Академический Документы

Профессиональный Документы

Культура Документы

Solid Fuel Boiler: Installation and Operation Manual

Загружено:

Shanthakumar PandianОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Solid Fuel Boiler: Installation and Operation Manual

Загружено:

Shanthakumar PandianАвторское право:

Доступные форматы

07.

2011

SOLI D FUEL BOI LER

I NSTALLATI ON AND OPERATI ON MANUAL

JSPI HEATING PROFESSIONAL

www.kaukora.fi

2

Contents

Contents ............................................................................................................................................... 2

Environmental instructions .................................................................................................................. 3

Packing ............................................................................................................................................. 3

Removal from Service ..................................................................................................................... 3

Operating Principle .............................................................................................................................. 3

Firewood Burning Phases ................................................................................................................ 3

Technical Data ..................................................................................................................................... 4

Parts .................................................................................................................................................. 5

Installation ............................................................................................................................................ 6

Boiler Room ..................................................................................................................................... 6

Stack ................................................................................................................................................. 7

Piping Installation ............................................................................................................................ 7

Electric Wiring ................................................................................................................................. 7

Electrical Diagram ........................................................................................................................... 7

Heat Connection Diagram ................................................................................................................ 8

Boiler Operation and Maintenance ...................................................................................................... 8

Fuel................................................................................................................................................... 8

Start-up ................................................................................................................................................. 9

Control Panel.................................................................................................................................... 9

Firewood burning ........................................................................................................................... 10

Combustion Air Control................................................................................................................. 11

Maintenance ................................................................................................................................... 12

Cleaning ......................................................................................................................................... 13

Troubleshooting ................................................................................................................................. 13

The boiler water temperature does not rise to the desired level ..................................................... 13

The boiler boils and sputters .......................................................................................................... 13

The flue gas temperature is too high .............................................................................................. 13

The flue gas temperature is too low ............................................................................................... 14

The extractor fan won't work ......................................................................................................... 14

Installation record .......................................................................................................................... 15

Warranty......................................................................................................................................... 15

EY Assurance Certificate ................................................................................................................... 16

3

Environmental instructions

Packing

Packing is made of 100 % waste materials.

Dispose of packing in accordance with local

waste disposal requirements.

Removal from Service

The boiler should be delivered to a waste dis-

posal point for electric and electronic compo-

nents.

Operating Principle

ECONATURE-40 is a solid-fuel water-

heating boiler operating on a rotating combus-

tion principle designed for heating systems in

private houses. The rotating combustion tech-

nique used in ECONATURE-40 is even 30 %

more energy saving than the conservative

upper burning technique.

Firewood Burning Phases

DRYING: Dehumidification of firewood.

PYROLYTIC DECOMPOSITION: Wood starts to

break apart and change to coal and gas. Pyro-

lytic decomposition begins at a temperature

above 100 C; when the temperature exceeds

280C the resulting reaction causes heat re-

lease. Secondary combustion (the reaction

between pyrolytic gases and oxygen) begins

at a temperature over 600 C.

REMAINING COAL BURNING: Remaining coal

burns after pyrolytic gases are removed.

After firewood starts to burn the temperature

must rise quickly since secondary burning

will not be efficient until the combustion tem-

perature is high enough. Efficient and clean

combustion implies full control over the burn-

ing process throughout its phases. The rotat-

ing combustion technique uses secondary

firewood burning efficiently where flue gases

provide additional burning in a separate firing

throat and obtain the hottest and cleanest

flame possible simultaneously reducing ha-

zardous flue gas emissions notably. During

the secondary burning process, the flame

temperature exceeds 1000 C making com-

bustion efficient and clean.

4

Technical Data

Power: 40 kW

Weight: 450 kg

Volume: 120 l

Max. temperature: 110 C

Min. temperature: 0 C

Max. pressure: 3.0 bar

Standard pressure: 1.5 bar

Proof-test pressure: 4.0 bar

Power consumption: 0.12 kW

Voltage: 230 V

Frequency: 50 Hz

Body protection: IP 2X

Furnace dimensions: height 600 mm, width

350 mm, and depth 550 mm

5

Parts

1. Flue gas extractor fan

2. 90 flue swiveling joint

3. Filling port

4. Maintenance hatch

5. Cleanout

6. Air chamber hatch

7. Electric leads

8. R32 FH (female threaded) outlet to accu-

mulator

9. R32 FH return from accumulator

10. R15 FH drain connection

11. R25 FH expansion connection

12. R15 FH flue gas sensor / analyzer connec-

tion

13. Sensor panel

14. Flame monitor glass

15. Upper primary air adjusting damper

16. Lower primary air adjusting damper

17. Secondary air adjusting damper

18. Mineral wool insulation 75 mm

19. Ceramic fire bar

20. Turbulent components

21. Firing throat

22. Storage furnace

23. Furnace

24. Convection ducting

6

Installation

When installing follow the requirements be-

low.

