Академический Документы

Профессиональный Документы

Культура Документы

Compensation of Friction and Backlash Effects in An Electrical Actuator by Merzouki

Загружено:

jacobwatsonОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Compensation of Friction and Backlash Effects in An Electrical Actuator by Merzouki

Загружено:

jacobwatsonАвторское право:

Доступные форматы

1 SPECIAL ISSUE PAPER

Compensation of friction and backlash eects in an

electrical actuator

R Merzouki*, J C Cadiou and N K MSirdi

Laboratoire de Robotique de Versailles, Velizy, France

Abstract: In this paper, non-linear observers, based on an estimation of the friction force and the

disturbed torque transmitted due to the dead zone, are developed for systems presenting mechanical

imperfections such as friction and backlash. Then an adaptive controller using these non-linear

observers is presented, to compensate for mechanical disturbances on-line. Simulation and experimental

results applied on an electrical actuator are given to support the theoretical demonstrations.

Keywords: friction force, non-linear observer, backlash eects, transmitted torque, electrical actuator,

dead zone, adaptive control

NOTATION 1 INTRODUCTION

a area contact width (m) The presence of non-linearities in mechanical systems

make them dicult to control with high accuracy. F global friction torque (N m)

F

friction torque error (N m) Among these imperfections are friction, which depends

on the relative velocity of the motion, and the backlash j

0

dead zone magnitude (rad)

J

m

motor inertia (N m2) phenomenon issued from the dead zone between two

involved parts. J

s

load inertia (N m2)

K elasticity constant (N m/rad) Among research dealing with friction eects, Friedland

[1] has developed an algorithm in order to estimate the N

0

reducer constant

w non-linear transmitted torque (N m) Coulomb friction force. This algorithm is a reduced-order

observer containing two non-linear functions, where w non-linear transmitted torque error (N m)

one corresponds to the Jacobean of the other. A good

choice of non-linear function in the observer allows a

0

Coulomb friction torque (N m)

a

1

stiction torque (N m) an asymptotic stability of the error. Amin et al. [2]

have developed two types of observers: the rst considers a

2

viscous friction coecient (N m s/rad)

e

e

input position error (rad) the friction force as a constant and the second is used

to estimate the relative velocity of the motion during e

e

input velocity error (rad/s)

e

s

output position error (rad) the contact. Canudas de Witt et al. [3] proposed a

model of friction that includes dierent eects, such e

s

output velocity error (rad/s)

h

e

input reducer position (rad) as hysteresis behaviour and the stiction eect. They

developed an adaptive control in order to estimate and h

e

input reducer velocity (rad/s)

h

e

input reducer acceleration (rad/s2) then compensate for the friction eects.

The presence of the dead zone in mechanical systems h

s

output reducer position (rad)

h

s

output reducer velocity (rad/s) introduces an hysteresis phenomenon between the input

and the output positions. This describes the backlash h

s

output reducer acceleration (rad/s2)

h

stri

Stibeck velocity (rad/s) phenomenon, which causes non-stable behaviour in the

controlled system. Backlash is inherent in mechanical m friction parameter

systems, especially when starting the motion, but if it

increases due to wear it will disturb the performance of

The MS was received on 7 April 2003 and was accepted after revision

the system. In such a case, compensation for these eects

for publication on 8 September 2003.

is due to mechanical or control methods. For a long

* Corresponding author: Laboratoire de Robotique de Versailles, 1012

avenue de lEurope, 78140 Velizy, France. time, mechanical solutions existed to eliminate these

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

2 R MERZOUKI, J C CADIOU AND N K MSIRDI

disturber eects by changing all imperfect parts on the The second imperfection is backlash and is represented

by a variable dead zone from 0 to 24. Finally, the trans- system. Some control solutions have also been proposed,

e.g. by Brandenburg and Schafter [4], who studied mitted motion to the output axis is via a string system

with changeable stiness. the inuence and the partial compensation of simul-

taneously acting backlash and Coulomb friction in a On this bench test, the measure of input and output

positions is taken by two incremental coders, as shown speed and position control of an elastic two-mass system.

Recker et al. [5] and Tao and Kokotovic [6] worked on in Fig. 1a.

the adaptive control of systems with backlash. Dierent

mathematical models were proposed, such as that of Tao

and Kokotivic [6], who modelled an inverse backlash

2.2 Estimation of the friction force

model based on an hysteresis cycle. Cadiou and MSirdi

[7] have developed a dierentiable model based on the

In order to explain the origin of the friction force

dead zone characteristic.

observer, two dierent modes are studied. The rst one

In this paper, two non-linear observers have been

is the nearly static mode, which corresponds to the low-

developed, to estimate the friction force and the dis-

velocity variation. The second one corresponds to the

turber transmitted torque. After that, an adaptive con-

dynamic mode, where the velocity variation is important.

troller is presented, to compensate for the disturbance

eects. In most applications, the friction and the back-

2.2.1 Nearly static mode

lash non-linearities could not be accurately known,

so only an estimation of these eects could be possible.

Consider that during mechanical motion between two

A mathematical model of imperfections is given, rep-

surfaces in contact, the pressure distribution P(x) [8] is

resenting an inverse sigmoid to represent the disturber

given by Fig. 2b. In this case, the distribution is chosen

torque observer [8] and Tustins model for the case of

as a half-ellipse in the plane and is limited by a and

friction [9]. Simulation and experimental results are pre-

+a, where a is a positive value that denes the maximum

sented in this paper, which are applicable to a bench test

of the deection [3]. The maximum pressure contact

constructed in the authors laboratory, and an important

acts at the centre and decreases progressively with the

number of mechanical imperfections are given.

width contact.

