Академический Документы

Профессиональный Документы

Культура Документы

SikaWrap Hex - 430G - VP

Загружено:

Hakiki SaputraИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SikaWrap Hex - 430G - VP

Загружено:

Hakiki SaputraАвторское право:

Доступные форматы

Technical Data Sheet

Edition 1, 2003

Identification no. 20.004

Version no. 0010

SikaWrap Hex 430G (VP) / Sikadur -330

1/3

SikaWrap Hex 430G(VP) / Sikadur -330 1

C

o

n

s

t

r

u

c

t

i

o

n

SikaWrap Hex

- 430G (VP)/Sikadur

- 330

Glass Fiber Fabric Strengthening System

Description Externally applied Strengthening or Repair system for structural members made of

reinforced concrete, masonry or timber

System components :

Glass fiber fabric SikaWrap Hex-430G (VP) and epoxy based impregnating resin

Sikadur-330

Uses Strengthening of reinforced structures, masonry and timber in case of flexural and

shear load due to :

Increase of loading capacity

Changes of building utilisation

Repair of defects

Prevention of defects caused by earth quakes

Meeting of changed standards or specifications.

Advantages Multifunctional use as bending or shear reinforcement

Thixotropic, solvent free impregnating resin for easy use on site

Flexibility of surface geometry (Beams, columns, chimneys, piles, walls).

Resistance against chemicals and environmental condition (no corrosion)

Fabric available in 2 widths for optimum utilisation

Thin coating even with layers of fabric (application up to 3)

Fibre orientation tailor-made

Application

Cutting to size

The fabric can be cut with a special scissors or a very sharp knife, but may never

be folded!

Surface preparation

Preparation of the substrate by sandblasting or grinding., Subsequently any

dust or loose particles must be removed by means of an industrial vacuum

cleaner. The substrate must be clean, free from grease and oil and should be

dry (max. moisture content of substrate 4%).

The surface to be bonded must be level, with steps and form work marks not

greater than 0.5 mm. Larger unevenness must be levelled using Sikadur 41 or

a mixture of Sikadur-30 and quartz sand Sikadur-501 (mix ratio 1:1 parts by

weight).

The adhesive tensile strength of the substrate to be reinforced must be at least

1.0 N/mm2

Structural corners must be rounded to a radius of at least 10 mm.

This can be achieved using a diamond grinding disk.

Back

2/3

2 SikaWrap Hex 430G(VP) / Sikadur -330

Mixing

First, mix the material in each container separately. Then add component B to

component A, ideally using the special Sika Spatula. Stir with an electric mixer for

approx. 3 minutes until all the coloured streaks have disappeared. Then, pour the

whole mix into a clean container and stir again for approximately 1 minute at low

speed to keep air entrainment at a minimum.

Potlife starts with the mixing of both components (resin and hardened). At low

ambient temperature it will be longer, at elevated temperatures, shorter.

The higher the quantity of material mixed, the shorter the potlife. To achieve a

longer potlife at high temperatures the mixed material may be divided into smaller

units or both components may be cooled before mixing.

System Application

a) Apply the mixed resin Sikadur-330 to the prepared substrate using a trowel or

brush in a quantity of approximately 0.7 to 1.2 kg/m2, depending on roughness

of substrate.

b) Place the SikaWrap Hex-430G (VP) Fabric onto the resin coating in the

required direction. Carefully work the fabric into this resin with the plastic Sika

Laminating Roller until the resin is squeezed out between the rovings.

c) Application of more than one fabric layer (max. 3).

Apply more resin, consumption approximately 0.5 kg/m2.

This must be done within 60 minute (at 20

o

C) after the application of the

previous layer.

If this is not possible, a waiting time of at least 12 hours must be observed

before the next layer is applied, Then repeat step B.

d) As a covering layer an additional resin layer of approximately 0.5 kg/m2

broadcast with quartz sand can be added, which will serve as a bonding coat

for following cementitious coatings.

Important Information

In fiber direction , overlapping of the fabric must be at least 100 mm.