The boiler should be installed upright on a

safe level support/surface. There are four ad-

justable legs supplied with the boiler.

It is recommended to fit the boiler with a flue

gas sensor. Flue gas temperature in the boiler

must be at least 150 C at normal use. Tem-

perature can be raised by removing the lowest

turbulent plate.

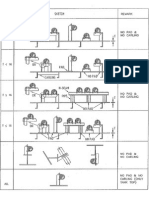

Boiler flue swiveling joint rotates by 90 to

the left, back and right. When rotated to the

right, the joint is turned upside down and fas-

tening and rotation direction of the flue gas

extractor fan motor is changed. Correct rota-

tion direction is marked on the flue swivelling

joint with an arrow.

Boiler Room

Leave free space of at least 1000 m in front of

the filling and maintenance hatches of the

boiler, at least 600 mm over the cleanout

hatch, and 400 mm on one side of the boiler.

Combustion air required for the boiler is sup-

plied from outside and the duct or valve area

should be at least half as large as the stack

area.

An arrow on flue

swiveling joint marks

motor rotation direc-

tion.

To the left,

rotation direction

counter-

clockwise.

To the back,

rotation direction

counter-

clockwise.

To the right,

rotation direction

clockwise, flue

swiveling joint

turned upside

down.

To the back,

rotation direction

clockwise, flue

swiveling joint

turned upside

down.

7

Stack

The stack should be round, 150 mm, whole

brick lined.

The minimum required boiler draft is 10 Pa.

The stack should be high enough to prevent

flue gases from polluting environment nearby.

Piping Installation

The boiler is always connected to a 1800-

3000 liter energy accumulator.

We recommend to install three thermometers

into the battery: bottom, middle, and top.

The system should be fitted with shutoff

valves in order to ensure easy filling and emp-

tying of the boiler, accumulator, and heating

system.

The boiler should contain at least one 1.5 bar

safety relief valve with a blowoff capacity of

at least 150 kg/h if the maximum boiler power

is 60 kW. The blowoff capacity can be dis-

tributed among two or three (maximum)

valves if necessary. To confirm functionality,

at least two safety relief valves are recom-

mended to be used at all times, each having

the required blowoff capacity. The blowoff

line of the safety valve should be laid to the

floor drain to ensure that the drain can be no-

ticed and escaping vapor cannot constitute a

hazard for people or property.

The volume of the membrane expansion tank

should be at least 5 % of the entire water

space in the system.

Piping should be installed to ensure that boiler

operation, maintenance, and cleaning are un-

obstructed.

Electric Wiring

The boiler power supply is 230 V / 50 Hz. The wiring should be connected to the termi-

nal block located behind the openable sensor

panel.

Electrical Diagram

Power

10 A

31.5 mm

2

Charging

pump

Service

switch

Flue gas thermostat 0-

150 C

Lamp

Lamp

Smoke exhauster

thermostat 90 C

Limiter

98 C

Extractor fan

Pump

thermostat

60-90 C

8

Heat Connection Diagram

1. Membrane expansion tank

2. 1.5 bar safety relief valve 2 ea.

3. ECONATURE40 boiler

4. Hot water mixing valve block

5. TERMOVAR DN32 / 72 C charging

pack

6. OVALI-1800 energy accumulator

7. J SPI tubular electric heater max. 5 ea.

8. Heating loop pump

9. Accumulator thermometer 3 ea.

10. Boiler water filling valve

11. Pump thermostat

Boiler Operation and Maintenance

Fuel

Use dry firewood for burning. Using wet

firewood will absorb energy during evapora-

tion and remove most of it through the stack

as unburnt flue gases, thus uselessly loosing

part of energy and resulting in soot formation

in the stack.

Firewood is considered dry when the moisture

content is 20 %. Such wood is lighter in

weight and smashing logs against each other

produces a clearer sound.

