieve

signifcant energy savings. By

using Parker SSDs variable speed

drive technology, instant savings

can be made.

By automatically adapting the

pumps speed to match changes

in demand, Parkers variable

speed drives are the perfect

addition to any hydraulic system.

Example of energy saving

Tests run on a hydraulic press

system clearly show that

substantial savings on energy is

possible using the Parker AC650V

variable speed drive. Te results

in this case was an average power

need of just 25kW compared to

38kW using an unregulated pump,

over the entire press cycle.

Parker supports you in the design

and implementation of frequency

controlled hydraulic systems

through all stages - initial planning,

measuring existing equipment,

rebuild and startup.

Motor

Electricity supply

(400VAC - 50Hz)

A

B

C

D

E

G

F

More efcient

Less efcient

21,888 / Yr

= 38kW x 7200h x 0.08/kWh

Motor

Electricity supply

(400VAC - 50Hz)

A

B

C

D

E

G

F

More efcient

25kW

Less efcient

14,400 / Yr

= 25kW x 7200h x 0.08/kWh

38kW

Conventional hydraulic system Frequency controlled hydraulic

system

+

Electric Motor

Hydraulic Pump Hydraulic Pump

+

Electric Motor

Hydraulic Pump Electronic control

10 11

Energy saving hydraulic solutions

Energy saving frequency inverters

Benefts with Parker AC650V - From a nancial point of view - From a technical point of view

Selection of system components

Standard motors can be used

Energy saving frequency drive

Standard pumps can be used

Works with 50/60HZ supply

Works with 230-500Vac supplies

Works with any motor speed

Smooth acceleration / braking

Longer motor service life

Less strain on the hydraulics and

other components

Less strain on the oil

No power surges

No pressure surges (cavitation)

Higher efficiency Savings on energy consumption

Reduced CO

2

emissions

Reduced peak power need

Reduced need for cooling

Compact dimensions Fewer, lighter and smaller parts

Takes up less space

Reduced hydraulic oil volume

Smaller pumps & coolers needed

Reduced noise levels

Less need for noise protection

Improved work environment

Reduced motor shaft rotations

Smoothed resonant frequencies

Integrated concept

Less external hardware

Simple customisation

Fieldbus options (Profbus, CAN)

System visualisation

Frequency control Higher effciency

Cost-optimised component

selection

Increased productivity through

higher motor speed

Volume fow that meets the exact

needs of the application, for

constant speed pumps across a

wide range.

Simple process diagnostics

Power range 0.25kW to 110kW

Total annual energy saving = 7,488

Features

Power ranges up to 110kW

Meets international standards

UL/cUL, CE,EMC, etc.

Simple installation

Easy to use

Easy change of parameters

Easy start-up

Compact

Removable operator station

Brochure HA500786 March 2009

2009 Parker Hannifn Corporation. All rights reserved.

Sales Offces

Spain

Parker Hannifn (Espana) SA

Parque Industrial Las Monjas

Calle de las Estaciones 8

28850 Torrejonde Ardoz

Madrid

Spain

Tel: +34 91 6757300

Fax: +34 91 6757711

Sweden

Parker Hannifn AB

Lundavgen 143

S-212 24 Malm

Tel: +46 (0)40 384550

Fax: +46 (0)40 183650

UK

Parker Hannifn Ltd

Tachbrook Park Drive

Tachbrook Park

Warwick

CV34 6TU

Tel: +44 (0) 1926 317970

Fax: +44 (0) 1926 317980

USA

Parker Hannifn Corp.

SSD Drives Division

9225 Forsyth Park Drive

Charlotte

North Carolina 28273-3884

Tel: +1 (704) 588 3246

Fax: +1 (704) 588 3249

Australia

Parker Hannifn

(Australia) Pty Ltd

9 Carrington Road

Private Bag 4, Castle Hill

NSW 1765

Tel: +61 2 9634 7777

Fax: +61 2 9699 6184

Belgium

Parker Hannifn SA NV

Sales Company BeLux

Business Park Les Portes de

lEurope

Avenue Alcide de Gasperi, 5

B-1400 Nivelles

Tel: +32 67 280 900

Fax : +32 67 280 999

Brasil

Parker Hannifn Ind.e Com. Ltda.