The easiest representation of this last distribution

could be formulated as follows:

2 DEFINITIONS AND MODELLING

P(x)=P

0 S

1

x2

a2

(1)

2.1 Description of the bench test

For the nearly static mode, the friction force F

1

depends

The experimental bench test of Fig. 1a corresponds to

on the normal force N, so that

an electrical actuator, divided into two parts. The rst

part represents the motor part and is driven by a d.c.

F

1

=mN (2)

motor. The second part describes the reducer part which

where m is the friction parameter at low velocities. The regroups three important mechanical imperfections.

normal force N could be deduced by integration of the The rst imperfection is static and viscous friction,

assumed pressure distribution P(x). The friction force where coecients can be changed for dierent appli-

could then be expressed as cations by using many brake parts made of aluminium,

metal, etc. These coecients could also be identied

approximately by using classical identication algorithms

F

1

=

P

+a

a

am P(x) dx (3)

[7], e.g. the recursive least mean squares method.

Fig. 1 (a) Bench test; (b) bloc scheme of the bench test

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

3 COMPENSATION OF FRICTION AND BACKLASH EFFECTS IN AN ELECTRICAL ACTUATOR

Fig. 2 (a) Surfaces in contact; (b) pressure distribution

Replacing equation (1) by equation (3) gives positive constants. The rule of this lter is to cut the

high frequencies of e

s

, issued as a result of the presence

of mechanical imperfections.

F

1

=

P

+a

a

am P

0 S

1

x2

a2

dx (4)

The formulation of the m observer and the friction

force F

2

estimator can now be rewritten from equations

Putting x=a sin a gives dx=a cos a da, with a

(9) and (10), which take the same mathematical

[p/2, p/2]; therefore

formulation as their corresponding model, adding the

term k

0

e

s

, as shown below:

F

1

=P

0

m

P

+p/2

p/2

a2 cos2 a da (5)

m

=

l

|h

stri

|

m +

pa

0

l

2a2P

0

|h

stri

|

sign(h

s

)k

0

e

s

F

1

=P

0

a2m

P

+p/2

p/2

A

1+cos 2a

2 B

da (6)

F

=

pP

0

a2m

2

+a

2

h

s

F

1

=

pP

0

a2m

2

(7)

(11)

From equations (11) and (9), the estimated friction error

where P

0

represents the maximum pressure over the

and the observed parameter error m are given as

contact surface and is supposed known in this case.

m

=

l

|h

stri

|

m +re

2.2.2 Dynamic mode

When P(xa)=0, evolution of the friction force will

F

=

pP

0

a2

2

m

depend principally on the relative velocity h

s

between

the surfaces in contact:

(12)

F

2

=a

2

h

s

(8)

Putting

where a

2

is the viscous friction coecient. The global

friction force F=F

1

+F

2

will therefore be expressed for

G=

pP

0

a2

2

(13)

both modes as follows:

thus gives the estimated friction error as

F=

pP

0

a2m

2

+a

2

h

s

(9)

F

=FF

=Gm (14)

2.2.3 Friction observer

2.3 Description of the transmitted torque

Consider a low-pass lter formulated as

Figure 3 shows an approximation of a transmitted

torque via a dead zone of magnitude 2j

0

, with exible

m =

1

(|h

stri

| /l)p+1 A

pa

0

2a2P

0

|h

stri

|

l

k

0

e

sB

(10)

links. The dierence between the input position h

e

and

the output position N

0

h

s

of the reducer part is put as

Dh, with N

0

as the reducer constant. The continuous and where a

0

is the Coulomb friction, supposed known, p is

the Laplace constant, h

stri

is the Stribeck velocity given derivable function, a sigmoid, is used to describe the

transmitted torque characteristic inside and outside the in reference [7], |h

stri

|/ l is the cut-o frequency, m corre-

sponds to the observer of parameter m, e

s

=h

s

hd

s

, dead zone [8], and is easy to implement in the control

scheme. where hd

s

represents the desired output, and k

0

, l are

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

4 R MERZOUKI, J C CADIOU AND N K MSIRDI

described by the following equations system:

J

s

h

s

+F=C

J

m

h

e

+f

m

h

e

+C=U

(20)

where J

s

, h

s

are the inertia of the reducer part supposed

known and the output reducer acceleration respectively,

J

m

, f

m

, h

e

, h

e

are the inertia of the motor part, the

viscous input friction, which are supposed known, the

input reducer acceleration and velocity respectively, U is

the control torque, F is the friction force, supposed

unknown in the actuator and has to be estimated, and

h

e

and h

s

are the input and output measured positions

of the reducer part respectively. C represents the trans-

Fig. 3 Approximation of transmitted torques

mitted torque to the load via a exible axis and a known

dead zone. It may be expressed as

Then the mathematical formulation of this transmitted

torque via a dead zone is dened by C=K Dh+w (21)

where K is the stiness of the exible parts and w is the

C=K

A

Dh4j

0

1ec Dh

1+ec DhB

(15)

disturber torque, described before.

