Академический Документы

Профессиональный Документы

Культура Документы

SEG Relay

Загружено:

Sudhir Ravipudi67%(3)67% нашли этот документ полезным (3 голоса)

2K просмотров30 страницThis document provides information about the WI1-3 three-phase inverse overcurrent time relay. It summarizes that the WI1-3 relay:

- Requires no auxiliary power supply as it draws energy from the current transformer circuits.

- Provides inverse-time overcurrent protection for medium voltage circuit breakers using current transformers as the sensing input.

- Can be adapted to different applications by selecting different current transformers and setting terminal bridges to adjust the tripping characteristics.

Исходное описание:

HH

Оригинальное название

SEG-relay

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides information about the WI1-3 three-phase inverse overcurrent time relay. It summarizes that the WI1-3 relay:

- Requires no auxiliary power supply as it draws energy from the current transformer circuits.

- Provides inverse-time overcurrent protection for medium voltage circuit breakers using current transformers as the sensing input.

- Can be adapted to different applications by selecting different current transformers and setting terminal bridges to adjust the tripping characteristics.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

67%(3)67% нашли этот документ полезным (3 голоса)

2K просмотров30 страницSEG Relay

Загружено:

Sudhir RavipudiThis document provides information about the WI1-3 three-phase inverse overcurrent time relay. It summarizes that the WI1-3 relay:

- Requires no auxiliary power supply as it draws energy from the current transformer circuits.

- Provides inverse-time overcurrent protection for medium voltage circuit breakers using current transformers as the sensing input.

- Can be adapted to different applications by selecting different current transformers and setting terminal bridges to adjust the tripping characteristics.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 30

WI1-3 - Three-phase Inverse Overcurrent Time Relay

independent of Auxiliary Supply

2 TB WI1-3 06.96 E

Contents

1 General

2 Characteristics

3 Functional mode

3.1 The protection system WI

3.2 Current transformers WI1-W

3.3 Adaptation to the object to be protected

3.4 The electronic circuit of WI1-3

4 Tripping Characteristic

5 Test of the protection system

6 Connection Diagrams

7 Technical Data

8 Ordering form

1 General

The inverse overcurrent time relay WI1-3 is used as a

c.t. tripping device. Together with the current trans-

formers WI1-W it represents a protection system de-

veloped especially for "unfused outdoor medium volt-

age circuit breakers" in transformer- or distribution sta-

tions without station batteries. In quality and climatic

versitility the relay- and current transformer arrangement

meets all the requirements for compact outdoor sta-

tions. The current transformers WI1-W as well as unit

WI1-3 are protected through cast resin cases.

Unit WI1-3 requires no supply voltage. It draws the

necessary energy from the current transformer circuits

and from this also the energy for the tripping of the

c.b. is made available.

The tripping impulses of relay WI1-3 are repeated un-

til the primary current is interrupted. This is of advan-

tage when the c.b. does not trip, caused for instance

by dirt accumulation in the mechanism, and therefore

the fault current continues to flow. A tripping character-

istic required by the customer can be arranged ac-

cording to prior agreement.

2 Characteristics

No auxiliary voltage required

Microprocessor technique with watchdog

Input for remote tripping

Test of the entire protection system via check

windings in the current transformers

Extremely wide measuring range: 2I

N

to 60I

N

Extremely wide time range: 10 ms to above 1 h

Exactly defined tripping characteristic curve with

high precision

Tripping output available as

- power output for direct connection to the tripping

coil of the c.b.

- potential free change over contact

Tripping impulse repetition till the primary current is

interrupted

Trip indication via a separately supplied flag indi-

cator with mechanical reset

Compact design

Working temperature range: -40

0

C to +85

0

C

Insensitive against extrem environmental conditions

Precision components and overdimensioning guar-

antee accuracy, reliability and long service life

Corresponds to the requirements acc. to:

VDE 0435 part 303, IEC 255

Interference resistance (burst) according to intensity

factor x (highest factor)

Type tested by TV-Rheinland

(Technical Control Board)

TB WI1-3 06.96 E 3

3 Functional mode

3.1 The protection system WI

The three ring type current transformers WI1-W trans-

form the primary current flowing through the medium

voltage cable into the secondary current, which forms

the measuring value and the energy supply for relay

WI1-3 (input terminals 5 - 10). In case of overcurrent

WI1-3 gives the tripping command acc. to its tripping

characteristic curve.

Tripping modes

There are two tripping modes to choose:

a) Power impulse output (10W during 50ms):

As tripping commands WI1-3 gives power im-

pulses directly to the tripping coil of the c.b (termi-

nals 1 and 2). Two capacitors with an energy of

0.5Ws before tripping are discharged through the

tripping coil in case of tripping. Depending on the

coil tripping impulses are generated in this way

with a peak voltage of 24 V and the duration of

50ms (at a power output of 10W). These impulses

are repeated periodically until the c.b. has

switched off. The interval time (t

pause

) between these

impulses is a function of the input current of WI1-3.

When the input current (I

Wsec

, proportionally to the

primary current) is getting larger the interval time

between the tripping impulses is decreasing. The

storage capacitors are again charged in a shorter

period. A permanent tripping starts from an input

current of 4A. The diagram (see fig. 1) shows the

interval time in dependence on the secondary cur-

rent (I

Wsec

) to the nominal current of WI1-3 (I

N WI1-3

=0.3A):

Fig. 1:

b) Potential free contacts tripping coil >10 W:

For applications where higher levels of tripping

power are required, relay WI1-3 is available with

a potential free change-over contact (see Fig. 6,

terminals 1; 2; 3). All WI1-3 relays of this design

have a slightly greater tripping delay (max. 8ms)

(exception: characteristic curve 9; this period was

here already considered).

Trip indication

The separately available flag indicators WI1-SZ2 and

WI1-SZ3 (connection to terminals 11;12) indicate the

tripping mechanically and are reset manually to they

initial position.

The incitation of the over current protection is indicated

by LED.

Remote tripping

Input "remote tripping" (terminals 20; 22) allows trip-

ping through external voltage impulses, e.g. from a

thermal tripping device, a Buchholz-protection or

through other remote tripping commands. This input

(220V AC, maximum 30 min) has an effect directly on

the tripping circuits through by-passing the measuring

circuits. The input terminals are galvanically separated

from the electronic part of the relay.

Adaptation to the object to be protected

Protection system WI1-3 with the appropriate c.t.'s

WI1-W are adapted to the object to be protected as

follows:

Current transformers WI1-W are provided with tap-

pings for rough adaptation (S1-S2 and S1-S3).

