Академический Документы

Профессиональный Документы

Культура Документы

Fe 1 Lecture 2

Загружено:

Jalaluddin JohanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fe 1 Lecture 2

Загружено:

Jalaluddin JohanАвторское право:

Доступные форматы

1

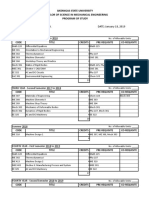

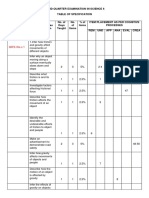

IN-SITU TESTS

Assist. Prof. Berrak TEYMUR

IN-SITU TESTING

Provide:

alternative design data

in-situ properties where undisturbed sampling

is not possible

Large volume of material

Methods:

Standard Penetration Test (SPT)

Cone Penetration Test (CPT)

Pressuremeter test

Dilatometer test

Other methods (vane shear, permeability etc.)

1- Standart Penetration Test (SPT):

63.5kg hammer weight (Donut, safety,automatic

trip hammer),

0.76m height,

Totaly 45cm penetration through soil.

First 15cm ignores,

Blow # versus last30cm.

Used primarily in granular soils

In-situ Tests

Test procedure may be found in ASTM D-1586, BS1377.

Advantages

Varying

diameters,

Low cost,

Widely used,

Experience.

Standart Penetration Test

(SPT):

Limitation

International standarts of variability

of procedures

Methods of drilling and supporting the

hole

Hammer mechanisms and rod sizes

used

The split-spoon geometry (minor effect)

Method of testing

Corrections - overburden pressure and PWP build-

up

Correction factor of blow number for fine sand, silty sand, silty soils

under GWT

2

) 15 (

15 '

+ =

N

N

2

SPT

Besides obtaining

soil samples, SPTs

provide correlations;

relative density

and friction angle

undrained shear

strength

direct estimate of

settlement

Empirical values for Dr and q

u

of granular and fine soils

based on SPT blow numbers

>400 Hard >30

200-400 Very stiff 15-30

100-200 Stiff 8-15

50-100 Medium 4-8

25-50 Soft 2-4

<25 Very soft 2

q

u

(kPa) Consistency N

Clay

Sand & Silts

>38

35 38

32 35

30 32

<30

Friction

angle, deg

85 - 100 >50 Very dense

65 - 85 30 - 50 Dense

35 - 65 10 - 30 Medium Dense

15 - 35 4 - 10 Loose

<15 <4 Very Loose

Relative

Density

(%)

N

*

(blows/

300mm)

State

CONE PENETRATION

TEST

The end resistance of the cone at any depth called the cone

penetration resistance is (q

c

) measured. q

c

is the force

required to advance the cone divided by the end area. Unlike

the SPT, soil samples cannot be recovered during the CPT.

Instrumented probe jacked into ground at constant rate of

penetration (2cm/sec)

Cone resistance (q

c

) and sleeve friction (q

s

) measured

cone resistance (q

c

) correlates with strength, and friction ratio

(q

s

/q

c)

with material type

Should always be correlated with borehole information

ASTM D-3441, BS 1377 (Part 9)

3

CONE

PENETRATION TEST

Applicable Not Applicable

Soft clays Very stiff clays

Fine to medium course

sands

Hard clays

Gravels

Advantages

Repeatable and reliable

data,

Faster and cheaper,

Continuous data profile.

60 cone,

10cm

2

base area,

150cm

2

friction sleeve,

10-50mm long sample collection.

CONE PENETRATION

TEST

Limitations

No samples,

Correlations with CPT are less,

Less experiences,

Drainage condition is unknown.

CONE PENETRATION TEST

Types of cones:

Mechanical cone (Dutch cone - reading every 200 mm)-

The tip is connected to an inner set of rods and it is first

advanced about 40mm giving the cone resistance. With further

thrusting, the tip engages the friction sleeve.

Electrical cone (constant readings)-The tip is attached to a

string of steel rods. It is pushed into the ground at the rate of

20mm/s. Wires from the transducers are threaded through the

centre of the rods and continuously give the cone and side

resistances.

Electrical piezocone

Seismic cone

CONE PENETRATION TEST

100 .

c

s

R

q

q

F =

Friction Ratio :

F

R

< 1% :sands,

F

R

> 5% :clays

Used for design of piles and to estimate the bearing

capacity and settlement of foundations.

