Академический Документы

Профессиональный Документы

Культура Документы

Elastimold Viejo

Загружено:

Victor VignolaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Elastimold Viejo

Загружено:

Victor VignolaАвторское право:

Доступные форматы

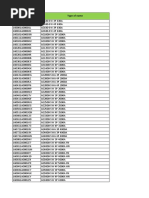

To view Product Specification Page(s), choose a product by clicking directly on the product number in the table

on the Product Number Page. To view Instruction Sheet, click on the Instruction Sheet button in the upper

right-hand corner. To view Crimp Chart click on the Crimp Chart button.

CD-ROM CATALOG V10-99A

Links To Catalog 2001

ELASTIMOLD

5kV-35kV Distribution Products

I SEPARABLE CONNECTORS

I CABLE JOINTS

I TERMINATIONS

I SURGE ARRESTERS

I FUSES

I LOADBREAK SWITCHES

Overview

Page

Product

Number Page

Product

Specification Page

Product

Instruction Sheet

This is the Home Page (page 1). Use this as the starting point

to access product information. You may also search by product number

using the viewer. If you need help, scroll down for diagram and additional instructions.

Scroll list and select pages

by clicking O or P

Introductory Product Information ..........

Component Application & Selection Help ..

Certified Tests & Performance ............

Separable Connector Interfaces .............

200 Amp Loadbreak Connectors ...........

200 Amp Deadbreak Connectors ...........

600 Series Deadbreak Connectors .........

600 Series Deadbreak Connectors

Cam-Op, Link-Op .........................

600 Series Deadbreak Connectors

Stick-Op, Window-Op ....................

600 Series Deadbreak Cable Joints .......

PCJ Cable Joints ...........................

Cable Terminations ...........................

Surge Arresters................................

Shield Adapters, Grounding Kits

& Jacket Seals.................................

How to specify size-sensitive products .....

WX Size Tables.................................

AEIC Cable Insulation Diameter Reference..

Cable Conductor Diameter Reference .......

Equipment Bushings ..........................

Loadbreak Switches, Molded Current

Limiting Fuses, Molded Power Fuses

& Transmission Class products .............

O for Overview Page

P for Product Number Page

166LR-WX

Use Tables W1

274LR-WX

Use Tables W1

NUMBER

O O

O O

O O

O O

O O

O O

O O

O O

O O

P P

P P

P P

O O

O O

O O

O O

O O

O O

O O

O O

P P

P P

P P

O O

O O

O O

P P

P P

P P

P P

ELASTIMOLD C ATA LO G 2001 Page 2 ID : 0198 ELASTIMOLD

CERTIFIED TESTS AND PERFORMANCE

TABLE 1 15kV Class Ratings 25kV Class Ratings 35kV Class Ratings

OPERATING VOLTAGE 8.3kV 15.2kV 21.1kV

M axim um line-to-ground

(See A pplication Info N ote 1)

BIL Im pulse w ithstand 1.2 x 50 m icrosecond w ave 95kV 125kV 150kV

WITHSTAND VOLTAGE

AC O ne M inute 34kV 40kV 50kV

D C Fifteen M inute 53kV 78kV 103kV

CORONA EXTINCTION LEVEL @ 3pC Sensitivity 11kV 19kV 26kV

200 AMP Products

C ontinuous C urrent: 200 A M P*

Sym m etrical M om entary C urrent: 10kA sym , 10 cycle duration

600 Series Products

C ontinuous C urrent: 600 and 900 A M P*

Sym m etrical M om entary C urrent: 25kA sym , 10 cycle duration

* D esigned for 90 C m axim um continuous operating tem perature

Elastim old Separable C onnectors, C able Joints, C able

Term inators, Surge A rresters, Fused Elbow s and other cable

accessory products have been designed and tested per

applicable portions of IEEE, A N SI, N EM A and other industry

standards including:

IEEE 386 Standard For Separable C onnectors

IEEE 404 Standard For C able Joints and Splices

IEEE 48 Standard For C able Term inations

IEEE C 62.11 Standard For M etal O xide Surge A rresters

A N SI C 37.41 Standard For C urrent Lim iting Fuses

IEEE 592 Standard For Exposed Sem iconducting Shields

A N SI C 119.4 Standard For C opper and A lum inum

C onductor C onnectors

A EIC C S5 and C S6 Standards For XLP and EPR

Insulated C ables

Application Information:

1. Loadbreak connectors are designed and rated for use on grounded W YE system s. For application on ungrounded W YE or delta system s, the next

higher voltage class product is recom m ended. Exam ples: 5kV ungrounded: use 15kV class products; 15kV ungrounded: use 25kV class products;

25kV ungrounded: use 35kV class products; 35kV ungrounded: contact factory.

2. Products are designed and constructed for all applications including padm ount, subsurface, vault, indoor, outdoor, direct sunlight, direct buried and

continuously subm erged in w ater.

3. Products are designed and rated for am bient tem peratures of -40 C to + 65 C . It is recom m ended that loadbreak connectors be hotstick operated at

-20 C to + 65 C am bient tem perature range and at altitudes not exceeding 6000 feet.

CABLE J OINTS, TERMINATIONS AND ARRESTER RATINGS

R efer to the pages listed below for rating inform ation:

PC J C able Joints, page 20. Surge A rresters, page 26.

C able Term inations, page 22

SEPARABLE CONNECTOR RATINGS

Table 1 show s voltage and current ratings w hich apply to all Separable C onnectors including 200 A M P Loadbreak, 200 A M P

D eadbreak and 600 Series D eadbreak products. Table 2 show s sw itching and fault close ratings w hich only apply to 200 A M P

Loadbreak C onnectors.

TABLE 2 LOADMAKE/LOADBREAK SWITCHING FAULT CLOSE

1 and 3 circuits 8.3kV line to ground, 14.4kV

m ax. across open contacts.

10 loadm ake/break operations at 200 A m ps m ax.

w ith 70 to 80% lagging pow er factor.

1 and 3 circuits 15.2kV line to ground, 26.3kV

m ax. across open contacts.

10 loadm ake/break operations at 200 A m ps m ax.

w ith 70 to 80% lagging pow er factor.

1 and 3 circuits 21.1kV line to ground, 36.6kV

m ax. across open contacts.

10 loadm ake/break operations at 200 A m ps m ax.

w ith 70 to 80% lagging pow er factor.

1 fault close operation at 8.3kV or 14.4kV; 10,000

A m ps, rm s, sym . 10 cycles (0.17 sec.) 1.3 m ax. asym

factor applies to new or used m ating parts (up to

m axim um designated sw itching operations.)

1 fault close operation at 15.2kV or 26.3kV; 10,000

A m ps, rm s, sym . 10 cycles (0.17 sec.) 1.3 m ax. asym

factor applies to new or used m ating parts (up to

m axim um designated sw itching operations.)

1 fault close operation at 21.1kV or 36.6kV; 10,000

A m ps, rm s, sym . 10 cycles (0.17 sec.) 1.3 m ax. asym

factor applies to new or used m ating parts (up to

m axim um designated sw itching operations.)

15kV

Class Ratings

25kV

Class Ratings

35kV

Class Ratings

SEPARABLE CONNECTOR INTERFACES

Bushing Interface Voltage Interface Standard No

Class Description Figure No.

200 A M P D EEPW ELL 15kV, 25kV 200 A M P B ushing IEEE

EQ U IPM EN T B U SH IN G and 35kV W ell Interface 386-1995

8.3kV, 15.2kV, Fig. 3

21.1kV

200 A M P LO A D B R EA K IN SERT 15kV 200 A M P Loadbreak IEEE

8.3kV and 386-1995

8.3kV/14.4kV Fig. 5

200 A M P LO A D B R EA K IN SERT 25kV 200 A M P Loadbreak IEEE

15.2kV and 386-1995

15.2kV/26.3kV Fig. 7, N ote 3

200 A M P LO A D B R EA K IN SERT 35kV 200 A M P Loadbreak IEEE

Interface N o. 2 386-1995

21.1kV and Fig. 7, N ote 3

21.1kV/36.6kV

200 A M P D EA D B R EA K IN SERT 15kV and 25kV 200 A M P D eadbreak IEEE

8.3kV and 15.2kV 386-1985

Fig. 4

600 SER IES EQ U IPM EN T B U SH IN G 15kV and 25kV 600 A M P D eadbreak IEEE

Interface N o.1 386-1995

8.3kV and 15.2kV Fig.11, N ote 1

600 SER IES EQ U IPM EN T B U SH IN G 35kV 600 A M P D eadbreak IEEE

Interface N o.1 386-1995

21.1kV Fig.13, N ote 2

A

B

C

D

E

F

G

A N SI/IEEE Standard 386 defines the specific interface

dim ensions that 200 A m p and 600 Series elbow s, inserts,

junctions, equipm ent bushings and any m ating com po-

nents m ust conform to insure interchangeability. The table

below provides inform ation concerning the types of inter-

faces supplied by Elastim old for various applications and

is useful to assure proper m atching of com ponents.

C ATA LO G 2001 Page 3 ID : 0198

N O TES:

1. W as Fig. 10 in previous IEEE 386-1985 publication.

2. W as Fig. 11 in previous IEEE 386-1985 publication.

3. Elastim old uses Fig. 7 interface for both 25 and 35kV applications.

STANDARD INTERFACES FOR SEPARABLE CONNECTORS,

COMPONENTS AND EQUIPMENT BUSHINGS

A

B

C

D

E

F

G

SEPARABLE CONNECTORS

200 AMP LOADBREAK

ELASTIMOLD

200 A m p loadbreak connectors and

accessories provide a convenient

m ethod to connect/disconnect cable

and equipm ent on pow er distribution

system s. Loadbreak elbow s include pro-

visions for energized operation using

standard hotstick tools, allow ing load-

m ake/break operation and a visible dis-

connect. C om ponents can be isolated

w ith insulated caps, plugs and parking

bushings.

O ptional accessories allow system

grounding, testing, bypass, lightning

surge protection and current lim iting fus-

ing. Additional connecting points and

taps can be provided by use of junctions

or feed-thrus.