Note that

where C is the approximate transmitted torque repre-

sented in Fig. 3. After decomposing the expression of

Dh=h

e

N

0

h

s

(22)

the transmitted torque C into two parts,

which represents the dierence between the input and

C=C

0

+w (16)

the output positions of the reducer part. N

0

is the reducer

with C

0

the linear transmitted torque, given by

constant.

System (20) can then be expressed as follows:

C

0

=K Dh (17)

and w the disturber and non-linear transmitted torque,

J

s

h

s

+F=Kh

e

KN

0

h

s

+w

formulated as follows:

J

m

h

e

+f

m

h

e

=UKh

e

+KN

0

h

s

w

w=4Kj

0

1ec Dh

1+ec Dh

(18)

(23)

e

s

=h

s

hd

s

The representation of w depends on the value of

the constant c, which depends on the magnitude j

0

.

e

e

=h

e

hd

e Expression (18) corresponds to the best approximation

z=Kh

e

KN

0

h

s

of the transmitted torque via a dead zone, as shown

in Fig. 3.

e

z

=zz

d According to the simulation and experimental tests,

the best decreasing value of w is obtained inside [j

0

, j

0

] w =ww

after putting

F

=FF

c=

1

2j

0

(19)

(24)

where hd

s

is the desired output position, hd

e

is the desired

For the next sections, the parameter c is calculated

input position, z is the dierence between the input and

on-line by giving an approximative and initial value to

the output positions of the reducer part and z

d

is its

j

0

. Then the torque w is estimated after observing the

desired value, w is the estimated disturber torque and w

evolution of the magnitude j

0

on-line.

corresponds to the estimated error of the disturber

torque. Now, system (23) may be expressed as

3 CONTROL OF THE BENCH TEST INCLUDING

J

s

h

s

+F=z+w

FRICTION AND BACKLASH

J

m

h

e

+f

m

h

e

+J

s

h

s

+F=U

The dynamic model of the bench test given in Fig. 1,

including the friction and backlash imperfections, is (25)

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

5 COMPENSATION OF FRICTION AND BACKLASH EFFECTS IN AN ELECTRICAL ACTUATOR

The control scheme to the bench test is given by Fig. 4. where K

P1

and K

D1

are the PD constants of the C

1

con-

troller and F

the estimated friction force given in Fig. 4. C

1

and C

2

are proportional derivative (PD) controller

blocs with transient blocs of H

1

and H

2

. According to the control scheme of Fig. 4,

In order to linearize the rst equation of system (25),

hd

e

=K

D2

e

s

+K

P2

e

s

(32)

the z and w values given in system (24) are replaced by

estimated values as follows:

where K

P2

and K

D2

represent the C

2

controller constants

of Fig. 4.

J

s

h

s

+F=e

z

+z

d

+w +w (26)

By replacing the expression for U in equation (30),

For that, z

d

is chosen as

the following equation is obtained:

z

d

=J

s

h

d

s

+F

w (27)

J

m

K

e

z

+

A

f

m

K

+

K

D1

K B

e

z

+

A

k

1

+

K

P1

K B

e

z By replacing expression (27) in equation (26), the

output system equation is given by

+( J

m

N

0

+J

s

K

D1

K

D2

)e

s

J

s

e

s

+F

=e

z

+w (28)

+( f

m

N

0

K

P1

K

D2

K

D1

K

P2

+K

D1

N

0

)e

s

which is the equation deduced after linearization of the

+(K

P1

N

0

K

P1

K

P2

)e

s

+F

=0 (33)

reducer part model.

Now, to linearize the second equation of system (25),

This last equation describes the linearization of the

the following aectations are used:

motor part of our bench test.

From equations (11) and (9), the estimation errors of

h

e

=

z

K

+N

0

h

s

the friction parameter m and the friction force are given

by the following equations system:

h

e

=

z

K

+N

0

h

s

m

=jm +k

0

e

s

F

=Gm

h

e

=

z

K

+N

0

h

s (34)

(29) where

The second equation of system (25) will become

G=

pP

0

a2

2

and j=

l

|h

stri

|

J

m

K

z +

f

m

K

z +( J

m

N

0

+J

s

)h

s

+f

m

N

0

h

s

+F=U (30)

The torque estimator has the same formulation as its

model (18) and is given by the following expression:

Thus, the control law U for global system (20) is

expressed as

w =4Kj

0

1ec Dh

1+ec Dh

(35)

U=

J

m

K

zd+

A

f

m

K

+

K

D1

K B

zd+

K

1

K

zd

with c supposed known. In the case of Dh&0, w will

take the following expression:

+(J

m

N

0

+J

s

)h

d

s

+( f

m

N

0

+K

D1

N

0

)h

d

s

+K

P1

N

0

hd

s

k

1

e

z

K

D1

e

e

K

P1

e

e

+F

(31) w =4Kj

0

(36)

Fig. 4 Control scheme of the bench test including friction and backlash

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

6 R MERZOUKI, J C CADIOU AND N K MSIRDI

after choosing a backlash magnitude model given by

dj

0

dt

=0 (37)

with j

0

the magnitude constant. Thus, the observer

magnitude can be expressed by the output position errors

and output velocity errors, as follows:

dj

0

dt

=k

2

e

s

k

3

e

s

(38)

where k

2

and k

3

are positive constants.

