Академический Документы

Профессиональный Документы

Культура Документы

Boiler Feed Water Analisys (Lenntech)

Загружено:

scofiel1Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Boiler Feed Water Analisys (Lenntech)

Загружено:

scofiel1Авторское право:

Доступные форматы

Boiler feed water

Search :

Go!

Contact us

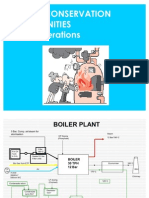

A boiler is a device for generating steam, which consists of two principal parts: the furnace, which provides heat, usually by burning a

fuel, and the boiler proper, a device in which the heat changes water into steam. The steam or hot fluid is then recirculated out of the

boiler for use in various processes in heating applications.

The water circuit of a water boiler can be summarized by the following pictures:

The boiler receives the feed water, which consists of

varying proportion of recovered condensed water

(return water) and fresh water, which has been

purified in varying degrees (make up water). The

make-up water is usually natural water either in its

raw state, or treated by some process before use.

eed-water composition therefore depends on the

!uality of the make-up water and the amount of

condensate returned to the boiler. The steam, which

escapes from the boiler, fre!uently contains li!uid

droplets and gases. The water remaining in li!uid

form at the bottom of the boiler picks up all the

foreign matter from the water that was converted to

steam. The impurities must be blown down by the

discharge of some of the water from the boiler to the

drains. The permissible percentage of blown down at

a plant is strictly limited by running costs and initial

outlay. The tendency is to reduce this percentage to

a very small figure.

Proper treatment of boiler feed water is an important part of operating and maintaining a boiler system. As steam is produced, dissolved

solids become concentrated and form deposits inside the boiler. This leads to poor heat transfer and reduces the efficiency of the boiler.

Dissolved gasses such as oxygen and carbon dioxide will react with the metals in the boiler system and lead to boiler corrosion. In

order to protect the boiler from these contaminants, they should be controlled or removed, trough external or internal treatment. or

more information chec! the boiler water treatment web page.

"n the following table you can find a list of the common boiler feed water contaminants, their effect and

their possible treatment.

ind extra information about the characteristics of boiler feed water.

IMPURITY RESULTING IN GOT RID OF BY COMMENTS

Soluble Gasses

Hyro!en Su"#h$e %H&S'

(ater s)e""s "$*e rotten

e!!s: Tastes +a, an $s

corros$-e to )ost )eta"s.

/erat$on, F$"trat$on, an

Ch"or$nat$on.

Foun )a$n"y $n

!roun0ater, an #o""ute

strea)s.

Car+on D$o1$e %CO&'

Corros$-e, 2or)s car+on$c

ac$ $n conensate.

Deaerat$on, neutra"$3at$on

0$th a"*a"$s.

F$")$n!, neutra"$3$n! a)$nes

use to #re-ent conensate

"$ne corros$on.

O1y!en %O&'

Corros$on an #$tt$n! o2

+o$"er tu+es.

Deaerat$on 4 che)$ca"

treat)ent 0$th %So$u)

Su"#h$te or Hyra3$ne'

P$tt$n! o2 +o$"er tu+es, an

tur+$ne +"aes, 2a$"ure o2

stea) "$nes, an 2$tt$n!s etc.

Suspended Solids

Se$)ent 4 Tur+$$ty S"u!e an sca"e carryo-er. C"ar$2$cat$on an 2$"trat$on.

To"erance o2 a##ro1. 5##)

)a1. 2or )ost a##"$cat$ons,

67##) 2or #ota+"e 0ater.

Or!an$c Matter Carryo-er, 2oa)$n!, e#os$ts

can c"o! #$#$n!, an cause

corros$on.

C"ar$2$cat$on8 2$"trat$on, an

che)$ca" treat)ent

Foun )ost"y $n sur2ace

0aters, cause +y rott$n!

-e!etat$on, an 2ar) run

o22s. Or!an$cs +rea* o0n to

2or) or!an$c ac$s. Resu"ts

$n "o0 o2 +o$"er 2ee90ater

#H, 0h$ch then attac*s +o$"er

tu+es. Inc"ues $ato)s,

)o"s, +acter$a" s"$)es,

$ron:)an!anese +acter$a.