When placing several fabric webs side by side overlapping is not necessary.

At low temperatures and/or high relative humidity, the surface may become

sticky .

Before a further coat or adhesive or a further layer of fabric is applied (later

than 12 hours after the previous one) the thickness must first be removed as

follows :

Wash down with sponge saturated with water and rinse with plenty of water.

Mixed leftover of Sikadur-330 may only left to harden in metal containers and

in quantities of max 1 kg.

Prevent exposure of the reinforcement to direct sunlight

Ambient temperature during application must be at least 3

o

C above dew

point.

Max. admissible service temperature +50

o

C

Cleaning

Clean all tools immediately with Colma Cleaner.

Cured Sikadur-330 can only be mechanically removed.

Safety Instructions

Safety precautions

Before starting work, cover hands and unprotected skin with barrier cream. Wear

protective clothing (gloves, glasses). In contact with eyes or mucous membranes

rinse thoroughly with warm, clean water and seek medical help.

Ecology

In liquid form Sikadur-330 contaminates water. Do not dispose of into water or soil

but according to local regulations.

Transport

Comp. A : 9/11c

Comp B 8/66c

Toxity

Please refer to labels of packing

For detailed information please ask for relevant safety data sheet.

3/3

3 SikaWrap Hex 430G(VP) / Sikadur -330

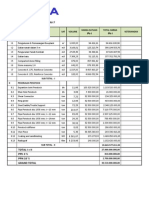

Technical Data

SikaWrap Hex 430G (VP)

Glass Fibre Fabric

Fibre Type

Glass fibers

Fibre Orientation 0

o

(undirectional). The fabric is equipped with special weft fibers which prevent

loosening of the rovings

Areal Weight 430 g/m

2

Fabric Design Thickness 0.17 mm (based on total area of glass fibres)

Tensile Strength of Fibers 2250 N/mm2

Tensile E-Modulus of

Fibers

70'000 N/mm2

Strain at Failure 3.1 %

Fabric Length/Roll 45.7 m

Fabric Width 305/610 mm

Shelf Life unlimited

Packaging 1 roll in card board box

Sikadur-330

Impregnating Resin

Appearance

Comp. A: white

Comp. B : grey

Density 1.31 kg/l (mixed)

Mixing Ratio 4:1 by weight (A:B)

POT Life + 15

o

C : 90 min (5 kg)

+ 35

o

C : 30 min (5 kg)

Open Time 30 min (at + 35

o

C)

Viscosity Plasty, not flowable

Application Temp. Range +10

o

C to +35

o

C

Adhesive Tensile Strength

on Concrete (EN 24624)

Concrete failure after 1 day (cured at > 15

o

C

on sandblasted substrate

Tensile Strength

(DIN 53455)

30 N/mm2 (cured 7 days at +23

o

C)

Flexural E-Modulus

(DIN 53452)

3'800 N/mm2 (cured 7 days at +23

o

C)

Heat Deflection

Temperature

(ASTM D 648)

Cured :

7 days, +15

o

C : 41

o

C

7 days, +23

o

C : 47

o

C

7 days, +35

o

C : 53

o

C

Shelf Life 18 months from manufacturing date in original packing stored at temperatures from

+5

o

C to 25

o

C.

Packaging Pre dosed units (A+B) at 5 kg

Disclaimer

In Technical Data Sheets

The information, and, in particular the recommendations relating to the application and end-use of Sika products are given in good faith based on Sikas

current knowledge and experience of the product when properly stored, handled and applied under normal conditions. In practice, the differences in

materials, substrates and actual site conditions are such that no warranty in respect of merchantability or of fitness for a particular purpose, nor any liability

arising out of any legal relationship whatsoever, can be inferred either from this information, or from any written recommendations, or from any other advice

offered. The proprietary rights of third parties must be observed. All orders are accepted subject to our current terms of sales and delivery. Users should

always refer to the most recent issue of the Technical Data Sheet for the product concerned, copies of which will be supplied on request.