RATINGS OVERVIEW

See page 2 for com plete inform ation

including sw itching and fault close

ratings.

CURRENT RATINGS

200A C ontinuous

10kA sym . 10 C ycles

VOLTAGE RATINGS

15kV Class

8.3kV Phase-to-G round

14.4kV Phase-to-Phase

95kV B IL

34kV AC W ithstand

53kV D C W ithstand

11kV C orona Extinction

25kV Class

15.2kV Phase-to-G round

26.3kV Phase-to Phase

125kV B IL

40kV AC W ithstand

78kV D C W ithstand

19kV C orona Extinction

35kV Class

21.1kV Phase-to-G round

36.6kV Phase-to-Phase

150kV B IL

50kV AC W ithstand

103kV D C W ithstand

26kV C orona Extinction

BUSHING WELL

PLUG

FUSED ELBOW

LOADBREAK

FEED-THRU INSERT

FEED THRU

CABLE TO EQUIPMENT

CONNECTIONS

PARKING

STAND

SEE CABLE NOTES

INSULATED CAP

WITH GROUND

ELBOW

GROUNDING

OPERATING ACCESSORIES

REPLACEMENT

ELBOW

INSULATED PARKING

BUSHING

LOADBREAK ELBOWCONNECTOR

WITH OR WITHOUT TEST POINT

BUSHING

WELL

ASSEMBLY TOOL

SEE CABLE NOTES

INSULATED CAP

SEE PAGE 6

BOLTED

ELBOW

W/TAP

GROUNDING

PLUG

REPAIR

ELBOW

SEE CABLE NOTES

LOADBREAK

BUSHING INSERT

TEST ROD

SURGE ARRESTER

APPLICATIONS

SEE PAGE 26 FOR

EXTENDED

BUSHING INSERT

C ATA LO G 2001 Page 4 ID : 0198

200 AMP LOADBREAK SEPARABLE CONNECTOR COMPONENTS

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

N 1. C opper lug for use on C O PPER C O N D U C TO R O N LY.

N 2. Incudes 02500X long bi-m etal com pression lug as standard.

N 3. A lso available as housing only. Specify: 165B LR -W ; 273B LR -W ;

375B LR -W ; 166B LR -W ; 274B LR -W ; 376B LR -W .

N 4. A lso available as elbow /insert com bination. Specify: 165A 4-W X;

273A 4-W X; 166A 4-W X; 274A 4-W X; 274A 4-W X.

N 5. A lso available w ith jacket seal included. Add - Ssuffix to part num ber.

See 200EC S page 28.

N 6. R ated for single-phase applications only.

N 7. Equipped w ith insulated cuff.

N 8. Includes internal torquing feature using 200AT Assem bly Tool.

N 9. R ated for 15kV thru 35kV applications.

N 10. R epair elbow has extended length (3-1/4) contact and elbow housing.

N 11. R eplacem ent elbow has extended length (9-7/8) contact and elbow

housing.

N 12.R ated for 25kV thru 35kV applications.

N 13.Includes long bi-m etal contact 00400X.

N 14.160C A C able Size Adapter can only be used w ith elbow part

num bers 165LR /166LR C size only.

N 15.See page 6 for W X size tables and for fuse sizes.

N 16.Fully rotatable for 360 positioning. Includes bail assem bly to secure

feed-thru insert to bushing w ell.

N 17.Incudes 02800X long bi-m etal contact.

N 18.Incudes 02509X long bi-m etal contact.

C ATA LO G 2001 Page 5 ID :0198

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

Elbow 15kV 165LR-WX N 2,3,4,5

C onnector

UseTables W1andX1

25kV 273LR-WX N 2,3,4,5

UseTables W2andX1

35kV 375LR-WX N 2,3, 5

UseTables W3andX2

Elbow 15kV 166LR-WX N 2,3,4,5

C onnector Use Tables W1 and X1

w / Test Point 25kV 274LR-WX N 2,3,4,5

Use Tables W2 and X1

35kV 376LR-WX N 2,3, 5

Use Tables W3 and X2

R epair Elbow 15kV 167ELR-WX N 5,10,18

C onnector Use Tables W5 and X1

25kV 273ELR-WX N 5,10,18

Use Tables W5 and X1

R epair Elbow 15kV 168ELR-WX N 5,10,18

C onnector Use Tables W5 and X1

w / Test Point 25kV 274ELR-WX N 5,10,18

Use Tables W5 and X1

R eplacem ent 15kV 167RLR-WX N 5,11,13

Elbow Use Tables W4 and X1

25kV 273RLR-WX N 5,11,13

Use Tables W2 and X1

R eplacem ent 15kV 168RLR-WX N 5,11,13

Elbow Use Tables W4 and X1

w / Test Point 25kV 274RLR-WX N 5,11,13

Use Tables W2 and X1

Fused Elbow 15kV 166FLR-WX N 5,15

(G eneral Purpose Use Wand X Tables

C urrent Lim iting) on Page 6

B olted Elbow 15kV 167LRT-WX N 17

w / Tap Use Tables W4 and X1

B ushing Insert 15kV 1601A4 N 4,8

25kV 2701A4 N 4,8

35kV 3701A4 N 6

35kV 3701A3 N 8

Extended 15kV 1601EA4 N 8

B ushing 25kV 2701EA4 N 8

Insert

Feed-Thru 15kV 1602A3R N 16

Insert 25kV 2702A1 N 16

35kV 3702A1 N 6,16

Insulated C ap 15kV 160DR

Insulated C ap 15kV 160DRG

w / G round 15kV 167DRG N 7

25kV 273DRG N 7

35kV 375DRG N 7

Insulated C ap 15kV 168DRG N 7

w / G round and 25kV 274DRG N 7

Test Point 35kV 376DRG N 7

G rounding 15kV 161GP

Plug 25kV 272GP

(1/0 AW G x 6'

G round Lead)

G rounding 15kV 160GLR

Elbow 25/35kV 370GLR N 12

(1/0 AW G x 6'

G round Lead)

Feed-Thru 15kV 164FT

25kV 274FT

35kV 373FT

Feed-Thru 15kV 164FTV

Vertical 25kV 274FTV

35kV 373FTV

200 AMP LOADBREAK

Feed-Thru 15/25kV K1601WFT

W ell

Feed-Thru 15/25kV K1601WFTV

W ell Vertical

Insulated 15kV 161SOP

Parking B ushing 25kV 272SOP

35kV 372SOP

Test R od A LL 370TR N 9

B ushing W ell 15/25kV 276BWP

Plug 35kV M276BWP

Assem bly Tool A LL 200AT N 8,9

Contacts: Use Table X1

Long B i-M etal A LL 02500X N 9

ELR B i-M etal 15/25kV 02509X N 10

C opper A LL 02702X N 1,9

LRT C ontact 15kV 02800X

R LR C ontact 15/25kV 00400X N 11

Elbow Probe 15kV 166LRF

25kV 274LRF

35kV 376LRF

Elbow A LL 10EP-W N 9

C able Entrance Use Table W6

Insulating Plug

C able Size 15kV 160CA-W N 14

Adapter Use Table W6

EB-FA Only

R efer to the W and X tables on pages 32 and 33 for sizing to cable

insulation diam eter and conductor size.

For cable shield adapters and jacket seals, see page 28.

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

J UNCTIONS CONTINUED

ON PAGE 6.

Part numbers that contain

the letters Wor Xare size

sensitive. To complete the

part number, refer to the

Wor Xtables indicated.

ELASTIMOLD

SEPARABLE CONNECTORS

200 AMP LOADBREAK Contd from Pg. 5

C ATA LO G 2001 Page 6 ID : 0198

RATINGS OVERVIEW

See page 2 for com plete inform ation

including sw itching and fault close

ratings.

CURRENT RATINGS

200A C ontinuous

10kA sym . 10 C ycles

VOLTAGE RATINGS

15kV Class

8.3kV Phase-to-G round

14.4kV Phase-to-Phase

95kV B IL

34kV AC W ithstand

53kV D C W ithstand

11kV C orona Extinction

25kV Class

15.2kV Phase-to-G round

26.3kV Phase-to Phase

125kV B IL

40kV AC W ithstand

78kV D C W ithstand

19kV C orona Extinction

35kV Class

21.1kV Phase-to-G round

36.6kV Phase-to-Phase

150kV B IL

50kV AC W ithstand

103kV D C W ithstand

26kV C orona Extinction

CABLE TO CABLE

CONNECTIONS

3-POINT

JUNCTION

4-POINT

JUNCTION

2-POINT

JUNCTION

LOADBREAK

BUSHING INSERT

LOADBREAK

BUSHING INSERT

LOADBREAK

BUSHING INSERT

4 POINT WELL

JUNCTION

3 POINT WELL

JUNCTION

2 POINT WELL

JUNCTION

SURGE ARRESTER

APPLICATIONS

SEE PAGE 26 FOR

200 AMP LOADBREAK SEPARABLE CONNECTOR COMPONENTS

FUSED ELBOWORDERING INSTRUCTIONS

Step 1 (W)

D eterm ine the insulation diam eter of the cable. Select the insulation letter

code that best straddles the insulation diam eter. Insert code into catalog

num ber.

Step 2 (X)

C hoose the proper connector code according to the conductor size.

Insert code into the catalog num ber after the insulation code.

Step 1 (W) Step 2 (X)

166FLR

The Fused Elbow kit

contains the following:

1 - U pper elbow half

1 - Low er elbow half

1 - U pper connector

1 - Low er connector

1 - Probe

1 - Torque-lim iting w rench

1 - Lubricant

1 - Instruction sheet

The Fuse Kit includes

the following:

1 - C urrent lim iting fuse

1 - A llen w rench

1 - A ir vent rod

1 - Instruction sheet

To order replacement parts,

specify the following:

For an upper elbow half, specify 166B FLR -T

For a low er elbow half, specify 166B FLR -W

For an upper connector, specify 166-88

For a low er connector, specify 02600X

For a probe, specify 166LR F

ORDERING INSTRUCTIONS FOR FUSE KIT

(to be ordered separately)

D eterm ine the am pere rating required.

