Академический Документы

Профессиональный Документы

Культура Документы

Manual de Mantenimiento de Gruas Jib PDF

Загружено:

alejandroaleman530 оценок0% нашли этот документ полезным (0 голосов)

284 просмотров20 страницThis manual contains important information to help you install, operate, maintain, and service your new jib crane. By practicing the recommended maintenance suggestions, with proper installation, and application of correct operating procedures, you will be assured maximum service from your crane. This manual is intended to be used in conjunction with the SPANCO (r) Model 301, which has been discontinued.

Исходное описание:

Оригинальное название

Manual de Mantenimiento de gruas jib.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis manual contains important information to help you install, operate, maintain, and service your new jib crane. By practicing the recommended maintenance suggestions, with proper installation, and application of correct operating procedures, you will be assured maximum service from your crane. This manual is intended to be used in conjunction with the SPANCO (r) Model 301, which has been discontinued.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

284 просмотров20 страницManual de Mantenimiento de Gruas Jib PDF

Загружено:

alejandroaleman53This manual contains important information to help you install, operate, maintain, and service your new jib crane. By practicing the recommended maintenance suggestions, with proper installation, and application of correct operating procedures, you will be assured maximum service from your crane. This manual is intended to be used in conjunction with the SPANCO (r) Model 301, which has been discontinued.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 20

Spare Parts, Instruction and Maintenance Manual for

SPANCO

Model 301Jib Cranes

Manual No. 103-0007

REV. 6/10

ISO 9001 REGISTERED

SPANCO, Inc.

2

3

Forward...................................................................................................................... 4

Installation.............................................................................................................. 4-6

Maintenance............................................................................................................... 6

Wall Cantilever Jib Crane 200 Rotation Model 301-050................................................7

Wall Cantilever Jib Crane 200 Rotation Model 301-100................................................8

Wall Cantilever Jib Crane 200 Rotation Model 301-200................................................9

Wall Cantilever Jib Crane 200 Rotation Model 301-300..............................................10

Wall Cantilever Jib Crane 200 Rotation Model 301-500..............................................11

Wall Bracket Model 301-050 to 500.......................................................................... 12

Bill of Materials: Wall Bracket (Tie Rod) Jib Crane

Model 301 (050/100)......................................................................................13

Model 301 (200).............................................................................................14

Model 301 (300).............................................................................................15

Model 301 (500).............................................................................................16

Tag Line Support System........................................................................................... 17

Warranty and Service Policy........................................................................................20

TABLE OF CONTENTS

4

FORWARD:

This manual contains important information to help you install, operate, maintain, and

service your new jib crane. We recommend that you study its contents thoroughly before

putting the jib into use. We also recommend that you obtain the latest issue of ANSI

B30.11 Safety Standard for Monorails and Underhung Cranes and study its contents

thoroughly. By practicing the recommended maintenance suggestions, with proper

installation, and application of correct operating procedures, you will be assured maximum

service from your jib crane.

The jibs described in this manual are intended for indoor service. Jib cranes used for outdoor

service require special consideration.

INSTALLATION:

Before attempting to install your new jib crane, the following items must be understood:

1. It is the customers responsibility to ensure that building columns or walls are adequate

to support the crane and its rated load.

2. Jib cranes should not be hung from an existing building structure without first

consulting a qualified architect or engineer for the purpose of determining the

structures adequacy.

3. The installer is responsible for supplying the correct size, length, number, and type of

bolts required to attach the jib crane brackets to the structure. SPANCO recommends

that the bolts be ASTM A325 grade.

4. Plan the installation such that the proper clearance as outlined in ANSI B30.11 will be

adhered to. In the design of jib crane systems, all factors that influence clearances,

such as roof truss sag, and boom deflection shall be considered.

NOTE: DO NOT MOUNT THE JIB CRANE TO ANY STRUCTURE UNLESS YOU

ARE SURE THE STRUCTURE CAN SAFELY SUPPORT THE LOADS IMPOSED

UPON THE STRUCTURE. FAILURE TO CHECK THIS ITEM CAN RESULT IN

SEVERE BODILY INJURY OR DEATH.

r

WARNING

!