C

o

n

s

t

r

u

c

t

i

o

n

PT. Sika Indonesia

Jl. Raya Cibinong- Bekasi km. 20

Limusnunggal - Cileungsi

BOGOR 16820 - Indonesia

Tel. +62 21 8230025

Fax. +62 21 8230026

www.sika.co. id

e-mail: marketing@sika.co.id

Branches

Surabaya,

Tel : 031-8420377

Fax : 031-8495018

Medan,

Tel : 061-4149224, 4552441

Fax : 061-4150805

Batam,

Tel : 0778-424928

Fax : 0778-426913

Sub Distributor

Bandung, Tel : 022-6018161, Fax : 022-6018272

Denpasar, Tel : 0361-235998,235973,237622, Fax:0361-237053

Makassar, Tel : 0411- 859147, 858527, Fax : 0411-858527

Balikpapan, Tel : 0542-411258, Fax : 0542-412230

Pekanbaru, Tel : 0761-46993,47677, Fax : 0761-45112

Duri/Dumai. Tel : 0765-595259, Fax : 0765-91135

Palembang, Tel : 0711-351523, Fax : 0711-369858

Palu, Tel : 0451-454855, 422122, Fax : 0451-454855

Вам также может понравиться

- Practice Quiz Reflection Project Initiation and Key ComponentsДокумент3 страницыPractice Quiz Reflection Project Initiation and Key ComponentsFalastin Tanani67% (3)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesОт EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsОт EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsОценок пока нет

- Bill of Quantity: Supply of Pipes and FittingsДокумент3 страницыBill of Quantity: Supply of Pipes and FittingssubxaanalahОценок пока нет

- Business EthicsДокумент10 страницBusiness EthicsTeguh HardiОценок пока нет

- SikaWrap Hex - 230CДокумент3 страницыSikaWrap Hex - 230CHakiki SaputraОценок пока нет

- Sikadur 30Документ3 страницыSikadur 30Hakiki SaputraОценок пока нет

- Sikadur 330 PDFДокумент6 страницSikadur 330 PDFDarwin SyahputraОценок пока нет

- Sikadur 31 CFДокумент4 страницыSikadur 31 CFRonald MassoraОценок пока нет

- Sikadur 31 CF NormalДокумент4 страницыSikadur 31 CF Normaldepi_rachmanОценок пока нет

- Sikadur-330 EpoxyДокумент6 страницSikadur-330 EpoxySarfraz MunirОценок пока нет

- Sika CarbodurДокумент3 страницыSika CarbodurHakiki SaputraОценок пока нет

- Sikadur 330Документ5 страницSikadur 330the pilotОценок пока нет

- Sikadur 30 PDFДокумент5 страницSikadur 30 PDFDarwin SyahputraОценок пока нет

- SikaMembran UniversalДокумент2 страницыSikaMembran UniversalColégio MilitarОценок пока нет

- Sikaflex Construction DДокумент3 страницыSikaflex Construction Dthe pilotОценок пока нет

- SikaWrap-231 C PDFДокумент3 страницыSikaWrap-231 C PDFDarwin SyahputraОценок пока нет

- Sikadur - 31 CF Rapid: 2-Part Thixotropic Epoxy AdhesiveДокумент6 страницSikadur - 31 CF Rapid: 2-Part Thixotropic Epoxy AdhesivevladodjuОценок пока нет

- Sikaflex Pro 3 WF Pds enДокумент4 страницыSikaflex Pro 3 WF Pds enrydocОценок пока нет

- SIKAWRAP Tensile Strength For DesignДокумент2 страницыSIKAWRAP Tensile Strength For DesignirckardОценок пока нет

- Sikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal CoatДокумент6 страницSikafloor - 325: 2-Part PUR Resin Self Smoothing Screed and Seal Coatthe pilotОценок пока нет

- Sikadur 42 MP Normal PDFДокумент5 страницSikadur 42 MP Normal PDFDarwin SyahputraОценок пока нет