A general view of the current transformer types WI1-

W is given in table 1. (Standard types; different CT

designs on request)

For fine adaptation, relay WI1-3 is equipped with

terminal bridges (terminals 13-18).

4 TB WI1-3 06.96 E

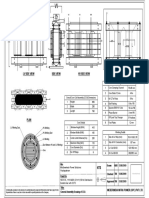

Fig. 2: Block diagram of WI1-3

1 = terminal bridges (see table 2)

2 = transducer

3 = sample and hold

4 = output amplifier

5 = flag indicator

6 = remote tripping

7 = tripping coil

8 = energy storage

9 = characteristic transmitter

TB WI1-3 06.96 E 5

3.2 Current transformers WI1-W

Current transformers WI1-W are ring type current

transformers especially coordinated with the power

demand of relay WI1-3 with the following data:

Regulations: VDE 0414, IEC 185

Housing: cast resin

Class: 5P

Overcurrent factor: 30

Nominal frequency: 50 to 60 Hz

Secondary nominal current: 0.3 A

Constant carrying capacity: 4 I

N

Test winding: 1A constant

I

therm

/I

dyn

: 25 kA / 100 kA

Operating voltage: 0.8 kV

Test voltage: 4 kV

Isolation class: E

Permissible operating temp.: -40

0

C to +85

0

C

Erecting height: 3.000m above NN

Mounting: fixing provisions

at the base

Important note!

The WI1-3 is either connected to c.t. terminals S1/S2

or S1/S3. The third terminal which is not connected

may not be short-circuited with other terminals. The

same applies to the test winding C/D!

Transformer type primary rated current/A I

Nprim

transformer ratio I

Wprim

I

Wsek

Winding

S1-S2

Winding

S1-S3

Winding

S1-S2

Winding

S1-S3

WI1-W2 7.2 - 14.4 14.4 - 28.8 7.2 / 0.3 14.4 / 0.3

WI1-WZ2-1 two-part 7.2 - 14.4 14.4 - 28.8 7.2 / 0.3 14.4 / 0.3

WI-WZ2-2 two-part

design with special pro-

tection against corrosion

7.2 - 14.4 14.4 - 28.8 7.2 / 0.3 14.4 / 0.3

WI1-W3 28.9 - 57.7 57.7 - 115 28.9 / 0.3 57.7 / 0.3

WI1-WZ3-1 two-part 28.9 - 57.7 57.7 - 115 28.9 / 0.3 57.7 / 0.3

WI1-WZ3-2 two-part

design with special pro-

tection against corrosion

28.9 - 57.7 57.7 - 115 28.9 / 0.3 57.7 / 0.3

WI1-W4 115 - 230 230 - 462 115 / 0.3 230 / 0.3

WI1-WZ4-1 two-part 115 - 230 230 - 462 115 / 0.3 230 / 0.3

WI1-WZ4-2 two-part

design with special pro-

tection against corrosion

115 - 230 230 - 462 115 / 0.3 230 / 0.3

Table 1: Current transformers, type WI1-W

Further transformer types (ratio/design) are available on request

6 TB WI1-3 06.96 E

Dimensions WI1-W

Dimensions and other C.T. data on request.

TB WI1-3 06.96 E 7

Dimensions of the WI1-WZ types 1+2 (with and without special protection against corrosion)

Dimensions and other C.T. data on request.

8 TB WI1-3 06.96 E

3.3 Adaptation to the object to be

protected

Overcurrent relay WI1-3 with its current transformers

WI1-W belonging to it is adapted to the object to be

protected through the selection of the current trans-

former ratio and the terminal bridges.

Calculation of the primary rated current of the object to

be protected:

I

S

U

Nprim

N

N

=

3

(as example for transformer protection)

Desired lowest tripping current:

I

A

= n I

Nprim

(usually:n = 2)

The current transformer ratio (see table 1) is selected in

such a way that the tripping current transformed on the

secondary side lies in the range of the lowest response

value of WI1-3 (0.6A-1.2A; see table 2):

I I

I

I

WsekA A

W

Wprim

=

sec

(0.6A I

WsecA

1.2A)

Acc. to table 2 the terminal bridge for fine adaptation

of WI1-3 is now to be connected according to the re-

sulting lowest response value of WI1-3.

lowest response va-

lue of WI1-3

at bridge bet-

ween terminals

Begin of the

charac. curve

I

Wsec

/I

NWI1-3*

0.60 A

0.76 A

0.96 A

1.20 A

13 a. 18

14 a. 18

15 a. 18

16 a. 18

2.0

2.57

3.2

4.0

Table 2: Tripping of protection system WI1-3

*I

NWI1-3

= 0.3 A

Example for transformer protection: S

NTrafo

= 500 kVA;

U

NTrafo

= 10 kV acc. to the above equasion the rated

value of the transformer arrives at: I

NTrafo

= 28.9 A

tripping at 2 I

Nprim

desired: from table 1 selected:

transformer WI1-W3, connection winding S1-S2; also

with a ratio of 28.9 A/0.3 A

I

WsecA

= (2 28.9 A)

03

289

06

.

.

.

A

A

A =

hence, acc. to table 2 a bridge is to be applied from

terminal 13 to 18.

I: secondary flowing current

I

Nprim

: primary rated current

I

A

: tripping current

I

Wprim

/I

Wsec

: transformer ratio

I

Wprim

: primary transformer rated current

I

Wsec

: secondary transformer rated current

I

WsecA

: secondary current at tripping

I

NWI1-3

: rated current of WI1-3

S

N

: rated apparent power

U

N

: rated voltage

3.4 The electronic circuit of WI1-3

Measuring circuit and tripping characteristic

The input current is converted into a proportional volt-

age which is rectified and adapted to the following

electronic circuit via a 3-phase electronic measuring

range selector (terminals 13-18). The "mean values"

are formed here separately for each phase. The trip-

ping is caused by the highest of the three current-

proportional DC-voltages.

A complex circuitry in a combined analog- and digital

technique defines the characteristic curve. The tripping

characteristic curve can be specified freely on cus-

tomer's request and therefore the circuitry has a high

level of flexibility and accuracy. Because of digital de-

tection of the tripping period a high level of immunity

to interference, very exact long term tripping and good

aging stability is reached.

The incitation of the overcurrent protection is indicated

through a LED placed next to the connection terminals.