5

After these points have been covered, you may begin the installation procedure as follows:

1. Refer to the appropriate table in this manual and locate the dimensions of the specific Model

301 jib crane to be installed.

2. Determine the elevation of the top wall bracket by adding the Bracket Centers dimension to

the desired elevation of the bottom of the boom plus 1/2 the boom height.

3. Hold the top wall bracket against the supporting column in its proper location with a C-clamp or

other supporting method.

4. Establish the correct distance from the top wall bracket to the bottom wall bracket from

the charts (Dimension B). Hold the bottom wall bracket against the supporting column with a

C-clamp or other supporting method.

5. Use a plumb bob to check the alignment of the bottom bracket with the top bracket in two

planes. The alignment must be within 1/16 inches from top to bottom.

6. Using the wall brackets as a template, mark the established hole locations.

7. Drill the holes in the column for the wall brackets.

8. Mount the wall brackets and their shims (if used) to the column with bolts (ASTM A-325)

supplied by the installer. Care should be taken to insure all bolts are properly tightened.

9. Lift the boom assembly with its brackets and tie rod assembly attached with a lift truck or other

means into place. Insert the top pivot assembly and the bottom pivot assembly into its

respective wall brackets. Insert the top and bottom bracket bolts into the bracket assemblies

and properly tighten the nuts to the torque listed.

6

10. Remove the end stop angles from the boom tip and install the hoist and trolley onto the boom.

Refer to the hoist manufacturers manual for proper setting of the trolley wheels to match the

boom beam. Remember to reinstall the end stop angles on the boom and properly tighten the

nuts after installation of the hoist trolley on the jib.

11. Position the unloaded hoist and trolley at the extreme tip of the boom and adjust the tie rod

assembly deflection, the boom tip should be adjusted to an elevation equal to

boom length (inches) 600 above level.

12. Connect the hoist to its source of power (either air or electric) if required, as per the hoist

manufacturers manual.

13. Now that the jib crane installation is complete, but before the unit is placed into service, it is

important to review and follow procedures outlined in Chapter 11-2 of ANSI B30.11 regarding

inspection, testing, and maintenance.

MAINTENANCE:

By definition, the term jib crane includes the jib, the trolley, and the hoist, along with any

attachment that may exist. The user should refer to the manual supplied with the hoist and trolley

for a listing of maintenance points and their suggested frequency.

With regards to the SPANCO jib, the only maintenance item is that of the wall bracket lubrication.

The sleeve bearings in those brackets are pre-lubricated at the factory. Field lubrication of those

bearings is required based upon usage of the crane. SPANCO recommends that the bearings be

lubricated at least once a year. The grease should be a lithium soap based grease, consistency

No. NLGI 2.

7

1/2 TON CAPACITY

WALL CANTILEVER JIB CRANE 200 ROTATION MODEL 301 - 050 -

8

1 TON CAPACITY

WALL CANTILEVER JIB CRANE 200 ROTATION MODEL 301 - 100 -

9

2 TON CAPACITY

WALL CANTILEVER JIB CRANE 200 ROTATION MODEL 301 - 200 -

10

WALL CANTILEVER JIB CRANE 200 ROTATION MODEL 301 - 300 -

3 TON CAPACITY

11

5 TON CAPACITY

WALL CANTILEVER JIB CRANE 200 ROTATION MODEL 301 - 500 -

12

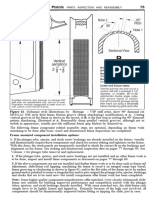

WALL BRACKET MODEL 301-050 to 500

5 TON ONLY

GREASE FITTING

BEAM CAPPED

WHEN REQUIRED

5 TON ONLY

WHEN REQUIRED

Serial Number

Location

starting

12/03

13

BILL OF MATERIALS

WALL BRACKET (TIE ROD) JIB CRANE

MODEL 301 (050/100)

Ordering Repair Parts

When ordering repair parts from this manual, be sure to state the model and serial number

of the unit. This information can be found on the small metal plate attached to the jib crane.

