Академический Документы

Профессиональный Документы

Культура Документы

The Reconstruction of Modelling Reinforcement

Загружено:

RobertD.ZebuaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

The Reconstruction of Modelling Reinforcement

Загружено:

RobertD.ZebuaАвторское право:

Доступные форматы

1

st

International Conference on Rehabilitation

and Maintenance in Civil Engineering (ICRMCE)

Solo, 21-22 March 2009

ISBN No

.

1

THE RECONSTRUCTION OF MODELLING REINFORCEMENT

FOR PREVENT THE EARLY FAILURE OF DEEP BEAM

REINFORCED CONCRETE

Erwin Rommel

1*

Civil Engineering Departement, Engineering Faculty, Muhammadiyah Malang University

1*

Raya Tlogomas 246 Malang 65114 Phone (0341) 464318 Fax (0341)468502

email : erwin67pro@yahoo.com

Abstract

The used of inclined stirrup and transverse reinforcement still can t increase the strength of deep beam

significantly, crack propagation still concentrated of mid-span and the deep beam is have a more

possibility of flexure failure. Longitudinal shear reinforcement can be used as reinforcement to optimize

the strength increasing, so that can prevent the failure of deep beam reinforced concrete. The trial are given

of sixteen concrete beam (13x40x100) cm that have many variation of longitudinal shear reinforcement

from 2 6 mm ( = 0,136%), 4 6 mm ( = 0,272%) and 6 6 mm ( = 0,408%) with each have 4 (four)

beam and being tested in shear span ratio, respectively 0,6 ; 0,8 ; 1,0 ; and 1,2. The result of this

researches explain that using longitudinal shear reinforcement can increase the first crack-load until 87,5%

and ultimate-load until 83,2% and also shear stiffness can increase up to 175%. The crack of beam is

happen more distribute and the increasing of crack propagation can be reduce. Failure pattern of beam is

the shear failure that have a ductility in beam that given some load with ratio a/d less than 1.0.

Keyword :

deep beam, longitudinal shear reinforcement

1. INTRODUCTION

The behavior of deep beam is very

different to conventional beam, where the

collapse occurred due to more dominant

shear strength so that shear reinforcement

design into the internal reinforcing as

important. Shear reinforcement not only can

increase the shear capacity of beam, but also

change the beam of ductility where shear

reinforcement to reduce the risk of occurred

brittle failure. In addition to stirrup shear

receive,so this research study varied use

shear reinforcement longitudinal that is

expected to be contributed to received of

shear capacity deep beam.

Research of shear compression

failure has been done on the deep beam

with ratio a/d between 1.0 to 2.5 with one

point-loading and two point-loading.

Explained that strength of concrete, the ratio

flexurel reinforcement, shear reinforcement

in the ratio a/d 1.0 to 2.5 will affect the shear

compressive failure of deep beam (Zararis,

2003).

Design of deep beams with CIRIA use

normal and hight strength concrete has been

revision made to estimate occurred shear

ultimit. Given the parameters vary in the

investigation, among other things, the ratio

a/d between 0.27 to 2.7; the number of

flexurel reinforcement (1.23 to 5.80%), the

number of shear reinforcement and quality

of concrete used between 25 to 100 MPa

(Leong and Tan, 2003).

Approximate of the region and

dimensions of shear compressive failure can

be carried out on the deep beam with AE

method, which measures the amount of

energy from local sensors provided on

concrete surface. Evaluation of regional

failure can be known from the compressive

uniaxial testing in the beam based on the

maximum amplitudo measured from the

stresses maximum. The length of the region

beam failure the test results appeared more

than 30% of the results of sensor

measurements made from various shapes

and size of the test specimen (Watanabe,

2002).

The effect of the concentration load

with a different shear reinforcement on deep

beams with high strength concrete (f'c> 55

1

st

International Conference on Rehabilitation

and Maintenance in Civil Engineering (ICRMCE)

Solo, 21-22 March 2009

ISBN No

.