If the current falls below the response value of the

WI1-3 before reaching the tripping time, the LED ex-

tinguishes and the time measured is reset.

In case the response value is exceeded again, the

output of the characteristic transmitter gives a tripping

command to the tripping amplifier according to the

characteristic curve.

Current supply

The current supply of the relay is subdevided into two

ranges:

Supply of the measuring circuitry:

The stabilizing circuitry makes a symmetrical supply

voltage and a highly accurate reference voltage for

the characteristic circuitry possible.

Supply of the tripping level amplifier:

In order to have sufficient tripping energy available for

the tripping coil, even at very small tripping currents,

WI1-3 is equipped with a special "energy storage". It

consists of a capacitor charging unit which charges

two capacitors of each 1000 F to 24 V. These ca-

pacitors are discharged via the tripping coil. If the cir-

cuit breaker does not trip, for instance because of a

soiled mechanism, the failure current continues to flow.

The storage capacitors are charged again. A voltage

measuring circuit in WI1-3 measures the charging

voltage and gives a new tripping impulse when reach-

ing 24 V. This procedure is repeated until the primary

current is interrupted.

TB WI1-3 06.96 E 9

4 Tripping Characteristic

To determine the tripping characteristic it is essential to

know the behavior of the object to be protected (in-

rush, continuous carrying capacity etc.). The inverse

overcurrent time relay WI1-3 must not yet respond to

these current-/time values. Furthermore it has to be

taken into consideration that a protection facility (HRC-

fuse) connected after WI1-3 is effective before the re-

lay WI1-3 trips, in order to guarantee the selectivity of

the overcurrent protection system.

Fig. 3 shows a typical example for inrush and the

HRC-tripping characteristic curve of an object to be

protected (transformer in a distribution station). The

tripping characteristic curve of WI1-3 belonging to this

shows the ideal tripping characteristic.

It combines:

good selectivity towards HRC- fuses to the under-

voltage side and the transformer magnitized inrush.

good selectivity towards superior protection de-

vices

transformer over-load protection starting from a two-

fold rated current,

extremely short command time laps

(10ms at 30 I

N

)

The following tripping characteristic curves are in-

cluded in the scope of delivery. On request special

characteristic curves are prepared (for this please do

not fill in the number for the characteristic curve in your

order form).

The change-over terminals at the electronic multiple

range change-over are being considered in the trip-

ping characteristic curves.

10

0

10

0

10

1

10

1 I

prim

/I

Nprim

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

10

0

10

0

10

1

10

1 I

prim

/I

Nprim

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

1 = magnitizing inrush of the transformer (peak values)

2 = HRC- characteristic curve

3 = WI1-3 tripping characteristic curve with tolerance band

1 2 3

Fig. 3:

10 TB WI1-3 06.96 E

Characteristic curve no. 3

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Test table with characteristic points to characteristic curve 3:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.5 A / 11 s

S1 - S2 14 and 18 1.9 A / 11 s

S1 - S2 15 and 18 2.4 A / 11 s

S1 - S2 16 and 18 3.0 A / 11 s

S1 - S3 13 and 18 3.0 A / 11 s

S1 - S3 14 and 18 3.9 A / 11 s

S1 - S3 15 and 18 4.7 A / 11 s

S1 - S3 16 and 18 6.0 A / 11 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

TB WI1-3 06.96 E 11

Characteristic curve no. 4: inverse (BS 142)

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Br. 13-18:

( )

t

014

I 06A 1

s

0 02

=

-

.

/ .

.

Br. 14-18:

( )

t

014

I 076A 1

s

0 02

=

-

.

/ .

.

Br. 15-18:

( )

t

014

I 096A 1

s

0 02

=

-

.

/ .

.

Br. 16-18:

( )

t

014

I 12A 1

s

0 02

=

-

.

/.

.

Test table with characteristic points to characteristic curve 4:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.2 A / 10 s 3.0 A / 4.3 s

S1 - S2 14 and 18 1.5 A / 10 s 3.8 A / 4.3 s

S1 - S2 15 and 18 1.9 A / 10 s 4.8 A / 4.3 s

S1 - S2 16 and 18 2.4 A / 10 s 6.0 A / 4.3 s

S1 - S3 13 and 18 2.4 A / 10 s 6.0 A / 4.3 s

S1 - S3 14 and 18 3.0 A / 10 s 7.6 A / 4.3 s

S1 - S3 15 and 18 3.8 A / 10 s 9.5 A / 4.3 s

S1 - S3 16 and 18 4.8 A / 10 s 12.0 A / 4.3 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

12 TB WI1-3 06.96 E

Characteristic curve no. 5: very inverse (BS 142)

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Br. 13-18:

( )

t

135

I 0 6A 1

s =

-

.

/ .

Br. 14-18:

( )

t

135

I 0 76A 1

s =

-

.

/ .

Br. 15-18:

( )

t

135

I 0 96A 1

s =

-

.

/ .

Br. 16-18:

( )

t

135

I 12A 1

s =

-

.

/.

Test table with characteristic points to characteristic curve 5:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.2 A / 13.6 s 3.0 A / 3.4 s

S1 - S2 14 and 18 1.5 A / 13.6 s 3.8 A / 3.4 s

S1 - S2 15 and 18 1.9 A / 13.6 s 4.8 A / 3.4 s

S1 - S2 16 and 18 2.4 A / 13.6 s 6.0 A / 3.4 s

S1 - S3 13 and 18 2.4 A / 13.6 s 6.0 A / 3.4 s

S1 - S3 14 and 18 3.0 A / 13.6 s 7.6 A / 3.4 s

S1 - S3 15 and 18 3.8 A / 13.6 s 9.5 A / 3.4 s

S1 - S3 16 and 18 4.8 A / 13.6 s 12.0 A / 3.4 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

TB WI1-3 06.96 E 13

Characteristic curve no. 6: extremely inverse (BS 142)

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Br. 13-18:

( )

t

80

I 06A 1

s

2

=

- / .

Br. 14-18:

( )

t

80

I 0 76A 1

s

2

=

- / .

Br. 15-18: t

80

I 096A 1

s

2

=

- ( / . )

Br. 16-18:

( )

t

80

I 12A 1

s

2

=

- /.