- SikaflexPRO TdsДокумент6 страницSikaflexPRO TdsidontlikeebooksОценок пока нет

- Sikadur 31 CF Normal: 2-Part Thixotropic Epoxy AdhesiveДокумент4 страницыSikadur 31 CF Normal: 2-Part Thixotropic Epoxy Adhesiverahayu59Оценок пока нет

- Sikaflex 11FCДокумент3 страницыSikaflex 11FCthe pilotОценок пока нет

- Sikadur31 TdsДокумент4 страницыSikadur31 TdsFrederick Linsangan CruzОценок пока нет

- Sikawrap - 930 G/45: Woven Glass Fiber Fabric For Structural StrengtheningДокумент4 страницыSikawrap - 930 G/45: Woven Glass Fiber Fabric For Structural StrengtheningArnel AguelОценок пока нет

- My Con Pds Sikadur 31 LPДокумент3 страницыMy Con Pds Sikadur 31 LPmcwong_98Оценок пока нет

- Sikaflex PRO 3 WFДокумент4 страницыSikaflex PRO 3 WFfrahliaОценок пока нет

- Sikadur - 31: 2-Part Thixotropic Epoxy AdhesiveДокумент4 страницыSikadur - 31: 2-Part Thixotropic Epoxy Adhesivecamelia_pirjan5776Оценок пока нет

- Sikagard - 670W: Emulsion Type Protective Coating For ConcreteДокумент2 страницыSikagard - 670W: Emulsion Type Protective Coating For Concretethe pilotОценок пока нет

- Sikagrout 215 (New)Документ3 страницыSikagrout 215 (New)ArbiОценок пока нет

- Sikalastic 870 BT PdsДокумент4 страницыSikalastic 870 BT PdscharlessimoОценок пока нет

- Sikafloor 2530 W-GL, 18kg (Ab)Документ5 страницSikafloor 2530 W-GL, 18kg (Ab)azheminОценок пока нет

- Sika® Microcrete®-218: Product Data SheetДокумент3 страницыSika® Microcrete®-218: Product Data SheetthowchinОценок пока нет

- Trocal Stone Floor Sheet 1.2Документ3 страницыTrocal Stone Floor Sheet 1.2the pilotОценок пока нет

- Pds CPD Sikadur42GroutPak UsДокумент2 страницыPds CPD Sikadur42GroutPak UsAHОценок пока нет

- Sikagard Wallcoat PdsДокумент5 страницSikagard Wallcoat PdscharlessimoОценок пока нет

- Sikacoat Pds enДокумент3 страницыSikacoat Pds enHendrawan PratamaОценок пока нет

- Sikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing SystemДокумент6 страницSikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing Systemthe pilotОценок пока нет

- SikaTop Seal 107 PDS (CE) PDFДокумент4 страницыSikaTop Seal 107 PDS (CE) PDFSed BeelzeОценок пока нет

- PDS - Sikaflex®-11 FC+ PDFДокумент5 страницPDS - Sikaflex®-11 FC+ PDFblancogonzalosОценок пока нет

- Pds CPD Sikadur22LM UsДокумент2 страницыPds CPD Sikadur22LM Uspandavision76Оценок пока нет

- Sikadur - 53 Uf GroutДокумент3 страницыSikadur - 53 Uf GroutJU SHUANGОценок пока нет

- Sika Plan 14.6Документ3 страницыSika Plan 14.6the pilotОценок пока нет

- Sikagard 675 ElastocolorДокумент4 страницыSikagard 675 ElastocolorAvan Setyo PratamaОценок пока нет

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarДокумент3 страницыSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarОценок пока нет

- Sikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarДокумент4 страницыSikagard 75 Epocem: Superfine Epoxy-Cement Sealing MortarAnonymous v1blzDsEWAОценок пока нет

- Sikagard ElastoColor-675 WДокумент4 страницыSikagard ElastoColor-675 WAgung RahmadiОценок пока нет