The hardware kits are determined by the capacity of the jib crane.

Hardware Model 301 (050/100) 1/2 and 1 Ton Capacity

14

BILL OF MATERIALS

WALL BRACKET (TIE ROD) JIB CRANE

MODEL 301 (200)

Ordering Repair Parts

When ordering repair parts from this manual, be sure to state the model and serial number

of the unit. This information can be found on the small metal plate attached to the jib crane.

The hardware kits are determined by the capacity of the jib crane.

Hardware Model 301 (200) 2 Ton Capacity

15

Hardware Model 301 (300) 3 Ton Capacity

Ordering Repair Parts

When ordering repair parts from this manual, be sure to state the model and serial number

of the unit. This information can be found on the small metal plate attached to the jib crane.

The hardware kits are determined by the capacity of the jib crane.

BILL OF MATERIALS

WALL BRACKET (TIE ROD) JIB CRANE

MODEL 301 (300)

16

Hardware Model 301 (500) 5 Ton Capacity

Ordering Repair Parts

When ordering repair parts from this manual, be sure to state the model and serial number

of the unit. This information can be found on the small metal plate attached to the jib crane.

The hardware kits are determined by the capacity of the jib crane.

BILL OF MATERIALS

WALL BRACKET (TIE ROD) JIB CRANE

MODEL 301 (500)

17

TAG LINE SUPPORT SYSTEM

FROM SUPPLY

(CONDUCTOR NOT SUPPLIED)

TO EQUIPMENT

MAX

X Y

2 FT. 5 FT.

18

19

20

FIVE-YEAR EQUIPMENT WARRANTY

SPANCO offers this Equipment Warranty (the Warranty) on the following equipment:

Manually propelled Free Standing and Ceiling Mounted Workstation Bridge Cranes.

Manually propelled Monorails.

Manually propelled ALU-TRACK Bridge Cranes and Monorails.

Manually rotated Enclosed Track and I-Beam Jib Cranes.

Manually propelled Gantries.

Manually propelled Articulating Jib Cranes.

ALL motorized SPANCO products come with a one year warranty on drive components.

SPANCO warrants the Equipment and wearable end truck and trolley wheels only, to be free from defects in material and

workmanship for a period of five (5) years or 10,000 hours (whichever occurs first), commencing on the date of shipment to the first

retail purchaser (Purchaser). This Warranty does not extend to Equipment which has been subject to misuse, use in excess of rated

capacity, negligent operation, use beyond SPANCO's published service factors, improper installation or maintenance, and does not

apply to any Equipment which has been repaired or altered without SPANCO's written authorization. Written notice of any claimed

defect must be given to SPANCO within thirty (30) days after such defect is discovered. SPANCO's obligation, and Purchaser's sole

remedy under this Warranty is limited to, at SPANCO's discretion, the replacement or repair of the Equipment at SPANCO's factory or

at a location approved by SPANCO. Purchaser is responsible for all freight and transportation costs relating to the repair or

replacement of the Equipment. THE FOREGOING WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES WHATSOEVER

WHETHER EXPRESS, IMPLIED, OR STATUTORY. SELLER MAKES NO WARRANTY AS TO THE MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE OF THE EQUIPMENT AND MAKES NO OTHER WARRANTY, EITHER EXPRESS OR IMPLIED. SPANCO shall

not be liable, under any circumstances, for any indirect, special or consequential damages including, but not limited to, lost profits,

increased operating costs or loss of production. This Warranty shall not extend to any components or accessories not manufactured by

SPANCO (such as casters), and Purchaser's remedy for such components and accessories shall be determined by the terms and

conditions of any warranty provided by the manufacturer of such components and accessories.