Test table with characteristic points to characteristic curve 6:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.2 A / 27 s 3.0 A / 3.3 s

S1 - S2 14 and 18 1.5 A / 27 s 3.8 A / 3.3 s

S1 - S2 15 and 18 1.9 A / 27 s 4.8 A / 3.3 s

S1 - S2 16 and 18 2.4 A / 27 s 6.0 A / 3.3 s

S1 - S3 13 and 18 2.4 A / 27 s 6.0 A / 3.3 s

S1 - S3 14 and 18 3.0 A / 27 s 7.6 A / 3.3 s

S1 - S3 15 and 18 3.8 A / 27 s 9.5 A / 3.3 s

S1 - S3 16 and 18 4.8 A / 27 s 12.0 A / 3.3 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

14 TB WI1-3 06.96 E

Characteristic curve no. 7

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Test table with characteristic points to characteristic curve 7:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.5 A / 11 s

S1 - S2 14 and 18 1.9 A / 11 s

S1 - S2 15 and 18 2.4 A / 11 s

S1 - S2 16 and 18 3.0 A / 11 s

S1 - S3 13 and 18 3.0 A / 11 s

S1 - S3 14 and 18 3.9 A / 11 s

S1 - S3 15 and 18 4.7 A / 11 s

S1 - S3 16 and 18 6.0 A / 11 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

TB WI1-3 06.96 E 15

Characteristic curve no. 8

10

0

10

1

10

1

10

2

10

2

I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

10

4

10

4

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Test table with characteristic points to characteristic curve 8:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.8 A / 30 s 3.0 A / 0.18 s

S1 - S2 14 and 18 2.3 A / 30 s 3.9 A / 0.18 s

S1 - S2 15 and 18 2.8 A / 30 s 4.8 A / 0.18 s

S1 - S2 16 and 18 3.6 A / 30 s 6.0 A / 0.18 s

S1 - S3 13 and 18 3.6 A / 30 s 6.0 A / 0.18 s

S1 - S3 14 and 18 4.6 A / 30 s 7.5 A / 0.18 s

S1 - S3 15 and 18 5.6 A / 30 s 9.5 A / 0.18 s

S1 - S3 16 and 18 7.2 A / 30 s 12.0A / 0.18 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

16 TB WI1-3 06.96 E

Characteristic curve no. 9

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Test table with characteristic points to characteristic curve 9:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.0 A / 11 s

S1 - S2 14 and 18 1.3 A / 11 s

S1 - S2 15 and 18 1.6 A / 11 s

S1 - S2 16 and 18 2.0 A / 11 s

S1 - S3 13 and 18 2.0 A / 11 s

S1 - S3 14 and 18 2.6 A / 11 s

S1 - S3 15 and 18 3.2 A / 11 s

S1 - S3 16 and 18 4.0 A / 11 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

TB WI1-3 06.96 E 17

Characteristic curve no. 10

10

0

10

1

10

1

10

2

10

2

I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

10

4

10

4

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Test table with characteristic points to characteristic curve 10:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.8 A / 30 s 3.0 A / 45 ms

S1 - S2 14 and 18 2.3 A / 30 s 3.9 A / 45 ms

S1 - S2 15 and 18 2.8 A / 30 s 4.8 A / 45 ms

S1 - S2 16 and 18 3.6 A / 30 s 6.0 A / 45 ms

S1 - S3 13 and 18 3.6 A / 30 s 6.0 A / 45 ms

S1 - S3 14 and 18 4.6 A / 30 s 7.5 A / 45 ms

S1 - S3 15 and 18 5.6 A / 30 s 9.5 A / 45 ms

S1 - S3 16 and 18 7.2 A / 30 s 12.0 A / 45 ms

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

18 TB WI1-3 06.96 E

Charateristic curve no. 11

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Test table with characteristic points to characteristic curve 11:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.5 A / 11 s

S1 - S2 14 and 18 1.9 A / 11 s

S1 - S2 15 and 18 2.4 A / 11 s

S1 - S2 16 and 18 3.0 A / 11 s

S1 - S3 13 and 18 3.0 A / 11 s

S1 - S3 14 and 18 3.9 A / 11 s

S1 - S3 15 and 18 4.7 A / 11 s

S1 - S3 16 and 18 6.0 A / 11 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

TB WI1-3 06.96 E 19

Characteristic curve no.12

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Test table with characteristic points to characteristic curve 12:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.5 A / 11 s

S1 - S2 14 and 18 1.9 A / 11 s

S1 - S2 15 and 18 2.4 A / 11 s

S1 - S2 16 and 18 3.0 A / 11 s

S1 - S3 13 and 18 3.0 A / 11 s

S1 - S3 14 and 18 3.9 A / 11 s

S1 - S3 15 and 18 4.7 A / 11 s

S1 - S3 16 and 18 6.0 A / 11 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

20 TB WI1-3 06.96 E

Characteristic curve no. 13

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Test table with characteristic points to characteristic curve 13:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 0.66 A / 11 s

S1 - S2 14 and 18 0.84 A / 11 s

S1 - S2 15 and 18 1.03 A / 11 s

S1 - S2 16 and 18 1.34 A / 11 s

S1 - S3 13 and 18 1.34 A / 11 s

S1 - S3 14 and 18 1.68 A / 11 s

S1 - S3 15 and 18 2.06 A / 11 s

S1 - S3 16 and 18 2.68 A / 11 s

Please observe: The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

Note: Only available with relay output (WI1-3-13-W-R-1)

TB WI1-3 06.96 E 21

Characteristic curve no. 14

10

0

10

1

10

1

10

2

10

2 I/I

NWI1-3

I [A]

10

-2

10

-1

10

-1

10

0

10

0

10

1

10

1

10

2

10

2

10

3

10

3

t[s]

B

r

.

1

3

-

1

8

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

0.3 3 30

Test table with characteristic points to characteristic curve 14:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.2 A / 22 s 3.0 A / 0.7 s

S1 - S2 14 and 18 1.5 A / 22 s 3.8 A / 0.7 s

S1 - S2 15 and 18 1.9 A / 22 s 4.8 A / 0.7 s

S1 - S2 16 and 18 2.4 A / 22 s 6.0 A / 0.7 s

S1 - S3 13 and 18 2.4 A / 22 s 6.0 A / 0.7 s

S1 - S3 14 and 18 3.0 A / 22 s 7.6 A / 0.7 s

S1 - S3 15 and 18 3.8 A / 22 s 9.6 A / 0.7 s

S1 - S3 16 and 18 4.8 A / 22 s 12.0 A / 0.7 s

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

22 TB WI1-3 06.96 E

Characteristic curve no. 15

10

0

10

1

10

2 I/I

NWI1-3

1 10

I [A]

10

-2

10

-1

10

0

10

1

10

2

10

3

t[s]

B

r

.