ECONATURE-40 is mainly designed for

birch firewood which has a length of 50 cm, a

diameter of 12 cm, and a weight of 1.5 to 1.9

kg.

Other foliferous and coniferous woods are

also suitable for combustion but coniferous

woods cause more contamination to the

boiler. Different woods burn differently.

Lighter woods with a smaller wood diameter

will burn better.

C

C

H

9

Start-up

Check that:

The flue is open and there is no installa-

tion or other waste at its base.

The boiler and the heating system are

filled with water and circulation is work-

ing.

Piping connections are tight.

The system is under pressure.

The safety relief valve is working, i.e.

water runs from the drain line during

valve testing.

Use a small amount of firewood for the first

burning to avoid bar splitting by boiling water

that could soak in the ceramic fire bar.

If the system is filled for the first time the air

dissolved in water will penetrate into the sys-

tem but will be removed from the boiler water

when the temperature exceeds 90 C. When

used for the first time, the system should be

deaerated.

Control Panel

1. Pressure gauge. Measures pressure in the

boiler.

2. Thermometer. Measures water tempera-

ture in the boiler.

3. Pump thermostat 60-90 C. Activates

the charging pump when the boiler water

achieves the setpoint. The setpoint should

be at least 85 C under normal operating

conditions.

4. Smoke exhauster thermostat 90 C. De-

activates the smoke exhauster if the boiler

water achieves the setpoint of 90 C.

5. Flue gas thermostat 0-150 C. Deacti-

vates the smoke exhauster when the flue

gas temperature drops to the setpoint.

6. Power switch. The power switch of the

smoke exhauster and the charging pump.

7. Pump thermostat indicator lamp. On

when the pump is on.

8. Flue gas thermostat indicator lamp. On

when the smoke exhauster is on.

9. Temperature limiter. Deactivates the

smoke exhauster and the charging pump if

the boiler water temperature exceeds

98 C. The limiter will not actuate unless

the instrumentation is improperly used or

until it fails. Acknowledgement is pro-

vided by opening the protective cap and

pressing the limiter. Note that the boiler

water should cool down before acknowl-

edgement.

10

Firewood burning

Position the power switch (6) to ON.

Put about eight 50 cm long pieces of

wood evenly onto the fire bar, altogether

weighing about 6 kg, and insert paper or

birch bark in between to ensure ignition.

Fire the wood and start the smoke ex-

hauster by rotating the thermostat to posi-

tion 0. The filling hatch is kept slightly

open during ignition.

Wait 15-20 minutes to allow about a 10

cm layer of live coals to form on the bar.

Charge blocks (about 18-20 birch logs

altogether weighing about 32 kg) evenly

and closely, bark upward, onto the bar so

that the blocks touch the rear wall of the

furnace.

Set the smoke exhauster thermostat to the

setpoint which is about 90 C. The set-

point is correct if the smoke exhauster

stops when there is a small amount of

coals left in the boiler.

Put new blocks onto the remaining coals.

One firewood charge will burn about 2.5

hours producing about 100 kW heat, i.e. a

1800 liter energy accumulator will be heated

to approximately 50 C.

If the boiler has not been used for a long

while, use a small amount of firewood for the

first burning to avoid bar splitting by boiling

water that could soak in the ceramic fire bar.

Charge the firewood on the fire bar so that

it does not block the firing hole located in

the middle of the bar.

11

Combustion Air Control

For clean boiler convection surfaces, the flue

gas temperature should be approximately 170

C. Raising temperature by increasing power

will reduce the boiler efficiency. Too low

power should not be used either as this will

drop the flue gas temperature below 150 C

due to corrosion hazard.

The required air quantity and ratio for burning

varies depending on the wood to be burnt.

Primary and secondary air is factory adjusted

for birch firewood.

Upper primary air does not have to be ad-

justed under normal operating conditions.

Lower primary air should be adjusted when

the boiler power needs to be changed. The

boiler power grows in correlation with the

flame length.

Secondary air can be adjusted when the boiler

water temperature has been unchanged for 45

minutes after the beginning of combustion.

Upper

primary air

Lower primary

air

Lower seconda-

ry air

12

SECONDARY AIR ADJUSTMENT

FLAME CAUSE ADJUSTMENT

Red flame with black swirling. Secondary air is not enough for

burning. The stack discharges

black or dark smoke.

Add secondary air.

Yellow white flame. Good air distribution. The

stack discharges light grey

smoke.