2

MPa) have also been examined, where the

test is done entirely with top edge of the

beam, bottom edge of the beam and the

combination of top edge and bottom edge,

with a ratio P

top

/P

bottom

1:1 and 2:1,

respectively. While variations shear

reinforcement that tested, among other deep

beam with the inclined flexurel

reinforcement, vertical shear reinforcement,

combination of horizontal and vertical shear

reinforcement. This research also explains

field of beam deflection, wide crack, form

patterns, failure model, the diagonal crack

load, strength and service ultimit (Tan and

Wei, 1999).

The use of variations of inclined

stirrup have been observed, where the stirrup

with slope of the 45

0

with a layer transverse

reinforcement will provide for increased

stiffness of beam 26%, but the crack beam

has not spread on the shear region, the

concentration of crack occur only the mid-

span toward the top side of beam

(Hermawan and Erwin, 2006). Failure

beams also often occur in the supported of

beam areas, where the distribution of the

shear is large enough before beam collapsed

suddenly (Fardho and Erwin, 2006). This

research aims to find out the influence of

shear longitudinal reinforcement against the

capacity of deep beam reinforced concrete

and other behavior reinforcement.

2. RESEARCH METHOD

Beam test of 12 (twelve) sized

(130x400x1000) mm with a full scale test.

The variables are taken 4 (four) beams

without using shear longitudinal

reinforcement, and then every 4 (four)

beams using, respectively ; 1 layer 6mm,

2 layers of 6mm and 3 layers of

6mm, shear longitudinal reinforcement. All

beams tested with of setting two-points

loading, with the ratio a/d respectively; 0.6;

0.8 ; 1.0 and 1.2. The concrete used 25

MPa. Testing equipment used, among other

things, loading capacity of 30 tons of the

frame, hydraulic jack capacity of 50 tons,

Load ceel capacity of 30 tons, with a load

indicator with a reading accuracy up to 1 kg,

the dial gauge accuracy 0,001 mm. Tests

beam is done with use a loading frame, as

shown in the picture 3.4. The reading test is

done at the expense of data provided every

increase of 250 kg, while load of the initial

cracked beams, load of diagonal crack

occurred, load of the condition ultimit

reached, and displacemen on the point load

(top edge and bottom edge beams). In

addition strain also observed that occur

through the strain gauge was installed in the

flexure reinforcement, stirrup and shear

longitudinal reinforcement, as shown in the

figure-2

Figure 1: Setting of test beam with two-point

loading

Figure-.2: Reinforcement of the test beam

2 10 mm

Dial gauge

Load Cell

Hidraulic Jack

Specimen

Beam-support

Actuator Frame

L

a

Loading Frame

Load Indicator

Hidraulic Pump

100 cm

13 cm

40

cm

2 10 mm

4 10 mm

6-100 mm

100 cm

13 cm

40

cm

2 10 mm

4 6 mm

6-100 mm

100 cm

40

cm

6-100 mm

13 cm

4 10 mm

2 6 mm

100 cm

13 cm

40

cm

2 10 mm

6 6 mm

6-100 mm

BT-TGL0

BT-TGL2

BT-TGL1

BT-TGL3

Strain gauges

1

st

International Conference on Rehabilitation

and Maintenance in Civil Engineering (ICRMCE)

Solo, 21-22 March 2009

ISBN No

.

3

0

5000

10000

15000

20000

25000

30000

BT TGL-0 BT TGL-1 BT TGL-2 BT TGL-3

Type Bal ok

B

e

b

a

n

r

e

t

a

k

a

w

a

l

(

k

g

)

a/d=0,6

a/d=0,8

a/d=1

a/d=1,2

0

5000

10000

15000

20000

25000

30000

BT TGL-0 BT TGL-1 BT TGL-2 BT TGL-3

Type balok

B

e

b

a

n

u

l

t

i

m

i

t

(

k

g

)

a/d=0,6

a/d=0,8

a/d=1

a/d=1,2

3. DISCUSSION

3.1 Shear Capacity

Figure 3 explains that with the

addition of shear longitudinal reinforcement,

increase the value of the load capacity that

can beam received deep beam for both first-

crack and ultimit load. The largest increase

occurred in the deep beams are given 3

(three) layer shear longitudinal

reinforcement (beam BT-TGL3) compared

with the deep beams without shear

longitudinal. Increase load of the initial

cracked beams, for the ratio a/d, respectively

of 65.4% (ratio a/d = 0.6); 23.8% (ratio a/d =

0.8); 87.5% (ratio a/d =1.0) and 86.9% (ratio

a/d=1.2). Similarly to load shear ultimit have

the same trend with increasing load ultimit

by 45%; 83.2%; 72.4% and 66.7%

respectively for the ratio a/d 0.6; 0.8; 1, 0

and 1.2.