Fig. 5 Equivalent scheme of the global system in a closed loop

The estimation error of the backlash magnitude is

given as

The characteristic equation of the global system (40) is

dj

0

dt

=

dj

0

dt

dj

0

dt

=k

2

e

s

+k

3

e

s

(39)

dened by the following equation:

Thus, the global system will be a combination of all the

C

8

p8+C

7

p7+C

6

p6+C

5

p5+C

4

p4+C

3

p3

following equations:

+C

2

p2+C

1

p=0 (41)

J

s

e

s

+F

=e

z

+w

with

J

m

K

e

z

+

A

f

m

K

+

K

D1

K B

e

z

+

A

k

1

+

K

P1

K B

e

z

C

8

=4KJ

s

a

3

C

7

=4KJ

s

(a

2

+ja

3

)

+( J

m

N

0

+J

s

K

D1

K

D2

)e

s

C

6

=4KJ

s

(j+1)a

2

+4Kb

3

+k

2

a

3

+( f

m

N

0

K

P1

K

D2

K

D1

K

P2

+K

D1

N

0

)e

s

C

5

=4KJ

s

a

0

+a

3

(4KGk

0

+k

3

)+4KJ

s

ja

2

+k

2

a

2

+(K

P1

N

0

K

P1

K

P2

)e

s

+F

=0

+4K(b

2

+jb

3

)

dj

0

dt

=k

2

e

s

+k

3

e

s

C

4

=4KJ

s

ja

0

+k

3

ja

3

+k

2

a

2

+4K(b

1

+jb

2

)+a

3

k

3

j

w =4Kj

0

C

3

=4K(b

0

+jb

1

)+k

2

a

0

+a

2

(4KGk

0

+k

3

)+a

2

k

3

j

m

=jm +k

0

e

s C

2

=4Kjb

0

+a

0

(4KGk

0

+k

3

)+k

3

jb

0

F

=Gm

C

1

=k

3

ja

0

(40)

To dene the conditions on the controller constants and

which is represented in Fig. 5, with

on constants k

0,

k

1

, k

2

, K

3

, use of the Routh criterium

determines the stability limits for the global system to

b

3

=

J

m

K

converge to the equilibrium state (e

s

0, e

e

0, w 0,

F

0).

b

2

=j

J

m

K

+

f

m

K

+

K

D1

K

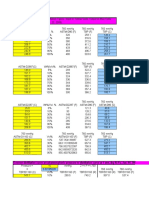

4 SIMULATION RESULTS

b

1

=j

A

f

m

K

+

K

D1

K B

+k

1

+

K

P1

K

The simulation tests are performed on a mechanical

model representative of the bench test of Fig. 1b. The

b

0

=j

A

k

1

+

K

P1

K B

parameters of the model for the simulation tests are

K

P1

=15, K

D1

=0.5, K

P2

=15, K

D2

=0.3

a

3

=K

D1

K

D2

J

m

N

0

J

s

K=1 N m/rad, J

m

=0.000 972 N m2

a

2

=K

P1

K

D2

+K

D1

K

P2

f

m

N

0

K

D1

N

0

f

m

=0.000 43 N m s/rad, J

s

=7.5 N m2

j( J

m

N

0

+J

s

K

D1

K

D2

)

a

0

=8 N m, a

1

=10.5 N m, a

2

=16 N m s/rad

a

1

=K

P1

K

P2

K

P1

N

0

j

0

=0.1 rad, k

1

=1, k

2

=0.01, k

3

=1

j( f

m

N

0

K

P1

K

D2

K

D1

K

P2

+K

D1

N

0

)

a

0

=Gk

0

j(K

P1

N

0

K

P1

K

P2

) and N

0

=59

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

7 COMPENSATION OF FRICTION AND BACKLASH EFFECTS IN AN ELECTRICAL ACTUATOR

Figure 6a describes the tracking of the output position in Fig. 8b before compensation and in Fig. 9b. After

adding observers, the output tracking error is reduced for a desired output signal hd

s

(t)=0.5 sin(0, 2pt) and a

PD controller applied on the system of Fig. 1. Figure 6b and is uniform for each period. However, a static error

is still present, due to the presence of the exibility eects represents the output position error before the adaptive

compensation of the imperfection eects. It can be seen in the mechanical system. Figure 10 describes the

hysteresis cycle between the input and the output reducer that the reel output position signal is less deformed at

the peak area due to the presence of the disturbances. positions. After compensating for the dead zone eect,

the width of the cycle is reduced. Knowing that the This deformation is compensated after introducing the

adaptive compensation, as shown in Fig. 7a. Then, the exibility eect is still present in the modelling, the

relation between the input and output positions is not real output position signal approaches the desired one,

with a position error described as in Fig. 7b. This error exactly linear after compensation. Figure 11a represents

the control signals before and after compensation. The is especially due to the exibility eects, which are

not considered in the adaptive compensation. Figure 8a signal before compensation is not as clear as the one

after compensation. This is due to the presence of the describes the tracking of the input signal before com-

pensation for the mechanical imperfection eects. The imperfections, dened by the disturber torque of Fig. 11b.

