Академический Документы

Профессиональный Документы

Культура Документы

Lm2500 Descrip

Загружено:

Denis JimenezИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lm2500 Descrip

Загружено:

Denis JimenezАвторское право:

Доступные форматы

Description

Page 1 of 2

Description

The LM2500-PE and LM2500-PH (STIG) series gas turbine is a simple cycle, two shaft engine

consisting of a gas generator and a six stage power turbine. Shaft power is extracted by means of a

Purchaser supplied flexible coupling extending through a shaft tunnel within the Purchasers exhaust

collector. The gas generator consists of a variable geometry compressor; a dry low emissions (DLE)

triple annular combustor; a high pressure turbine (HPT); an accessory drive gearbox; and controls and

accessories. The power turbine (PT) is a six stage, low pressure turbine, aerodynamically coupled to the

gas generator and driven by the gas generator exhaust gas. The LM2500-PE and LM2500-PH (STIG)

series gas turbines are identical, with the exception of the flow function of the high pressure and low

pressure turbines, both of which, in the LM2500-PH gas turbine, are modified to accommodate the

increased mass flow resulting from injection of steam in quantities greater than that which can be

accepted (without modification) by steam-injected models of the LM2500-PE gas turbines.

The cycle of the gas turbine begins with air entering the inlet bellmouth of the gas generator and directed

into the compressor by the variable pitch inlet guide vanes (IGVs). Gas generator normal operating

speed is 6,800 to 10,050 rpm. The compressed air leaving the compressor is directed into the single

annular combustor section where it mixes with fuel. The fuel/air mixture is initially ignited by a single

igniter. Once initiated, combustion is self sustaining and the ignitor is turned off. The hot combustion

gases are directed into the HPT, and the HPT drives the compressor rotor. Hot gases from the gas

generator are then directed into the power turbine, and the PT drives the output shaft. The power turbine

normal operating speed is 2000 - 3600 rpm. Exhaust gases from the PT are turned 90 by the

Purchasers exhaust duct.

The gas generator rotor is supported by three main roller bearings and one ball thrust bearing. The power

turbine rotor is supported by two roller bearings and one thrust bearing. For detail descriptions of each

gas turbine component, select it in the table below.

Inlet Section

Front Frame Assembly

Compressor Stator

Compressor Rear Frame

High Pressure Turbine

Accessory Gearbox

Turbine Rear Frame

Lubrication System

Electrical System

Compressor Section

Compressor Rotor

Variable Stator Control System

Combustion System

Turbine Midframe

Power Turbine

Flexible Coupling Adapter

Ignition System

Air Cooling and Pressurization System

Fuel and Steam System

Starting System

Instrumentation

http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/LM25bssac/sec02.h... 19/11/2005

Description

Page 2 of 2

The LM2500 SAC gas turbine is equipped with the following instrumentation:

Gas generator speed sensors, magnetic pickup type

PT speed sensor, magnetic pickup type

1

1

1

1

5

5

1

1

1

2

Set (qty 11) PT inlet (T54) temperature sensors

Gas generator mounted accelerometer

PT mounted accelerometer

GT Oil supply resistance temperature detector (RTD)

GT Oil scavenge RTD

GT Oil scavenge electrical chip detectors

Pressure tap for lube oil supply

Pressure tap for lube oil scavenge

LVDT for VSV position

Pressure taps for compressor discharge

Pressure taps for fuel manifold pressures

1

2

1

Pressure tap for PT inlet (P54)

Pressure taps for HP recoup

Dual element T3 sensors (T/Cs)

Redundant P2/T2 sensor (one sensor, two

temperature RTD's, and one pressure tap)

,1'(;

%$&. 72 723

+20(

http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/LM25bssac/sec02.h... 19/11/2005

Вам также может понравиться

- WTUI - NewUserPrestentation TM2500 GEДокумент35 страницWTUI - NewUserPrestentation TM2500 GEjoravicaОценок пока нет

- LM6000 PC Time Limited ComponentsДокумент7 страницLM6000 PC Time Limited ComponentsmstaszelОценок пока нет