No need to adjust burning.

Dazzling white flame. Too much secondary air. The

stack discharges white smoke.

Reduce the amount of secon-

dary air.

Maintenance

Regularly check that the system is filled

with water; if you have to add water con-

stantly, then the system is leaking. Con-

stantly adding fresh water causes corro-

sion to the heating system since fresh wa-

ter contains air (oxygen).

The hot system pressure should be lower

than 1.5 bar and the cold system pressure

higher than 0.5 bar ( 1.5 bar safety relief).

The water volume varies as the tempera-

ture, i.e. the higher the temperature, the

higher the volume and the pressure. The

expansion tank serves to smooth such vo-

lume variations.

Check the pre-pressure of the expansion

tank at several years' intervals.

Check the safety relief valves at least

twice a year by rotating the knob/lever in

order to prevent sticking. Add water to the

system after the check.

While burning firewood take care to en-

sure that the boiler water temperature is

always higher than the flue gas due point

i.e. at least 70 C and the flue gas tem-

perature is at least 150 C in order to pre-

vent corrosion.

Remove ashes from the furnace and the

firing throat as required.

13

Cleaning

Keeping a daily watch on the burning process

in the boiler and making necessary adjust-

ments make the cleaning process a problem

free and infrequent job. Good burning forms a

thin grey or coffee colored layer on the firing

surfaces of the boiler, which falls off itself.

Poor burning forms a dirty layer of soot,

ashes, and tar on the firing surfaces and inside

the flue. This prevents thermal energy from

transferring to water thus increasing the flue

gas temperature and lowering the efficiency.

Cleaning should be performed as follows:

1. Remove ashes from the fire bar and fur-

nace.

2. Remove turbulators from the convection

ducts.

3. Clean the convection ducts with a metal

brush.

4. Clean the firing surfaces with a metal

brush.

To control contamination of the boiler check

the flue gas temperature. When the tempera-

ture rises 30 50 C higher as compared with

the clean boiler, it means that the boiler needs

to be cleaned.

Note that tar can stick to the walls of the stor-

age furnace, which is normal so you do not

have to clean the walls.

When cleaning the stack check also the smoke

exhauster blades.

Troubleshooting

The boiler water temperature does not rise to the desired level

Ensure that the primary and secondary air

ratio and access are correct.

Ensure that the firewood is dry.

If there is a cooling coil in the boiler

Make sure that the mixing valve functions

properly.

The boiler boils and sputters

Ensure that there is enough water in the

system and the pressure is between 1 and

1.5 bar. If there is no water in the system

stop the heating process immediately by

extinguishing fire. Do not add water to the

boiler but let it cool down by driving cold

air through it. When the boiler is cool, you

can fill the system with water and restart

heating.

Check that the pump and the mixing valve

are working and check the circulation

through the pump and piping. The air pre-

sent in the system can inhibit water circu-

lation.

Ensure that the furnace bottom bricks are

in place and in good condition.

The flue gas temperature is too high

Clean the boiler. Soot, ashes, and tar con-

taminate the firing surface and act as

thermal insulation.

The flue gas temperature should not ex-

ceed 350 C as the boiler can break down

and the flues cannot withstand high tem-

peratures. Ensure that the primary and

secondary air ratio and volume are cor-

rect.

Ensure that turbulators are in place and in

good condition.

Ensure that the firing throat seal is in good

order.

14

The flue gas temperature is too low

Ensure that the primary and secondary air

ratio and volume are correct.

Ensure that the firewood is dry.

Shorten the turbulators if necessary by

removing the lower plate from each ele-

ment in order to increase the flue gas tem-

perature.

The extractor fan won't work

Ensure that the boiler water temperature is

below 90 C and that the thermostat indi-

cator lamp is on since the set value of the

extractor thermostat is 90 C.

Check the set value of the flue gas ther-

mostat.

Check that the temperature limiter has not

tripped. For acknowledgement, open the

protective cap and press the limiter. How-

ever, let the boiler temperature cool down

before acknowledgement. Find out why

the temperature limiter tripped.

If the extractor fan produces abnormal

sound when working the trouble can be

caused by a motor bearing or a blade.

If the extractor power has dropped then

the blades have to be cleaned.