After compensation, a linear representation of the torque tracking is very good in the two cases but is clearer in

the case after compensation (Fig. 9a). The dierence is obtained, which is transmitted via a exible axis, as

shown in Fig. 11b. between the error input position tracking is shown

Fig. 6 (a) Desired and real output signals before compensation; (b) output position error before compensation

Fig. 7 (a) Desired and real output signals after compensation; (b) output position error after compensation

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

8 R MERZOUKI, J C CADIOU AND N K MSIRDI

Fig. 8 (a) Desired and real input signals before compensation; (b) input position error before compensation

Fig. 9 (a) Desired and real input signals after compensation; (b) input position error after compensation

Fig. 10 Hysteresis backlash behaviour before and after compensation

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

9 COMPENSATION OF FRICTION AND BACKLASH EFFECTS IN AN ELECTRICAL ACTUATOR

Fig. 11 (a) Control torque before and after compensation; (b) linearization of the disturbed torque after

compensation

5 EXPERIMENTAL RESULTS and friction force. Figure 13 shows the output velocity

signals before and after the adaptive compensation. There-

fore, before the compensation case, undesired oscillations The experimental tests have been applied on the bench

test of Fig. 1a, using the following control parameters: around h

s

(0)=0 rad/s are present and represent the non-

linearity eects. These imperfections are compensated

K

P1

=1, K

D1

=0.01, K

P2

=10, K

D2

=5

after applying the estimated disturber torque and friction

force. Finally, the control signals before and after com- K=2 N m/rad, j

0

=0.48 rad, k

1

=1

pensating the backlash and friction eects are shown

k

2

=0.02, k

3

=1, a

0

=8 N m

in Fig. 14. In the case after compensation, the control

signal is clearer than its equivalent before the com-

a

1

=10.5 N m, a

2

=16 N m s/rad

pensation due to the adaptive compensation of the

In these tests, the motor reducer was required to

disturbance eects of friction and backlash.

move from the initial static output position h

s

(0)=

p/2 rad and output velocity h

s

(0)=0 rad/s to the origin

h

s

(0)=0 rad, h

s

(0)=0 rad/s.

Figure 12 represents the tracking output position before 6 CONCLUSION

(i.e. the regulation is made by only a PD controller) and

after applying the adaptive compensation. The static The presence of mechanical imperfections such as

position error is about 0.32 rad and is compensated after friction and backlash in controlled systems make them

adding the estimators of the undesired dead zone torque dicult to control with high accuracy. The mechanical

Fig. 12 Output position before and after adaptive compensation Fig. 13 Output velocity before and after adaptive compensation

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

10 R MERZOUKI, J C CADIOU AND N K MSIRDI

2 Amin, J., Friedland, B. and Harnoy, A. Implementation of

friction estimation and compensation technique. In 5th

IEEE International Conference on Control Applications,

Dearborn, Illinois, 1518 September, 1996.

3 Canudas de Wit, C., Olsson, H., Astrom, K. J. and

Lischinsky, P. A new model for control of systems with

friction. IEEE Trans. Autom. Control, March 1995,

40(3), 419424.

4 Brandenburg, G. and Schafer, U. Inuence and partial com-

pensation of simultaneously acting backlash and Coulomb

friction in a speed and position controlled elastic two-mass

system. In Proceedings of International Conference on

Electrical Drives (ICED88), Romania, 1988, pp. 112.

5 Recker, D. A., Kokotovic, P. V., Rhode, D. and

Winkelman, J. Adaptive nonlinear control of system con-

taining a dead zone. In Proceedings of the 30th Conference

on Decision and Control, Vol. 3, Brighton, December 1991,

pp. 21112115.

Fig. 14 Control signal before and after adaptive compensation

6 Tao, G. and Kokotovic, P. V. Adaptive control of systems

with unknown output backlash. Automatica, 1995, 40(2),

326330.

imperfection eects could be reduced by estimating the

7 Cadiou, J. C. and MSirdi, N. K. Modelization and analysis

necessary disturber torque inside the dead zone and the

of a system with torque transmitted through a backlash.

friction force acting during the motion. After adding

In 9th World Congress on The Theory of Machines and

these observers into the control law, the undesired non-

Mechanisms (IFTPMM), Vol. 2, Milan, Italy, August

linearities can be reduced. For the case of friction esti-

September 1995, pp. 14671470.

mation, a dynamic model describing the friction force

8 Merzouki, R., Cadiou, J. C. and MSirdi, N. K.

variation as a function of the output system velocity is

Compensation of backlash eects in an electrical actuator.

presented. Then, the friction observer corresponds to a

In the IASTED International Conference on Intelligent

lter bloc, where its input is the output position error Systems and Control (IASTED2000), Hawaii, 1416 August

2000. and its output is the friction parameter. For the case of

9 Merzouki, R., Cadiou, J. C. and MSirdi, N. K. Adaptive

backlash, a non-linear and derivable mathematical model

control of an electrical actuator. In the IEEE International

for the disturber torque is presented, where the dead

Conference on Intelligtent Systems and Control (ICAR2001),

zone magnitude approaches a constant value. Estimation

Budapest, Hungary, August 2001.

of the magnitude variation is observed as a function of

10 Merzouki, R., Cadiou, J. C. and MSirdi, N. K.

the output position error and output velocity error. A

Compensation of stick-slip eect in an electrical actuator.

good choice of control system parameters allows the con-

In Proceedings of the 2002 IEEE/RSJ International

vergence of the global system to the original state, as

Conference on Intelligent Robots and Systems (IROS2002),

shown in the simulation and experimental results.

