Академический Документы

Профессиональный Документы

Культура Документы

Datasheet Foxboro VisualizationandConfigurationTools 12-12

Загружено:

Jorge TenorioАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Datasheet Foxboro VisualizationandConfigurationTools 12-12

Загружено:

Jorge TenorioАвторское право:

Доступные форматы

Software Datasheet

Summary

Optimize engineering

workflow

Design, configure

deploy your control

strategies faster and

easier

Promote collaboration,

synchronization,

execution across your

operations

Increase operator

efficiency and

productivity with

intuitive visualization

tools

Preserve engineering

efforts and cost

through re-use and

standardization

Improve decision-

making to maximize

profitability

Offer superior

flexibility, adaptability

and responsiveness

Business Value

Foxboro Visualization

and Configuration

tools enable improved

process efficiency and

business performance to

achieve lowest total cost

of ownership for your

operations .

Signicantly reduce and simplify your engineering and operational efforts. This

powerful toolset provides cutting-edge graphical advantages in a consistent

environment to enhance your overall experience. Start your journey to improved

business performance today with superior collaboration, execution & visibility

across your entire enterprise.

Foxboro Visualization and Conguration Tools include:

Conguration tools for highly intuitive design & integrated engineering

Cutting-edge HMI for visualization optimization & operational best practices

Seamless integration and standardization of all operations data signicantly

reducing cost and efforts

Powerfully productive capabilities of advanced software applications like SQL-

based Historian and Client for real-time historical data storage and time-based

retrieval for dramatically increased operational efciency

Foxboro Visualization and

Conguration Tools

High-performing, productivity-enhancing visualization

and engineering tools for the Foxboro Control system.

SIMPLIFIED, INTEGRATED ENGINEERING

Optimize Engineering Workow

Enhance engineering productivity

and reduce efforts with Foxboro

conguration tools. Simplied

toolsets, common human interfacing

and standardized template-based

objects for building and maintaining

Foxboro I/A Series control

strategies and congurations can

be easily deployed and reused

across multi-site operations. Based

upon a standardized function set,

conguration of the Foxboro Control

system now becomes a matter of

assembling application objects

in a fashion similar to constructing a process ow diagram. By shifting the emphasis away from

programming and toward assembling strategies, you can now spend more time devising better,

safer control strategies.

Design, implement, deploy faster and easier

Reduce mundane programming tasks and reduce risk associated with implementing application

changes ensuring global consistency and best practices. The cost of project implementation is

greatly reduced making your job easier and more productive.

Maximize cost-savings and plant uptime

Foxboro Field Device Manager (FDM) is a software

application within Conguration Tools that offers complete

support and management of intelligent devices from

any vendor utilizing any eldbus protocol. FDM provides

superior device management, greatly reducing the

probability that an unexpected device failure will cause plant

downtime. This predictive device maintenance approach

allows you to locate problems early, before they become

severe and grants the time to plan corrective actions

without downtime. FDM offers simplied conguration,

commissioning, and maintenance to optimize your eld

devices. With Foxboro Any bus interoperability, you

maintain your preferences because Foxboro adapts to you.

Graphical construction,

deployment of Foxboro control

strategies

User-dened renderings of

re-usable control strategies

Printed reports of control

strategy drawings and support

Live updates of real-time values

superimposed on control

strategy drawings

Control strategy bulk generation

and migration

Ability to import and export

Supports any intelligent devices

from any vendor utilizing any

eldbus protocol

Concurrent access to the

database

POWERFULLY INTUITIVE VISUALIZATION TOOLS

Foxboro InTouch HMI combines industry leading visualization software with cutting-edge graphical

advances enabling you to quickly and easily be more productive and effective.

Maximize productivity and optimize user

effectiveness

Foxboro HMI tools include easy-to-use, object-

oriented programmable graphics and tightly

integrated communication connectivity to the

Foxboro Mesh Control network. This open and

extensible HMI enables exibility

in custom application design with

connectivity to the broadest set of

control and automation devices

in the industry. Resulting in a well

designed standards-driven systems

that maximize productivity, optimize

user effectiveness, increase quality,

and lower costs.