15

Installation record

Boiler serial number / year

Boiler type

Installer / company

Date

Wiring installer / company

Date

System tuning / training

Installer / company

Date

Factory Date

setting

Flue gas temperature 170 C

Reduced flue pressure

Pump speed

Pump speed

Upper primary air 0

Lower primary air 0

Secondary air 0

Expansion tank pre-

pressure

Signature

Warranty

The warranty is confirmed to be two years for the boiler and one year for the components. The war-

ranty is effective provided that installation, start-up, and maintenance are done or approved by an

authorized agent/dealer in accordance with this manual.

16

EY Assurance Certificate

www.kaukora.fi

certifies that its solid-fuel heating boiler

complies with the pressure vessels requirements according to

the Ministry of Finance and Industry's Decision 938/1999 and Directive 97/23/EY

Modules B1

Quality audit agency

Declared agency 0424

Inspecta EY inspection certificate for the development of RS 419-07

Testing has been conducted to EN 303-5, test agency

SP Sveriges Tekniska Forskningsinstitut, declared agency 1002

Inspection report P7 00360-02

Applicable compliance standards:

EN 303-5

Applicable directives:

PED Directive (97/23/EY 3.3)

EMC Directive (89/336/EEC, 92/31/EEC, and 93/68/EEC)

LVD Directive (73/23/EEC and 93/68/EEC)

Raisio 30.01.09

Kimmo Virtanen

Вам также может понравиться

- Manual ECG - en - v2.1Документ25 страницManual ECG - en - v2.1JeremyYmerehОценок пока нет

- ATMOS Manual DC100 Boiler English 71221Документ32 страницыATMOS Manual DC100 Boiler English 71221gigimalureanuОценок пока нет

- Burner Training BookДокумент32 страницыBurner Training BookNguyễn Thanh Hải100% (3)

- Stratified 24kwe ManualДокумент20 страницStratified 24kwe Manualshivanandr2481Оценок пока нет

- Attack dp35 PDFДокумент22 страницыAttack dp35 PDFb92gllОценок пока нет

- Manufacture OF Producer GasДокумент36 страницManufacture OF Producer GasSai PavanОценок пока нет

- 1.1 Salient Features of CFBC BoilerДокумент17 страниц1.1 Salient Features of CFBC BoilerJAY PARIKHОценок пока нет

- H425 EKO Manual - EN - 30.3.16Документ31 страницаH425 EKO Manual - EN - 30.3.16ghiocel apinteiОценок пока нет

- Instruction2EN PDFДокумент7 страницInstruction2EN PDFIoannis NtouvlisОценок пока нет

- Spec BoilerДокумент9 страницSpec BoilerAchmad MakmuriОценок пока нет

- Production OF Producer GasДокумент19 страницProduction OF Producer Gassaipa1Оценок пока нет

- Burner Training Book PDFДокумент32 страницыBurner Training Book PDFjns1606Оценок пока нет

- Cazan Peleti Attack 8 30 KW Fisa TehnicaДокумент74 страницыCazan Peleti Attack 8 30 KW Fisa TehnicaPredrag MarkovicОценок пока нет

- Co HenДокумент40 страницCo HenHiltonОценок пока нет

- Pag 1 Contract No. 511-4620 Pucala, Peru Description of Plant 1.1. GeneralДокумент15 страницPag 1 Contract No. 511-4620 Pucala, Peru Description of Plant 1.1. GeneralRony Joel Cordova SánchezОценок пока нет

- Xviii. Soot Blowers and Furnace Temperature ProbeДокумент18 страницXviii. Soot Blowers and Furnace Temperature Probeupt vadodaraОценок пока нет

- Keston 170 Boiler ManualДокумент54 страницыKeston 170 Boiler ManualPaul HendersonОценок пока нет

- Fired HeatersДокумент19 страницFired HeatersCelestine OzokechiОценок пока нет

- Kiln-Operation KURT PERAYДокумент99 страницKiln-Operation KURT PERAYAli HüthütОценок пока нет

- Effectiveness of Sootblowers in Boilers Thermal Power StationДокумент7 страницEffectiveness of Sootblowers in Boilers Thermal Power Stationdillipsh123Оценок пока нет

- Suspension Preheater 1998Документ22 страницыSuspension Preheater 1998Sajal Gupta100% (2)

- Review of Waste Heat Recovery Boiler Operation in A Coke Oven PlantДокумент31 страницаReview of Waste Heat Recovery Boiler Operation in A Coke Oven Plantparthi20065768Оценок пока нет

- Boiler Optimization PDFДокумент6 страницBoiler Optimization PDFvijayk1968Оценок пока нет