Sus#ene #art$c"es co""ect

on the sur2ace o2 the 0ater

$n the +o$"er an rener

$22$cu"t the "$+erat$on o2

stea) +u++"es r$s$n! to that

sur2ace.. Foa)$n! can a"so

+e attr$+ute to 0aters

conta$n$n! car+onates $n

so"ut$on $n 0h$ch a "$!ht

2"occu"ent #rec$#$tate 0$"" +e

2or)e on the sur2ace o2 the

0ater. It $s usua""y trace to

an e1cess o2 so$u)

car+onate use $n treat)ent

2or so)e other $22$cu"ty

0here an$)a" or -e!eta+"e

o$" 2$ns $ts 0ay $nto the

+o$"er.

Dissolved Colloidal Solids

O$" 4 Grease Foa)$n!, e#os$ts $n +o$"er Coa!u"at$on 4 2$"trat$on

Enters +o$"er 0$th

conensate

Hardness, Ca"c$u) %Ca',

an Ma!nes$u) %M!'

Sca"e e#os$ts $n +o$"er,

$nh$+$ts heat trans2er, an

ther)a" e22$c$ency. In se-ere

cases can "ea to +o$"er tu+e

+urn thru, an 2a$"ure.

So2ten$n!, #"us $nterna"

treat)ent $n +o$"er.

For)s are +$car+onates,

su"#hates, ch"or$es, an

n$trates, $n that orer. So)e

ca"c$u) sa"ts are re-ers$+"y

so"u+"e. Ma!nes$u) reacts

0$th car+onates to 2or)

co)#ouns o2 "o0 so"u+$"$ty.

So$u), a"*a"$n$ty, NaOH,

NaHCO;, Na&CO;

Foa)$n!, car+onates 2or)

car+on$c ac$ $n stea),

causes conensate return

"$ne, an stea) tra#

corros$on, can cause

e)+r$tt"e)ent.

Deaerat$on o2 )a*e9u#

0ater an conensate

return. Ion e1chan!e8

e$on$3at$on, ac$ treat)ent

o2 )a*e9u# 0ater.

So$u) sa"ts are 2oun $n

)ost 0aters. They are -ery

so"u+"e, an cannot +e

re)o-e +y che)$ca"

#rec$#$tat$on.

Su"#hates %SO<'

Har sca"e $2 ca"c$u) $s

#resent

De$on$3at$on

To"erance "$)$ts are a+out

6779;77##) as CaCO;

Ch"or$es, %C"'

Pr$)$n!, $.e. une-en e"$-ery

o2 stea) 2ro) the +o$"er

%+e"ch$n!', carryo-er o2

0ater $n stea) "o0er$n!

stea) e22$c$ency, can e#os$t

as sa"ts on su#erheaters an

tur+$ne +"aes. Foa)$n! $2

#resent $n "ar!e a)ounts.

De$on$3at$on

Pr$)$n!, or the #assa!e o2

stea) 2ro) a +o$"er $n

=+e"ches=, $s cause +y the

concentrat$on so$u)

car+onate, so$u) su"#hate,

or so$u) ch"or$e $n

so"ut$on. So$u) su"#hate $s

2oun $n )any 0aters $n the

US/, an $n 0aters 0here

ca"c$u) or )a!nes$u) $s

#rec$#$tate 0$th soa ash.

Iron %Fe' an

Man!anese %Mn'

De#os$ts $n +o$"er, $n "ar!e

a)ounts can $nh$+$t heat

trans2er.

/erat$on, 2$"trat$on, $on

e1chan!e.

Most co))on 2or) $s 2errous

+$car+onate.

S$"$ca %S$'

Har sca"e $n +o$"ers an

coo"$n! syste)s: tur+$ne

+"ae e#os$ts.

De$on$3at$on8 "$)e soa

#rocess, hot9"$)e93eo"$te

treat)ent.