Av. Lucas Nogueira Garcez, 2181

Esperana - Caixa Postal 148

Tel: +55 0800 7275374

Fax: +55 12 3954 5262

Canada

Parker Motion and Control

160 Chisholm Drive

Milton

Ontario L9T 3G9

Tel: +1 (905) 693 3000

Fax: +1 (905) 876 1958

China

Parker Hannifn Motion & Control

(Shanghai) Co.Ltd

SSD Drives

280 Yunqiao Road

Export Processing Zone

Pudong District

Shanghai 201206

P.R.China

Tel: +86 (21) 5031 2525

Fax: +86 (21) 5854 7599

France

Parker SSD Parvex

8, Avenue du Lac

BP 30749

F-21007 Dijon Cedex

Tel: +33 (0) 3 80 42 41 40

Fax: +33 (0) 3 80 42 41 39

Germany

Parker Hannifn GmbH

Pat-Parker-Platz 1

41564 Kaarst

Tel: +49 (0)2131 4016-0

Fax: +49 (0)2131 4016-9199

India

Parker Hannifn India Pvt Limited

Automation Group -

SSD Drives Division.

151, Developed Plots Estate,

Perungudi, Chennai - 600 096

Tel: +91 44 43910799

Fax: +91 44 43910700

Italy

Parker Hannifn SPA

Via Gounod, 1

20092 Cinisello Balsamo,

Milano

Tel: +39-02 361081

Fax: +39 (02) 36108400

Singapore

Parker Hannifn Singapore Pte Ltd

11, Fourth Chin Bee Rd

Singapore 619702

Tel: +65 6887 6300

Fax: +65 6265 5125

Parker Hannin Ltd

SSD Drives Division

New Courtwick Lane, Littlehampton

West Sussex BN17 7RZ United Kingdon

Tel: +44 (0) 1903 737 000 Fax: +44 (0) 1903 737 100

epic@parker.com

www.parker.com/ssd

Your local authorized Parker distributor

Printed in England. HA500786

Issue 2 September 2010

2009 Parker Hannifin Limited.

HA500786

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Bosch Injector Data SheetДокумент124 страницыBosch Injector Data SheetThibaut Lrt56% (9)

- Concrete CoolingДокумент19 страницConcrete CoolingAbdulrahman AlnagarОценок пока нет

- Electric Motors Drives Vol 4Документ112 страницElectric Motors Drives Vol 4matealoredana8015100% (5)

- Controls InstrumentationДокумент245 страницControls InstrumentationFreddy Yánez100% (1)

- Lifeboat Engine Operation Manual 380JДокумент29 страницLifeboat Engine Operation Manual 380JDuarte100% (2)

- KD Engine Specs and Systems GuideДокумент72 страницыKD Engine Specs and Systems Guidemoises valenzuela janampaОценок пока нет

- Power Electronics For Renewable Energy Systems PDFДокумент160 страницPower Electronics For Renewable Energy Systems PDFSUSHITAОценок пока нет

- ACI 229 Enhanced CLSM 20160415 PDFДокумент30 страницACI 229 Enhanced CLSM 20160415 PDFerosОценок пока нет

- Truly International Reach of HDEE MethodologyДокумент40 страницTruly International Reach of HDEE Methodologymatealoredana8015Оценок пока нет

- E GEA M1019Документ8 страницE GEA M1019matealoredana8015100% (1)

- CASTELUL de CALCAR - Eugen Dorcescu (Ilustratii de Done Stan, 1988)Документ72 страницыCASTELUL de CALCAR - Eugen Dorcescu (Ilustratii de Done Stan, 1988)Amy JohnsonОценок пока нет

- Lubrication of Gear SystemsДокумент80 страницLubrication of Gear Systemsnunoaguiar8Оценок пока нет

- 2011 - Technical Study Report - Energy Efficiency ImprovemenДокумент85 страниц2011 - Technical Study Report - Energy Efficiency Improvemenmatealoredana8015Оценок пока нет

- Abb - The Motor GuideДокумент118 страницAbb - The Motor GuideRolando DaclanОценок пока нет

- Alkanes: Structure, Naming, Properties and ReactivityДокумент73 страницыAlkanes: Structure, Naming, Properties and ReactivityChona TuyОценок пока нет

- Ch-5 Sheet Metal OperationДокумент20 страницCh-5 Sheet Metal OperationJAYANT KUMARОценок пока нет

- 29B - Acid Gas Removal TechnologyДокумент17 страниц29B - Acid Gas Removal Technologyarlucky5459100% (1)

- MotorДокумент116 страницMotorRutvi Vishal Vaghela100% (1)

- Randunica PDFДокумент16 страницRandunica PDFliviacovaci691503Оценок пока нет

- Organizational Annoucemet BOM - PTSДокумент2 страницыOrganizational Annoucemet BOM - PTSmatealoredana8015Оценок пока нет

- Cartofi Umpluti La CuptorДокумент1 страницаCartofi Umpluti La Cuptormatealoredana8015Оценок пока нет

- Framework Maths C 8 Volume 8 Part 3Документ25 страницFramework Maths C 8 Volume 8 Part 3matealoredana8015Оценок пока нет

- Permanent Magnet Motors enДокумент31 страницаPermanent Magnet Motors enAhmet ErecekОценок пока нет