- Boiler MannualДокумент49 страницBoiler MannualShailenderОценок пока нет

- Extending Kettle LifeДокумент7 страницExtending Kettle LifeSky Ong CwОценок пока нет

- Slimpel Uputstvo Za UoptrebuДокумент25 страницSlimpel Uputstvo Za UoptrebuBrksaОценок пока нет

- Presentation On CDCP Boilers - NEWДокумент145 страницPresentation On CDCP Boilers - NEWmohanivar77100% (4)

- Cazan Cu Gazeificare Attack ManualДокумент84 страницыCazan Cu Gazeificare Attack ManualGeorge RomanescuОценок пока нет

- Basics of Thermal Power PlantДокумент119 страницBasics of Thermal Power Plantsiva7448163Оценок пока нет

- Manual For Installation and Maintenance: Therm Trio 90Документ20 страницManual For Installation and Maintenance: Therm Trio 90Marko ManevskiОценок пока нет

- STEAM SavingДокумент30 страницSTEAM SavingShariq AliОценок пока нет

- Thermal Power PlantДокумент44 страницыThermal Power PlantArun kumar rouniyarОценок пока нет

- TPV PDFДокумент2 страницыTPV PDFAntyox StarkОценок пока нет

- Paperwhr SBДокумент10 страницPaperwhr SBSuchismita Bhattacharya BhaumikОценок пока нет

- GSL 1100X6Документ19 страницGSL 1100X6Adolfo LopezОценок пока нет

- IGNIS Uputstvo ENGДокумент13 страницIGNIS Uputstvo ENGVeronica WaltersОценок пока нет

- Auxiliary BoilerДокумент56 страницAuxiliary BoilerNirdosh AnanthОценок пока нет

- ATD Unit-4 NotesДокумент44 страницыATD Unit-4 NotesSanjay KatreddyОценок пока нет

- DR NTTPSДокумент41 страницаDR NTTPSnagasuresh100% (1)

- Fired Heater Specification PDFДокумент5 страницFired Heater Specification PDFsvnaik14100% (1)

- MitsubishiДокумент10 страницMitsubishiPrabhat Kisku100% (1)

- Boiler ManualДокумент24 страницыBoiler ManualMajidpkОценок пока нет

- June Report For Dennis Tavonga MuzilaДокумент17 страницJune Report For Dennis Tavonga MuzilaDennis MuzilaОценок пока нет

- Steam-Calc-Medina 500 Bed - Rev2Документ8 страницSteam-Calc-Medina 500 Bed - Rev2alialavi2Оценок пока нет

- Module 2 - Boilers - Steam SystemДокумент29 страницModule 2 - Boilers - Steam Systemmadan karkiОценок пока нет

- Steam System Basics: Watertube BoilersДокумент4 страницыSteam System Basics: Watertube BoilersNaОценок пока нет

- Trouble Shooting 30 MW CFBC Boiler Light Up & Load Raising by K.K.parthibanДокумент40 страницTrouble Shooting 30 MW CFBC Boiler Light Up & Load Raising by K.K.parthibanparthi2006576883% (6)

- QAДокумент40 страницQANarmad RavalОценок пока нет

- Boilers, Boiler Fuel andДокумент7 страницBoilers, Boiler Fuel andVivek RamnohurОценок пока нет

- How To Deal Emergencies in Thermal Power PlantДокумент4 страницыHow To Deal Emergencies in Thermal Power PlantEr Mahendra KeshriОценок пока нет

- Boiler 2Документ57 страницBoiler 2azmisabran100% (1)

- 660 MW Super Critical Unit Operation ExperiencesДокумент38 страниц660 MW Super Critical Unit Operation ExperiencesHoncho Abhi Sinha100% (4)

- Uni AssignmentДокумент10 страницUni AssignmentIt's MaharОценок пока нет

- NTPC Ltd. - Simhadri Super Thermal Power Station, Visakhapatnam, Andhra PradeshДокумент27 страницNTPC Ltd. - Simhadri Super Thermal Power Station, Visakhapatnam, Andhra PradeshNiharika KolliОценок пока нет

- SuperCritical BoilerДокумент0 страницSuperCritical BoilerSreenivas100% (1)

- Tugas BoilerДокумент33 страницыTugas BoilerAgus Dwi Nurcahyo JemberОценок пока нет