S$"$ca co)+$nes 0$th )any

e"e)ents to #rouce

s$"$cates. S$"$cates 2or) -ery

tenac$ous e#os$ts $n +o$"er

tu+$n!. >ery $22$cu"t to

re)o-e, o2ten on"y +y

2"ouro$c ac$s. Most cr$t$ca"

cons$erat$on $s -o"at$"e

carryo-er to tur+$ne

co)#onents.

Source: http://energyconcepts.tripod.com/energyconcepts/water_treatment.htm

The principal difficulties caused by water in boiler are:

#caling$

oaming and priming$

"orrosion.

Re2erences

%Water treatment handbook &ol. '-(, )egremont, '**'

Industrial water conditioning, +elts)earborn, '**'

htt#:::000.ther)$a$re.on.ca:+o$"er92ee.ht)"

, -ome . , +ack . , /ore "nfo .

0opyright 1 '**2-(334 5enntech 6ater treatment 7 air purification -olding +.&.

8otterdamseweg 93( /

(4(* -- )elft, The :etherlands

tel: (;<')(3)'= (4.'3.*33

fa>: (;<')(3)'= (4.'4.(2*

e-mail: info?lenntech.com

#earch the 5enntech site

+ack

-ome

0opy

0ontact @s

#end to a friend

Add to favorites

0opyright 1 5enntech '**2-(334

Menu

Odour Control

Water Treatment

Air Treatment

Products

Cooling Towers

Applications

Library

Search

General

cosorb

!io"ilter

Process water

#rin$ing water

#isin"ection

Waste water

%ecycling

Ad&anced O'idation

General

(iltration

)ron remo&al

So"tening

#isin"ection

General

O*one disin"ection

+, disin"ection

Chlorine dio'ide

General

(iltration

!iological

O'idation

#isin"ection

(ysical-Chemical

OT AM series o*one

copure o*one

cosorb

O*one generators

+, disin"ection

(iltration

Analytical e.uipment

Cooling Towers

copure

!io"ilter

Terra*yme

cosorb Home

What is cosorb/

Technology

Test results

MS#S cosorb

OT series 0 g-h 1 2333 g-h

AM series air treatment

O'ygen concentrators

O*one sensor

O*one in4ection

""luent treatment

+, pool range

+, domestic range

Sur"ace disin"ection

Hydroponic horticulture

#rum"ilter

#isc"ilter

%e&ersed osmosis

(ilters and Cartridges

General

O*one in water meters

O*on ambient monitoring

High concentration o*one meter

%ange

Cooling water monitoring

%ange

Cooling water monitoring

#isin"ection

Process water treatment

Waste water treatment

Cooling Tower water treatment

Legionella control

!io"ilm remo&al

General

O*one

+ltra ,iolet

Chlorine dio'ide

General

#isin"ection

)ron remo&al

So"tening

)onen e'change

General

(iltration

O'idation

#isin"ection

!iological

Physical - Chemical

Algemeen

O*one in cooling towers

Cooling water monitoring

(A56s

mail +s

)ndustry lin$s

Standards

Search on $eyword

Website o&er&iew

%oute description

Вам также может понравиться

- How it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useОт EverandHow it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useОценок пока нет

- Power - Plant - Engineering 2 MarksДокумент16 страницPower - Plant - Engineering 2 MarksSachi DhanandamОценок пока нет

- Recommended Procedure For Alkali Boil OutДокумент18 страницRecommended Procedure For Alkali Boil OutsprotkarОценок пока нет

- Section - A: ChemistryДокумент4 страницыSection - A: ChemistryGadde Gopala KrishnaОценок пока нет

- Paper 2 - Set A Solutions: General InstructionsДокумент18 страницPaper 2 - Set A Solutions: General InstructionsKattukolu KishorereddyОценок пока нет

- Presented By:-Rasmiranjan Tarai Biswabhusan Nayak Abhishek Kumar Nilamani Umashankar JenaДокумент27 страницPresented By:-Rasmiranjan Tarai Biswabhusan Nayak Abhishek Kumar Nilamani Umashankar JenaNilamani Umashankar JenaОценок пока нет