Lausanne, Switzerland, October 2002, EPFL, pp. 22452249.

11 Tao, G. and Kokotovic, P. V. Adaptive control of systems

with backlash. Automatica, 1993, 29(2), 323335.

12 Tao, G. and Kokotovic, P. V. Adaptive control of systems

REFERENCES

with unknown output backlash. Automatica, 1995, 40(2),

326330.

1 Friedland, B. A non-linear observer for estimating parameters 13 Spinnler, G. Conception des Machines, Vols 1 and 2 (Presses

in dynamic systems. Automatica, 1997, 33(8), 15251530. Polytechniques et Universitaires Romandes).

I03303 IMechE 2004 Proc. Instn Mech. Engrs Vol. 218 Part I: J. Systems and Control Engineering

mi00003303 16-01-04 17:03:53 Rev 14.05

The Charlesworth Group, Huddersfield 01484 517077

Вам также может понравиться

- Solution Methods of Overhead Transmission Line Mechanics: Ladislav VARGA, Stanislav ILENIN, Vladimír CHLADNÝДокумент4 страницыSolution Methods of Overhead Transmission Line Mechanics: Ladislav VARGA, Stanislav ILENIN, Vladimír CHLADNÝUdomkarn SmtОценок пока нет

- Electromagnetic Levitation System: An Experimental ApproachДокумент7 страницElectromagnetic Levitation System: An Experimental Approachsh1n00b1Оценок пока нет

- A Robust Optimal Sliding-Mode Control Approach For Magnetic Levitation SystemsДокумент8 страницA Robust Optimal Sliding-Mode Control Approach For Magnetic Levitation Systemsankurgoel1975Оценок пока нет

- Campeanu Tranzitoriu SincronДокумент10 страницCampeanu Tranzitoriu SincronvalentinmullerОценок пока нет

- ACMSM23 083 CameraReadyДокумент6 страницACMSM23 083 CameraReadypiscesas45Оценок пока нет

- MD Robotic DeburringДокумент6 страницMD Robotic DeburringAldo BustamanteОценок пока нет

- Comparison of Different FE Calculation Methods For The Electromagnetic Torque of PM MachinesДокумент8 страницComparison of Different FE Calculation Methods For The Electromagnetic Torque of PM Machinesmlkz_01Оценок пока нет

- Disk-Rotor Servomotor Fed by An ACDC Converter PDFДокумент12 страницDisk-Rotor Servomotor Fed by An ACDC Converter PDFPFAОценок пока нет

- Iahr 2006 2Документ15 страницIahr 2006 2Pixing ZuoОценок пока нет

- Hysteresis Modelling For A MR Damper: Rmm@itesm - MX (Ruben Morales-Menendez)Документ9 страницHysteresis Modelling For A MR Damper: Rmm@itesm - MX (Ruben Morales-Menendez)dvarsastryОценок пока нет

- Icee2015 Paper Id3911Документ4 страницыIcee2015 Paper Id3911Zellagui EnergyОценок пока нет

- Matrix Analysis Techniques in Cage Induction Machines: David G. DorrellДокумент7 страницMatrix Analysis Techniques in Cage Induction Machines: David G. Dorrellni60Оценок пока нет

- Validation of A Tip Feedback Sensor Based Flexible Manipulator ModelДокумент12 страницValidation of A Tip Feedback Sensor Based Flexible Manipulator ModelChristopher MendozaОценок пока нет

- Determination of Blockage Correction in Open-Jet Wind TunnelДокумент6 страницDetermination of Blockage Correction in Open-Jet Wind Tunnelmoro1381100% (1)

- 02 Modelling, Parameter Identification, and ControlДокумент14 страниц02 Modelling, Parameter Identification, and Controlgurudev001Оценок пока нет

- Non-Parametric Models For Magneto-Rheological DampersДокумент18 страницNon-Parametric Models For Magneto-Rheological DampersUmanath R PoojaryОценок пока нет

- Cumulative Fatigue Damage Under Random LoadsДокумент11 страницCumulative Fatigue Damage Under Random LoadsMuhammad FaizОценок пока нет

- A New Analytical Method On The Field Calculation of IPMДокумент9 страницA New Analytical Method On The Field Calculation of IPMYusuf YaşaОценок пока нет

- Analysis of Detent Torque in Hybrid Stepping Motors: Jonathan U AgberДокумент7 страницAnalysis of Detent Torque in Hybrid Stepping Motors: Jonathan U AgbertheijesОценок пока нет

- Application of Space Vector Modulation in Direct Torque Control of PMSMДокумент4 страницыApplication of Space Vector Modulation in Direct Torque Control of PMSMenmnabilОценок пока нет

- Simulation of Electric Machine and Drive Systems Using Matlab and SimulinkДокумент17 страницSimulation of Electric Machine and Drive Systems Using Matlab and SimulinkSamuel Alves de SouzaОценок пока нет

- The Calculation of Contact Forces Between Particles Using Spring andДокумент6 страницThe Calculation of Contact Forces Between Particles Using Spring andAbhishek KulkarniОценок пока нет

- Design and Simulation of Control System For Bearingless Synchronous Reluctance Motor PDFДокумент5 страницDesign and Simulation of Control System For Bearingless Synchronous Reluctance Motor PDFKrishnam NaiduОценок пока нет