Figure 3: Relations shear force of beam to shear

longitudinal reinforcement

From the results of the analysis, it

can be inferred that with the addition of

shear longitudinal reinforcement, will

increase the load capacity that can be

accepted by the deep beam. This increase

occurred due to the additional reinforcing of

longitudinal direction or horizontal that is

able to receive shear force occurred as a

result of the loading. Longitudinal

reinforcement would be able to provide

action together stirrup after diagonal crack

occurred in the region shear span. However,

the addition shear longitudinal

reinforcement this must be calculated to

limit fixed rate reinforcing maximum ratio

max

to avoid the over-reinforced condition.

Figure 4: Capacity of deep beam to use inclined

stirrup and transverse reinforcement

(Erwin, 2006)

If the influence of views on the use

of inclined stirrup as shear reinforcement

(Erwin, 2006), that shear longitudinal

reinforcement clearly provide improvements

to capacity shear beam as seen from Figure

4, where the combination of stirrup and

Two-point loading (a/d = 1.0)

0

5000

10000

15000

20000

BT-SV0 BT-SV1 BT-SV2 BT-SM0 BT-SM1

Type Balok

B

e

b

a

n

(

k

g

)

First crack

Ultimit

diagonal crack

Two-point Loading (a/d = 1.2)

0

5000

10000

15000

20000

BT-SV0 BT-SV1 BT-SV2 BT-SM0 BT-SM1

Type Balok

B

e

b

a

n

(

k

g

)

First crack

ultimit

diagonal crack

Two-point Loading (a/d = 0.8)

0

5000

10000

15000

20000

BT-SV0 BT-SV1 BT-SV2 BT-SM0 BT-SM1

Type Balok

B

e

b

a

n

(

k

g

)

first crack

ultimit

diagonal crack

1

st

International Conference on Rehabilitation

and Maintenance in Civil Engineering (ICRMCE)

Solo, 21-22 March 2009

ISBN No

.

4

0

5000

10000

15000

20000

25000

30000

0,6 0,8 1 1,2

Rasio a/d

B

e

b

a

n

U

l

t

i

m

i

t

(

k

g

)

BT TGL-0

BT TGL-1

BT TGL-2

BT TGL-3

0

5000

10000

15000

20000

25000

30000

0,6 0,8 1 1,2

Rasio a/d

B

e

b

a

n

R

e

t

a

k

(

k

g

)

BT TGL-0

BT TGL-1

BT TGL-2

BT TGL-3

transverse reinforcement that just reduce the

capacity ultimit deep beams. Even in the

ratio a/d = 0.8 load ultimit deep beams trend

to be constant (no-effect) with the stirrup

and transverse reinforcement. Increase the

load cracking diagonal and initial crack of

beams, although the initial fluctuate but have

not seen significant.

3.2 Ratio Shear Span a/d

With see Figure-5, that changes

location based on the ratio a/d give a very

significant to the amount of first-crack load

that can be accepted by the beams. In all

type beams that the more visible a small

ratio a/d, so first-crack load that can be

accepted will be increasingly small. In the

beam without shear longitudinal

reinforcement (beam BTTGL-0) decrease

the shear beam of 49.8% for crack-load and

51.3% for ultimit load beams. Similarly for

the deep beam with shear longitudinal

reinforcement, respectively 1 layer; 2 layer

and 3 layer of decrease 55.3% 59.7% 43.2%

of the crack-load beams and 56.4%; 47.9%;

44% of the ultimit load beams when

compared with a ratio placement location of

the load a/d = 0.6 and 1.2.

Figure-5: Relations with the capacity of beam

ratio a/d on the deep beams

This shows that the loading of the

small distance received beam the ability of

the support beams to receive first-crack load

will increase. Results of this study supports

the results of that research has been done by

Zarraris in 2003 stating that the variations

of a/d between 1 to 2.5 with a single-point

and two-point loading determine the load

capacity that is able to receive deep beams.