4

Parameter Determination(Sands)

45 80 - 100 Very dense >20

40 - 45 60 80 Dense 12 20

35 - 40 40 60 Med dense 4 12

30 35 20 40 Loose 2 4

<30 <20 Very Loose <2

Friction

angle, deg

Dr (%) State q

c

, MPa

Based on Meyerhof (1965)

Parameter Determination(Clays)

Approximate relationship

c

u

= (q

c

p)/N

k

q

c

= cone resistance

p = total over-burden pressure

N

k = 10 15 for NC clays

= 15 20 for OC Clays

CONE PENETRATION TEST

q

C

q

S

F

R

u

(Mpa) (kPa) (%) (kPa)

Data collected during electrical CPT

PC: q

C

can be correlated to : ,D

r

,c

U

, N http://www.ce.gatech.edu/~geosys/Faculty/Mayne/Research/devices/cpt.htm

5

CPT-Related Websites

The Liquefaction Site (and CPT site):

www.liquefaction.com

Link page to manufacturers, suppliers, and CPT

services: http://www.usucger.org/insitulinks.html

Listing of available videos on CPT and other in-situ

tests: http://www.geoinstitute.org/in-situ.html

The book Cone Penetration Testing in Geotechnical

Practice (Lunne, Robertson, & Powell, 1997)

THE PRESSUREMETER

TEST

The Pressuremeter test is an in-situ test developed by

Menard in 1956. Applicable for : soft clay , fine to medium

sands.

The pressuremeter is a cylindrical device designed to apply

a uniform radial pressure to the sides of a borehole in which

it is placed. There are two different basic types:

The Menard pressuremeter which is lowered into a pre-

formed borehole

The Self-boring pressuremeter which forms its own

borehole and thus causes much less disturbance to the soil

prior to testing

THE PRESSUREMETER

TEST

In both cases, the pressuremeter test involves the

application of known stresses to the soil and the

measurement of the resulting soil deformation.

The sides of the borehole are loaded by pressurising

a fluid contained within a flexible rubber membrane.

The expansion of the cavity is determined either by measuring the

volume of fluid needed to pressurise the membrane and/or by

measuring the movement of the soil at the cavity wall using lvdts

(displacement transducers).

Generally, pressuremeters are designed for maximum inflation

pressures in the ranges 2.5-10MPa in soils and 10-20 MPa in very

stiff soils and weak rocks. E and K

0

can be determined.

THE PRESSUREMETER TEST (MPT)

The device consists of three parts (top, cell and bottom) as

shown below:

Bowles, 1997

6

THE PRESSUREMETER TEST

Zone 1

Reloading

Zone 2

Pseudo

Elastic

zone Zone 3

Plastic Zone

V

0

P

o

Measuring

Cell

Volume (V)

Measuring

Cell Pressure (p)

P

V

Zone 1: Soil pushed back to

initial state

Zone 2: Pseudo elastic, V vs P

is linear

Zone3: Plastic Zone

For Zone 2 :

where E : Youngs Modulus of soil

: Poissons ratio

V

o

: Volume corresponding to

beginning

of zone 2 at p

o

p/ V = 1 / (slope of line in zone 2)

V

p V

E

o

+

=

) 1 ( 2

THE PRESSUREMETER TEST

V

p V

G

G E

o

=

+ = ). 1 ( 2

Also, the relationship between E and G is given by

'

o

P

Ko =

Pressuremeter test results can also be used to

determine the at rest earth pressure coefficient;

Note:In France, shallow and deep foundation design is all

based on pressuremeter tests.

FIELD VANE

TEST

The vane shear test may be used during the

drilling operation to determine the in-situ

undrained shear strength (c

u

) of clay soils,

particularly soft clays.

The vane shear apparatus consists of four blades

on the end of a rod. The height, H of the vane is

twice the diameter, D. The dimensions of vanes

are; D=38.1mm, H=76.2mm, 1.6mm thick blades and

12.7mm diameter of rod.

This test is performed every 0.75 to 1 m of

depth.

The vanes of the apparatus are pushed into the soil

at the bottom of a borehole without disturbing the

soil appreciably.

Torque is applied at the top of the rod to rotate the

vanes at a standard rate of 0.1/sec. This rotation

will induce failure in a soil of cylindrical shape

surrounding the vanes.

The maximum torque, T applied to cause failure is

measured.