Insert rating into the catalog num ber below.

166PF8 -

Voltage

(kV)

8.3

Ampere

Rating

5

8

12

18

30

Conductor

Size*

(AWG)

2

1

1/0

2/0

3/0

Symbol For X

Stranded/ Solid/

Compr. Compact

0220 0210

0230 0220

0240 0230

0250 0240

0250

*C u or A I C onductor

Cable Insulation Diameter Range Symbol

Inches For W

.610 -.735 FAB

.675 - .785 FB

.725 - .835 FG

.775 - .885 GA

.825 - .935 GAB

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

C ATA LO G 2001 Page 7 ID : 0198

N 1. A lso available w ithout straps. Specify suffix -4in place of -5in the

part num ber.

N 2. Supplied w ith replaceable stud. R eplacem ent stud available separately.

Specify 1601R S.

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

2-W ay W ell 15/25kV K1601WJ 2 N 2

Junction w /

s.s. B racket

2-W ay W ell 15/25kV K1601WJ 2-5 N 1, N 2

Junction w /

U Straps

3-W ay W ell 15/25kV K1601WJ 3 N 2

Junction w /

s.s. B racket

3-W ay W ell 15/25kV K1601WJ 3-5 N 1, N 2

Junction w /

U Straps

4-W ay W ell 15/25kV K1601WJ 4 N 2

Junction w /

s.s. B racket

4-W ay W ell 15/25kV K1601WJ 4-5 N 1, N 2

Junction w /

U Straps

2-Point Junction 15kV 164J 2

w ith/stainless 25kV 274J 2

steel bracket 35kV 373J 2

2-Point Junction 15kV 164J 2-5 N 1

w /U -straps 25kV 274J 2-5 N 1

35kV 373J 2-5 N 1

3-Point Junction 15kV 164J 3

w ith/stainless 25kV 274J 3

steel bracket 35kV 373J 3

3-Point Junction 15kV 164J 3-5 N 1

w /U -straps 25kV 274J 3-5 N 1

35kV 373J 3-5 N 1

4-Point Junction 15kV 164J 4

w ith/stainless 25kV 274J 4

steel bracket 35kV 373J 4

4-Point Junction 15kV 164J 4-5 N 1

w /U -straps 25kV 274J 4-5 N 1

35kV 373J 4-5 N 1

200 AMP LOADBREAK

Part numbers that contain

the letters Wor Xare size

sensitive. To complete the

part number, refer to the

Wor Xtables indicated.

SEPARABLE CONNECTORS

200 AMP DEADBREAK

ELASTIMOLD

200 A m p deadbreak connectors and

accessories provide a quick disconnect

feature for cable and equipm ent connec-

tions on pow er distribution system s.

A ll deadbreak connectors m ust be D E-

EN ER G IZED before operating and m ust

be m echanically secured w ith bails w hen

connected. C om ponents can be isolated

w ith insulated caps, plugs and parking

bushings.

A ll deadbreak elbow s are equipped

w ith test points as standard. O ptional

accessories allow system grounding,

bypass and lightning surge protection.

Additional connecting points and taps

can be provided by use of junctions or

feed-thrus.

RATINGS OVERVIEW

See page 2 for com plete inform ation.

CURRENT RATINGS

200A C ontinuous

10kA sym . 10 C ycles

VOLTAGE RATINGS

15kV Class

8.3kV Phase-to-G round

14.4kV Phase-to-Phase

95kV B IL

34kV AC W ithstand

53kV D C W ithstand

11kV C orona Extinction

25kV Class

15.2kV Phase-to-G round

26.3kV Phase-to-G round

125kV B IL

40kV AC W ithstand

78kV D C W ithstand

19kV C orona Extinction

C ATA LO G 2001 Page 8 ID : 0198

200 AMP DEADBREAK SEPARABLE CONNECTOR COMPONENTS

ALL 200 A DEADBREAK

CONNECTIONS MUST BE

MECHANICALLY SECURED WITH

SEE PAGE 26 FOR SURGE

ARRESTERS APPLICATIONS

INTEGRAL BUSHING

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

Elbow C onnector 15/25kV 156LR-WX N 1,2

w / Test Point Use Tables W4 and X1

B ail Assem bly 15/25kV 150BA

for 156LR Elbow

B ushing Insert 15/25kV K1501A1 N 3

Feed-thru Insert 15/25kV K1502A1 N 3,4

Insulated Plug 15/25kV K150DP N 3

Insulated C ap 15/25kV K150DR N 3

Insulated Parking 15/25kV K150SOP N 3

B ushing

G rounding Plug 15/25kV 151GP N 3

Feed-Thru 15/25kV K1501FT N 3,6

2-Point Junction 15/25kV K1501J 2-U N 3,6

3-Point Junction 15/25kV K1501J 3-U N 3,6,7

4-Point Junction 15/25kV K1501J 4-U N 3,6,7

Elbow Probe 15/25kV 156LRF

Straight 15/25kV K151SR-WX N 3,12

R eceptacle Use Tables W6 and X5

Straight Plug 15/25kV K151SP-WX N 3,12

Use Tables W6 and X5

Tee Splice 15/25kV K150T N 3

In-Line Junction 15/25kV K150S N 3

Locking Splice 15/25kV K151LS-WX N 8,9

Use Tables W6 and X8

Locking Y 15/25kV K151LY-WX N 8,9

Splice Use Tables W6 and X8

BA IL 15/25kV 150TB1 N 5

BA IL 15/25kV 150TB2 N 5

BA IL 15/25kV 150TB3 N 5

N 1.Includes bail assem bly.

N 2.Includes 02500X long, bi-m etal com pression lug as standard.

N 3.B ails are required but not included. O rder separately. C onsult factory

for bails not listed for a specific application.

N 4.Fully rotatable for 360 positioning. Includes bail assem bly to secure

feed-thru insert to bushing w ell.

N 5.R efer to general catalog for application details.

N 6.C enter-to-center spacing equals 4 inches.

N 7.C opper lug for copper cable only.

N 8.To order cable legs for different cable sizes, list each leg size W and X.

Exam ple: K 151LY-FB 240-FB 240-FA B 220. See Tables W 6 and

X8 for sizes.

N 9.To order locking contacts for K 151LS and K 151LY, order 01401X (A l)

or 01402X (C u) for plug contact. O rder 01301X (A l) or 01302X (C u) for

receptacle. See Table X8 for sizes.

N 10.For use w ith 156LR elbow s.

N 11.For use w ith K 151SR , K 151SP, K 151LS, K 151LY receptacles, plugs and

splices.

N 12.A lso available as housing only. Specify K 151SPH -W or K 151SR H -W .

C ATA LO G 2001 Page 9 ID : 0198

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

BA IL 15/25kV 150TB4 N 5

BA IL 15/25kV 150TB5 N 5

Contacts:

Long B i-M etal 15/25kV 02500X

C opper 15/25kV 02702X N 7

Elbow 15/25kV 10EP-W N 10

C able Entrance Use Table W6

Insulating Plug

C able Entrance 15/25kV 152EA-W N 11

Insulating Plug Use Table W6

200 AMP DEADBREAK

R efer to the W and X tables on pages 32 and 33 for sizing to cable

insulation diam eter and conductor size.

For cable shield adapters and jacket seals, see page 28.

Part numbers that contain

the letters Wor Xare size

sensitive. To complete the

part number, refer to the

Wor Xtables indicated.

SEPARABLE CONNECTORS

600 SERIES DEADBREAK

ELASTIMOLD

600 Series deadbreak elbow s, straight recepta-

cles, junctions, vault stretchers and accessories

are used to connect equipm ent and cable on

prim ary feeder and netw ork circuits. D esigns

accom m odate large conductors and feature

bolted connections and deadfront m odular

construction for m axim um reliability, perfor-

m ance and versatility.

D E-EN ER G IZED connectors can be quickly

and easily connected and disconnected

using standard hand tools and equipm ent

in accordance w ith accepted operating

practices. O ptional accessories allow visible

external separation, by-pass, isolation, dead-

ending, grounding, and testing as w ell as

adding taps, surge arresters and circuit

protection.

H ot-stick operable and separable joint system s

are show n on pages 14 thru 19.

RATINGS OVERVIEW

See page 2 for com plete inform ation.

CURRENT RATINGS

(Prefixes: 650, K650, K655, K656,

750, 755, 756 & 03700)

600 A m p C ontinuous

25kA sym .,10 cycles

(Prefixes 675,K675,K676,775,

776 & 03702)

900 A m p C ontinuous

25kA sym .,10 cycles

N O TE: 900 A m p ratings require copper cable

and copper current-carrying com ponents.

VOLTAGE RATINGS

15/25kV Class (5kV thru 28kV)

16.2kV Phase-to-G round

28kV Phase-to Phase

140kV B IL

45kV AC W ithstand

84kV D C W ithstand

21.5kV C orona Extinction

35kV Class

21.1kV Phase-to-G round

36.6kV Phase-to-Phase

150kV B IL

50kV AC W ithstand

103kV D C W ithstand

26kV C orona Extinction

N ote: Elastim old has increased the IEEE Standard

Production and D esign Test levels for 25kV C lass

products to include 27kV and 28kV system s.