SERVICE POLICY

1. Obtain as much information as possible concerning the problem through personal observation by yourself or other authorized personnel

familiar with the job and equipment: include model, serial and/or part numbers, voltages, speeds and any other special identifying

features. Be prepared to discuss the situation in detail.

2. All authorized labor charges will be based on straight time. Hourly rates, estimated man hours, and not to exceed total dollar amount

required for corrections are to be agreed upon before authorization is given. There will be no allowances for overtime except in dire

emergencies and then only with prior approval.

3. A verbal agreement may be reached immediately on both the method of correction and the approximate cost. A warranty authorization

number will be assigned for the specific incident. A confirming written authorization will be forwarded to the distributor.

4. The distributor must send an itemized invoice, showing our release number or invoice number and warranty authorization number after

authorized corrections have been made. A credit memo will be issued by accounting after the invoice has been received and approved.

Warranty charges ARE NOT to be deducted from outstanding open account invoices under any circumstances.

5. Any field corrections made prior to an authorization by SPANCO will not be accepted as a warranty charge or the responsibility of

SPANCO. Any modification to the equipment made without the prior approval of the seller will void all warranties. A verbal authorization

for modification may be obtained, in which event a warranty authorization number will be assigned for the specific modification.

A confirming written authorization will be forwarded to the distributor.

This warranty and service policy will be incorporated as a permanent section of the current price book as issued by SPANCO.

SPANCO, Inc.

604 Hemlock Road

Morgantown, PA, 19543

Toll Free: (800) 869-2080

Local: (610) 286-7200

Fax: (610) 286-0085

spanco.com

Вам также может понравиться

- GL Cargo CraneДокумент2 страницыGL Cargo CraneDharmawan100% (1)

- Rotating Axle Application - 115326-18-1100Документ16 страницRotating Axle Application - 115326-18-1100Erc Nunez VОценок пока нет

- Slewing Jib Crane CatalogueДокумент12 страницSlewing Jib Crane CatalogueListianto NugrohoОценок пока нет

- J-76-1 IKS Wellhead Installation and Operation ManualДокумент72 страницыJ-76-1 IKS Wellhead Installation and Operation Manualmam100% (1)

- 15 572 H - 653cvccДокумент54 страницы15 572 H - 653cvccJaime ArreolaОценок пока нет

- Jib Crane IntroductionДокумент12 страницJib Crane IntroductionRameez Ali FaridiОценок пока нет

- Jibjib - Crane - Rev - 1 - Crane - Rev - 1Документ20 страницJibjib - Crane - Rev - 1 - Crane - Rev - 1Matheus BordignonОценок пока нет

- Jib Cranes: Ree StandingДокумент6 страницJib Cranes: Ree StandingtintucinbОценок пока нет

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 300 Jib CranesДокумент16 страницSpare Parts, Instruction and Maintenance Manual For Spanco Model 300 Jib CranesAndres LopezОценок пока нет

- Jib Cranes Brochure PDFДокумент28 страницJib Cranes Brochure PDFEgemen AkbulutОценок пока нет

- Free Standing Jib CranesДокумент7 страницFree Standing Jib CranesJean Grey ValerОценок пока нет

- Verlinde EUROSTYLE GB PDFДокумент8 страницVerlinde EUROSTYLE GB PDFcandra trisilawatiОценок пока нет

- End Carriage DFW S E AssmeblyДокумент52 страницыEnd Carriage DFW S E AssmeblycutenganОценок пока нет

- Cmaa 70 Cmaa 70 Crane Classification: Aisc Crane Building Classification Class A (Scrap Yard) - 500000-2000000 RepДокумент3 страницыCmaa 70 Cmaa 70 Crane Classification: Aisc Crane Building Classification Class A (Scrap Yard) - 500000-2000000 RepmrnicusОценок пока нет

- Rigging FittingsДокумент52 страницыRigging FittingsbhaskarjalanОценок пока нет

- Catalog ChinaДокумент61 страницаCatalog Chinaa.muhammadОценок пока нет

- 3-d Modelling and Finite Element Analysis of Eot CraneДокумент4 страницы3-d Modelling and Finite Element Analysis of Eot CraneGogyОценок пока нет