- Properties of Solutions - 2018 Filled in Chem 1048Документ87 страницProperties of Solutions - 2018 Filled in Chem 1048Saajid AmraОценок пока нет

- 1.2 Exercise 3 - Ideal Gas EquationДокумент1 страница1.2 Exercise 3 - Ideal Gas EquationAAEFDSAFDSAFОценок пока нет

- Bahasa Inggris - Makalah SaltДокумент10 страницBahasa Inggris - Makalah SaltNurul Fuadi PratiwiОценок пока нет

- Monday Oct 27th Balancing SynthesisdecompositionreactionsДокумент29 страницMonday Oct 27th Balancing Synthesisdecompositionreactionsapi-269239850Оценок пока нет

- Chemistry Form 4 NotesДокумент46 страницChemistry Form 4 Notessegarthana1567% (3)

- 2010 A Level CH P2 AnsДокумент6 страниц2010 A Level CH P2 AnsClementMakОценок пока нет

- SOP Banquet SampleДокумент6 страницSOP Banquet SamplebunmeongОценок пока нет

- Solutions To Crystallization ProblemsДокумент5 страницSolutions To Crystallization ProblemsmadhavanssnОценок пока нет

- Diwali A SSGNДокумент1 страницаDiwali A SSGNPunit GuptaОценок пока нет

- Power Utility Voith - Datasheet-522Документ15 страницPower Utility Voith - Datasheet-522Edo TivruskyОценок пока нет

- Metallic Transmutations by Acetic AcidДокумент7 страницMetallic Transmutations by Acetic Acidfulcanelli1922@libero.it50% (2)

- Rowan HEX HYSYS HandoutДокумент7 страницRowan HEX HYSYS HandoutAyoub SoufmaneОценок пока нет

- Carbonates BicarbonateДокумент6 страницCarbonates BicarbonateYktashОценок пока нет

- Iceland Geothermal PlantsДокумент10 страницIceland Geothermal Plantslov3lyjoannaОценок пока нет

- Industrial Crops and ProductsДокумент8 страницIndustrial Crops and ProductsAiny KusumaОценок пока нет

- Utilities Sungai GerongДокумент11 страницUtilities Sungai GerongRheny BiantariОценок пока нет

- Effecti Vely: S H E L L-And-Tube He AT Ex ChangersДокумент38 страницEffecti Vely: S H E L L-And-Tube He AT Ex ChangersNovi Retno SariОценок пока нет

- Bioclimatic Homes FeatureДокумент3 страницыBioclimatic Homes FeatureJames TweedieОценок пока нет

- Sustainable Hotels - Environmental Reporting According To Green Globe 21, Green Globes Canada / Gem Uk, Ihei Benchmarkhotel and Hilton Environmental ReportingДокумент3 страницыSustainable Hotels - Environmental Reporting According To Green Globe 21, Green Globes Canada / Gem Uk, Ihei Benchmarkhotel and Hilton Environmental ReportingSushant NalawadeОценок пока нет

- Chapter - 2: 2.1 Demineralization (DM) Water Treatment PlantsДокумент17 страницChapter - 2: 2.1 Demineralization (DM) Water Treatment PlantskoolmanojsainiОценок пока нет

- Causes and PreventionДокумент38 страницCauses and PreventionHamed RazaОценок пока нет

- Articol Daniela T Engleza 12.12.13 - CatalinДокумент23 страницыArticol Daniela T Engleza 12.12.13 - Catalindanibiz2Оценок пока нет

- Answers Chemistry, 12e (Brown, LeMay, Bursten, Murphy) Chapter 3, 4, & 10Документ11 страницAnswers Chemistry, 12e (Brown, LeMay, Bursten, Murphy) Chapter 3, 4, & 10Jose RiveraОценок пока нет

- Anion-Cation BalancesДокумент4 страницыAnion-Cation BalancesFikri Adam DermawanОценок пока нет