- GT Gas Fuel and Air FlowДокумент38 страницGT Gas Fuel and Air FlowhinaОценок пока нет

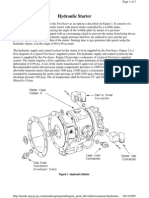

- Figure 1. Hydraulic StarterДокумент3 страницыFigure 1. Hydraulic StarterDenis JimenezОценок пока нет

- Gas Turb Optimum Operation Lm2500Документ109 страницGas Turb Optimum Operation Lm2500Samir Benabdallah100% (1)

- Ger 3658d Speedtronic Mark V Gas Turbine Control System PDFДокумент19 страницGer 3658d Speedtronic Mark V Gas Turbine Control System PDFyos100% (1)

- Proven Solutions GE-EvuletДокумент48 страницProven Solutions GE-EvuletmohamedhasОценок пока нет

- APA DOC No. 2014 PDFДокумент67 страницAPA DOC No. 2014 PDFThanapaet RittirutОценок пока нет

- SAC and DLE PDFДокумент29 страницSAC and DLE PDFMehulkumar PatelОценок пока нет

- LM 2500Документ12 страницLM 2500pramodtryОценок пока нет

- Fuel Control Requirements: Fuel Scheduling at Steady State OperationДокумент11 страницFuel Control Requirements: Fuel Scheduling at Steady State OperationDenis Jimenez100% (1)

- 9FA Failures in DabholДокумент10 страниц9FA Failures in Dabholsenthil031277100% (3)

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesДокумент4 страницыList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZОценок пока нет

- 3 - Gas Turbine Overview 8.09Документ25 страниц3 - Gas Turbine Overview 8.09Sujeet Kumar100% (1)

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceДокумент3 страницыDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezОценок пока нет

- Siemens GTДокумент8 страницSiemens GThbalu007Оценок пока нет

- Pivot Arm Turning GearДокумент24 страницыPivot Arm Turning Gearoom_tgw100% (1)

- GTs World Comparison Picture - 1-130 MW - 2015 01Документ2 страницыGTs World Comparison Picture - 1-130 MW - 2015 01dvcher78Оценок пока нет

- MS5002EДокумент8 страницMS5002Eamir8100100% (1)

- Lm2500 InstrumentationДокумент4 страницыLm2500 InstrumentationDenis JimenezОценок пока нет

- Proven Upgrade SGT5-4000FДокумент9 страницProven Upgrade SGT5-4000FThanapaet Rittirut100% (1)

- Ger4250 LM2500G4Документ12 страницGer4250 LM2500G4Denis JimenezОценок пока нет

- lIQUID FUEL SYSTEM PDFДокумент23 страницыlIQUID FUEL SYSTEM PDFJJОценок пока нет

- Gek105060 File0060 PDFДокумент12 страницGek105060 File0060 PDFHelton OliveiraОценок пока нет

- Ge Mid Idm 6000 1.Lm6000 PerformanceДокумент10 страницGe Mid Idm 6000 1.Lm6000 PerformanceChristopher HamptonОценок пока нет

- Scope of Work Gas TurbineДокумент13 страницScope of Work Gas TurbinePhong le100% (2)

- PDFДокумент124 страницыPDFEmanuel Conde100% (1)

- Ge LM6000 Training 1Документ74 страницыGe LM6000 Training 1sasa hh100% (1)

- SBLM2500 Ind 217Документ5 страницSBLM2500 Ind 217Daniil SerovОценок пока нет

- 10.1115 1.3240303Документ6 страниц10.1115 1.3240303ali a100% (1)

- SBLM2500 IND 174rev1Документ7 страницSBLM2500 IND 174rev1Daniil SerovОценок пока нет

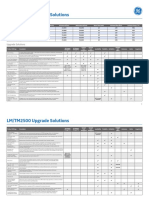

- LM TM2500 Upgrade Solutions PDFДокумент2 страницыLM TM2500 Upgrade Solutions PDFLibyanManОценок пока нет

- Sb-Lm2500-Ind-303 R1Документ11 страницSb-Lm2500-Ind-303 R1Daniil SerovОценок пока нет

- Siemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use OnlyДокумент2 страницыSiemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use Onlythunder0% (1)

- Comp Amp Turbine COURS 9001EДокумент27 страницComp Amp Turbine COURS 9001Enabil160874100% (1)

- Starting Gas TurbineДокумент3 страницыStarting Gas Turbineanup_nairОценок пока нет

- CT Inspection IntervalsДокумент19 страницCT Inspection IntervalsSantiago67% (3)

- Ge Ms5001pДокумент14 страницGe Ms5001pMohamed Hamed100% (1)

- CatalogoPGT25 PDFДокумент4 страницыCatalogoPGT25 PDFshihabjamaan100% (4)

- MS6001FAДокумент14 страницMS6001FAsureshkumar908Оценок пока нет

- LM2500+ Shutdown SequencesДокумент6 страницLM2500+ Shutdown Sequencesrenzobermudez89Оценок пока нет

- Lm2500 IntroДокумент4 страницыLm2500 IntroDenis JimenezОценок пока нет

- LM2500 AssessmentДокумент3 страницыLM2500 AssessmentKALPUSH50% (2)

- CPM - Ap - Lm6000-Ind-024 (1) 2009Документ64 страницыCPM - Ap - Lm6000-Ind-024 (1) 2009Victor Nahun ReyesОценок пока нет

- 9FA Recommended Parts ListingДокумент1 страница9FA Recommended Parts Listingalexandr_popov_2Оценок пока нет

- T48 SpreadДокумент1 страницаT48 SpreadKarim MuhammedОценок пока нет

- Gek105162 Operating InstructionДокумент72 страницыGek105162 Operating InstructionMiguel Francisco Goytia100% (1)

- H25-H15 CatalogueДокумент12 страницH25-H15 CatalogueTong Chaipanyakul100% (1)

- SB LM6000 Ind 0310Документ11 страницSB LM6000 Ind 0310Daniil Serov100% (1)

- MHPS GT F ClassДокумент9 страницMHPS GT F Classkp pkОценок пока нет

- MS5002E NewДокумент8 страницMS5002E Newecs71100% (2)

- IGV AssamblyДокумент31 страницаIGV AssamblyPhong le100% (1)

- Technical Procedures: Gas Turbine Water-Wash (Level 1 Maintenance)Документ8 страницTechnical Procedures: Gas Turbine Water-Wash (Level 1 Maintenance)Ant Yi0% (1)

- TIL 1880 Trip Risk When Liquid Fuel Recirculation Is Turned Off While Running On Gas PDFДокумент5 страницTIL 1880 Trip Risk When Liquid Fuel Recirculation Is Turned Off While Running On Gas PDFManuel L LombarderoОценок пока нет

- Flashback Mechanisms in Lean Premixed Gas Turbine CombustionОт EverandFlashback Mechanisms in Lean Premixed Gas Turbine CombustionОценок пока нет

- GT1Документ91 страницаGT1Irfan Ullah100% (1)

- File No.5 - GT Operating ManualДокумент27 страницFile No.5 - GT Operating ManualMani Kandan0% (1)

- PT6 Training ManualДокумент69 страницPT6 Training ManualMassimo Derco89% (19)

- Combined Cycle Power PlantДокумент11 страницCombined Cycle Power PlantPGPalomaОценок пока нет

- E7700 10 10 13 - Prozesstechnik - WebДокумент24 страницыE7700 10 10 13 - Prozesstechnik - WebDenis JimenezОценок пока нет

- 460-119 Hoja de Especificaciones.Документ2 страницы460-119 Hoja de Especificaciones.Denis JimenezОценок пока нет

- Hydac SCAДокумент6 страницHydac SCADenis JimenezОценок пока нет

- Dse4610 Dse4620 Data SheetДокумент2 страницыDse4610 Dse4620 Data SheetDenis Jimenez0% (1)

- E79000-2-04-13 FS Buch WWWДокумент291 страницаE79000-2-04-13 FS Buch WWWDenis JimenezОценок пока нет

- 3612tale Jgd6 DesignДокумент1 страница3612tale Jgd6 DesignDenis JimenezОценок пока нет