Easy to-use wizards and templates

Realize considerable savings by

reducing application engineering,

testing and deployment time, with

the creation of reusable templates

from graphics. SmartSymbol graphics enable rapid propagation of changes throughout the

application and even across multiple networked PC workstations. This makes changing, upgrading

and modifying very fast and simple

Unequaled device integration and connectivity

Connect to virtually any device using hundreds of available I/O and OPC servers that are designed to

connect to control systems and devices.

Avoid costly downtime, enable faster responses

Leverage built-in real time and historical capabilities that

offer several alarm analysis tools to provide the information

needed to proactively correct situations. You can now

determine the nature of an alarm, its location and options

for supporting fast analysis of alarm conditions coupled with

immediate response capabilities.

Resolution independent

graphics and intelligent

symbols

Intuitive, easy to navigate

display hierarchy

Sophisticated scripting

to extend and customize

applications for your needs

Foxboro control block faceplate

overlays

Role-based security options

Real-time distributed Alarming

with historical views for analysis

Invensys, the Invensys logo, ArchestrA, Avantis, Eurotherm, Foxboro, IMServ, InFusion, SimSci-Esscor, Skelta, Triconex, and Wonderware are trademarks of Invensys plc, its subsidiaries or afliates.

All other brands and product names may be the trademarks or service marks of their representative owners.

2012 Invensys Systems, Inc. All rights reserved. No part of the material protected by this copyright may be reproduced or utilized in any form or by any means, electronic or mechanical, including

photocopying, recording, broadcasting, or by any information storage and retrieval system, without permission in writing from Invensys Systems, Inc.

Invensys Operations Management 10900 Equity Drive, Houston, TX 77041 Tel: (713) 329-1600 Fax: (713) 329-1700 iom.invensys.com

START YOUR JOURNEY TO BUSINESS OPTIMIZATION

Leverage plant-wide collaboration of products, processes and people

Foxboro visualization and conguration tools extend a common object-based technology from

your Foxboro control system throughout your enterprise. You can now take advantage of powerful

applications and an open environment to integrate plant wide processes, people and products .

You can standardize on best practices when designing, deploying and maintaining your control

applications to realize lowest total cost of ownership.

Unlock hidden potential to gain signicant competitive advantage

Accelerated decision-making for maximum protability

Elimination of automation islands through integration of all devices, systems, databases and

software applications within manufacturing and infrastructure environments

Synchronization of industrial operations with business objectives for sustained protability

Standardization of operating practices and techniques across the organization

Flexibility to easily change plant-wide applications, control programs, and workow to quickly

respond to any business issue

A LOW COST, LOW RISK APPROACH TO GET YOU HERE

Protect your investment with the Continuously Current Foxboro control system

The Foxboro control system adheres to a Continuously Current philosophy that promises the platform

is continually infused with the latest technology while maintaining interoperability with previous

generations of your system. This ensures your investment is protected with cost-effective upgrade

paths at your own pace. Backwards compatibility is fundamental in our design to assure that classic

and the latest products communicate and share critical messaging structures. Keeping your system

Continuously Current promotes savings with the preservation of intellectual property, such as designing

and engineering control strategies, historian conguration, graphic displays and databases.

Upgrade at minimum risk, cost, and impact to your process

Not a Foxboro user? Foxboro migration solutions minimize the cost, risk and process impact of

system replacements. Invensys offer incremental migrations that allow you to take advantage of

Foxboro visualization and conguration tools in phases while keeping much of your existing hardware

infrastructure in place. Once you are ready to migrate the remaining components, the Foxboro Plug-

in migration solution enables you to simply plug-in new Foxboro I/O modules & controllers into your

existing cabinetry. This approach offers you a 100% newcontrol system at minimum cost, risk and

impact to your operations.

For more information contact your local sales representative or visit our web page at

http://iom.invensys.com/EN/Pages/Foxboro.aspx

Rel. 12/12 PN FX-0225

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Ck-Nac FsДокумент2 страницыCk-Nac Fsadamalay wardiwiraОценок пока нет

- History of Downtown San Diego - TimelineДокумент3 страницыHistory of Downtown San Diego - Timelineapi-671103457Оценок пока нет

- NAME: - CLASS: - Describing Things Size Shape Colour Taste TextureДокумент1 страницаNAME: - CLASS: - Describing Things Size Shape Colour Taste TextureAnny GSОценок пока нет