- 1314lab - Reaction Prediction and ObservationsshortДокумент3 страницы1314lab - Reaction Prediction and Observationsshortapi-239420863Оценок пока нет

- Idiomatic Expressions Iftikhar Ahmed M.A.English, M.A.TEFL, B.ED Bright Future College Muridke 03004760528Документ1 страницаIdiomatic Expressions Iftikhar Ahmed M.A.English, M.A.TEFL, B.ED Bright Future College Muridke 03004760528Ansir YaqoobОценок пока нет

- Restaurant Procedure 2-1Документ23 страницыRestaurant Procedure 2-1mackybhoyamoresОценок пока нет

- Related Texts: Suggested Books As Authorized by GuidesДокумент9 страницRelated Texts: Suggested Books As Authorized by GuidesSama Sh Al-araj0% (1)

- Effect of Li Co Addition On The Sintering Behavior and Physical Properties of PZT-PZN-PMNN CeramicsДокумент5 страницEffect of Li Co Addition On The Sintering Behavior and Physical Properties of PZT-PZN-PMNN CeramicsJudith Ramirez MorenoОценок пока нет

- Chemical Properties Reactivity of Alkenes: Double Covalent BondДокумент24 страницыChemical Properties Reactivity of Alkenes: Double Covalent BondJaybeeAngelОценок пока нет

- TSXFV Vxfaxfbx Q: 140,91 (M) (Kondisi Gembur)Документ2 страницыTSXFV Vxfaxfbx Q: 140,91 (M) (Kondisi Gembur)hendrawantsОценок пока нет

- CSC ProjectДокумент11 страницCSC Projectapi-248118605Оценок пока нет

- 1a Model SolutionДокумент15 страниц1a Model SolutionRamKannanОценок пока нет

- Distillation Column Design MulticomponentДокумент23 страницыDistillation Column Design Multicomponentsuleman205100% (1)

- Total Points Noted in Each Section Must Clearly Show Equations With Values and Units, Drawings, Assumptions, Etc.Документ7 страницTotal Points Noted in Each Section Must Clearly Show Equations With Values and Units, Drawings, Assumptions, Etc.ARUNGREESMAОценок пока нет

- 2012 Edexcel Foundation A Paper 2Документ23 страницы2012 Edexcel Foundation A Paper 2Brenda WaltersОценок пока нет

- Food Processing NC IIДокумент9 страницFood Processing NC IIChenelly Doromal Alcasid100% (1)

- Keep The Heat AnswersДокумент6 страницKeep The Heat AnswersCarl WeinfieldОценок пока нет

- Role of Solid in Purifying Waste Water EffluentДокумент9 страницRole of Solid in Purifying Waste Water EffluentYogendra Patil75% (4)

- 05 - PumpsДокумент77 страниц05 - PumpsMichelle SmithОценок пока нет

- Yishun Town Secondary School: Mid Year Examination 2010 Secondary 2 Express Lower Secondary ScienceДокумент15 страницYishun Town Secondary School: Mid Year Examination 2010 Secondary 2 Express Lower Secondary ScienceAgustina TedjaОценок пока нет

- MECHANICAL VIBRATIONS RAO 4th EDITION Solution ManualДокумент4 страницыMECHANICAL VIBRATIONS RAO 4th EDITION Solution ManualOwombi0% (3)

- Vapour Absorption Refregiration CycleДокумент26 страницVapour Absorption Refregiration CycleM Uzair Shaikh100% (1)

- Day: Monday Date: July 10 Name: - IC: - Class: Lower Six Science Experiment 1 Topic: PurposeДокумент4 страницыDay: Monday Date: July 10 Name: - IC: - Class: Lower Six Science Experiment 1 Topic: Purposealiengamerz1152Оценок пока нет

- SOLAR AIR (Standard)Документ5 страницSOLAR AIR (Standard)pingui1790Оценок пока нет

- Kuliah 2 Perpan 1Документ9 страницKuliah 2 Perpan 1Yongky Harja Winata VengeancyОценок пока нет