1

4

-

1

8

B

r

.

1

5

-

1

8

B

r

.

1

6

-

1

8

B

r

.

1

3

-

1

8

Test table with characteristic points to characteristic curve 15:

Current-Transformer connection Bridge between terminals Test current/tripping time about

S1 - S2 13 and 18 1.20 A / 9,1 s 3.0 A / 66 ms

S1 - S2 14 and 18 1.5 A / 9,1 s 3.8 A / 66 ms

S1 - S2 15 and 18 1.9 A / 9,1 s 4.8 A / 66 ms

S1 - S2 16 and 18 2.4 A / 9,1 s 6.0 A / 66 ms

S1 - S3 13 and 18 2.4 A / 9,1 s 6.0 A / 66 ms

S1 - S3 14 and 18 3.0 A / 9,1 s 7.6 A / 66 ms

S1 - S3 15 and 18 3.8 A / 9,1 s 9.6 A / 66 ms

S1 - S3 16 and 18 4.8 A / 9,1 s 12.0 A / 66 ms

Please observe:

The test current must not exist longer than 1.5 times of the tripping time acc. to the above table.

TB WI1-3 06.96 E 23

5 Test of the protection system

For testing the protection devices a fixed test current

must flow into the test windings C and D of the current

transformer. Hereby is to be observed that during this

test no current should flow on the primary side and that

the test current must not flow longer than 30 s through

the test windings.

When switching on the test current and measuring the

tripping time the system, consisting of current trans-

formers WI1-W, wiring, WI1-3 incl. characteristic

curve, tripping coil and circuit breaker, is completely

checked over.

Hence, a simple and fast control of the entire protec-

tion system is guaranteed.

Basically the test wiring of current transformers WI1-W

has the following ratio to both secondary windings:

C-D/S1-S2/S1-S3

in the ratio of

2/2/1

thus e.g.

0.6A/0.6A/0.3A

The required test current and the tripping time belong-

ing to can be taken from the test table of the respective

characteristic curves or determined by the following

ranges:

Transformer tapping (S1-S2 or S1-S3),

Fine adaption of WI1-3 (terminals 13 - 18),

Tripping characteristic (course of the

characteristic curve)

In the diagram of the tripping characteristic a point

suitable for testing has to be selected at which a trip-

ping after a time pre-determined by the characteristic

curve must just occur. The test current calculated acc.

to the above ranges is fed into the test winding and

the pertaining tripping time measured.

Please observe:

Insignificant deviations to the ideal tripping time may

occur during the test. Because the input impedance of

WI1-3 is not linear the harmonic curve can "change its

form" acc. to the test current source. Furthermore the

actual tripping time is depending upon the impedance

of the primary current circuit in a small degree be-

cause it acts as additional load of the current trans-

former.

6 Connection Diagrams

The cable screen must be grounded acc. to fig. 4. The

grounding wire is led back through the current trans-

former.

Grounding measures

when using a ring type

current transformer

Conductor

Sealing end,

mounted isolated

Cable

Current transformer

Grounding

wire

E

Fig. 4: Grounding of the cable screen

Impulse-

output

Example for customer

specific characteristic

curve

Remote

tripping

Fig. 5: Connection diagram of WI1-3 with power impulse output

Fig. 6: Connection diagram of WI1-3 with potential free relay contacts

24 TB WI1-3 06.96 E

7 Technical Data

General Data

Type: WI1-3

Design: static measuring relay

Requirements: VDE 0435; VDE 0110; IEC 255-6

Tests: VDE 0435, part 303

Maintenance: none

Permissible operating time: continuous operation

Mounting position: optional

Measuring circuit

Rated current: I

N

= 0.3 A

Continuous current: I = 4 I

N

Short time current: I = 100 I

N

for 1s

Rated frequency: f

N

= 50 to 60 Hz

Burden: 0.6 VA at 0.3 A

2.2 VA at 0.6 A

5.2 VA at 1.2 A

Measuring circuit: 2 I

N

to 60 I

N

with changing of measuring range

Changing of measuring range: Bridge from terminal to terminal lowest tripping current

13 and 18 0.60 A

14 and 18 0.76 A

15 and 18 0.96 A

16 and 18 1.20 A

Tripping characteristic: fixed, see resp. diagram

Input for Remote Tripping

Rated voltage: 220 V AC, maximum 30 min.

Minimum input voltage: 180 V AC, maximum 60 min.

Maximum input voltage: 250 V AC, maximum 15 min.

Rated burden: 6 VA at 220 V

Outputs

Potential free contacts

Returning time: approx. 60 ms

Maximum breaking capacity: 2000 VA/150 W (AC/DC)

Maximum breaking voltage: 250 V

Rated current: 8 A

Making current (16 ms): 50 A

Contact material: AgCdO

Contact life span: 10

5

switching operation at maximum breaking capacity

Impulse output

Voltage: 24 V DC 2 V

Returning time: approx. 60 ms

Power: approx. 10 W for 50 ms,

repeated periodically;

frequency depending on measuring current

Tripping Energy: 0.5 Ws for each tripping impulse

TB WI1-3 06.96 E 25

Ambient Conditions

Permissible storage temperature: -40

0

C to +85

0

C

Permissible operating temperature: -40

0

C to +85

0

C

Accuracy

referred to current Accuracy

at reference condition: f 5.0 %

Influence of temp. between

- 5

0

C...+55

0

C: f 2.5 %

-40

0

C...+85

0

C: f 5.0 %

Influence of frequency between

45Hz...66Hz: f 2.5 %

Tests

Insulation test: all independent circuits

acc. to VDE 0435 against each other and against

housing: 2 kV; 50 Hz; 1 min.