- Adjusted School Reading Program of Buneg EsДокумент7 страницAdjusted School Reading Program of Buneg EsGener Taña AntonioОценок пока нет

- Farm Policy Options ChecklistДокумент2 страницыFarm Policy Options ChecklistJoEllyn AndersonОценок пока нет

- Torts and DamagesДокумент63 страницыTorts and DamagesStevensonYuОценок пока нет

- Alsa Alsatom MB, MC - Service ManualДокумент26 страницAlsa Alsatom MB, MC - Service ManualJoão Francisco MontanhaniОценок пока нет

- Mental Health Admission & Discharge Dip NursingДокумент7 страницMental Health Admission & Discharge Dip NursingMuranatu CynthiaОценок пока нет

- Perilaku Ramah Lingkungan Peserta Didik Sma Di Kota BandungДокумент11 страницPerilaku Ramah Lingkungan Peserta Didik Sma Di Kota Bandungnurulhafizhah01Оценок пока нет

- Design Thinking SyllabusДокумент6 страницDesign Thinking Syllabussarbast piroОценок пока нет

- The Scavenger's Handbook v1 SmallerДокумент33 страницыThe Scavenger's Handbook v1 SmallerBeto TОценок пока нет

- Surgical Orthodontics Library DissertationДокумент5 страницSurgical Orthodontics Library DissertationNAVEEN ROY100% (2)

- Global Pre-Qualification - Registration of Vendors For Supply of Various Raw Materials - ProductsДокумент2 страницыGlobal Pre-Qualification - Registration of Vendors For Supply of Various Raw Materials - Productsjavaidkhan83Оценок пока нет

- Dead Can Dance - How Fortunate The Man With None LyricsДокумент3 страницыDead Can Dance - How Fortunate The Man With None LyricstheourgikonОценок пока нет

- Commissioning GuideДокумент78 страницCommissioning GuideNabilBouabanaОценок пока нет

- How To Make Wall Moulding Design For Rooms Accent Wall Video TutorialsДокумент15 страницHow To Make Wall Moulding Design For Rooms Accent Wall Video Tutorialsdonaldwhale1151Оценок пока нет

- Booklet - CopyxДокумент20 страницBooklet - CopyxHåkon HallenbergОценок пока нет

- Diaz, Rony V. - at War's End An ElegyДокумент6 страницDiaz, Rony V. - at War's End An ElegyIan Rosales CasocotОценок пока нет

- Cambridge IGCSE: 0500/12 First Language EnglishДокумент16 страницCambridge IGCSE: 0500/12 First Language EnglishJonathan ChuОценок пока нет

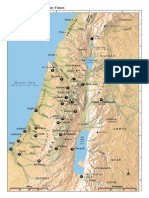

- Israel Bible MapДокумент1 страницаIsrael Bible MapMoses_JakkalaОценок пока нет

- iPhone Repair FormДокумент1 страницаiPhone Repair Formkabainc0% (1)

- Cycling Coaching Guide. Cycling Rules & Etiquette Author Special OlympicsДокумент20 страницCycling Coaching Guide. Cycling Rules & Etiquette Author Special Olympicskrishna sundarОценок пока нет

- Evolution of The Indian Legal System 2Документ7 страницEvolution of The Indian Legal System 2Akhil YarramreddyОценок пока нет

- Ausensi (2020) A New Resultative Construction in SpanishДокумент29 страницAusensi (2020) A New Resultative Construction in SpanishcfmaОценок пока нет

- Absolute Advantage and Comparative AdvantageДокумент11 страницAbsolute Advantage and Comparative AdvantageLouie ManaoОценок пока нет

- UNIMED Past Questions-1Документ6 страницUNIMED Past Questions-1snazzyОценок пока нет

- Adult Education and Training in Europe 2020 21Документ224 страницыAdult Education and Training in Europe 2020 21Măndița BaiasОценок пока нет

- NDA Template Non Disclosure Non Circumvent No Company NameДокумент9 страницNDA Template Non Disclosure Non Circumvent No Company NamepvorsterОценок пока нет

- Unit 6 Lesson 3 Congruent Vs SimilarДокумент7 страницUnit 6 Lesson 3 Congruent Vs Similar012 Ni Putu Devi AgustinaОценок пока нет

- Consolidation of AccountsДокумент14 страницConsolidation of Accountsram_alaways0% (1)