- Uputstvo Pelet Model 2Документ24 страницыUputstvo Pelet Model 212300ivanОценок пока нет

- Chandrapur CTPS 15 Days Training ReportДокумент21 страницаChandrapur CTPS 15 Days Training ReportUday Wankar0% (1)

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОт EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- DefiniДокумент1 страницаDefiniShanthakumar PandianОценок пока нет

- Offshore Pipe CourseДокумент1 страницаOffshore Pipe CourseShanthakumar PandianОценок пока нет

- Flow DiaДокумент1 страницаFlow DiaShanthakumar PandianОценок пока нет

- Offshore PipelineДокумент1 страницаOffshore PipelineShanthakumar PandianОценок пока нет

- Software Datasheet: Risers, Pipelines and Moorings Design SoftwareДокумент1 страницаSoftware Datasheet: Risers, Pipelines and Moorings Design SoftwareShanthakumar PandianОценок пока нет

- Above Ground PPGДокумент1 страницаAbove Ground PPGShanthakumar PandianОценок пока нет

- The INGAA Foundation, Inc. Guidelines For Crossing Natural Gas PipelinesДокумент1 страницаThe INGAA Foundation, Inc. Guidelines For Crossing Natural Gas PipelinesShanthakumar PandianОценок пока нет

- Product SteelДокумент1 страницаProduct SteelShanthakumar PandianОценок пока нет

- Tube ProductionДокумент1 страницаTube ProductionShanthakumar PandianОценок пока нет

- Steel PipesДокумент1 страницаSteel PipesShanthakumar PandianОценок пока нет

- Features - SteelДокумент1 страницаFeatures - SteelShanthakumar PandianОценок пока нет

- Sequence of Tube Pipe ProductionДокумент1 страницаSequence of Tube Pipe ProductionShanthakumar PandianОценок пока нет

- Gas PPG Guidelines1Документ1 страницаGas PPG Guidelines1Shanthakumar PandianОценок пока нет

- Deeplines 1Документ1 страницаDeeplines 1Shanthakumar PandianОценок пока нет

- PIPE Operation at SiteДокумент1 страницаPIPE Operation at SiteShanthakumar PandianОценок пока нет

- User Interface: Innovative Engineering With Cost-Saving SolutionsДокумент1 страницаUser Interface: Innovative Engineering With Cost-Saving SolutionsShanthakumar PandianОценок пока нет

- Air Vs Flue GraphДокумент1 страницаAir Vs Flue GraphShanthakumar PandianОценок пока нет

- Air Flue GraphДокумент1 страницаAir Flue GraphShanthakumar PandianОценок пока нет

- SpanДокумент1 страницаSpanShanthakumar PandianОценок пока нет

- Electricals 1Документ1 страницаElectricals 1Shanthakumar PandianОценок пока нет

- Linear Coefficient of Thermal Expansion TableДокумент1 страницаLinear Coefficient of Thermal Expansion TableShanthakumar PandianОценок пока нет

- PIPE SpanДокумент1 страницаPIPE SpanJeffery TateОценок пока нет

- Sketch Support Spec 1Документ1 страницаSketch Support Spec 1Shanthakumar PandianОценок пока нет

- PIPE SpanДокумент1 страницаPIPE SpanJeffery TateОценок пока нет

- Modern ToolsДокумент2 страницыModern ToolsShanthakumar PandianОценок пока нет

- Piping Standards and CodesДокумент3 страницыPiping Standards and CodesShanthakumar PandianОценок пока нет

- What Is MathematicsДокумент1 страницаWhat Is MathematicsShanthakumar PandianОценок пока нет

- What Is MathematicsДокумент1 страницаWhat Is MathematicsShanthakumar PandianОценок пока нет

- Piping StandardsДокумент3 страницыPiping StandardsShanthakumar PandianОценок пока нет

- Standards and CodesДокумент2 страницыStandards and CodesShanthakumar PandianОценок пока нет

- OUH Tech ManualДокумент32 страницыOUH Tech ManualChris MartinОценок пока нет

- FMDS0796Документ26 страницFMDS0796Felipe Mees FaracoОценок пока нет

- PCXSMT1603A R410A Light Commercial Series StandardДокумент28 страницPCXSMT1603A R410A Light Commercial Series StandardWai Lwin Ko0% (1)

- Shiploader Rev2 27may2010Документ24 страницыShiploader Rev2 27may2010hazopmanОценок пока нет