INTEGRAL BUSHING

RETAINING

RING

CABLE TO EQUIPMENT

COMPRESSION

LUG

CABLE

ADAPTER

CABLE TO CABLE

STRAIGHT RECEPTACLE

HOUSING

LOADBREAK

REDUCING

TAP PLUG

200A LOADBREAK

SEE PAGES 4 &5

200A DEADBREAK

SEE PAGES 8 &9

LINK-OP

LINK CONNECTOR

SPANNER WRENCH

OPERATING

ACCESSORIES

4 PT J UNCTION

3 PT J UNCTION

2 PT J UNCTION

(UTILIZING J UNCTIONS)

HOTSTICK OPERABLE 600 SERIES

CONNECTORS - SEE PAGES 14- 17

STICK-OP

LINK-OP

COMPRESSION

LUG

CABLE

ADAPTER

VAULT

STRETCHER

CONNECTOR

CABLE TO CABLE

L-1

UTILIZING L-KITS

L-2

ELBOWCONNECTOR

STICK-OP

LOADBREAK REDUCING

TAP PLUG

BOLT &

WASHERS

STRAIGHT

RECEPTACLE ADAPTER

L-3

L-4

THREADED

STUD

LINK-OP

RETAINER

SLEEVES

200A TAPS

INSULATING

PLUG

INSULATED

PARKING BUSHING

BUSHING

EXTENDER

THREADED

COMPRESSION

LUG

600 SERIES

ELBOW

CABLE

ADAPTER

COMPRESSION

LUG

CONNECTING

PLUG

STRAIGHT RECEPTACLE

REDUCING TAP

WELL

THREADED

STUD VOLTAGE

DETECTION

CAP

INSULATED CAP

WITH TEST POINT

GROUNDING

PLUG

DEADBREAK

REDUCING

TAP PLUG

600 SERIES

TAPS

CAM-OP

RETAINER

SLEEVES

CONNECTING

PLUG

VAULT

STRETCHER

BUSHING

EXTENDER

THREADED

STUD

THREADED

STUD

WINDOW-OP

SEE PGS 16 &17

CAM-OP

CABLE

ADAPTER

COMPRESSION

LUG

SEE PGS 12 &13

SEE PGS 12 &13

CAM-OP

LINK CONNECTOR

SEE PGS 14 &15

SEE PGS 14 &15

SEE PGS 16 &17

VS2

VS3

VS4

VAULT STRETCHERS

CABLE TO CABLE UTILIZING

C ATA LO G 2001 Page 10 ID : 0198

SEPARABLE CONNECTORS 600 SERIES DEADBREAK

SEE PAGE 26 FOR

SURGE ARRESTER

APPLICATIONS

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

600 Series Elbow 15/25kV K655LR-W0X N 1,2

(w / Insul. Plug, Use Tables W7 and X6

C ap, Stud, Lug & 35kV 755LR-W0X N 1,2

C able Adapter) Use Tables W9 and X6

600 Series Elbow 15/25kV K656LR-W0X N 1,2

w / Test Point Use Tables W7 and X6

(w / Insul. Plug, 35kV 756LR-W0X N 1,2

C ap, Stud, Lug & Use Tables W9 and X6

C able Adapter)

600 Series Elbow 15/25kV K655BLR N 1,3

H ousing only 35kV 755BLR N 1,3

(w / Stud)

600 Series Elbow 15/25kV K656BLR N 1,3

w / Test Point 35kV 756BLR N 1,3

(H ousing only

w / Stud)

600 Series Straight15/25kV K655SR-W0X N 1,2,12

R eceptacle Use Tables W7 and X6

(w /C able Adapter,

Lug &

R etaining R ing)

600 Series Straight15/25kV K655BSR N 1,12

R eceptacle

H ousing (Lug

& C able Adapter

not included)

Straight R eceptacle 15/25kV K650SRA N 1,4

Adapter

600 Series 15/25kV K655BVS N 1,9

Vault Stretcher

(H ousing only

w / Stud)

C able Size 15/25kV 655CA-W

Adapter Use Table W7

35kV 755CA-W

Use Table W9

C om pression A LL 03700X N 5

Lug Use Table X6

A LL 03702X N 6

Use Table X6

600 Series Elbow 15/25kV 655CK-W0X N 2

Size Sensitive K it Use Tables W7 and X6

(C able Adapter 35kV 755CK-W0X N 2

& Lug) Use Tables W9 and X6

Adapter A LL 650ARR-X

R etaining R ing Use Table X6

600 Series Straight15/25kV 655CK-W0X-ARR N 2

R eceptacle Size Use Tables W7 and X6

Sensitive K it (C able 35kV 755CK-W0X-ARR N 2

Adapter, R etaining Use Tables W9 and X6

R ing & Lug)

B ushing 15/25kV K655BE N 1,3

Extender 35kV 755BE N 1,3

(w / Stud)

Insulated C ap 15/25kV K656DR N 3,7

w / Test Point

(w / Stud)

Insulating Plug 15/25kV K650BIP N 1,7,8

(w / C ap) 35kV 750BIP N 1,7,8

G rounding Plug 15/25kV 650GP N 1,7,8

(G round Lead 35kV 750GP N 1,7,8

2/0 AW G x 30")

Insulated 15/25kV K650SOP N 7,8

Parking B ushing 35kV 750SOP N 7,8

C onnecting Plug 15/25kV K650CP N 1,7,8,9

35kV 750CP N 1,7,8,9

C ATA LO G 2001 Page 11 ID : 0198

600 SERIES DEADBREAK

N 1. For 900 A m p ratings, substitute 675 for 650 and 655; 676 for 656; K 675

for K 650 and K 655; K 676 for K 656; 775 for 750 and 755; 776 for 756

and 2X for 0X in the part num ber. The 900 A m p rating requires copper

current-carrying connector com ponents and copper conductor cable.

N 2. Add suffix sym bol from page 29 to include cable shield grounding kit

and/or cable jacket sealing kit.

N 3. Available w ithout the stud by adding N to the part num ber.

N 4. Straight R eceptacle Adapter is used to connect Straight R eceptacles

K 655YB SR and K 655YSR -W 0X (Pg.14) to equipm ent bushings.

N 5. A lum inum lug for use on alum inum or copper conductors. D O N O T

substitute threaded 03600X lug.

N 6. C opper lug for use on C O PPER C O N D U C TO R O N LY. D O N O T substitute

threaded 03602X lug.

N 7. Available w ith the stud factory-assem bled by adding SPto the part

num ber.

N 8. Available w ith a loose stud by adding suffix Sto the part num ber.

N 9. 600SW spanner w rench is recom m ended for installation of connecting

plugs, deadbreak reducing tap plugs and reducing tap w ells..

N 10. 600AT assem bly tool is required for installation of loadbreak reducing

tap plugs.

N 11. R ubber junction w ith stainless steel m ounting plate and back plate.

Add -U for rubber junction w ith stainless steel m ounting plate, back

plate and adjustable bracket.

Add -4for rubber junction only.

Add -5for rubber junction, stainless steel U -straps and back plate.

N 12. 600 Series Elbow s and Straight R eceptacles w ith IEEE Std. 386

capacitive test points are available by substituting 656 for 655; K 656 for

K 655; K 676 for K 675; 756 for 755; 676 for 675; K 676 for K 675 and 776

for 775 in the part num ber.

N 13. See page 17 for W indow -O p C onnector K it.

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

D eadbreak 15/25kV K650RTP N 1,7,8,9

R educing

Tap Plug

R educing Tap 15/25kV K650RTW N 1,7,8,9

W ell

Loadbreak 15kV 650ETP N 1,7,8,10,13

R educing 25kV K650ETP N 1,7,8,10,13

Tap Plug 35kV 750ETP N 1,7,8,10,13

Vault Stretcher 15/25kV 650VSA N 1

Threaded Stud

600 Series Elbow 15/25kV 650SA N 1

Threaded Stud 35kV 750SA N 1

Assem bly Tool A LL 600AT N 10

Spanner W rench A LL 600SW N 9

2-Point Junction 15/25kV K650J 2 N 1,11

35kV 750J 2 N 1,11

3-Point Junction 15/25kV K650J 3 N 1,11

35kV 750J 3 N 1,11

4-Point Junction 15/25kV K650J 4 N 1,11

35kV 750J 4 N 1,11

R efer to the W and X tables on pages 32 and 33 for sizing to cable

insulation diam eter and conductor size.

For cable shield adapters and jacket seals, see page 28.

Part numbers that contain

the letters Wor Xare size

sensitive. To complete the

part number, refer to the

Wor Xtables indicated.

C ATA LO G 2001 Page 12 ID : 0198 ELASTIMOLD

SEPARABLE CONNECTORS

600 SERIES DEADBREAK Contd from Pg. 11

600 Series deadbreak elbow s, straight recepta-

cles, junctions, vault stretchers and accessories

are used to connect equipm ent and cable on

prim ary feeder and netw ork circuits. D esigns

accom m odate large conductors and feature

bolted connections and deadfront m odular

construction for m axim um reliability, perfor-

m ance and versatility.

D E-EN ER G IZED connectors can be quickly

and easily connected and disconnected

using standard hand tools and equipm ent

in accordance w ith accepted operating

practices. O ptional accessories allow visible

external separation, by-pass, isolation, dead-

ending, grounding, and testing as w ell as

adding taps, surge arresters and circuit

protection.

H ot-stick operable and separable joint system s

are show n on pages 14 thru 19.

RATINGS OVERVIEW

See page 2 for com plete inform ation.

CURRENT RATINGS

(Prefixes: 650, K650, K655, K656,

750, 755, 756 & 03700)

600 A m p C ontinuous

25kA sym .,10 cycles

(Prefixes 675,K675,K676,775,

776 & 03702)

900 A m p C ontinuous

25kA sym .,10 cycles

N O TE: 900 A m p ratings require copper cable

and copper current-carrying com ponents.

VOLTAGE RATINGS

15/25kV Class (5kV thru 28kV)

16.2kV Phase-to-G round

28kV Phase-to Phase

140kV B IL

45kV AC W ithstand

84kV D C W ithstand

21.5kV C orona Extinction

35kV Class

21.1kV Phase-to-G round

36.6kV Phase-to-Phase

150kV B IL

50kV AC W ithstand

103kV D C W ithstand

26kV C orona Extinction

N ote: Elastim old has increased the IEEE Standard

Production and D esign Test levels for 25kV C lass

products to include 27kV and 28kV system s.