- E2000 0 03 11 - SYSTEMTECHNIK - WWWДокумент8 страницE2000 0 03 11 - SYSTEMTECHNIK - WWWDenis JimenezОценок пока нет

- 1303-1512 SSPF Final InoxidableДокумент16 страниц1303-1512 SSPF Final InoxidableDenis JimenezОценок пока нет

- E7710 1 06 11 - Leitungsfilter ProzessДокумент8 страницE7710 1 06 11 - Leitungsfilter Prozessvikram_007Оценок пока нет

- Inline Process FiltersДокумент7 страницInline Process FiltersDenis JimenezОценок пока нет

- Filter Bound CatalogДокумент248 страницFilter Bound CatalogDenis JimenezОценок пока нет

- 1403013194Документ1 страница1403013194Denis JimenezОценок пока нет

- Filter Bound CatalogДокумент248 страницFilter Bound CatalogDenis JimenezОценок пока нет

- Fluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsДокумент12 страницFluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDenis JimenezОценок пока нет

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsДокумент20 страницBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezОценок пока нет

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryДокумент12 страницAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezОценок пока нет

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryДокумент12 страницAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezОценок пока нет

- E18061 2 0 11 13 - HNS3000Документ2 страницыE18061 2 0 11 13 - HNS3000Denis JimenezОценок пока нет

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsДокумент20 страницBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezОценок пока нет

- E5601 PTKДокумент4 страницыE5601 PTKDenis JimenezОценок пока нет

- E831BДокумент4 страницыE831BDenis JimenezОценок пока нет

- 105388Документ4 страницы105388Denis JimenezОценок пока нет

- 1403013194Документ1 страница1403013194Denis JimenezОценок пока нет

- E5601 13 04 07 - PT Neu2Документ5 страницE5601 13 04 07 - PT Neu2Denis JimenezОценок пока нет

- E2902 4 03 13 - Pumpen Uebersicht - LQДокумент20 страницE2902 4 03 13 - Pumpen Uebersicht - LQDenis Jimenez0% (1)

- E7109 4-03-12 RFLD Guss KatalogversionДокумент8 страницE7109 4-03-12 RFLD Guss KatalogversionDenis JimenezОценок пока нет

- E831BДокумент4 страницыE831BDenis JimenezОценок пока нет

- Pastillas HSH 1v 1t 5wДокумент1 страницаPastillas HSH 1v 1t 5wDenis JimenezОценок пока нет

- E7113 4 03 12 - NFD KatalogversionДокумент8 страницE7113 4 03 12 - NFD KatalogversionDenis JimenezОценок пока нет

- E7113 4 03 12 - NFD KatalogversionДокумент8 страницE7113 4 03 12 - NFD KatalogversionDenis JimenezОценок пока нет

- Arc Detection in Electro-Discharge MachiningДокумент16 страницArc Detection in Electro-Discharge MachiningMitu Leonard-GabrielОценок пока нет

- A Facile Synthesis, Characterization of N-Substituted 7-Methoxy 3-Phenyl 4 (3-Piperzin - 1-Yl-Propoxy) Chromen-2-OneДокумент21 страницаA Facile Synthesis, Characterization of N-Substituted 7-Methoxy 3-Phenyl 4 (3-Piperzin - 1-Yl-Propoxy) Chromen-2-OneNalla Umapathi ReddyОценок пока нет

- Quality Control Handbook Street LightingДокумент36 страницQuality Control Handbook Street LightingbalaafconsОценок пока нет

- Fan 7316Документ21 страницаFan 7316sontuyet82Оценок пока нет

- Car Plate Recognition by Neural Networks and Image Processing Using Integration of WaveletsДокумент5 страницCar Plate Recognition by Neural Networks and Image Processing Using Integration of Waveletsjamal fathiОценок пока нет

- Topic 4. Binary DistillationДокумент123 страницыTopic 4. Binary DistillationAngela Lorena DíazОценок пока нет