FIELD VANE TEST

7

FIELD VANE TEST

where

2/3 : uniform end shear

a = 3/5 : parabolic end shear

1/2 : triangular end shear

T : Nm f(c

u

,H,D)

2

4 2

3 2

=

+ =

D

H

aD H D

c T

u

H

D

are rapid, economical and extensively used

gives good results in soft and medium-stiff clays

errors can occur due to poor calibration of torque

measurement and damaged vanes

correlations with preconsolidation pressure and OCR exist

FIELD VANE TEST

When ; H/D= 2 & a=2/3

120

0,6

0,8

1,0

1,2

0,4

0

PI %

field u design u

u

c c

D

T

c

) ( ) (

2728 . 0

3

=

=

FIELD TESTS-Plate Loading

Test

Is carried out to estimate the bearing capacity and

settlement beneath the single footings.

A loading plate is circular or square in shape and is

manufactured from machined steel plate with a min.

thickness of 25mm. The diamater of circular plates

ranges from 150-760mm.

The load is either of gravity type applied through a

platform or reaction type applied by a hydraulic jack.

The plate loading test procedure may be found in

ASTM D-1194, ASTM D-1195 and ASTM D-1196.

8

PLATE LOAD TEST

Most reliable way to obtain the ultimate bearing capacity

at a site is to perform a load test.

Bowles, 1997

PLATE LOAD TEST

Procedure

1) Piles should be driven first, to avoid excess vibration &

loosening of soil in excavation area.

2) Excavate a hole a certain depth that the test is to be

performed. Test hole depth > 4B

3) A load is placed on the plate (usually steel) and

settlements are recorded from a gauge. Load increments

1/5 bearing capacity of soil or 1/10 estimated failure load.

Time of loading 1 hr & should be same duration for all

increments.

4) Test should continue until settlement = 25 mm or,

until capacity of testing apparatus is reached.

PLATE LOAD TEST

Settlement (cm)

Settlement

Load

Load (t/m

2

)

2.5

0

50 0 25

5

Hard/dense

soils

Loose/soft

soils

lim

If H = 2.5cm

failure

q

ult

= 50 t/m

2

lim

1/2 load corresponding

to 10 mm settlement

Note: Plate load test results do not include effects of

CONSOLIDATION

PLATE LOAD TEST

Coefficient of Subgrade Reaction , k

s

:

Load

q

Settlement

s

(use secant) : k

s

= q / s

[units: kg/cm

3

,kN/m

3

]

Used to obtain E: when

modelling soil as elastic

springs (Winkler)

kBy

dx

y d

EI =

4

4

9

Coring of Rocks

When a rock layer is encountered during a drilling

operation, rock coring may be necessary. For

coring of rocks, a core barrel is attached to a

drilling rod. A coring bit is attached to the bottom of

the core barrel. The coring is advanced by rotary

drilling. Water is circulated through the drilling rod

during coring and the cutting is washed out. To

evaluate the rock quality encountered, Rock

Quality Designation (RQD) is used.

RQD=

cored rock of length l Theoretica

101.6mm n larger tha or to equal pieces recovered of Length

0-0.25 very poor and 0.9-1 is excellent rock

quality.

Geophysical Testing

Advantages

relatively cheap compared to borehole and

in-situ testing option

non-destructive (no holes/excavations are

required)

Disadvantages

results are often inconclusive or unreliable

not yet fully accepted by the industry.

GEOPHYSICAL METHODS

Useful in ground investigation in reconnaissance

stage

Supplementary method (not suitable for all soils)

Capable of

estimating depth to bedrock

estimating depth to water table

filling in detail between borehole

Less cost than other in-situ tests

Definitive interpretation of the results is

difficult, so should be used for preliminary work

GEOPHYSICAL METHODS

1) Seismic Refraction Method:

Seismic waves have different velocities in

different types

of soil.

Two types of stress waves:

P Waves : plane waves

200 m/s in sands to 2500 m/s in clays

S Waves : shear waves

10

GEOPHYSICAL METHODS

Seismic refraction surveys are useful in obtaining

preliminary information about the thickness of the

layering of various soils and the depth to rock or hard soil

at a site.

They are conducted by impacting the surface at a point

and observing the first arrival of the disturbance (stress

waves) at other points.

The impact can be created by a hammer blow or by a

small explosives charge. The first arrival of disturbance

waves at various points can be recorded by geophones.

GEOPHYSICAL METHODS

( )

( )

1 3

1 3

T T

L L

V

T

L

V

rock

o

o

soil

=

=

( )

( )( )

+

=

1 2 1

1

g

E

P

g

G

s

=

P-S waves velocities:

First arrival time to detectors are determined :

2 1

2 2

=

s

p

87 . 1 =

s

p

For a typical Poissons ratio 0.3, the ratio;

GEOPHYSICAL METHODS

2) Electrical Resistivity Method:

Differences in electrical resistance of different soil

types.