INTEGRAL BUSHING

RETAINING

RING

CABLE TO EQUIPMENT

COMPRESSION

LUG

CABLE

ADAPTER

CABLE TO CABLE

STRAIGHT RECEPTACLE

HOUSING

LOADBREAK

REDUCING

TAP PLUG

200A LOADBREAK

SEE PAGES 4, &5

200A DEADBREAK

SEE PAGES 8 &9

LINK-OP

LINK CONNECTOR

SPANNER WRENCH

OPERATING

ACCESSORIES

4 PT J UNCTION

3 PT J UNCTION

2 PT J UNCTION

(UTILIZING J UNCTIONS)

HOTSTICK OPERABLE 600 SERIES

CONNECTORS - SEE PAGES 14- 17

STICK-OP

LINK-OP

COMPRESSION

LUG

CABLE

ADAPTER

VAULT

STRETCHER

CONNECTOR

CABLE TO CABLE

L-1

UTILIZING L-KITS

L-2

ELBOWCONNECTOR

STICK-OP

LOADBREAK REDUCING

TAP PLUG

BOLT &

WASHERS

STRAIGHT

RECEPTACLE ADAPTER

L-3

L-4

THREADED

STUD

LINK-OP

RETAINER

SLEEVES

200A TAPS

INSULATING

PLUG

INSULATED

PARKING BUSHING

BUSHING

EXTENDER

THREADED

COMPRESSION

LUG

600 SERIES

ELBOW

CABLE

ADAPTER

COMPRESSION

LUG

CONNECTING

PLUG

STRAIGHT RECEPTACLE

REDUCING TAP

WELL

THREADED

STUD VOLTAGE

DETECTION

CAP

INSULATED CAP

WITH TEST POINT

GROUNDING

PLUG

DEADBREAK

REDUCING

TAP PLUG

600 SERIES

TAPS

CAM-OP

RETAINER

SLEEVES

CONNECTING

PLUG

VAULT

STRETCHER

BUSHING

EXTENDER

THREADED

STUD

THREADED

STUD

WINDOW-OP

SEE PGS 16 &17

CAM-OP

CABLE

ADAPTER

COMPRESSION

LUG

CAM-OP

LINK CONNECTOR

SEE PGS 14 &15

SEE PGS 14 &15

SEE PGS 16 &17

VS2

VS3

VS4

VAULT STRETCHERS

CABLE TO CABLE UTILIZING

SEPARABLE CONNECTORS 600 SERIES DEADBREAK

SEE PAGE 26 FOR

SURGE ARRESTER

APPLICATIONS

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

C ATA LO G 2001 Page 13 ID : 0198

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

1-w ay 15/25kV K655L1 N 1,2,3,4

L-K it 35kV 755L1 N 1,2,3,4

2-w ay 15/25kV K655L2 N 1,2,3,4

L-K it 35kV 755L2 N 1,2,3,4

2-w ay 15/25kV K655VS2 N 1,2,3

VS-K it

3-w ay 15/25kV K655L3 N 1,2,3,4

L-K it 35kV 755L3 N 1,2,3,4

3-W ay 15/25kV K655VS3 N 1,2,3

VS K it

4-W ay 15/25kV K655L4 N 1,2,3,4

L-K it 35kV 755L4 N 1,2,3,4

4-W ay 15/25kV K655VS4 N 1,2,3

VS-K it

Spanner W rench A LL 600SW N 2

600 SERIES DEADBREAK

N 1. For 900 A m p ratings, substitute 675 for 650 and 655; 676 for 656; K 675

for K 650 and K 655; K 676 for K 656; 775 for 750 and 755; 776 for 756 and

2X for 0X in the part num ber. The 900 A m p rating requires copper current-

carrying connector com ponents and copper conductor cable.

N 2. 600SW spanner w rench is recom m ended for installation of connecting

plugs, deadbreak reducing tap plugs and reducing tap w ells.

N 3. L-K its and VS-K its do not include cable adapters, com pression lugs or

adapter retaining rings. These item s m ust be ordered separately.

N 4. 600 Series Elbow s and Straight R eceptacles w ith IEEE Std. 386 capacitive

test points are available by substituting 656 for 655; K 656 for K 655; K 676

for K 675; 756 for 755; 676 for 675; K 676 for K 675 and 776 for 775 in the

part num ber.

R efer to the W and X tables on pages 32 and 33 for sizing to cable

insulation diam eter and conductor size.

For cable shield adapters and jacket seals, see page 28.

VAULT STRETCHER

Provides an alternate m ethod of splicing and joining

various types and styles of cables using standard

600 Series com ponents.

Part numbers that contain

the letters Wor Xare size

sensitive. To complete the

part number, refer to the

Wor Xtables indicated.

SEPARABLE CONNECTORS CAM-OP, LINK-OP

600 SERIES DEADBREAK

C ATA LO G 2001 Page 14 ID : 0198 ELASTIMOLD

Elastim olds 600 Series C am -O p

~, and

Link-O p~ deadbreak connector system s

incorporate provisions for hotstick opera-

tion of D E-EN ER G IZED prim ary feeder

or netw ork circuits. C onfigurations allow

external visible break, testing, grounding

and isolation. R etrofit kits allow upgrad-

ing existing equipm ent.

C am -O p system s utilize pin and socket

connectors. Link-O p connectors are

bolted and installed using torque con-

trolled tools. Either system can be retro-

fitted to existing equipm ent.

The C am -O p and Link-O p connectors

are unique, allow ing all hotstick opera-

tions to be com pleted w ithout m oving

the cable, an im portant consideration

w hen large, stiff cables prohibit m ove-

m ent.

The C am -O p connector is easily in-

stalled or rem oved by hotstick operation

of the cam action disconnect lever.

LOADBREAK

ELBOWCONNECTOR

INSULATED

CAP ELBOW

ARRESTER

LINK

CONNECTOR

LINK-OP

LINK-OP

CAM-OP

CAM-OP

RETAINER

SLEEVES

OR

2-POINT INSULATED

BUSHINGS

OR

OR OR

OR

OR

OR

600 SERIES

ELBOW

600 SERIES

ELBOW

COMPRESSION

LUG

COMPRESSION

LUG

SEE

CABLE

NOTES

SEE

CABLE

NOTES

CABLE

ADAPTER

600 SERIES

ELBOW

COMPRESSION

LUG

SEE CABLE NOTES

CABLE

ADAPTER

CABLE

ADAPTER

LOADBREAK

ELBOWCONNECTOR

INSULATED

CAP

ELBOW

ARRESTER

LINK CONNECTOR

BUSING

EXTENDER

ALIGNMENT

BRACKET

ALIGNMENT

BRACKET

LINK-OP

CAM-OP

LINK-OP

LINK-OP

CAM-OP

CAM-OP

RETAINER

SLEEVES

INSULATED

PARKING

BUSHING

EQUIPMENT

BUSHING

EQUIPMENT

BUSHING

MOUNTABLE INSULATED

PARKING BUSHING

OR

LINK-OP

CAM-OP

LOADBREEAK

REDUCING TAP PLUG

OPERATING TOOL

TEST ROD

GROUNDING

ELBOW

RETROFIT COMPONENTS FOR

EXISTING EQUIPMENT W/O

PROVISIONS FOR MOUNTABLE

INSULATED BUSHING

CABLE TO EQUIPMENT

CABLE TO CABLE CONNECTION

CAM-OP & LINK-OP SYSTEM 600 SERIES DEADBREAK

RATINGS OVERVIEW

See page 2 for com plete inform ation.

CURRENT RATINGS

600 & 900 A m p C ontinuous

25kA sym .,10 cycles

N O TE: 900 A m p ratings require copper cable

and copper current-carrying com ponents.

CONTINUOUS

VOLTAGE RATINGS

15kV Class

8.3kV Phase-to-G round

14.4kV Phase-to Phase

95kV B IL

34kV AC W ithstand

53kV D C W ithstand

11kV C orona Extinction

25kV Class

15.2kV Phase-to-G round

26.3kV Phase-to Phase

125kV B IL

40kV AC W ithstand

78kV D C W ithstand

19kV C orona Extinction

35kV Class

21.1kV Phase-to-G round

36.6kV Phase-to-Phase

150kV B IL

50kV AC W ithstand

103kV D C W ithstand

26kV C orona Extinction

SEE PAGE 26 FOR

SURGE ARRESTER

APPLICATIONS

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

C ATA LO G 2001 Page 15 ID : 0198

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

C A M -O P 15kV 655LINK-C-LR-W0X-B-DRG N 1,3,11,

C O N N EC TO R Use Tables W7 and X6 13,14,18

K IT 25kV K655LINK-C-LR-W0X-B-DRG N 1,3,11,

Use Tables W7 and X6 13,14,18

35kV 755LINK-C-LR-W0X-B-DRG N 1,3,11,

Use Tables W9 and X6 13,14,18

LIN K-O P 15kV 655LINK-B-LR-W0X-B-DRG N 2,3,11,12

C O N N EC TO R Use Tables W7 and X6 13,14,18

K IT 25kV K655LINK-B-LR-W0X-B-DRG N 2,3,11,

Use Tables W7 and X6 13,14,18

35kV 755LINK-B-LR-W0X-B-DRG N 2,3,11,

Use Tables W9 and X6 13,14,18

M ountable 25kV K650LBM-3 N 3

Insulated 35kV 750LBM-3 N 3

B ushing

R ETR O FIT 15kV 655LINK-C-LR-W0X-A-DRG N 5,11,13

C A M -O P Use Tables W7 and X6 14,18

C O N N EC TO R 25kV K655LINK-C-LR-W0X-A-DRG N 5,11,13

K IT Use Tables W7 and X6 14,18

35kV 755LINK-C-LR-W0X-A-DRG N 5,11,13

Use Tables W9 and X6 14,18

R ETR O FIT 15kV 655LINK-B-LR-W0X-A-DRG N 6,11,12,

LIN K-O P Use Tables W7 and X6 13,14,18

C O N N EC TO R 25kV K655LINK-B-LR-W0X-A-DRG N 6,11,12,

K IT Use Tables W7 and X6 13,14,18

35kV 755LINK-B-LR-W0X-A-DRG N 6,11,12,

Use Tables W9 and X6 13,14,18

Insulating 25kV K650LB N 4

Plug 35kV 750LB N 4

C A M -O P 15kV 650CAB

A lignm ent 25kV K650CAB

B racket 35kV 750CAB

LIN K -O P A LL 650AB N 15

A lignm ent A LL 650ABV N 15

B racket(R etrofit

LIN K-O P O nly)