Surge-compression test acc.: all circuits against each other

to VDE 0435, IEC 255-6 and against housing: 5kV; 1.2/50 s; 2.5 J

except terminals 13 to 18

High frequency failure test: between all terminals and housing,

acc. to VDE 0435, IEC 255-6 between independent circuits,

between terminals of the same current circuit

Transverse- and longitudinal voltage:

2.5 kV; 1 Mhz

Repeating rate: 400 times/s

except terminals 13 to 18

Interference resistance (burst): Capacitive interference to all outwardly

against rapid transient influence or inwardly leading lines (lines for signals,

quantities according to intensity control and supply).

factor x (highest factor acc. to Test voltage: 5 kV

VDE 0843, part 4 or IEC 801-4) Burst duration: 1-15 ms

Spike frequency: 1, 2.5, 5, 10kHz

Interference resistance against: According to intensity factor 4:

electrostatic discharges in Test voltage: 15 kmV

compliance with

VDE 0843, part 2 or IEC 801-2

Housing, Dimensions,

Weight and Installation

Material: Macrolon 6030, self-extinguishing

Height width depth: see dimensional diagrams

Mounting position: optional

Weight: 2.4 kg

Mounting: screwed

Protection class: electronic circuit: IP 67

terminals: IP 20

26 TB WI1-3 06.96 E

Dimensional drawings

Data in mm

Housing WI1-3

TB WI1-3 06.96 E 27

Flag indicator WI1-SZ2

Flag indicator WI1-SZ4

cut-out of the panel

28 TB WI1-3 06.96 E

8 Ordering form

Number of required

units WI1-3

Number of charact.

curve (see para. 4)

Output:

E-impulse

R.-contact

(nos.) (E or R)

WI1-3 - - W- -1

Please enter the constellation of system WI1-3 required for your protection system.

for special requirements do not fill in number of characteristic curve, otherwise

enter the resp. number.

output can be chosen as impulse output (E) or relay output (R).

please indicate when a test certificate is required (additional charge)

Current Transformer WI1-W

Number of required current

transformers WI1-W

Transformers ratio

(see table 1)

Design

(nos.) 2, 3, 4

WI1-

WI1-

WI1-

-W

WZ

WZ

- one part

-1 two-part design without

special protection

against corrosion

-2 two-part design with

special protection

against corrosion

Flag indicators WI 1-SZ2 and WI1-SZ3

Nos. of flag indicators needed

(nos.)

WI1-SZ2

WI1-SZ4

Woodward SEG GmbH & Co. KG

Krefelder Weg 47 D 47906 Kempen (Germany)

Postfach 10 07 55 (P.O.Box) D 47884 Kempen (Germany)

Phone: +49 (0) 21 52 145 1

Internet

Homepage http://www.woodward-seg.com

Documentation http://doc.seg-pp.com

Sales

Phone: +49 (0) 21 52 145 635 Telefax: +49 (0) 21 52 145 354

e-mail: kemp.electronics@woodward.com

Service

Phone: +49 (0) 21 52 145 614 Telefax: +49 (0) 21 52 145 455

e-mail: kemp.pd@woodward.com

Вам также может понравиться

- Mvaa Techdata enДокумент5 страницMvaa Techdata enAdip ChyОценок пока нет

- Overcurrent and Earthfault Relay Type CDG. Millenium VersionДокумент8 страницOvercurrent and Earthfault Relay Type CDG. Millenium VersionAONLAОценок пока нет

- ABB Distribution: SF - Circuit Breaker ManualДокумент28 страницABB Distribution: SF - Circuit Breaker Manualdeepak2628100% (1)

- Tech REF615 High-Impedance Differential 757207 ENaДокумент10 страницTech REF615 High-Impedance Differential 757207 ENaFredrikОценок пока нет

- 7PA27 30 en-AuxiliaryRelayДокумент5 страниц7PA27 30 en-AuxiliaryRelayLê Văn Phú100% (1)

- ABB RET 521 TRANS DIFFERENTIAL PROTECTION INSTALLATION and COMMISSIONING MANUALДокумент67 страницABB RET 521 TRANS DIFFERENTIAL PROTECTION INSTALLATION and COMMISSIONING MANUALNima Mahmoudpour100% (1)

- MINILEC Full Cat PDFДокумент68 страницMINILEC Full Cat PDFDakshinaMoorthyОценок пока нет

- 1000 KVA Type Test From ERDA, IndiaДокумент9 страниц1000 KVA Type Test From ERDA, IndiasaikatОценок пока нет

- Vagm 22Документ4 страницыVagm 22AONLAОценок пока нет

- Percentage Impedance of Transformer & Its CalculationДокумент6 страницPercentage Impedance of Transformer & Its CalculationTran Quoc Thinh - M&EОценок пока нет

- MasterPact PresentationДокумент5 страницMasterPact Presentationtomek453Оценок пока нет

- 7PA22 - Lockout RelayДокумент6 страниц7PA22 - Lockout RelayJack JohnsonОценок пока нет

- Motor-Drive Mechanism, Type BUE 2: Technical GuideДокумент16 страницMotor-Drive Mechanism, Type BUE 2: Technical GuideBarry79xОценок пока нет

- CTMFM Motor Protection RelayДокумент10 страницCTMFM Motor Protection RelayAjay Das100% (2)

- MVAA Aux. Relay ManualДокумент7 страницMVAA Aux. Relay ManualMushtaq Ahmed Jan100% (5)

- Modeling of Three Phase Autotransformer For Short Circuit StudiesДокумент8 страницModeling of Three Phase Autotransformer For Short Circuit Studiesbubo28Оценок пока нет

- Problems in Overall Differential Protection of Generator and GTДокумент4 страницыProblems in Overall Differential Protection of Generator and GTsirsa11100% (1)

- Sverker 760Документ6 страницSverker 760Junior Ramirez ReyesОценок пока нет

- Operacion Recloser RoclwillДокумент54 страницыOperacion Recloser RoclwillChristian Vasquez MedranoОценок пока нет

- Rogowski FactorДокумент5 страницRogowski FactorRiddhi GhoshОценок пока нет

- Right Choice of Dry Type or Liquid-Filled TransformerДокумент7 страницRight Choice of Dry Type or Liquid-Filled TransformerEngr. AbdullahОценок пока нет

- Circulating CurrentДокумент6 страницCirculating CurrentjogiyajeeОценок пока нет

- Abb Oltc Ordering Info PDFДокумент13 страницAbb Oltc Ordering Info PDFSellappan MuthusamyОценок пока нет

- Transformer Impedance OptimizationДокумент2 страницыTransformer Impedance OptimizationDundi Kumar Bevara100% (1)

- Maintenance Chart of An OltcДокумент2 страницыMaintenance Chart of An OltcBestwick Braveen Sylvester100% (1)

- Kolma, Kola, Kokm, Kori, Kolt EngДокумент40 страницKolma, Kola, Kokm, Kori, Kolt EngIlian Teofilov100% (2)

- 15 Transformer Voltage Control and Tap Changing: Booster Transformer Booster TransformerДокумент9 страниц15 Transformer Voltage Control and Tap Changing: Booster Transformer Booster TransformerFaizan 'Fezar' RabbaniОценок пока нет