From the results of the analysis of

the above can be concluded that changes in

the ratio a/d is very influential on the

loading can be accepted by the beams. This

can be explained that the more a small

distance (the distance between the support

beam with the load), the bending moment

that there will be flexible increasingly small

so shear stress will be greater.

Figure 6: Relations ratio a/d and inclined stirrup

with shear capacity of deep beam (Erwin, 2006)

In research deep-beam in use

inclined stirrup and transverse reinforcement

(Erwin, 2006) also illustrate that the use of

the ratio a/d increasingly smaller yet provide

a significant increase in the ability to

capacity shear deep beams. The increase

Balok BT-SM0

0

5,000

10,000

15,000

20,000

25,000

30,000

35,000

one-load a/d=1.2 a/d=1 a/d=0.8

Rasio a/d

B

e

b

a

n

(

k

g

)

First crack ultimit

Balok BT-SM1

0

5,000

10,000

15,000

20,000

25,000

30,000

35,000

one-load a/d=1.2 a/d=1 a/d=0.8

Rasio a/d

B

e

b

a

n

(

k

g

)

First crack ultimit

1

st

International Conference on Rehabilitation

and Maintenance in Civil Engineering (ICRMCE)

Solo, 21-22 March 2009

ISBN No

.

5

0

50

100

150

200

250

300

350

400

450

500

BT TGL-0 BT TGL-1 BT TGL-2 BT TGL-3

Type balok

T

e

g

a

n

g

a

n

b

a

j

a

(

M

P

a

)

tulangan pokok

tul. Geser long.

sengkang

0

10.000

20.000

30.000

40.000

50.000

60.000

70.000

80.000

90.000

BT TGL-0 BT TGL-1 BT TGL-2 BT TGL-3

Type balok (jumlah tul.geser long)

K

e

k

a

k

u

a

n

g

e

s

e

r

(

k

g

/

c

m

)

a/d = 1,0

a/d = 0,8

a/d = 0,6

ranged up to 10% compared to deep beam

with a stirrup of conventional (see Figure 6).

Shear longitudinal reinforcement so that

siginifikan give more ability shear beam the

increase compared with inclined stirrup, or

combination of inclined stirrup and

transverse reinforcement.

3.3 Reinforcement of Beam

In the deep beams which are

longitudinal reinforcement obtained on the

behavior stress of reinforcement different

because of the stirrup and shear longitudinal

reinforcement as reinforcing a received

shear force of beam and flexure

reinforcement function as a reinforcing

bending of beam. Figure-7 explains that the

influence of the addition shear longitudinal

reinforcement of deep beams are visible

high real behave the stirrup of deep beams.

The more the number of shear longitudinal

will reduce the stirrup in receive shear beam,

so stress that occurs in the steel stirrup also

showed a decrease, but increase the value of

stress on the steel shear longitudinal.

Some of the load will hold by

longitudinal reinforcement and the other by

the stirrup. This will cause the decreasing

strain value in stirrup. The more shear

longitudinal given the increasingly small

strain also occurred on the stirrup. However,

should note that the addition of shear

longitudinal reinforcement this must also

remain to be the maximum limit to avoid the

over-reinforced.

This is seen in the behavior of different

stress in the flexure reinforcement, look at

that strain of flexure reinforcement

measured in the middle of beam (mid-span)

continues to increase with the addition of

bending moment beams in region mid-span

due to shear of beam which is also

increasing.

3.4 Shear Stiffness.

The tendency of changes shear

stiffness in the deep beams due to the

addition shear longitudinal reinforcement

more clearly seen in Figure 5.6 below. From

the relationship graph load received at the

cracked shear of beam with deflection

shown in Figure 9, that the use of deep

beams longitudinal reinforcement that will

generate more, which is also larger shear

stiffness beams. Deep beam with use of

shear longitudinal reinforcement produce the

largest shear stiffness, respectively ; 49,508

kg/cm for the beam with 2 layers

reinforcement (BT TGL-2) and 79,714

kg/cm for the beam with 3 layers

reinforcement(BT TGL-3), where increased

stiffness of deep beam reached 71% and

175%, respectively in the ratio a/d = 0.8.