- ANSI Mh27.1 (2003) Patented Track Underhung Cranes and Monorail SystemsДокумент0 страницANSI Mh27.1 (2003) Patented Track Underhung Cranes and Monorail SystemsJavier Gamboa RОценок пока нет

- Monitor Compliance With Legislative RequirementsДокумент30 страницMonitor Compliance With Legislative Requirementsjosep julius100% (1)

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesДокумент20 страницSpare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesGuillermoОценок пока нет

- GruasДокумент32 страницыGruasP. Guderian MainsteinОценок пока нет

- End Truck Rt/Rs Manual: Installation Operating Maintenance & Spare PartsДокумент29 страницEnd Truck Rt/Rs Manual: Installation Operating Maintenance & Spare PartsKovács EndreОценок пока нет

- 2013 Wright Specifications CatalogДокумент189 страниц2013 Wright Specifications CatalogcenicercОценок пока нет

- AISC Crane Runway TipsДокумент25 страницAISC Crane Runway Tipstpaterno77100% (10)

- Installation of Monorail CraneДокумент28 страницInstallation of Monorail CraneVijay Bhushan EkkaОценок пока нет

- Overview of SAP MM ModuleДокумент167 страницOverview of SAP MM Modulevadamalaiathimoolam100% (2)

- Commercial Catalogue Jib Cranes Low ResДокумент32 страницыCommercial Catalogue Jib Cranes Low Resstalin vОценок пока нет

- Fiji Ports Development ProjectДокумент71 страницаFiji Ports Development ProjectIndependent Evaluation at Asian Development BankОценок пока нет

- ETN ESN ETL KerékszekrenyДокумент66 страницETN ESN ETL KerékszekrenyKovács EndreОценок пока нет

- Trolley Winch DesignДокумент16 страницTrolley Winch DesignUtaya Kumar VeelmuruganОценок пока нет

- Client:: Structural Analysis and Design Report Office BuildingДокумент27 страницClient:: Structural Analysis and Design Report Office BuildingRoshan KejariwalОценок пока нет

- Case StudyДокумент3 страницыCase StudyRavi Jaiswal0% (2)

- Rate Con 7889285Документ2 страницыRate Con 7889285Mustafa Musa Sejdinovic100% (3)

- Design of TEE Sections in BendingДокумент3 страницыDesign of TEE Sections in BendingJimmyОценок пока нет

- Tube Properties PDFДокумент19 страницTube Properties PDFjamoneoОценок пока нет

- Paper Gondola WagonДокумент2 страницыPaper Gondola WagonrentizahariaОценок пока нет

- 06 St. Paul Fire and Marine V MacondrayДокумент2 страницы06 St. Paul Fire and Marine V MacondrayDaryl DumayasОценок пока нет

- R&M Crane AssemblyДокумент76 страницR&M Crane AssemblyJuan Carlos RuizОценок пока нет

- Demag Crane BrochureДокумент20 страницDemag Crane BrochureSugiarto SaptomoОценок пока нет

- Crane Parts - ENG - REL - 002 PDFДокумент38 страницCrane Parts - ENG - REL - 002 PDFJavier E GodoyОценок пока нет

- Manual Misia1 End CarriageДокумент44 страницыManual Misia1 End CarriageEpure GabrielОценок пока нет

- Reidhangarsemail PDFДокумент20 страницReidhangarsemail PDFAnonymous ww55t9CОценок пока нет

- Van Leusden Catalogue 2008Документ66 страницVan Leusden Catalogue 2008Marcel VanОценок пока нет

- GlobalCOAL SCoTA Version 7e - FINALДокумент88 страницGlobalCOAL SCoTA Version 7e - FINALFachransjah Aliunir100% (2)

- AETNA Casualty and Surety Co Vs Pacific Star Line DigestДокумент2 страницыAETNA Casualty and Surety Co Vs Pacific Star Line DigestKlaire EsdenОценок пока нет