- 132KV Transfer Buscoupler...............Документ13 страниц132KV Transfer Buscoupler...............apsОценок пока нет

- Busbar Clearance BarrierДокумент2 страницыBusbar Clearance BarrierSundaresan Sabanayagam100% (1)

- Non-Directional Overcurrent and Earth Fault ProtectionДокумент35 страницNon-Directional Overcurrent and Earth Fault ProtectionShahzad Bhatti50% (2)

- Outdoor Instrument TransformersДокумент124 страницыOutdoor Instrument TransformersscribistОценок пока нет

- Difference Between Live Tank Type and Dead Tank Circuit BreakerДокумент2 страницыDifference Between Live Tank Type and Dead Tank Circuit BreakerHUDA ANTARОценок пока нет

- Interpretation of Sweep Frequency Response AnalysiДокумент8 страницInterpretation of Sweep Frequency Response AnalysiRyan JohnОценок пока нет

- 21-06-2017 16-45-31 - MCOMP - Protection Relays - Manual PDFДокумент249 страниц21-06-2017 16-45-31 - MCOMP - Protection Relays - Manual PDFmehtaabhi99_27916695Оценок пока нет

- Understanding Vector Group of Transformer 1 PDFДокумент9 страницUnderstanding Vector Group of Transformer 1 PDFkishansaiОценок пока нет

- PirДокумент31 страницаPirdilipelineОценок пока нет

- Calculation of Short Circuit ForcesДокумент10 страницCalculation of Short Circuit Forcesishwer kushwahОценок пока нет

- Power Circuit Breaker TrainingДокумент4 страницыPower Circuit Breaker TrainingKaleem UllahОценок пока нет

- 1 Compact Substation Type 8fb20Документ6 страниц1 Compact Substation Type 8fb20oadipphone7031Оценок пока нет

- 100KVA GA DrawingДокумент1 страница100KVA GA DrawingMahidhar TalapaneniОценок пока нет

- BROKEN DELTA Vs OPEN DELTAДокумент1 страницаBROKEN DELTA Vs OPEN DELTANimesh Patel100% (1)

- Polarised Mho RelayДокумент11 страницPolarised Mho RelayPavan Gowda100% (2)

- Circulating Current Relay Cag14&34Документ6 страницCirculating Current Relay Cag14&34sivaguruk2Оценок пока нет

- Rej 601Документ20 страницRej 601Ram RKОценок пока нет

- Alstom Relay CDG 21Документ4 страницыAlstom Relay CDG 21Jeffrey ChavezОценок пока нет

- ACB Technical+Manual EДокумент156 страницACB Technical+Manual EDũng Nguyễn Thế100% (2)

- HPA Spare Price ListДокумент12 страницHPA Spare Price ListSRD SHUBHENDU MAHAKURОценок пока нет

- SEL Relay Logic Diagram PDFДокумент13 страницSEL Relay Logic Diagram PDFngocanhvyОценок пока нет

- C Power ACB ManualДокумент9 страницC Power ACB ManualanilerОценок пока нет

- DinisДокумент8 страницDinisChristopher PerkinsОценок пока нет

- Dual Ratio Transformer MonographДокумент7 страницDual Ratio Transformer MonographGhanshyam Lalwani0% (1)

- Advances in High Voltage Insulation and Arc Interruption in SF6 and VacuumОт EverandAdvances in High Voltage Insulation and Arc Interruption in SF6 and VacuumОценок пока нет

- Auto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenОт EverandAuto-Transformer Design - A Practical Handbook for Manufacturers, Contractors and WiremenРейтинг: 4 из 5 звезд4/5 (2)

- WI1 3E RelayДокумент30 страницWI1 3E RelayJordan JohnsОценок пока нет

- Protection of Three Winding Transformer enДокумент10 страницProtection of Three Winding Transformer enreply2amit1986Оценок пока нет

- Neg. Seq. RelayДокумент16 страницNeg. Seq. Relaywas00266Оценок пока нет

- Appl 19 Protection of Autotransformer enДокумент10 страницAppl 19 Protection of Autotransformer enGyan SagarОценок пока нет

- AC DC Mixing - Case Study PDFДокумент3 страницыAC DC Mixing - Case Study PDFAnonymous g0InJ4BLBОценок пока нет

- ELECTRA - 322 Cigre 2022 Kyoto Symposium Final ReportДокумент19 страницELECTRA - 322 Cigre 2022 Kyoto Symposium Final ReportSudhir RavipudiОценок пока нет

- Mobile Innovations Content SponsorshipДокумент2 страницыMobile Innovations Content SponsorshipSudhir RavipudiОценок пока нет

- Mobile Innovations BulletinДокумент18 страницMobile Innovations BulletinSudhir RavipudiОценок пока нет

- 1-ph Fault at 50302 and Tripping 50302-51951 (ckt1) and 50302-51951 (ckt2) Speed Deviation (PU)Документ1 страница1-ph Fault at 50302 and Tripping 50302-51951 (ckt1) and 50302-51951 (ckt2) Speed Deviation (PU)Sudhir RavipudiОценок пока нет

- EMTP UC Atlanta 2019-Anton StepanovДокумент19 страницEMTP UC Atlanta 2019-Anton StepanovSudhir RavipudiОценок пока нет

- Powerfactory Applications For Power System Analysis: January 2015Документ2 страницыPowerfactory Applications For Power System Analysis: January 2015Sudhir RavipudiОценок пока нет

- KG 2 Coding Activity SheetДокумент1 страницаKG 2 Coding Activity SheetSudhir RavipudiОценок пока нет

- Verb List: Akool - Means I EatДокумент6 страницVerb List: Akool - Means I EatSudhir RavipudiОценок пока нет

- EMTP Simulation of Micro-GridsДокумент18 страницEMTP Simulation of Micro-GridsSudhir RavipudiОценок пока нет

- Best Reference of ATC: November 2015Документ11 страницBest Reference of ATC: November 2015Sudhir RavipudiОценок пока нет

- Z-Transforms: Definition: The - Transform of A SequenceДокумент15 страницZ-Transforms: Definition: The - Transform of A SequenceSudhir RavipudiОценок пока нет

- Surge-Transferred Overvoltages in Earthing/Auxiliary TransformersДокумент6 страницSurge-Transferred Overvoltages in Earthing/Auxiliary TransformersSudhir RavipudiОценок пока нет