- P 4 - Q 4Документ4 страницыP 4 - Q 4Rodriguez MamaniОценок пока нет

- D.Sc. (Technology) Pysarenko Cand. Sc. (Technology) Voynalovich Cand. Sc. (Technology) Maylo Postgraduate PysarenkoДокумент11 страницD.Sc. (Technology) Pysarenko Cand. Sc. (Technology) Voynalovich Cand. Sc. (Technology) Maylo Postgraduate PysarenkoГеоргий ПисаренкоОценок пока нет

- BiwaveletДокумент29 страницBiwaveletThiago MelquíadesОценок пока нет

- Banner Engineering - Glass Fiber Series - CatalogДокумент43 страницыBanner Engineering - Glass Fiber Series - CatalogTavo CoxОценок пока нет

- Sleipner A - North Sea Oil Platform CollapseДокумент28 страницSleipner A - North Sea Oil Platform Collapsemacynthia26Оценок пока нет

- Datasheet For Steel Grades Carbon Steel 1.1141: 1.1141 Standard NumberДокумент2 страницыDatasheet For Steel Grades Carbon Steel 1.1141: 1.1141 Standard NumberCricri CriОценок пока нет

- E 777 - Gidarakos 2005 - Ultimate - C and HДокумент5 страницE 777 - Gidarakos 2005 - Ultimate - C and HTamara Aulia RachimОценок пока нет

- Small Signal AnalysisДокумент4 страницыSmall Signal Analysissamaiyasamp3Оценок пока нет

- Chem 11 - Lab 1 - How Thick Is Aluminum FoilДокумент1 страницаChem 11 - Lab 1 - How Thick Is Aluminum FoilabmacphailОценок пока нет

- ECBC Implementation Experience Case StudyДокумент16 страницECBC Implementation Experience Case StudysiddharthaОценок пока нет

- Effect of Sawdust Filler With Kevlarbasalt Fiber On The MechanicalДокумент6 страницEffect of Sawdust Filler With Kevlarbasalt Fiber On The MechanicalKarim WagdyОценок пока нет

- (Doi 10.1002/9781119013228.Ch1) Kassapoglou, Christos - Modeling the Effect of Damage in Composite Structures (Simplified Approaches) Damage in Composite Structures- Notch SensitiДокумент7 страниц(Doi 10.1002/9781119013228.Ch1) Kassapoglou, Christos - Modeling the Effect of Damage in Composite Structures (Simplified Approaches) Damage in Composite Structures- Notch SensitiAdimasu AyeleОценок пока нет

- 6-Quantum-Particle (Students Copy)Документ12 страниц6-Quantum-Particle (Students Copy)Kunal kumarОценок пока нет

- Research StatementДокумент5 страницResearch StatementEmad AbdurasulОценок пока нет

- Mathematics in The Modern WorldДокумент15 страницMathematics in The Modern WorldMikaela MelegritoОценок пока нет

- Eye TrackingДокумент13 страницEye TrackingRohit KoulОценок пока нет

- Dow Elite 5401G TDSДокумент3 страницыDow Elite 5401G TDSAli RazuОценок пока нет

- 1.'motivation For SoC Design - by Raveendra SomanaДокумент13 страниц1.'motivation For SoC Design - by Raveendra SomanaSantosh Shivapuji100% (1)

- 2011 JC1 H2 Chemistry Promo P2Документ19 страниц2011 JC1 H2 Chemistry Promo P2joshua_98548Оценок пока нет

- 2021 HSC Mathematics Extension 2 Hardest QuestionДокумент3 страницы2021 HSC Mathematics Extension 2 Hardest QuestionThe Sydney Morning HeraldОценок пока нет

- Air Pollution by Grade 6Документ4 страницыAir Pollution by Grade 6Eljay VinsonОценок пока нет

- History of MaichewДокумент2 страницыHistory of MaichewSehabom Geberhiwot100% (1)

- Experimental Investigation On Mechanical Performance of Aluminium CompositeДокумент10 страницExperimental Investigation On Mechanical Performance of Aluminium CompositeMadhu KotlaОценок пока нет

- Reliability and Performance Indices of Power Generating Units in PolandДокумент7 страницReliability and Performance Indices of Power Generating Units in Polandwoldemariam workuОценок пока нет