C om pression A LL 03700X N 7

Lug Use Table X6 N 8

A LL 03702X

Use Table X6

C A M -O P & 15/25kV 655CK-W0X N 13

LIN K-O P Size Use Tables W7 and X6

Sensitive K it 35kV 755CK-W0X N 13

(C able Adapter Use Tables W9 and X6

& Lug)

C A M -O P R e- A LL 650RSC N 11

taining Sleeve

LIN K-O P A LL 650RS N 11

R etaining

Sleeve

C A M -O P 15kV 655BI-LINK-C-LR-WOX-DRG N 9,11,13

C A B LE JO IN T Use Tables W7 and X6 14,18

K IT 25kV K655BI-LINK-C-LR-WOX-DRG N 9,11,13

Use Tables W7 and X6 14,18

35kV 755BI-LINK-C-LR-WOX-DRG N 9,11,13

Use Tables W9 and X6 14,18

LIN K-O P 15kV 655BI-LINK-B-LR-WOX-DRG N 10,11,12,

C A B LE JO IN T Use Tables W7 and X6 13,14,18

K IT 25kV K655BI-LINK-B-LR-WOX-DRG N 10,11,12,

Use Tables W7 and X6 13,14,18

35kV 755BI-LINK-B-LR-WOX-DRG N 10,11,12,

Use Tables W9 and X6 13,14,18

C A M -O P 15kV 650LK-C-VB

Loadbreak 25kV K650LK-C-VB

R educing 35kV 750LK-C-VB

Tap Plugs

(Visi-B reak)

LIN K-O P 15kV 650LT-B N 11

Loadbreak 25kV K650LT-B

R educing 35kV 750LT-B

Tap Plug

CAM-OP& LINK-OP

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

G rounding 15kV 160GLR

Elbow 25kV 370GLR N 19

(1/0 AW G x 6' 35kV 370GLR N 19

G round Lead)

Test R od A LL 370TR

Assem bly Tool A LL 600AT N 11

C A M -O P 15kV 650CAM-OK N 16

O PER ATIN G 25kV K650CAM-OK N 16

K IT 35kV 750CAM-OK N 16

LIN K-O P 15kV 650LINK-OK N 17

O PER ATIN G 25kV K650LINK-OK N 17

K IT 35kV 750LINK-OK N 17

AB ABV

N 1. C am -O p connector kit includes: 1- C am -O p link; 1- elbow housing; 1-

cable adapter; 1-0370 style lug; 1- bushing extender; 2- retainer sleeves;

1- insulated cap; 1- m ountable insulated bushing and 1- alignm ent

bracket.

N 2. Link-O p connector kit includes: 1- Link-O p link; 1- elbow housing; 1-

cable adapter; 1-0370 style lug; 1- bushing extender; 2- retainer sleeves;

2- insulated caps; and 1- m ountable insulated bushing.

N 3. M ountable insulated bushing included w ith C am -O p and Link-O p connec-

tor kit. R equires 3 threaded studs on equipm ent faceplate for installation.

N 4. U se w ith the R etrofit C am -O p and R etrofit Link-O p connector kit.

N 5. R etrofit C am -O p connector kit includes: 1- link; 1- elbow housing; 1-

cable adapter; 1-0370 style lug; 1- bushing extender; 2- retainer sleeves;

1- insulated cap; 1- insulating plug; and 1- alignm ent bracket.

N 6. R etrofit Link-O p connector kit includes: 1- link; 1- elbow housing; 1-

cable adapter; 1-0370 style lug; 1- bushing extender; 2- retainer sleeves;

2- insulated caps; 1- insulating plug; and 1- alignm ent bracket.

N 7. A lum inum lug for use on alum inum or copper conductors. D O N O T sub-

stitute threaded 03600X lug.

N 8. C opper lug for use on C O PPER C O N D U C TO R O N LY. D O N O T substi-

tute 03602X threaded lug.

N 9. C am -O p C able Joint K it includes: 1- C am -O p link; 1- C am -O p B I-SO P; 2-

elbow housings; 2- cable adapters; 2- 0370 style lugs; 2- retainer

sleeves; 1- insulated cap.

N 10. Link-O p C able Joint K it includes: 1- Link-O p link; 1- Link-O p B I-SO P; 2-

elbow housings; 2- cable adapters; 2- 0370 style lugs; 2- retainer

sleeves; 2- insulated caps.

N 11. 600AT assem bly tool required for operation and/or installation.

N 12.For 900 A m p ratings, substitute 675 for 650 and 655; 676 for 656; K 675

for K 650 and K 655; K 676 for K 656; 775 for 750 and 755; 776 for 756

and 2X for 0X in the part num ber. The 900 A m p rating requires copper

current-carrying connector com ponents and copper conductor cable.

N 13.Add suffix sym bol from page 29 to include cable shield grounding kit

and/or cable jacket sealing kit.

N 14.To add elbow s or arresters instead of insulating caps, replace the D R G

w ith LR -W Xfor elbow s (w ith test point) or ESAfor elbow arresters.

N 15.The 650A BV is required w hen the bushing horizontal spacing on the

equipm ent or junctions is less than 5".

N 16.C am -O p operating kit includes accessories that enable visible break,

testing, isolation and grounding functions to be perform ed. K it includes:

3- C am -O p loadbreak reducing tap plugs; 3- grounding elbow s; 1- as-

sem bly tool; 1- test rod; 1- carry case; 1- lubricant; 1- instructions.

N 17.Link-O p operating kit includes accessories that enable visible break,

testing, isolation and grounding functions to be perform ed. K it includes:

6- Link-O p loadbreak reducing tap plugs; 3- grounding elbow s; 1- as-

sem bly tool; 1- test rod; 1- carry case; 1- lubricant; 1- instructions.

N 18.600 Series Elbow s and Straight R eceptacles w ith IEEE Std. 386 capaci-

tive test points are available by substituting 656 for 655; K 656 for K 655;

K 676 for K 675; 756 for 755; 676 for 675; K 676 for K 675 and 776 for 775

in the part num ber.

N 19.R ated for both 25kV and 35kV applications.

R efer to the W and X tables on pages 32 and 33 for sizing to cable

insulation diam eter and conductor size.

For cable shield adapters and jacket seals, see page 28.

Part numbers that contain

the letters Wor Xare size

sensitive. To complete the

part number, refer to the

Wor Xtables indicated.

ELASTIMOLD

SEPARABLE CONNECTORS STICK-OP, WINDOW-OP

600 SERIES DEADBREAK

C ATA LO G 2001 Page 16 ID : 0198

Elastim olds 600 Series W indow -O p~

and Stick-O p~ deadbreak connector

system s incorporate provisions for

hotstick operation of D E-EN ER G IZED

prim ary feeder or netw ork circuits.

The W indow -O p and Stick-O p connec-

tors allow direct testing and grounding

w ith no required cable m ovem ent.

W indow -O p is ideal for equipm ent

applications w hich include view ing

w indow s to provide an internal visible

break that does not require hot stick

rem oval of the elbow s.

Stick-O p provides an external visible

break by hot stick rem oval of the elbow.

W indow -O p and Stick-O p connectors

are bolted and installed using torque

controlled tools.

600 SERIES

ELBOW

CABLE ADAPTER

TEST ROD

OPERATING ACCESSORIES

INTEGRAL

BUSHING

ASSEMBLY TOOL

(STICK-OP)

ASSEMBLY TOOL

(WINDOW-OP)

GROUNDING

ELBOW

STAND-OFF

PLUG

SEE CABLE NOTES

LOADBREAK

REDUCING

TAP PLUG

STICK-OP

600DB/ 200LB

BUSHING/ELBOW

ADAPTER

THREADED

COMPRESSION LUG

STICK-OP

GROUNDING

PLUG

INSULATED CAP

STICK-OP

WINDOW-OP

COMPRESSION LUG

WINDOW-OP

OR

STICK-OP & WINDOW-OP SYSTEM 600 SERIES DEADBREAK

BOLTED CONNECTION

LOADBREAK REDUCING

TAP PLUG

INSULATED

CAP

STICK-OPERABLE

RATINGS OVERVIEW

See page 2 for com plete inform ation.

CURRENT RATINGS

600 & 900 A m p C ontinuous

25kA sym .,10 cycles

N O TE: 900 A m p ratings require copper cable

and copper current-carrying com ponents.

CONTINUOUS

VOLTAGE RATINGS

15kV Class

8.3kV Phase-to-G round

14.4kV Phase-to Phase

95kV B IL

34kV AC W ithstand

53kV D C W ithstand

11kV C orona Extinction

25kV Class

15.2kV Phase-to-G round

26.3kV Phase-to Phase

125kV B IL

40kV AC W ithstand

78kV D C W ithstand

19kV C orona Extinction

35kV Class

21.1kV Phase-to-G round

36.6kV Phase-to-Phase

150kV B IL

50kV AC W ithstand

103kV D C W ithstand

26kV C orona Extinction

SEE PAGE 26 FOR

SURGE ARRESTER

APPLICATIONS

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

C ATA LO G 2001 Page 17 ID : 0198

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

W IN D O W -O P 15kV 655ETP-W0X-DRG N 1,3,4,5,

C O N N EC TO R Use Tables W7 and X6 6,13

K IT 25kV K655ETP-W0X-DRG

Use Tables W7 and X6

35kV 755ETP-W0X-DRG

Use Tables W9 and X6

STIC K-O P 15kV 655LRTP-W0X-DRG N 2,3,4,5,

C O N N EC TO R Use Tables W7 and X6 8,13

K IT 25kV K655LRTP-W0X-DRG

Use Tables W7 and X6

35kV 755LRTP-W0X-DRG

Use Tables W9 and X6

W IN D O W -O P 15kV 650ETP N 4,15

Loadbreak 25kV K650ETP N 4,15

R educing 35kV 750ETP N 4,15

Tap Plug

STIC K-O P 15kV 650LRTPA3 N 3,4

Loadbreak 25kV K650LRTPA2

R educing 35kV 750LRTPA2

Tap Plug

STIC K-O P 15kV 650BEA3 N 3,4

B ushing 25kV K650BEA2

Adapter 35kV 750BEA2

C om pression A LL 03700X N 6

Lug Use Tables X6

W IN D O W -O P A LL 03702X N 7

Use Tables X6

Threaded A LL 03600X N 8

C om pression Use Tables X6

Lug A LL 03602X N 9

STIC K-O P Use Tables X6

W IN D O W -O P 15/25kV 655CK-W0X N 5

Size Sensitive K it Use Tables W7 and X6

(C able Adapter 35kV 755CK-W0X N 5

& Lug) Use Tables W9 and X6

STIC K-O P 15/25kV 655TCK-W0X N 5

Size Sensitive K it Use Tables W7 and X6

(C able Adapter 35kV 755TCK-W0X N 5

& Threaded Lug) Use Tables W9 and X6

Extraction Tool A LL 600ET N 3,10

G rounding 15kV 160GLR

Elbow 25kV 370GLR N 14

(1/0 AW G x 6' 35kV 370GLR N 14

G round Lead)