Figure-7: Stress on steel reinforcement of the

deep beam

Figure 8: The curve between the shear stiffness

with type of beam

This clarify that the use of shear

longitudinal reinforcement also influenced

by how the location of shear load given deep

beams. Giving the load on the beam with

shear ratio a/d = 1.2 is also seen in-effective

because of arch action zone will be

concentrated in areas where the combination

of shear and bending moment tends to be

large. While, on the beam with 1 layer shear

longitudinal reinforcement (BT TGL-1), and

the beam without shear longitudinal

reinforcement (BT TGL-0), shear stiffness

only reached 37,900 kg/cm and 31,704

1

st

International Conference on Rehabilitation

and Maintenance in Civil Engineering (ICRMCE)

Solo, 21-22 March 2009

ISBN No

.

6

BT TGL-0

0

5000

10000

15000

20000

25000

30000

0 200 400 600 800 1000

Defl eksi ( x 0,01 mm )

B

e

b

a

n

(

k

g

)

a/d = 1,2

a/d = 1,0

a/d = 0,8

a/d = 0,6

BT TGL-1

0

5000

10000

15000

20000

25000

30000

0 200 400 600 800 1000

Defl eksi ( x 0,01 mm)

B

e

b

a

n

(

k

g

)

a/d = 1,0

a/d = 1,2

a/d = 0,6

a/d = 0,8

BT TGL-2

0

5000

10000

15000

20000

25000

30000

0 200 400 600 800 1000

Defleksi ( x 0,01 mm)

B

e

b

a

n

(

k

g

)

a/d = 1,2

a/d = 1,0

a/d = 0,6

a/d = 0,8

BT TGL-3

0

5000

10000

15000

20000

25000

30000

0 200 400 600 800 1000

Defleksi ( x 0,01 mm)

B

e

b

a

n

(

k

g

)

a/d = 0,8

a/d = 0,6

a/d = 1,0

a/d = 1,2

kg/cm, almost the same beam with use

reinforcement inclined stirrup (Erwin,

2005).

In the research that has been done

before, about the influence of the inclined

stirrup of deep beam (Erwin, 2005) the

results that the stiffness beam only use

inclined stirrup will be increased 125%

compared with conventional stirrup,

wherease if use a combination of inclined

stirrup and transverse reinforcement,

stiffness of beam is not increased

significantly.

Figure 9: The curve between load and deflection

on each type of beam

This clarify that the use of shear

longitudinal reinforcement with

conventional stirrup so far better than if the

beams using a combination of transverse

reinforcement and inclined stirrup. Give

shear longitudinal reinforcement (the

horizontal direction beams) will be able to

prevent and reduce the crack, which

occurred as a result of shear, because

trajektori of tension on the deep beams tend

to have a horizontal direction, especially in

areas shear span, the ratio a/d. Meanwhile,

inclined stirrup is done in-effective because

receive compressive stress of arch action

concrete trend to the direction perpendicular

to the inclined stirrup.

3.5 Crack Propagation

Addition shear longitudinal

reinforcement will improve the ability of

longitudinal beams hold the load in the first-

crack, the slowly propagation crack and

increase in the ability to receive ultimit load

of beam. Relations load history and long

crack on each shear span ratio a/d given can

be seen in Figure 10. From the graph that

looks at the ratio a/d=1, adding shear

longitudinal reinforcement provides a

significant influence on the pattern

propagation crack of deep beam. In the

beam BT TGL-0, when the load reached

9,500 kg of the approaching peak load of

9,635 kg, the length of the crack occurred

reach 35.25 cm. But on the beam with a

single layer longitudinal reinforcement(BT

TGL-1), with the same load (of 9,500 kg)

long crack can be hampered, so crack

occurred only during the 24 cm. This will be

long crack on the wane for the beam to get

the additional reinforcing of shear

longitudinal more than one layer. In the BT

TGL-2 long crack that happens reached 15.5

cm, while the BT TGL-3 long crack on the

wane until 0 cm (not yet occurred in the

cracked of beam load 9,500 kg). The same

trend is also visible in the ratio a/d = 0.8 and

0.6

Based on the analysis of the above

can be concluded that the shear longitudinal

reinforcement provide a very real influence

on the propagation crack of deep beam. The

propagation crack can be hampered by the

existence of shear longitudinal

1

st

International Conference on Rehabilitation

and Maintenance in Civil Engineering (ICRMCE)

Solo, 21-22 March 2009

ISBN No

.