- Hydraulic Tubes and PipesДокумент18 страницHydraulic Tubes and Pipeshp_vijaykОценок пока нет

- Beam Design Chapter 9 BДокумент19 страницBeam Design Chapter 9 BjdfdfererОценок пока нет

- Model A360 CatalogДокумент12 страницModel A360 CatalogThomas StempienОценок пока нет

- Gorbel Freestanding I Beam Jib BrochureДокумент28 страницGorbel Freestanding I Beam Jib BrochureMarceloPolicastroОценок пока нет

- Heavy Duty WALKING BEAM SUSPENSIONДокумент3 страницыHeavy Duty WALKING BEAM SUSPENSIONclintonОценок пока нет

- Designing Parametric Bevel ...Документ10 страницDesigning Parametric Bevel ...ankit kumarОценок пока нет

- AsrsДокумент58 страницAsrsaman_88_vermaОценок пока нет

- Idea - Wheel CalculationДокумент35 страницIdea - Wheel Calculationbambang satryojatiОценок пока нет

- Part 14 - Crane & HoistsДокумент11 страницPart 14 - Crane & HoistsrickymmaОценок пока нет

- Trolley Weight EstimationДокумент7 страницTrolley Weight EstimationRaj KumarОценок пока нет

- 4 PulleysДокумент14 страниц4 PulleysMuhammadTaufikAliRahmanОценок пока нет

- Piston Vibrator BrochureДокумент3 страницыPiston Vibrator BrochuregemagdyОценок пока нет

- 3220-CRN-001 - 5t X 8.5m Arm X 30m HOL Pillar Jib Crane - GA Drawing PDFДокумент1 страница3220-CRN-001 - 5t X 8.5m Arm X 30m HOL Pillar Jib Crane - GA Drawing PDFpawan100% (1)

- Mini ContainerДокумент1 страницаMini ContainerRezza AdityaОценок пока нет

- Designing of Cranes With StandardsДокумент95 страницDesigning of Cranes With Standardsank_mehraОценок пока нет

- 080M40 (EN8) Specification Chemical CompositionДокумент1 страница080M40 (EN8) Specification Chemical CompositionAmar ThakurОценок пока нет

- A-344, A-347 Master LinkДокумент1 страницаA-344, A-347 Master LinkAekJayОценок пока нет

- ABB CatalogueДокумент6 страницABB CatalogueNavneet SinghОценок пока нет

- 1635 File2011 Powertec CatalogДокумент26 страниц1635 File2011 Powertec Cataloggojara2009Оценок пока нет

- FEM9.311 EnglДокумент6 страницFEM9.311 EnglPınar SunОценок пока нет

- STAAD Design Parameter GeneratorДокумент48 страницSTAAD Design Parameter GeneratorwxwmnstrОценок пока нет

- Demag DC-PRO4 PDFДокумент176 страницDemag DC-PRO4 PDFRudianto SohandjajaОценок пока нет

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesДокумент20 страницSpare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib Cranesabhi aroteОценок пока нет

- Perf MGMT BSC TrainingДокумент12 страницPerf MGMT BSC Trainingchibssa alemayehuОценок пока нет

- Installation, Operation, & Maintenance Manual: Wall Mounted Articulating Jib CraneДокумент12 страницInstallation, Operation, & Maintenance Manual: Wall Mounted Articulating Jib CraneFernando Gonzales HОценок пока нет

- The U.S. M1911 M1911A1 Pistols and Commercial M1911 Type Pistols - A Shop Manual (PDFDrive) - Unlocked-6Документ15 страницThe U.S. M1911 M1911A1 Pistols and Commercial M1911 Type Pistols - A Shop Manual (PDFDrive) - Unlocked-6Violeta Sosa rosarioОценок пока нет

- Gantrex Technical Bulletin 43 - Riel Ferrocarrilero PDFДокумент2 страницыGantrex Technical Bulletin 43 - Riel Ferrocarrilero PDFalejandroaleman53Оценок пока нет