Test R od A LL 370TR

Assem bly Tool A LL 600AT N 3

(Stick-O p)

Assem bly Tool A LL 600ATM N 15

(W indow -O p)

STIC K-O P 15kV 650STICK-OK N 11

O PER ATIN G 25kV K650STICK-OK N 11

K IT 35kV 750STICK-OK N 11

W IN D O W -O P 15kV 650WINDOW-OK N 12

O PER ATIN G 25kV K650WINDOW-OK N 12

K IT 35kV 750WINDOW-OK N 12

N 1. W indow -O p K it includes: insulated cap; W indow -O p reducing tap plug;

600 Series elbow housing; cable adapter; and 0370 style com pression

lug.

N 2. Stick-O p K it includes insulated cap; Stick-O p Loadbreak reducing tap

plug; 600A Elbow H ousing; cable adapter; and threaded 0360 style

com pression lug.

N 3. 600AT assem bly tool required for operation and/or installation.

N 4. For 900 A m p ratings, substitute 675 for 650 and 655; 676 for 656; K 675

for K 650 and K 655; K 676 for K 656; 775 for 750 and 755; 776 for 756

and 2X for 0X in the part num ber. The 900 A m p rating requires copper

current-carrying connector com ponents and copper conductor cable.

N 5. Add suffix sym bol from page 29 to include cable shield grounding kit

and/or cable jacket sealing kit.

N 6. A lum inum lug for use on alum inum or copper conductors. D O N O T

substitute threaded 03600X lug.

N 7. C opper lug for use on C O PPER C O N D U C TO R O N LY. D O N O T

substitute 03602X threaded lug.

N 8. Threaded alum inum lug (Stick-O p only) for use on copper or alum inum

conductors. D O N O T substitute unthreaded 03700X lugs. D O N O T use

w ith 675, 676, K 675, K 676, 775 or 776 part num bers.

N 9. Threaded copper lug (Stick-O p only) for use on copper conductors only.

D O N O T substitute unthreaded 03702X lugs.

N 10. R equired to disassem ble Stick-O p loadbreak reducing tap plug from the

threaded com pression lug and 600 Series elbow after the shear-pin is

broken during assem bly.

N 11. Stick-O p O perating K it includes accessories that enable visible break

direct testing, isolation, and grounding functions to be perform ed. K it

includes: 3-insulated parking bushings; 3-grounding elbow s; 3-

600D B /200LB bushing/elbow adapters; 1-assem bly tool; 1-test rod;

1-carry case; l-lubricant; 1-instructions.

N 12.W indow -O p O perating K it includes accessories that enable visible

grounding and direct testing functions to be perform ed. K it includes:

3-grounding elbow s; 1-test rod; 1-carry case; 1-lubricant; 1-instructions.

N 13.600 Series Elbow s and Straight R eceptacles w ith IEEE Std. 386

capacitive test points are available by substituting 656 for 655; K 656 for

K 655; K 676 for K 675; 756 for 755; 676 for 675; K 676 for K 675 and 776

for 775 in the part num ber.

N 14.R ated for both 25kV and 35kV applications.

N 15.600ATM assem bly tool required for W indow -O p assem bly.

STICK-OP& WINDOW-OP

R efer to the W and X tables on pages 32 and 33 for sizing to cable

insulation diam eter and conductor size.

For cable shield adapters and jacket seals, see page 28.

Part numbers that contain

the letters Wor Xare size

sensitive. To complete the

part number, refer to the

Wor Xtables indicated.

SEPARABLE CONNECTORS CABLE J OINTS

600 SERIES DEADBREAK

C ATA LO G 2001 Page 18 ID : 0198 ELASTIMOLD

600 Series Separable C able Joints are available

in 2, 3 and 4-w ay versions and include a capaci-

tive test point as standard. U nits are interchange-

able, featuring bolted connections. D esigns are

com pact and ideally suited for sm all vaults and

m anholes.

D E-EN ER G IZED joints can be quickly and easily

connected and disconnected using standard

hand tools and equipm ent in accordance w ith

accepted operating practices. B us bars can be

changed to add or rem ove cables from the joint.

O ptional accessories include insulating and

grounding caps and plugs w hich allow visible ex-

ternal separation, by-pass, isolation, dead-ending,

grounding and testing.

OPERATING ACCESSORIES

COMPRESSION LUG

STRAIGHT RECEPTACLE HOUSING

BOLT &

WASHERS RETAINING

RING

CABLE ADAPTER

GROUNDING PLUG GROUNDING CAP

INSULATED CAP WITH BAIL

INSULATING PLUG

W/TEST POINT & CAP

3 7/8

8 1/8

37 1/8

4 1/4

W/ TEST POINT

D

A

C

2-WAY INSULATED BUS BAR

3-WAY INSULATED BUS BAR

B

4-WAY INSULATED BUS BAR

A

D

C

B

A

DIMENSION INCHES

SEPARABLE

STRAIGHT JOINT

(2-WAY)

SEPARABLE

WYE-JOINT

(3-WAY)

SEPARABLE

H-JOINT

(4-WAY)

SEPARABLE CABLE J OINTS 600 SERIES DEADBREAK

RATINGS OVERVIEW

See page 2 for com plete inform ation

CURRENT RATINGS

(Prefixes: 650, K650, K655, K656

& 03700)

600 A m p C ontinuous

25kA sym .,10 cycles

(Prefixes: 675, K675, K676 & 03702)

900 A m p C ontinuous

25kA sym .,10 cycles

N O TE: 900 A m p ratings require copper cable

and copper current-carrying com ponents.

VOLTAGE RATINGS

15/25kV Class (5kV thru 28kV)

16.2kV Phase-to-G round

28kV Phase-to Phase

140kV B IL

45kV AC W ithstand

84kV D C W ithstand

21.5kV C orona Extinction

N ote: Elastim old has increased the IEEE Standard

Production and D esign Test levels for 25kV C lass

products to include 27kV and 28kV system s.

Note: The separable

cable joints shown

here use a special Y

interface that may not

be interchangeable

with other 600 Series

interfaces.

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

C ATA LO G 2001 Page 19 ID : 0198

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

Separable 15/25kV K656I-W0X N 1,6,8

Straight Joint Pkg. Use Tables W7 and X6

(2-w ay)

w / Test Point

B asic H ousing Pkg.15/25kV K656I-HP N 2,6

Straight Joint

w / Test Point

Separable 15/25kV K656CY-W0X N 1,6,8

W ye Joint Pkg. Use Tables W7 and X6

(3-W ay)

w / Test Point

B asic H ousing Pkg.15/25kV K656CY-HP N 2,6

W ye Joint

w / Test point

Separable 15/25kV K656CH-W0X N 1,6,8

H Joint Pkg. Use Tables W7 and X6

(4-W ay)

w / Test Point

B asic H ousing Pkg.15/25kV K656CH-HP N 2,6

H Joint

w / Test Point

2-W ay 15/25kV K656I-BUS N 3,6

Insulated B us B ar

w /Test Point

3-W ay 15/25kV K656CY-BUS N 3,6

Insulated B us B ar

w /Test Point

4-W ay 15/25kV K656CH-BUS N 3,6

Insulated B us B ar

w /Test Point

Straight 15/25kV K655YSR-W0X N 4,6,8

R eceptacle Use Tables W7 and X6

Straight 15/25kV K655YBSR N 5,6,

R eceptacle 10

H ousing

O nly

Insulated C ap 15/25kV K655YDR

w / B ail

B ail 15/25kV 650BA

O nly

C able Adapter 15/25kV 655CA-W

Use Table W7

Adapter 15/25kV 650ARR-X

R etaining R ing Use Table X6

C om pression Lug 15/25kV 03700X N 6,7

15/25kV 03702X N 6,9

Use Table X6

600 Series 15/25kV 655CK-W0X N 8

Straight R eceptacle Use Tables W7 and X6

Size Sensitive K it

(C able Adapter,

R etaining R ing

& Lug)

Assem bly/ 15/25kV 600YADT

D isassem bly

Tool

N 1. C om plete Joint Packages consisting of: insulated bus bar; straight

receptacle housings, retaining rings, cable size adapters, lugs, bolts and

w ashers.

N 2. H ousing Packages consisting of the follow ing non-size sensitive

com ponents of the joint: insulated bus bar, straight receptacle housings,

bolts and w ashers.

N 3. Insulated bus bar only.

N 4. Straight R eceptacle consisting of: straight receptacle housing, retaining

ring, cable adapter, lug, bolt and w ashers.

N 5. Straight receptacle housing consisting of: straight receptacle housing,

bolt and w ashers.

N 6. For 900 A m p ratings, substitute 675 for 650 and 655; 676 for 656; K 675

for K 650 and K 655; K 676 for K 656; 775 for 750 and 755; 776 for 756

and 2X for 0X in the part num ber. The 900 A m p rating requires copper

current-carrying connector com ponents and copper conductor cable.