7

Rasio a/d = 0,8

0

5000

10000

15000

20000

25000

30000

0 5 10 15 20 25 30 35 40

Panjang Retak (cm)

B

e

b

a

n

(

k

g

)

BTTB-0

BTTB-1

BTTB-2

BTTB-3

Rasio a/d = 1

0

5000

10000

15000

20000

25000

30000

0 5 10 15 20 25 30 35 40

Panjang Retak (cm)

B

e

b

a

n

(

k

g

)

BTTB-0

BTTB-1

BTTB-2

BTTB-3

Rasio a/d = 0,6

0

5000

10000

15000

20000

25000

30000

0 5 10 15 20 25 30 35 40

Panjang Retak (cm)

B

e

b

a

n

(

k

g

)

BTTB-0

BTTB-1

BTTB-2

BTTB-3

reinforcement, so that it can increase the

load capacity that can be accepted by the

deep beams.

Figure 10: The curve between load and length

crack on the deep beams

3.6 Crack of Pattern and Failure of Beam

In the ratio a/d = 1.0 and 1.2, crack

of beams begins from the mid-span and

cracked it will be long in line with addition

load to the top of the beam with propagation

direction that tends to vertical. The

propagation crack this kind shows that the

patterns of behavior occurs is flexure crack.

Meanwhile, the ratio a/d = 0.6 and 0.8 crack

started in support of beam the region toward

to the concentrated of load with the pattern

of diagonal crack. This pattern of

propagation shows the behavior shear

dominant of beam.

Based on the pattern of crack

occurred can be concluded that the deep

beams, the failure occurred is a combination

of shear and flexure failure. Meanwhile, the

ratio a/d = 0.6 and 0.8 crack of beam

occurred below the point load and then

spread to the diagonal direction toward the

point load itself, which means that the

behavior cracked more toward the behavior

of shear, but with the addition of the number

of reinforcement will change the behavior

shear of beams into the behavior of shear

ductility.

Based on the above discussion can

be taken conclusion that changes in the ratio

a/d of beams cause differences in the types

of failure beams where with the ratio a/d =

1.2 and 1.0 tend to collapse the flexure

failure, while beam with a ratio of a/d = 0.6

and 0.8 tend to collapse the failure shear, but

have better ductile with the decreasing ratio

of a/d.

So the shear force of location determine the

failure of pattern occurred on the deep

beams. When the load is near the support of

beam (a/d increasingly small), the failure

that occurred more patterns tend to collapse

due to shear stress. Conversely, if given the

shear force that keep the support (a/d larger),

then the failure that occurred more patterns

tend to collapse due to flexure stress.

Meanwhile, due to the addition shear

longitudinal reinforcement will change the

behavior of failure beams from the shear

failure britlle into failure ductile. This is due

to the contribution shear longitudinal

reinforcement in receive the shear stress so

that failure beam more dominant caused by

the stress flexure.

CONCLUSION

Addition rshear longitudinal

reinforcement as the reinforcing of deep

beams can increase the crack-load capacity

up to 87.5% (P

craks

max = 18,930 kg in the

ratio a/d = 1,0) and the ultimit load to 83.2%

(P

ult

max = 24,562 kg in the ratio a/d=0.8)

compared to deep beams without

longitudinal reinforcement, trend where

more and more small ratio a/d, the ability to

deep beam larger. Shear stiffness of deep

beam also increased to 175% in the ratio

1

st

International Conference on Rehabilitation

and Maintenance in Civil Engineering (ICRMCE)

Solo, 21-22 March 2009

ISBN No

.

8

a/d= 1.0 due to the addition shear

longitudinal reinforcement.

Improving the ability shear of beam

the followed transfer of shear reinforcing of

deep beams, namely the reduction of tension

on steel of stirrup so that increased tension

in steel of the shear longitudinal

reinforcement.