- Machine DesignДокумент8 страницMachine DesignSirajuddin AОценок пока нет

- 3D-Multi Body Simulation of Wind Turbines With Flexible ComponentsДокумент4 страницы3D-Multi Body Simulation of Wind Turbines With Flexible ComponentsJesus MamaniОценок пока нет

- Comparison of Field Oriented Control and Direct Torque Control For Permanent Magnet Synchronous Motor PMSMДокумент6 страницComparison of Field Oriented Control and Direct Torque Control For Permanent Magnet Synchronous Motor PMSMjp_20_20Оценок пока нет

- Parametric Study of Flexibility Factor For Curved Pipe and Welding ElbowsДокумент9 страницParametric Study of Flexibility Factor For Curved Pipe and Welding Elbowsbam_1962Оценок пока нет

- 01 Driver Seat Semi-Active Vibration Control PDFДокумент6 страниц01 Driver Seat Semi-Active Vibration Control PDFgurudev001Оценок пока нет

- 03 2008 JA PS A 1 008 CleanДокумент6 страниц03 2008 JA PS A 1 008 CleanBentarfa IslamОценок пока нет

- Sensorless Control PMSMДокумент5 страницSensorless Control PMSMSandeep RaiОценок пока нет

- Design of Electromagnetic RelayДокумент5 страницDesign of Electromagnetic RelaySEP-Publisher100% (1)

- Design Methodology of A Permanent MagnetДокумент10 страницDesign Methodology of A Permanent MagnetJian ZhangОценок пока нет

- Extraction of Ritz Vectors Using A Complete Flexibility MatrixДокумент6 страницExtraction of Ritz Vectors Using A Complete Flexibility MatrixRamprasad SrinivasanОценок пока нет

- Regular Paper Impact of Mechanical Forces in A 25ka Current Injection TransformerДокумент14 страницRegular Paper Impact of Mechanical Forces in A 25ka Current Injection TransformerConstantin DorinelОценок пока нет

- Application Of..... (ICEE2010) PDFДокумент6 страницApplication Of..... (ICEE2010) PDFdennypolariszОценок пока нет

- Robust Control Design For Maglev Train With Parametric Uncertainties Using - SynthesisДокумент7 страницRobust Control Design For Maglev Train With Parametric Uncertainties Using - SynthesisRaj PurohitОценок пока нет

- Modelling Asynchronous Machines by Electric Circuits: SebestyenДокумент27 страницModelling Asynchronous Machines by Electric Circuits: Sebestyenni60Оценок пока нет

- A Fast Method For Calculation of Transformers Leakage Reactance Using Energy TechniqueДокумент8 страницA Fast Method For Calculation of Transformers Leakage Reactance Using Energy TechniqueAkash VermaОценок пока нет

- A Modified Sensorless Control of Induction Motor Based On Reactive PowerДокумент4 страницыA Modified Sensorless Control of Induction Motor Based On Reactive PowerSherif M. DabourОценок пока нет

- An Optimal Balancing Structure For Small and Medium Electrical Machine RotorsДокумент9 страницAn Optimal Balancing Structure For Small and Medium Electrical Machine Rotorsikram09568519Оценок пока нет

- Small Signal Stability AnalysisДокумент6 страницSmall Signal Stability AnalysischeshankarОценок пока нет

- Dieu Khien He Thong Bi Trong Tu TruongДокумент5 страницDieu Khien He Thong Bi Trong Tu TruongNinhĐứcThànhОценок пока нет

- Makalah Intrumentasi PengukuranДокумент21 страницаMakalah Intrumentasi PengukuranMukhtar AnasОценок пока нет

- Assignment 5: Non-Linear Lateral Tire Dynamics: Parameter Value UnitДокумент3 страницыAssignment 5: Non-Linear Lateral Tire Dynamics: Parameter Value Unitshashank saiОценок пока нет

- Wiener Filter Design in Power Quality ImprovmentДокумент8 страницWiener Filter Design in Power Quality Improvmentsweetu_adit_eeОценок пока нет

- Calculation of Power Losses in The Damper Winding Winding of Large Hidrogenerators at Open-Circuit and Load ConditionsДокумент8 страницCalculation of Power Losses in The Damper Winding Winding of Large Hidrogenerators at Open-Circuit and Load ConditionsWalter SantiОценок пока нет

- Harmonics Reduction 1Документ10 страницHarmonics Reduction 1Swaminathan SrinivasanОценок пока нет

- IJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchДокумент8 страницIJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchInternational Journal of computational Engineering research (IJCER)Оценок пока нет

- Vibration Prediction in Switched Reluctance Motors With Transfer Function Identification From Shaker and Force Hammer TestsДокумент8 страницVibration Prediction in Switched Reluctance Motors With Transfer Function Identification From Shaker and Force Hammer TestsKaran ShahОценок пока нет

- Real Modes ExtractionДокумент10 страницReal Modes ExtractionrenatobellarosaОценок пока нет

- JESV5SI0109Документ5 страницJESV5SI0109Kiran YaddanapudiОценок пока нет

- Arindam Seminar 11Документ6 страницArindam Seminar 11Arindam BhattacharjeeОценок пока нет

- Sync Nous Ma Ters Identification Using Test: L DataДокумент3 страницыSync Nous Ma Ters Identification Using Test: L Datalilasaid2010Оценок пока нет