- S IKAДокумент4 страницыS IKAQuevara AntonОценок пока нет

- Sika PDS - E - Sikadur-Combiflex SG TapeДокумент4 страницыSika PDS - E - Sikadur-Combiflex SG Tapelwin_oo2435Оценок пока нет

- Sikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsДокумент4 страницыSikafloor - Proseal-22: Curing and Sealing Compound For Concrete FloorsSholikhinIbnuRamadhanОценок пока нет

- Sikadur 31 CF Normal PDS (CE)Документ5 страницSikadur 31 CF Normal PDS (CE)Satria AdityaОценок пока нет

- Sikadur - 42 HS: High Strength Pourable Epoxy GroutДокумент4 страницыSikadur - 42 HS: High Strength Pourable Epoxy GroutMuhammad Azlan AhmadОценок пока нет

- Icosit KC 330-2MДокумент4 страницыIcosit KC 330-2MNelu IvascuОценок пока нет

- Flex 68wДокумент2 страницыFlex 68wYasher Meera SaibОценок пока нет

- Sika Anchorfix - 1: Fast Curing Anchoring AdhesiveДокумент6 страницSika Anchorfix - 1: Fast Curing Anchoring Adhesiveeye4aneye1989Оценок пока нет

- Sikagard-670 WMYДокумент3 страницыSikagard-670 WMYNARUdaARCОценок пока нет

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIОт EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiОценок пока нет

- The Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsОт EverandThe Science of Superhydrophobicity: Enhancing Outdoor Electrical InsulatorsОценок пока нет

- Justek, Approval Material HowsolpanДокумент5 страницJustek, Approval Material HowsolpanHakiki SaputraОценок пока нет

- IRCHRBJournal Jan Jun 13Документ84 страницыIRCHRBJournal Jan Jun 13Himagiri Subramaniam100% (1)

- Medium Tensile Steel A Is I 1045Документ2 страницыMedium Tensile Steel A Is I 1045Madhav RajpurohitОценок пока нет

- 03 Denah LT AtapДокумент1 страница03 Denah LT AtapHakiki SaputraОценок пока нет

- (New) Facade Curtain Wall, Asahi MasДокумент16 страниц(New) Facade Curtain Wall, Asahi MasHakiki SaputraОценок пока нет

- Facade Curtain Wall, Alexindo - Asahi MasДокумент10 страницFacade Curtain Wall, Alexindo - Asahi MasHakiki SaputraОценок пока нет

- 11final Pro - OucpredДокумент44 страницы11final Pro - OucpredHakiki SaputraОценок пока нет

- (New) Facade Curtain Wall, Asahi Mas PDFДокумент16 страниц(New) Facade Curtain Wall, Asahi Mas PDFHakiki SaputraОценок пока нет

- Plastiment RTD-01: Water Reducing and Set RetardingДокумент2 страницыPlastiment RTD-01: Water Reducing and Set RetardingBoby culiusОценок пока нет

- Sika AerДокумент2 страницыSika AerBoby culiusОценок пока нет

- Larihan MatematikanvcncvncgmnДокумент1 страницаLarihan MatematikanvcncvncgmnHakiki SaputraОценок пока нет

- Sika Fume - PDSДокумент3 страницыSika Fume - PDSHakiki SaputraОценок пока нет

- Plastiment RTD-01: Water Reducing and Set RetardingДокумент2 страницыPlastiment RTD-01: Water Reducing and Set RetardingBoby culiusОценок пока нет

- Spec2500 A8eДокумент6 страницSpec2500 A8eHakiki SaputraОценок пока нет

- Sika CarbodurДокумент3 страницыSika CarbodurHakiki SaputraОценок пока нет

- FM-LiftSpec by Imperial CollegeДокумент182 страницыFM-LiftSpec by Imperial CollegeKelvin Chih-Yong LeeОценок пока нет

- Sika Powerfix 1Документ3 страницыSika Powerfix 1Hakiki SaputraОценок пока нет

- BoQ Revisi 02 07Документ1 страницаBoQ Revisi 02 07Hakiki SaputraОценок пока нет