- Investigation of A Transferred Voltage Surge Distribution Within A Tertiary Winding of A Power TransformerДокумент4 страницыInvestigation of A Transferred Voltage Surge Distribution Within A Tertiary Winding of A Power TransformerSudhir RavipudiОценок пока нет

- Day Three: Numerals 20-MillionДокумент11 страницDay Three: Numerals 20-MillionSudhir RavipudiОценок пока нет

- The Resiliency Continuum: N. Placer and A.F. SnyderДокумент17 страницThe Resiliency Continuum: N. Placer and A.F. SnyderSudhir RavipudiОценок пока нет

- Insulation Coordination Study Report - 2019phxp0901u PDFДокумент16 страницInsulation Coordination Study Report - 2019phxp0901u PDFSudhir Ravipudi100% (1)

- Small Signal Analysis Tool: ToolsДокумент4 страницыSmall Signal Analysis Tool: ToolsSudhir RavipudiОценок пока нет

- Diagram 5Документ1 страницаDiagram 5Sudhir RavipudiОценок пока нет

- Dar Presentation Dubai JTДокумент36 страницDar Presentation Dubai JTSudhir RavipudiОценок пока нет

- Rules of Thumb For Load SheddingДокумент3 страницыRules of Thumb For Load SheddingSudhir RavipudiОценок пока нет

- Abstract 3 PQДокумент2 страницыAbstract 3 PQSudhir RavipudiОценок пока нет

- Egat Pmu Smart Grid v1Документ22 страницыEgat Pmu Smart Grid v1Sudhir Ravipudi100% (1)

- Electrical Power and Energy Systems: Juri Belikov, Yoash LevronДокумент10 страницElectrical Power and Energy Systems: Juri Belikov, Yoash LevronSudhir RavipudiОценок пока нет

- Digest 176 NEC TablesДокумент1 страницаDigest 176 NEC TablesHernan Dario Alvarez BenitezОценок пока нет

- Extracts Abc of Capacitors Capacitor Types PDFДокумент2 страницыExtracts Abc of Capacitors Capacitor Types PDFManuel José Cano AlzateОценок пока нет

- Vigilohm in Healthcare PresentationДокумент64 страницыVigilohm in Healthcare PresentationnooruddinkhanОценок пока нет

- Is 1885 38 1993 PDFДокумент20 страницIs 1885 38 1993 PDFSubhasish PaulОценок пока нет

- Atv320 Atv12 Is Emc Plate Bbv46505 03Документ6 страницAtv320 Atv12 Is Emc Plate Bbv46505 03George StanОценок пока нет

- Group 1 Compilation of Quizes and ReviewerДокумент40 страницGroup 1 Compilation of Quizes and ReviewerCatherine PalarcaОценок пока нет

- Esquema Eléctrico - Motores C9.3, C13, C15 & C18 (J1939 Instrument Panel)Документ6 страницEsquema Eléctrico - Motores C9.3, C13, C15 & C18 (J1939 Instrument Panel)DavidОценок пока нет

- Electrical Machines - II - by Er - NirajkandelДокумент122 страницыElectrical Machines - II - by Er - NirajkandelNIRAJ KANDEL100% (2)

- Reverse Tesla CoilДокумент17 страницReverse Tesla Coilmarin_marin88100% (1)

- History Is The Tutor of Life: (Moving The Rotor Koepchenwerk, RWE, 1988)Документ7 страницHistory Is The Tutor of Life: (Moving The Rotor Koepchenwerk, RWE, 1988)shyam_krishnan_16Оценок пока нет

- ASR 9006 PowerДокумент5 страницASR 9006 PowerrenuОценок пока нет

- Maxwell Condis High Voltage 2010 PDFДокумент20 страницMaxwell Condis High Voltage 2010 PDFrahmanОценок пока нет

- k355l 4 315kw Test ReportДокумент4 страницыk355l 4 315kw Test ReportmersiumОценок пока нет

- L-s1 Led t8 Uspma - MPT 130513Документ6 страницL-s1 Led t8 Uspma - MPT 130513Evon ChayОценок пока нет

- Kompakt Prekidaci General Electric English Ed02 2006Документ69 страницKompakt Prekidaci General Electric English Ed02 2006d.olivericОценок пока нет

- Magnet-Mount Strain Sensor: Main FeaturesДокумент2 страницыMagnet-Mount Strain Sensor: Main Featuresmuhammad taufik rahmanОценок пока нет

- GuanellaДокумент2 страницыGuanellaleorajОценок пока нет

- Cf4ul10 36VДокумент2 страницыCf4ul10 36VNitinОценок пока нет

- Instructions: Voltage Regulator AVC63-4AДокумент3 страницыInstructions: Voltage Regulator AVC63-4AMaxiSanchezОценок пока нет

- S2 Science SSS - 16 Electrical SystemsДокумент6 страницS2 Science SSS - 16 Electrical SystemsSHANNON TAN S2-02Оценок пока нет

- AUH ElecWiringRegs2007Rev01Документ240 страницAUH ElecWiringRegs2007Rev01Muhammad RazaОценок пока нет

- WiNbreak MCCBДокумент26 страницWiNbreak MCCBnicesreekanthОценок пока нет

- Physics HW QuestionsДокумент7 страницPhysics HW QuestionsClaudia HuoОценок пока нет

- TSSOP8 Plastic-Encapsulate MOSFETS: Jiangsu Changjiang Electronics Technology Co., LTDДокумент5 страницTSSOP8 Plastic-Encapsulate MOSFETS: Jiangsu Changjiang Electronics Technology Co., LTDakash shuklaОценок пока нет

- Lithonia Outdoor KV Series Vertical Area Brochure 2-86Документ4 страницыLithonia Outdoor KV Series Vertical Area Brochure 2-86Alan MastersОценок пока нет

- H S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolДокумент58 страницH S ™ PHC P H C: Ypertherm Ensor Lasma Eight OntrolCRISTIANОценок пока нет

- Light FittingДокумент3 страницыLight FittingPrasadОценок пока нет

- Assembly Instruction: NP X SeriesДокумент1 страницаAssembly Instruction: NP X SeriesRodolfo Amaral de AlmeidaОценок пока нет

- GFE H ManualДокумент2 страницыGFE H Manualparallax1957Оценок пока нет

- Horno de Microondas Sharp R481cwaДокумент40 страницHorno de Microondas Sharp R481cwaErick RodriguezОценок пока нет