- Jeas 0408 94Документ7 страницJeas 0408 94Jun Chee LimОценок пока нет

- Modelling Electromagnetic Suspension Force Using Measured Inductance-Airgap DataДокумент4 страницыModelling Electromagnetic Suspension Force Using Measured Inductance-Airgap DataRizky DsОценок пока нет

- Paper Title: Ajay Kumar Gudla and Saikat ChakrabartiДокумент5 страницPaper Title: Ajay Kumar Gudla and Saikat ChakrabartiAshutosh KumarОценок пока нет

- Maths 1 P16 Solutions 10-11-2Документ11 страницMaths 1 P16 Solutions 10-11-2jacobwatsonОценок пока нет

- Lec03 2x2Документ6 страницLec03 2x2jacobwatsonОценок пока нет

- Muallim Ul QuranДокумент64 страницыMuallim Ul Quranjacobwatson100% (3)

- The Ultimate Writing Guide Arabic GCSE AsДокумент177 страницThe Ultimate Writing Guide Arabic GCSE Asjacobwatson0% (1)

- Vocabulary of The Qasas-un-Nabiyeen Volume IДокумент16 страницVocabulary of The Qasas-un-Nabiyeen Volume Iskhanani83% (24)

- Radial Consolidation TheoriesДокумент13 страницRadial Consolidation TheoriesSidi Yéhia SounfountéraОценок пока нет

- Bednar - Pressure Vessel Design HandbookДокумент230 страницBednar - Pressure Vessel Design Handbookkarthiksoft50100% (17)

- Thermodynamic ReportДокумент4 страницыThermodynamic ReportAbbas RoziminОценок пока нет

- Sizing of Servo ValveДокумент19 страницSizing of Servo Valveragdapattice100% (3)

- Quantum Brochure - 2018-03-06Документ4 страницыQuantum Brochure - 2018-03-06dchyОценок пока нет

- Chapter 1 (2017) DR KhamidunДокумент9 страницChapter 1 (2017) DR Khamidunamar aimanОценок пока нет

- Applied Pipeline HydraulicsДокумент59 страницApplied Pipeline HydraulicsOlusayoОценок пока нет

- WS1.1 ASTMConvertДокумент9 страницWS1.1 ASTMConvert李天Оценок пока нет

- Thermodynamics Lab 4 Thermal Conductivity and Heat TransferДокумент10 страницThermodynamics Lab 4 Thermal Conductivity and Heat TransferAkagbulem RuthОценок пока нет

- Ptorr: Outgassing of Vacuum materials-IIДокумент15 страницPtorr: Outgassing of Vacuum materials-IIratneshtОценок пока нет

- FMM - Unit I QBДокумент43 страницыFMM - Unit I QBThiruvasagamoorthy KaОценок пока нет

- Anchored Sheet-Pile WallsДокумент68 страницAnchored Sheet-Pile WallsJose MartinezОценок пока нет

- Bernoulli & HydrostaticДокумент25 страницBernoulli & HydrostaticAB20 219 RUTHIRAN ARUMUGAMОценок пока нет

- Wse Ibps CV DD 2Документ146 страницWse Ibps CV DD 2Lagnajit DasОценок пока нет

- Chapter R10Документ67 страницChapter R10Kevin TranОценок пока нет

- Sheet 2 - HydraulicДокумент4 страницыSheet 2 - HydraulicbassemОценок пока нет

- Recommended Testing Procedures For HDPE PipeДокумент1 страницаRecommended Testing Procedures For HDPE Pipeosto72Оценок пока нет

- Garlock Mastercatalog 0509Документ314 страницGarlock Mastercatalog 0509Adam Gordon100% (1)

- Self-Assessment Exercise 1Документ3 страницыSelf-Assessment Exercise 1Deniz YiğitОценок пока нет

- Introduction To Chemical Processes Murphy Chapter06 SolutionsДокумент94 страницыIntroduction To Chemical Processes Murphy Chapter06 SolutionsEric Barnett29% (7)

- 12 DM Ship WaveДокумент27 страниц12 DM Ship Waveharold1aguirre-1Оценок пока нет

- Vibration and Air-Overpressure Handout - October 2013Документ21 страницаVibration and Air-Overpressure Handout - October 2013Ashish DasОценок пока нет

- Transpiration Mechanism of Capillary Transport in The Xylem of PlantsДокумент6 страницTranspiration Mechanism of Capillary Transport in The Xylem of PlantsIrfanОценок пока нет

- Pump ManualДокумент42 страницыPump Manualnelforu100% (2)

- Transport Mechanics: A. Reynolds Number C. Mach NumberДокумент22 страницыTransport Mechanics: A. Reynolds Number C. Mach Numberjerome deiparineОценок пока нет

- Chimney Height CalculationsДокумент2 страницыChimney Height CalculationsashwaniОценок пока нет

- HYDRODYNAMICSДокумент28 страницHYDRODYNAMICSSysy monmonОценок пока нет

- Leaflet S23 2020 - Cavagna Pressure RegulatorДокумент4 страницыLeaflet S23 2020 - Cavagna Pressure RegulatorWND PRTMОценок пока нет

- 02-FusionCol8000-C210H-MEX 5Документ2 страницы02-FusionCol8000-C210H-MEX 5samiramixОценок пока нет

- Flow Between Parallel PlatesДокумент13 страницFlow Between Parallel Platesbala89krishnanОценок пока нет