- Two-Storey Residential Building PDFДокумент3 страницыTwo-Storey Residential Building PDFFajardo Carl AxelОценок пока нет

- FM Global Property Loss Prevention Data Sheets: List of FiguresДокумент25 страницFM Global Property Loss Prevention Data Sheets: List of FiguresTienda JoselenaОценок пока нет

- VAQ Station For Climate Control: Application NotesДокумент11 страницVAQ Station For Climate Control: Application NotesAnkit JainОценок пока нет

- Air Conditioning System Selection&DesignДокумент17 страницAir Conditioning System Selection&DesignMuhammedShareefОценок пока нет

- Inspection Checklist For: Ductwork: Inspection and Test Plans (ITP) - MUM-15 Duct Work Installation ChecklistДокумент2 страницыInspection Checklist For: Ductwork: Inspection and Test Plans (ITP) - MUM-15 Duct Work Installation Checklistvusal huseynliОценок пока нет

- CO2 Sensor RoomДокумент8 страницCO2 Sensor RoomTrần Khắc ĐộОценок пока нет

- 000 Technical Standards - Luxury & Premium - V1 - Dec-21Документ173 страницы000 Technical Standards - Luxury & Premium - V1 - Dec-21HoangDung LeОценок пока нет

- Engineering Manual Expansion JointsДокумент24 страницыEngineering Manual Expansion JointsbrockОценок пока нет

- Ilide - Info Smacna Industrial Rounded Duct Construction Tabla Contenidos PRДокумент4 страницыIlide - Info Smacna Industrial Rounded Duct Construction Tabla Contenidos PRHarry KoОценок пока нет

- 655 RДокумент12 страниц655 R9810482818Оценок пока нет

- 1.duct System and ADPДокумент26 страниц1.duct System and ADPMUHAMMED SHAFEEQОценок пока нет

- Supco 1Документ12 страницSupco 1Anoop Jacob KunnappuzhaОценок пока нет

- York DM180 Technical GuideДокумент24 страницыYork DM180 Technical GuideMartin BourgonОценок пока нет

- Enga DJ DG Series May 12 r5Документ32 страницыEnga DJ DG Series May 12 r5Christian CuynoОценок пока нет

- Smacna Cad StandardДокумент149 страницSmacna Cad Standardilm11280088% (8)

- GROHE Digital Planning Master 2016 DSДокумент25 страницGROHE Digital Planning Master 2016 DSEduard CollОценок пока нет

- ANSI-AIHA Z9 Committee Recommendations for the Management, Operation, Testing and Maintenance of HVAC Systems - Maintaining Acceptable Indoor Air Quality in Nonindustrial Employee Occupancies through Dilution Venti.pdfДокумент49 страницANSI-AIHA Z9 Committee Recommendations for the Management, Operation, Testing and Maintenance of HVAC Systems - Maintaining Acceptable Indoor Air Quality in Nonindustrial Employee Occupancies through Dilution Venti.pdfSara Adnan100% (1)

- Adh and Adht SeriesДокумент3 страницыAdh and Adht SeriesNurul Aqsha FauziahОценок пока нет

- Solution Air Handling Units: Field Disassembly and ReassemblyДокумент24 страницыSolution Air Handling Units: Field Disassembly and ReassemblyMiguelangel MelendezОценок пока нет

- Mechanical System Modeling Guide: Variable Refrigerant Flow (VRF) SystemsДокумент15 страницMechanical System Modeling Guide: Variable Refrigerant Flow (VRF) SystemsAnonymous 73gEYyEtLОценок пока нет

- CWK - 2.6 - KPNS-CP1Документ3 страницыCWK - 2.6 - KPNS-CP1Ruslans HabibulinsОценок пока нет

- 06 Design Guide Clean RoomsДокумент31 страница06 Design Guide Clean Roomszabiruddin786Оценок пока нет

- PAS 79-1 (2020) Download - Fire Risk Assessment - Non HousingДокумент144 страницыPAS 79-1 (2020) Download - Fire Risk Assessment - Non HousingAaron Fillis100% (1)

- Desktop StudiesДокумент50 страницDesktop StudiesHarshitha namaОценок пока нет

- PVC PE Outer Shealth ComparisonДокумент5 страницPVC PE Outer Shealth ComparisoncatgiadlОценок пока нет

- IMO Conventions MatrixДокумент22 страницыIMO Conventions Matrixhackey720Оценок пока нет