- Paper 2 - Set B Answer Key: General InstructionsДокумент13 страницPaper 2 - Set B Answer Key: General Instructionsash_chhatbarОценок пока нет

- Properties & Units Hydrolysis Constant (K)Документ2 страницыProperties & Units Hydrolysis Constant (K)Daniel Pulido RojasОценок пока нет

- Sunday BulletinДокумент2 страницыSunday BulletinRandallMassengillОценок пока нет

- Water and Steam Circulation SystemДокумент79 страницWater and Steam Circulation SystemAshwin NarayanОценок пока нет

- Maxims and Instructions for the Boiler Room: Useful to Engineers, Firemen & Mechanics; Relating to Steam Generators, Pumps, Appliances, Steam Heating, Practical Plumbing, etcОт EverandMaxims and Instructions for the Boiler Room: Useful to Engineers, Firemen & Mechanics; Relating to Steam Generators, Pumps, Appliances, Steam Heating, Practical Plumbing, etcОценок пока нет

- AGFA Radiographer's Weld InterpretationДокумент23 страницыAGFA Radiographer's Weld Interpretationscofiel1Оценок пока нет

- Filler Material Selection GuideДокумент32 страницыFiller Material Selection GuidemaknileОценок пока нет

- Gorbel Crane CatalogueДокумент14 страницGorbel Crane Cataloguescofiel1Оценок пока нет

- Iso 9934 1 2016 en PDFДокумент8 страницIso 9934 1 2016 en PDFedcam13Оценок пока нет

- BS en ISO 9934-3-2007, NondestructiveДокумент20 страницBS en ISO 9934-3-2007, Nondestructivescofiel1Оценок пока нет

- 7 ASNT - Q&A - Book - D - Liquid - PenetrantДокумент40 страниц7 ASNT - Q&A - Book - D - Liquid - Penetrantangel507p90% (10)

- Asmeb30.18 2004 PDFДокумент34 страницыAsmeb30.18 2004 PDFscofiel1Оценок пока нет

- Wire Hoist CatalogueДокумент21 страницаWire Hoist Cataloguescofiel1Оценок пока нет

- Discontinued NER1 SeriesДокумент42 страницыDiscontinued NER1 Seriesscofiel1Оценок пока нет

- IACS NDT ForginsДокумент18 страницIACS NDT Forginsflore73Оценок пока нет

- DBhoist CatalogueДокумент8 страницDBhoist Cataloguescofiel1Оценок пока нет

- Bureau Veritas Materials and WeldingДокумент227 страницBureau Veritas Materials and Weldingscofiel1Оценок пока нет

- Crane CatalogueДокумент12 страницCrane Cataloguescofiel1Оценок пока нет

- IACS - REC - 20 NDT of Ship Hull Steel StructuresДокумент11 страницIACS - REC - 20 NDT of Ship Hull Steel Structuresalinor_tnОценок пока нет

- MQPS 0 1 WPQДокумент29 страницMQPS 0 1 WPQscofiel1Оценок пока нет

- IACS For Non Destructive Examination of Marine Steel CastinДокумент15 страницIACS For Non Destructive Examination of Marine Steel Castinscofiel1Оценок пока нет

- Bs en 729-4-1995-Quality Requirements For Welding PDFДокумент10 страницBs en 729-4-1995-Quality Requirements For Welding PDFscofiel1Оценок пока нет

- ABS Rules For Building and ClassingДокумент80 страницABS Rules For Building and ClassingdianitaherОценок пока нет

- 5asmeb30 2 1 16 PDFДокумент1 страница5asmeb30 2 1 16 PDFscofiel1Оценок пока нет

- Bs en 1435-1997Документ36 страницBs en 1435-1997Jimmy JohnОценок пока нет

- Bureau Veritas Materials and WeldingДокумент227 страницBureau Veritas Materials and Weldingscofiel1Оценок пока нет

- MQPS 0 2 WQДокумент28 страницMQPS 0 2 WQscofiel1Оценок пока нет

- RecUL 47 SHPBDG RPR QSДокумент121 страницаRecUL 47 SHPBDG RPR QSscofiel1Оценок пока нет