With the shear longitudinal

reinforcement propagation crack

increasingly hampered where the crack

spread more evenly on the entire beam, both

in the region mid-span and the support areas

of beam, with the failure occurred is the

shear failure of ductile in the ratio a/d more

small or a/d<1.0

ACKNOWLEDGMENTS

The author would like to thank all of the

financing of this research from the

Directorate of Research and Public Services

to the Directorate General of Higher

Education Ministry of National Education,

Indonesian, Jakarta, for Fiscal Year 2008

with the number of contract

229/SP2H/PP/DP2M/III/2008.

REFFERENCES

1. Anonim (2005) Design of Beams for

Shear, Dept. of Civil Engineering

University of Pretoria

2. Anonim (1996) ACI Code 318-95,

Building Code Requirements for

Structural Concrete, Portland Cement

Association, Illinois, Chichago

3. Erwin R (2006) Pengaruh Pemakaian

Tulangan Bagi Terhadap Rambatan dan

Lebar Retak pada Balok Tinggi,

Proceeding Seminar Nasional, 9

Desember 2006, Universitas

Muhammadiyah Malang, ISBN 979-

796-09-0

4. Erwin R (2006) Pengaruh Jumlah

Tulangan Bagi dan Arah Sengkang pada

Kemampuan Geser Balok Tinggi, Jurnal

Teknik GELAGAR, Volume 17, Nomor

01, edisi April 2006, ISSN 0853-2850,

Terakreditasi, Fakultas Teknik UMS,

Surakarta.

5. Erwin R (2005) Pengaruh Jumlah dan

Arah Penulangan Geser pada Perilaku

Balok Tinggi Beton Bertulang, Laporan

Hibah Penelitian PHK-A2 Tahun 2005,

Jurusan Teknik Sipil Universitas

Muhammadiyah Malang

6. Leong, C.L., and Tan. K.H (2003)

Proposed Revision on CIRIA Design

Equation for Normal and High Strength

Concrete Deep Beams, Magazine of

Concrete Research, Vol.55 Issue.3, pp

267-278.

7. Tan, K.H., C.Y Tang, and K.Tong,

(2004) Shear Strength Prediction of

Pierced Deep Beams with Inclined Web

Reinforcement, Magazine of Concrete

Research, Vol.56, Issue.8, pp.443-452.

8. Tan, K.H and Weng, L.W (1999) High-

strength Concrete Deep Beams with

Different Web Reinforcement under

Combined Loading, Australian

Conference on the Mechanics of

Structures and Materials, 8-10

December 1999, Sydney.

9. Teng, Susanto., Fung-Kew.K., Soon-

Ping. P., Lingwei W.G, and Tan K.H,

(1996) Performance of Strengthened

Concrete Deep Beams Predamaged in

Shear, ACI Structural Journal, Vol.93,

No.2, March-April 1996, pp159-171.

10. Watanabe, Ken., Mitsuyasu Iwanami,

Hiroshi Yokota, and Junichiro Niwa,

(2002) Estimation of The Localized

Compressive Failure Zone of Concrete

by AE Method, Proceeding of the 1

st

fib

Congress, Osaka, Session 13, October

2002, pp.117-124.

11. Zararis, Prodromos.D., (2003) Shear

Compression Failure in Reinforced

Concreted Deep Beams, Journal of

Structural Engineering, Vol.129, No.4,

April 2003, pp 544-553.

Вам также может понравиться

- K3 Physical HazardДокумент22 страницыK3 Physical HazardRobertD.ZebuaОценок пока нет

- Perhitungan COD Dan BODДокумент14 страницPerhitungan COD Dan BODRobertD.ZebuaОценок пока нет

- Cross PDFДокумент8 страницCross PDFqilleОценок пока нет

- DPT-Batu KalI 2,0Документ16 страницDPT-Batu KalI 2,0RobertD.Zebua100% (1)

- Lumion ForumДокумент6 страницLumion ForumRobertD.ZebuaОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Nanoworld of Science and TechnologyДокумент8 страницNanoworld of Science and TechnologyAurelia Marie Aguinaldo TactacОценок пока нет