Method

* Place 4 electrodes with equal spacing A.

* Apply a direct current to outer electrodes I.

* Measure potential drop in inner electrode.

GEOPHYSICAL METHODS

I

LV

2

=

The resistivity of soil is

determined by:

V:Voltage drop

The resistivity survey

is particularly useful

in locating gravel

deposits within a fine-

grained soil.

Craig, 1992

11

GEOPHYSICAL METHODS

3) Cross Hole Seismic Survey:

Two holes are drilled a distance, L, apart. A vertical

impulse is created at the bottom of one of the boreholes

by an impulse. The shear waves generated are recorded

by a transducer at the other borehole.

Method

Shear wave velocity:

Shear modulus :

g

V G

t

L

V

s

s

2

=

=

SOIL EXPLORATION REPORT

Scope

Description of structure

Description of location of site

Geological setting

Detailed field exploration

Subgrade conditions

Water table conditions

Foundation recommendations

Conclusions and limitations

Summary

Goal: estimate geometry of soil strata and

ground water and estimate pertinent

engineering properties

Field Investigation identify materials and

layering, retrieve samples and engineering

properties through in-situ testing

Laboratory Testing determine engineering

properties from samples

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Road Category and HierarchyДокумент45 страницRoad Category and HierarchyJalaluddin JohanОценок пока нет

- 103321Документ7 страниц103321Jalaluddin JohanОценок пока нет

- Specification Asphalt 80/100: Test MethodsДокумент2 страницыSpecification Asphalt 80/100: Test MethodsJalaluddin JohanОценок пока нет

- Thiessen PolyДокумент1 страницаThiessen PolyJalaluddin JohanОценок пока нет

- Types of Slope FailureДокумент14 страницTypes of Slope FailureJpver1000Оценок пока нет

- App CДокумент18 страницApp CJalaluddin JohanОценок пока нет

- 103321Документ7 страниц103321Jalaluddin JohanОценок пока нет

- Core CutterДокумент5 страницCore CutterprincerattanОценок пока нет

- 3 SedimentationДокумент78 страниц3 SedimentationJalaluddin JohanОценок пока нет

- Types of Damages On Flexible Pavement For Malaysian Federal RoadДокумент12 страницTypes of Damages On Flexible Pavement For Malaysian Federal Roadfarahazura100% (1)

- Road Category and HierarchyДокумент45 страницRoad Category and HierarchyJalaluddin JohanОценок пока нет

- Ce1255 Highway EngineeringДокумент10 страницCe1255 Highway Engineeringsaamy100% (2)

- Thickness DesignДокумент50 страницThickness DesignJalaluddin JohanОценок пока нет

- TNB Pillar@2nd EntranceДокумент2 страницыTNB Pillar@2nd EntranceJalaluddin JohanОценок пока нет

- Mud WaterДокумент4 страницыMud WaterJalaluddin JohanОценок пока нет

- Add Mathematics Project 2015Документ1 страницаAdd Mathematics Project 2015Justin Chan0% (1)

- Biological Wastewater Treatment: Aerobic & AnaerobicДокумент8 страницBiological Wastewater Treatment: Aerobic & Anaerobic007_pppqqqОценок пока нет

- Mud WaterДокумент4 страницыMud WaterJalaluddin JohanОценок пока нет

- Road Surface: DescriptionДокумент16 страницRoad Surface: DescriptionJalaluddin JohanОценок пока нет

- 2001 02Документ6 страниц2001 02Jalaluddin JohanОценок пока нет

- Procedure For Sewerage Submission 010515 UpdatingДокумент24 страницыProcedure For Sewerage Submission 010515 UpdatingTan Kang Yao67% (3)

- 1969 MalДокумент58 страниц1969 MalJalaluddin JohanОценок пока нет

- Clean Water An Introduction To Water Quality and Water Pollution ControlДокумент192 страницыClean Water An Introduction To Water Quality and Water Pollution ControlVerónica Morales-FélixОценок пока нет

- WSD0313 CДокумент2 страницыWSD0313 CJalaluddin JohanОценок пока нет

- Epl Manual PhewДокумент70 страницEpl Manual PhewRanjit Raj RОценок пока нет

- Air Quality Q&aДокумент3 страницыAir Quality Q&aJalaluddin JohanОценок пока нет