- Acacia Suites: - With Anti Bacterial GlazeДокумент3 страницыAcacia Suites: - With Anti Bacterial GlazeHakiki SaputraОценок пока нет

- Episode Transcript: Episode 34 - Chinese Han Lacquer CupДокумент2 страницыEpisode Transcript: Episode 34 - Chinese Han Lacquer CupParvathy SubramanianОценок пока нет

- 7 ApportionmentДокумент46 страниц7 Apportionmentsass sofОценок пока нет

- Education Programme: The School of Concrete TechnologyДокумент28 страницEducation Programme: The School of Concrete TechnologyThabiso Jacob MokwenaОценок пока нет

- Market Challengers StrategiesДокумент19 страницMarket Challengers Strategiestobbob007100% (20)

- Claudio MonteverdiДокумент2 страницыClaudio MonteverdiBrendan LynchОценок пока нет

- Pointers in CДокумент25 страницPointers in CSainiNishrithОценок пока нет

- 10 Problem For The Topic 9 & 10 Hicao GroupДокумент4 страницы10 Problem For The Topic 9 & 10 Hicao GroupArvin ArmojallasОценок пока нет

- Shaft DeflectionДокумент15 страницShaft Deflectionfreek_jamesОценок пока нет

- AC AMMETER / Moving Iron: Model AECДокумент33 страницыAC AMMETER / Moving Iron: Model AECRoonar Aponte NoaОценок пока нет

- Paper Format IJRDTДокумент3 страницыPaper Format IJRDTrock starОценок пока нет

- The Incidence of COVID-19 Along The ThaiCambodian Border Using Geographic Information System (GIS), Sa Kaeo Province, Thailand PDFДокумент5 страницThe Incidence of COVID-19 Along The ThaiCambodian Border Using Geographic Information System (GIS), Sa Kaeo Province, Thailand PDFInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Unseen Passage 2Документ6 страницUnseen Passage 2Vinay OjhaОценок пока нет

- NUFLO Low Power Pre-Amplifier: SpecificationsДокумент2 страницыNUFLO Low Power Pre-Amplifier: SpecificationsJorge ParraОценок пока нет

- Procedures Involved in The Ansys ACP17.2Документ10 страницProcedures Involved in The Ansys ACP17.2Vijayanandh RОценок пока нет

- Project Proposal DraftДокумент1 страницаProject Proposal DraftCarl Axel M. FajardoОценок пока нет

- RCD ManagementДокумент6 страницRCD ManagementPindoterOОценок пока нет

- Lesson Plan Wid Awt Method 2Документ7 страницLesson Plan Wid Awt Method 2Yan LianОценок пока нет

- KPI's Troubleshooting GuideДокумент27 страницKPI's Troubleshooting GuideMohamed SayedОценок пока нет

- m07srt Lesson KmarlinkДокумент3 страницыm07srt Lesson Kmarlinkapi-515106812Оценок пока нет

- Introduction To Object Oriented Database: Unit-IДокумент67 страницIntroduction To Object Oriented Database: Unit-Ipreetham rОценок пока нет

- Writing Short StoriesДокумент10 страницWriting Short StoriesRodiatun YooОценок пока нет

- Unit 4 Transistor Frequency ResponseДокумент6 страницUnit 4 Transistor Frequency ResponseShaina MabborangОценок пока нет

- Haldex Valve Catalog: Quality Parts For Vehicles at Any Life StageДокумент108 страницHaldex Valve Catalog: Quality Parts For Vehicles at Any Life Stagehoussem houssemОценок пока нет

- Moinho Disco PKM PDFДокумент6 страницMoinho Disco PKM PDFPaulo WilkerОценок пока нет

- THE Ketofeed Diet Book v2Документ43 страницыTHE Ketofeed Diet Book v2jacosta12100% (1)

- Nursing EnglishДокумент139 страницNursing EnglishSara Williams100% (3)

- U04 Fxs of Humeral ShaftДокумент88 страницU04 Fxs of Humeral Shaftadrian_mogosОценок пока нет