- Alloy 030Документ2 страницыAlloy 030Nookang SeaSunОценок пока нет

- STC 1105007 Short FormДокумент1 страницаSTC 1105007 Short FormAdam Amanda SchwemleinОценок пока нет

- Consulting ProposalДокумент14 страницConsulting ProposalKalpesh JainОценок пока нет

- Low Carbon SteelДокумент2 страницыLow Carbon SteelDaniel Dowding100% (1)

- ASTM A29/A29M GB EN 10083/3 JIS G4053 GB: Round Sheet Square PlateДокумент3 страницыASTM A29/A29M GB EN 10083/3 JIS G4053 GB: Round Sheet Square PlateximicayОценок пока нет

- Low Voltage FuseДокумент27 страницLow Voltage FuseDE VERA, KENNETH GABRIEL D.Оценок пока нет

- Response of Ferrocement Confinement On Behavior of Square RC Short ColumnДокумент10 страницResponse of Ferrocement Confinement On Behavior of Square RC Short ColumnPANKAJ TAMBAKHEОценок пока нет

- Mpi - Fill in The Blanks - Ii - QДокумент2 страницыMpi - Fill in The Blanks - Ii - QVishal ChudasamaОценок пока нет

- Module 4a - Line Sizing CalculationДокумент9 страницModule 4a - Line Sizing CalculationEkundayo JohnОценок пока нет

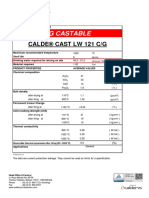

- Tds Calde Cast LW 121 CGДокумент1 страницаTds Calde Cast LW 121 CGAfronie Cepoz D'nextОценок пока нет

- Assignment 3Документ2 страницыAssignment 3Spring RollsОценок пока нет

- 5054 On 2022 P22Документ14 страниц5054 On 2022 P22Raahin RahimОценок пока нет

- Assignment On TE 4245 Assignment On TE 4245: TopicДокумент25 страницAssignment On TE 4245 Assignment On TE 4245: TopicNaimul HasanОценок пока нет

- Thermoplastics and Thermosetting PlasticДокумент24 страницыThermoplastics and Thermosetting PlasticKAPIL SINGHОценок пока нет

- Non Ideal BehaviorДокумент9 страницNon Ideal BehaviorTushar DaveОценок пока нет

- Rigid Pavement: Postgraduate Studies Highways EngineeringДокумент15 страницRigid Pavement: Postgraduate Studies Highways EngineeringHANAN HUSSОценок пока нет

- High Voltage Precaution Safety MomentДокумент28 страницHigh Voltage Precaution Safety MomentAdipramono PutraОценок пока нет

- Frank P Incropera - Fundamentals of Heat and Mass Transfer (2007, John Wiley)Документ19 страницFrank P Incropera - Fundamentals of Heat and Mass Transfer (2007, John Wiley)shahzad aliОценок пока нет

- Notes 03Документ18 страницNotes 03agnivnath77Оценок пока нет

- Water Structure and ScienceДокумент35 страницWater Structure and ScienceKarthick VelayuthamОценок пока нет

- Week 3 - Fiber Optics and Waveguides SolutionsДокумент6 страницWeek 3 - Fiber Optics and Waveguides SolutionsAli hassanОценок пока нет

- Behaviour of Sand Confined With Single and Multiple GeocellsДокумент14 страницBehaviour of Sand Confined With Single and Multiple GeocellsManaswini VadlamaniОценок пока нет

- ThermodynamicsДокумент69 страницThermodynamicssushma panugantiОценок пока нет

- EC - Unit 2 - Transistor BiasingДокумент19 страницEC - Unit 2 - Transistor Biasingnanobala15Оценок пока нет

- Design Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFДокумент6 страницDesign Calculation of Spherical MSM Slide Guide (T) Bearing - 1800 KN (GB7) PDFDusmantaKumarSahooОценок пока нет

- Paper 6Документ14 страницPaper 6UmaibalanОценок пока нет

- The Ohsol PresentationДокумент53 страницыThe Ohsol PresentationArsalan QadirОценок пока нет

- Material ScienceДокумент13 страницMaterial ScienceolingxjcОценок пока нет

- Quantum Dot LasersДокумент24 страницыQuantum Dot LasersSpandana InvincibleОценок пока нет