- Examples of Kinetic Energy ProblemsДокумент4 страницыExamples of Kinetic Energy ProblemsJalaluddin JohanОценок пока нет

- Clean Water An Introduction To Water Quality and Water Pollution ControlДокумент192 страницыClean Water An Introduction To Water Quality and Water Pollution ControlVerónica Morales-FélixОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Solid StateДокумент49 страницSolid Statekishangopi123Оценок пока нет

- 17 Eh PH DiagramsДокумент16 страниц17 Eh PH Diagramsmuhammad yusufОценок пока нет

- 2 Energy, Power, Work #2Документ5 страниц2 Energy, Power, Work #2Lil homieОценок пока нет

- BTech CSEДокумент122 страницыBTech CSEJohn HarrisonОценок пока нет

- GP1 - Q2 - Week 8Документ5 страницGP1 - Q2 - Week 8Shekaina Faith Cuizon LozadaОценок пока нет

- Session 2-1 - Introduction To Electricity and Electrical SystemsДокумент59 страницSession 2-1 - Introduction To Electricity and Electrical SystemsCeino Rey QuimintanОценок пока нет

- Smscom Manual Twin Controller Pro MK2 2017Документ6 страницSmscom Manual Twin Controller Pro MK2 2017saborespurpuraagroОценок пока нет

- Rinsing - A Critical Process in Contamination RemovalДокумент6 страницRinsing - A Critical Process in Contamination Removalfreebee12345Оценок пока нет

- How To Build A BombДокумент11 страницHow To Build A Bombgpduf100% (1)

- Atomic Structure QB 2Документ8 страницAtomic Structure QB 2vengateshwaran kОценок пока нет

- 12 Ea PDA 0 DantecPDA 2011Документ29 страниц12 Ea PDA 0 DantecPDA 2011Ali AbdoОценок пока нет

- Design of Flexural MembersДокумент10 страницDesign of Flexural MembersOlusegun S. Ajibola100% (1)

- Acceleration, Force, Momentum and EnergyДокумент28 страницAcceleration, Force, Momentum and Energyjayesh1997Оценок пока нет

- Tuned Mass Damper Report PDFДокумент21 страницаTuned Mass Damper Report PDFRitu t Raj100% (1)

- Questio 1Документ2 страницыQuestio 1Ankit GuptaОценок пока нет

- Grade 7 Daily Lesson Plan: I. ObjectivesДокумент3 страницыGrade 7 Daily Lesson Plan: I. ObjectivesJanecil A. BonzaОценок пока нет

- UNITS AND MEASUREMENTS Assignment PDFДокумент3 страницыUNITS AND MEASUREMENTS Assignment PDFvanshika MorОценок пока нет

- Latihan Soal Teg Geser - 1Документ9 страницLatihan Soal Teg Geser - 1Benjamin SoerjaОценок пока нет

- Chem Form-6-Sem-1-01 PDFДокумент44 страницыChem Form-6-Sem-1-01 PDFXuerong ChinОценок пока нет

- Overview of Vertical Axis Wind Turbine VAWT Is OneДокумент6 страницOverview of Vertical Axis Wind Turbine VAWT Is OneAjeem DurraniОценок пока нет

- PosДокумент3 страницыPosAndre De VillaОценок пока нет

- ICT 9A04406 Electromagnetic Theory and Transmission LinesДокумент1 страницаICT 9A04406 Electromagnetic Theory and Transmission LinessivabharathamurthyОценок пока нет

- Frontiers in Relativistic Celestial MechДокумент372 страницыFrontiers in Relativistic Celestial MechCarl MarksОценок пока нет

- Design of 765kv Transmission LineДокумент10 страницDesign of 765kv Transmission LineNaveen SabbavarapuОценок пока нет

- Ground and Excited State Intramolecular Proton Transfer in Salicylic Acid: An Ab Initio Electronic Structure InvestigationДокумент6 страницGround and Excited State Intramolecular Proton Transfer in Salicylic Acid: An Ab Initio Electronic Structure InvestigationSukumar PaniОценок пока нет

- Quantum ComputingДокумент13 страницQuantum ComputingSrikanthОценок пока нет

- Mri ArtifactsДокумент59 страницMri ArtifactsMarc Michael Dela CruzОценок пока нет

- Composites For Machine Tool Beds: National Institute of Technology Rourkela (India)Документ64 страницыComposites For Machine Tool Beds: National Institute of Technology Rourkela (India)kunalОценок пока нет

- 3rd PT Science 6Документ14 страниц3rd PT Science 6Dhines CBОценок пока нет