- Framework Maths C 8 Volume 8 Part 3Документ25 страницFramework Maths C 8 Volume 8 Part 3matealoredana8015Оценок пока нет

- Novatorque Final ReportДокумент12 страницNovatorque Final Reportmatealoredana8015Оценок пока нет

- PM MotorsДокумент116 страницPM Motorsmatealoredana8015Оценок пока нет

- RiepilogoДокумент3 страницыRiepilogomatealoredana8015Оценок пока нет

- Fundamentals Topic 7Документ65 страницFundamentals Topic 7Catalin CiubotariuОценок пока нет

- Saving Energy: Through Innovation and TechnologyДокумент24 страницыSaving Energy: Through Innovation and Technologymatealoredana8015Оценок пока нет

- Methods To Optimize Electric Motor EfficiencyДокумент7 страницMethods To Optimize Electric Motor Efficiencymatealoredana8015Оценок пока нет

- AbДокумент4 страницыAbChristopher HillОценок пока нет

- Energy Efficient Drives enДокумент25 страницEnergy Efficient Drives enmatealoredana8015Оценок пока нет

- Super-Premium Efficiency Class Electric Motors: Anibal de Almeida and Fernando FerreiraДокумент24 страницыSuper-Premium Efficiency Class Electric Motors: Anibal de Almeida and Fernando Ferreiramatealoredana8015Оценок пока нет

- Energy Efficiency MotorCatalogue - Eff1Документ2 страницыEnergy Efficiency MotorCatalogue - Eff1matealoredana8015Оценок пока нет

- Cee Motor GuidebookДокумент29 страницCee Motor GuidebookcarlosmandopintoОценок пока нет

- Cee Motor GuidebookДокумент39 страницCee Motor Guidebookhansenmike698105Оценок пока нет

- ROI From VFDs - OPFMA NewsletterДокумент1 страницаROI From VFDs - OPFMA Newslettermatealoredana8015Оценок пока нет

- ConveyorДокумент20 страницConveyormatealoredana8015Оценок пока нет

- HexaneДокумент3 страницыHexaneIan RidzuanОценок пока нет

- Liu JCP2019 Data Driven Intelligent Location Public Charging StationsДокумент11 страницLiu JCP2019 Data Driven Intelligent Location Public Charging StationsRodrigoОценок пока нет

- Ato and Nuclear LongДокумент74 страницыAto and Nuclear LongtitancryОценок пока нет

- J300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesДокумент6 страницJ300, J4ATS, J7ATS Transfer Switches 260, 400, and 600 Amp SizesMatt PittmanОценок пока нет

- Hypercell 1994 Engl by Hans HassДокумент126 страницHypercell 1994 Engl by Hans HassClaimDestinyОценок пока нет

- Siemens Overload RelayДокумент6 страницSiemens Overload Relaykhairalla mohamedОценок пока нет

- Chapter 1Документ27 страницChapter 1Omotayo PaulОценок пока нет

- Aluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsДокумент6 страницAluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsAvs ElectronОценок пока нет

- Tk09 Report Assignment 4Документ112 страницTk09 Report Assignment 4Bella Novia BerlianaОценок пока нет

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342Документ18 страницPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342EstebanОценок пока нет

- SPE 69708 Experiences Using An ESP Application On Heavy-Oil Cold-Production Automation in Eastern Venezuela FieldsДокумент3 страницыSPE 69708 Experiences Using An ESP Application On Heavy-Oil Cold-Production Automation in Eastern Venezuela FieldsM.Оценок пока нет

- Technical Specification TREO CF I48CA1Документ1 страницаTechnical Specification TREO CF I48CA1Razvan CorciuОценок пока нет

- AC192Документ1 страницаAC192soares_alexОценок пока нет

- Catalase TestДокумент2 страницыCatalase TestsekaralingamОценок пока нет

- 66 KV Design Parameters in GujaratДокумент1 страница66 KV Design Parameters in GujaratAkhilesh SolankiОценок пока нет

- BBBV3 ForegroundReading Solar UPS MarineДокумент7 страницBBBV3 ForegroundReading Solar UPS MarineSaibal BhattacharyyaОценок пока нет

- ARKIQUIZДокумент53 страницыARKIQUIZJane Louraigne Apilado GabrilloОценок пока нет

- Data Base Questions PhotosynthesisДокумент10 страницData Base Questions PhotosynthesisValeCalderónОценок пока нет

- Data Sheet (English) - 8036 Industrial ControlsДокумент44 страницыData Sheet (English) - 8036 Industrial ControlsNabil ShaukatОценок пока нет

- Air Entrainment in Manhole Drops-Paper - Final - ReviewedДокумент8 страницAir Entrainment in Manhole Drops-Paper - Final - ReviewedManuel SueroОценок пока нет