- SPANCO Jib Crane BrochureДокумент16 страницSPANCO Jib Crane Brochurehessam_seifiОценок пока нет

- Grúas JibДокумент26 страницGrúas Jibalejandroaleman53Оценок пока нет

- SPANCO Jib Crane BrochureДокумент16 страницSPANCO Jib Crane Brochurehessam_seifiОценок пока нет

- LabVIEW Tutorial ManualДокумент250 страницLabVIEW Tutorial ManualCesar Rodriguez Pz100% (1)

- Biraddali Inter-Island Shipping CorporationДокумент1 страницаBiraddali Inter-Island Shipping CorporationBoalan OfficeОценок пока нет

- Technical Efficiency of Container Terminal Operations: A Dea ApproachДокумент19 страницTechnical Efficiency of Container Terminal Operations: A Dea ApproachAndreea BurceaОценок пока нет

- ESM Assignment1 - Prashant Gupta - 2018PGP267Документ2 страницыESM Assignment1 - Prashant Gupta - 2018PGP267Prashant GuptaОценок пока нет

- CB NetworkerДокумент4 страницыCB NetworkerredchaozОценок пока нет

- Management of Shipping Companies Preview PDFДокумент16 страницManagement of Shipping Companies Preview PDFSergioVictorRadovichОценок пока нет

- Asdem London Laytime and Demurrage Brochure 2018-08-13Документ4 страницыAsdem London Laytime and Demurrage Brochure 2018-08-13Khaddou KarimОценок пока нет

- ERICCSONДокумент2 страницыERICCSONHoku's Nick100% (1)

- Swift Society for Worldwide Interbank Financial Telecommunication 環球銀行財務電信協會Документ7 страницSwift Society for Worldwide Interbank Financial Telecommunication 環球銀行財務電信協會Florencia PaisОценок пока нет

- SIMP Model Catch Certificates PDFДокумент9 страницSIMP Model Catch Certificates PDFElvita RizkyОценок пока нет

- International BusinessДокумент66 страницInternational BusinessHarpal Singh MassanОценок пока нет

- DHL Express Optional Services in en PDFДокумент1 страницаDHL Express Optional Services in en PDFPoojaОценок пока нет

- SCM - Subhradeep HazraДокумент22 страницыSCM - Subhradeep HazraSubhradeep HazraОценок пока нет

- 2019 Summary of Annual Work: Taihua Ship Management LimitedДокумент1 страница2019 Summary of Annual Work: Taihua Ship Management LimitedSobuj Biplob BhuyianОценок пока нет

- International Shore Connections For Marine FireДокумент2 страницыInternational Shore Connections For Marine FireMeleti Meleti Meletiou100% (1)

- American President LinesДокумент1 страницаAmerican President LinesJoanne besoyОценок пока нет

- Ship Sheet PDFДокумент5 страницShip Sheet PDFCarlos GonzalezОценок пока нет

- Solution Manual For Horngrens Financial Managerial Accounting 6th EditionДокумент36 страницSolution Manual For Horngrens Financial Managerial Accounting 6th Editioncupric.diaphane1xmf100% (44)

- 04 A SCM Mod E 2014 v1Документ38 страниц04 A SCM Mod E 2014 v1mansie139Оценок пока нет

- Documentation in International ProcurementДокумент36 страницDocumentation in International ProcurementLucky ManyasaОценок пока нет

- Regulation of MoT No. 04/M-Dag/Per/1/2014 Indonesia Export of Processed and Refined/Smelted Mining ProductsДокумент40 страницRegulation of MoT No. 04/M-Dag/Per/1/2014 Indonesia Export of Processed and Refined/Smelted Mining ProductsWishnu BasukiОценок пока нет

- Now If You'l Look To Your Left: A Tour Guide's Manual For Knysna, South AfricaДокумент280 страницNow If You'l Look To Your Left: A Tour Guide's Manual For Knysna, South AfricaMartin HatchuelОценок пока нет