N 7. A lum inum lug for use on alum inum or copper conductors. D O N O T

substitute threaded 03600X lug.

N 8. Add suffix sym bol from page 29 to include cable shield grounding kit

and/or cable jacket sealing kit.

N 9. C opper lug for use w ith C O PPER C O N D U C TO R O N LY. D O N O T

substitute threaded 03602X lug.

N 10.Available w ithout the bolt & w ashers by adding N to the part num ber.

Illustration Description Voltage ELASTIMOLD Notes

(not to scale) Class Part Number

Insulating Plug w / 15/25kV K650YBIP

Test Point & C ap

G rounding Plug 15/25kV 650YGP

(4/0 AW G x 6'

G round Lead)

G rounding C ap 15/25kV 650YGDR

(4/0 AW G x 6'

G round Lead)

A lum inum B olt 15/25kV 650BAW N 6

& W ashers

B rass B olt & 15/25kV 675BAW N 6

W ashers

600 SERIES DEADBREAK

R efer to the W and X tables on pages 32 and 33 for sizing to cable

insulation diam eter and conductor size.

For cable shield adapters and jacket seals, see page 28.

Part numbers that contain

the letters Wor Xare size

sensitive. To complete the

part number, refer to the

Wor Xtables indicated.

PCJ CABLE J OINTS

ELASTIMOLD

PC J~Pow er C able Joints utilize perm a-

nently crim ped connectors. PC J H ousings

are fully insulated, shielded and sealed for

direct buried, vault, subm ersible and other

severe service applications. U nits have

been designed and tested per IEEE

Standard 404 to assure system m atched

perform ance and ratings equal to the cable

to w hich the splice w ill be installed.

PC J Pow er C able Joints are available in

2 styles:

Style 1 uses a single piece housing that is

sized to accom m odate a specific range of

cable. Style 1 units are ideally suited for

straight splicing of the sam e or sim ilar

cable.

Style 2 designs incorporate a universal

housing w ith separate cable adapters to

allow transition splices of different types

and sizes of cable.

ELECTRICAL RATINGS SUMMARY

The follow ratings sum m ary is based on IEEE Std. 404and applies to

all Elastim old PC J Pow er C able Joints.

VOLTAGE

A. 15kV C lass (8.7kV Phase-to-G round)

B. 25kV C lass (14.4kV Phase-to-G round)

C. 35kV C lass (20.2kV Phase-to-G round)

Impulse Withstand: A = 110kV, B = 150kV, C = 200kV B IL,1.2 x 50

m icrosecond w ave.

Corona Extinction Voltage: A = 13kV, B = 22kV, C = 31kV

m inim um , 3pC sensitivity.

DC Withstand: D uring installation: A = 56kV, B = 80kV, C = 100kV

(R eference A EIC C S5 and C S6, Section L.1.)

DC Withstand:

After installation and in service for the first 5 years:

A = 18kV, B = 25kV, C = 31kV for XLPE Insulated C ables

and A = 45kV, B = 64kV, C = 80kV for EPR Insulated C ables.

(R eference A EIC C S5 and C S6, Section L.2.)

CURRENT

C ontinuous rating equal to the rating of the cable.

Short-Tim e rating equall to the rating of the cable.

SHIELD DESIGN

M eets IEEE standard 592 for Exposed Sem iconducting Shields on

Prem olded H igh Voltage C able Joints and Separable Insulated

C onnectors.

Production tests include 100% tests of the

premolded joints to assure:

Corona Extinction Voltage: A = 13kV, B = 22kV, C = 31kV

m inim um , 3pC sensitivity.

AC Withstand: A = 35kV, B = 52kV, C = 69kV, 60 H z, 1 m inute.

Design tests on production joints demonstrate

compliance with IEEE 404 including:

Corona Extinction Voltage: A = 13.0kV, B = 21.6kV, C = 30.3kV

m inim um , 3pC sensitivity.

AC Withstand: A = 35kV, B = 52kV, C = 69kV, 60 H z 1 m inute.

DC Withstand: A = 70kV, B = 100kV, C = 125kV negative polarity,

15 m inutes.

Impulse Withstand (BIL): A = 110kV, B = 150kV, C = 200kV, 10

positive and 10 negative, 1.2 x 50 m icrosecond w ave, at conductor

tem peratures of 20 and 130C , nom inal.

Short-Time Current: m agnitude equal to cable.

Cyclic Aging: 30 days at: A = 26.1kV, B = 43.2kV, C = 60.2kV AC

continuous, load current for 8 hours per day providing 130

conductor tem perature. Joints then subjected to: A = 35kV, B = 52kV,

C = 69kV for 5 hours follow ed by: A = 53kV, B = 78kV, C = 104kV for

1 hour.

Load Cycle: C onnectors m eet therm al and m echanical require-

m ents of A N SI C 119.4, C lass A heat cycle, C lass 2 partial tension.

C ATA LO G 2001 Page 20 ID : 0198

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

DEADFRONT

LIVEFRONT

SEPARABLECONNECTORS

FUSEDELBOWS

CABLEJOINTS

SURGEARRESTERS

200AMPDEADBREAK

200AMPLOADBREAK

600SERIESDEADBREAK TERMINATIONS

5-15kV

25kV

35kV

PART#

STYLE 1

A B

PART NUMBER inches inches

15PCJ 1FX 10 1/4" 1 3/4"

15PCJ 1GX 10 1/4" 1 3/4"

25PCJ 1GX 14 3/8" 2 7/16"

15/25/35PCJ 1HX 14 3/8" 2 7/16"

15/25/35PCJ 1J X 14 3/8" 2 7/16"

15/25/35PCJ 1KX 14 3/8" 2 25/32"

15/25/35PCJ 1LX 14 3/8" 2 25/32"

15/25/35PCJ 1LMX 14 3/8" 2 25/32"

15/25/35PCJ 1MX 14 3/8" 2 25/32"

15/25/35PCJ 1NX 15 3/4" 3 3/16"

15/25/35PCJ 1PX 15 3/4" 3 3/16"

15/25/35PCJ 1QX 15 3/4" 3 3/16"

Description Voltage ELASTIMOLD Notes

Class Part Number

Pow er C able 15kV 15PCJ 1W1X N 1

Joint 15kV 15PCJ 1W2X N 2

25kV 25PCJ 1W1X N 1

Style 1 25kV 25PCJ 1W2X N 2

35kV 35PCJ 1W1X N 1

35kV 35PCJ 1W2X N 2

Pow er C able 15kV 15PCJ 2W1X N 1

Joint 15kV 15PCJ 2W2X N 2

25kV 25PCJ 2W1X N 1

Style 2 25kV 25PCJ 2W2X N 2

35kV 35PCJ 2W1X N 1

35kV 35PCJ 2W2X N 2

N 1. K it includes alum inum com pression connector suitable for splicing

alum inum conductor to alum inum conductor or alum inum conductor to

copper conductor.

N 2. K it includes copper com pression connector suitable for splicing copper

conductor to copper conductor only.

C ATA LO G 2001 Page 21 ID : 0198

STYLE 2

A B

PART NUMBER inches inches

15PCJ 2EX 16 3/8" 2 25/32"

15PCJ 2FX 16 3/8" 2 25/32"

15/25PCJ 2GX 16 3/8" 2 25/32"

15/25/35PCJ 2HX 16 3/8" 2 25/32"

15/25/35PCJ 2J X 16 3/8" 2 25/32"

15/25/35PCJ 2KX 21" 3 3/4"

15/25/35PCJ 2LX 21" 3 3/4"

15/25/35PCJ 2MX 21" 3 3/4"

15/25/35PCJ 2NX 21" 3 3/4"

15/25/35PCJ 2PX 21" 3 3/4"

15/25/35PCJ 2QX 21" 3 3/4"

DIMENSIONAL DATA

ORDERING INFORMATION PCJ Style 1

with single-piece housing

PCJ Style 2

with universal housing and separate cable adapters

that can be varied with the cable application.

DIMENSION A

OVERALL LENGTH

DIMENSION B

OUTSIDE DIA.

R efer to the W and X tables on pages 32 and 33 for sizing to cable

insulation diam eter and conductor size.

For cable shield adapters and jacket seals, see page 28.

P

o

w

e

r

C

a

b

l

e

J

o

i

n

t

S

t

y

l

e

I

n

s

u

l

a

t

i

o

n

D

i

a

m

e

t

e

r

V

o

l

t

a

g

e

C

l

a

s

s

C

o

n

d

u

c

t

o

r

C

o

n

d

u

c

t

o

r

S

i

z

e

C

o

d

e

1- Aluminum

2- Copper

1- Style 1

2- Style 2

W SIZING INFORMATION AND SELECTION

Use Table W8 for 15PCJ

Use Table W9 for 25PCJ

Use Table W10 for 35PCJ

X SIZING INFORMATION AND SELECTION

Use Table X7 for 15PCJ , 25PCJ and 35PCJ

Part numbers that contain

the letters Wor Xare size

sensitive. To complete the

part number, refer to the

Wor Xtables indicated.

CABLE TERMINATIONS

ELASTIMOLD

ELECTRICAL RATINGS

SUMMARY

The follow ing ratings sum m ary is based

on IEEE Std. 48 and applies to all the

term inations on page 22 thru 25. Elastim old

term inations are designed for use on three-

phase system s, either 3-w ire or 4-w ire and

the single-phase laterals of these system s.

VOLTAGE RATINGS

15kV Class

9.5kV Phase-to-G round

110kV B IL 1.2 x 50 m icrosecond w ave

AC W ithstand:

50kV 1 m in. dry

35kV 6 hr. dry

45kV 10 sec. w et

13kV C orona Extinction

25kV Class

16kV Phase-to-G round

150kV B IL 1.2 x 50 m icrosecond w ave

AC W ithstand:

65kV 1 m in. dry

55kV 6 hr. dry

60kV 10 sec. w et

21.5kV C orona Extinction

35kV Class

22kV Phase-to-G round