- EPOCH LT Training Presentation: Introduction and Basic OperationДокумент58 страницEPOCH LT Training Presentation: Introduction and Basic Operationdhasdj100% (1)

- Overhead Crane Governing Bodies and Specs PDFДокумент1 страницаOverhead Crane Governing Bodies and Specs PDFscofiel1Оценок пока нет

- XRSIM Lessons - Student PacketДокумент59 страницXRSIM Lessons - Student PacketWilliam Pinto HernándezОценок пока нет

- Matrix BS en SatandardДокумент1 страницаMatrix BS en SatandardAliano007100% (1)

- Interpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain SlingsДокумент2 страницыInterpretation of Sections of ASME B30.9 Standard: Alloy Steel Chain Slingsscofiel1Оценок пока нет

- Welding Fabrication Standards CrackedДокумент95 страницWelding Fabrication Standards CrackedNatraji100% (2)

- Eutectic Boiler Repair Single Pages PDFДокумент12 страницEutectic Boiler Repair Single Pages PDFscofiel1Оценок пока нет

- Drum Level ControlДокумент16 страницDrum Level ControlAakanksha GahlautОценок пока нет

- Standard For Closed Feedwater HeatersДокумент80 страницStandard For Closed Feedwater Heatersrenoyabo100% (2)

- BoilerДокумент7 страницBoilerAlexander LakraОценок пока нет

- Instrument Index List 10089-1E-J0X-J000-00001: Saleh MansiДокумент29 страницInstrument Index List 10089-1E-J0X-J000-00001: Saleh Mansimohamed abourayaОценок пока нет

- Boiler Furnace PDFДокумент8 страницBoiler Furnace PDFசுந்தர மூர்த்தி சேப்பிளையார்Оценок пока нет

- General Plant Operation EnggДокумент243 страницыGeneral Plant Operation Enggsumusail100% (3)

- Front Page and Expirement Number 1Документ3 страницыFront Page and Expirement Number 1Ron Kristian OpolintoОценок пока нет

- Tadit: Why Condensate Recovery System (CRS) ?Документ2 страницыTadit: Why Condensate Recovery System (CRS) ?Himanshu PanchalОценок пока нет

- Barge Mounted Power Plants Full PaperДокумент12 страницBarge Mounted Power Plants Full PaperGyoheeОценок пока нет

- Titanium Complete ReportДокумент26 страницTitanium Complete ReportRohan Stephen Luke67% (3)

- Shivani ReportДокумент26 страницShivani ReportShubham SinghОценок пока нет

- Encon in BoilerДокумент51 страницаEncon in BoilerSatish JajooОценок пока нет

- Operating and Maintenance Manual FOR Horizontal Immersion Heated Steam BoilersДокумент10 страницOperating and Maintenance Manual FOR Horizontal Immersion Heated Steam BoilersSubburajMechОценок пока нет

- MUCLecture 2022 123134814Документ17 страницMUCLecture 2022 123134814Raja ArifОценок пока нет

- Api 570 127-188Документ46 страницApi 570 127-188nancyОценок пока нет

- Boiler Manual Fulton IcxДокумент102 страницыBoiler Manual Fulton IcxReymundo ChanОценок пока нет

- Mini - Power - Station-Report TemplatesДокумент31 страницаMini - Power - Station-Report Templatesمحمد الرمالي100% (1)

- Jericho Hyansalem Wicaksono - 5019201004Документ3 страницыJericho Hyansalem Wicaksono - 5019201004Lucas JerichoОценок пока нет

- Steam Turbine Auxiliaries Question & AnswersДокумент10 страницSteam Turbine Auxiliaries Question & AnswersLaxman Veerepalli100% (1)

- SEM-9486E Boiler Feed Water Chemical TreatmentДокумент19 страницSEM-9486E Boiler Feed Water Chemical TreatmentRexx MexxОценок пока нет

- Disadvantages of Hard Water Boiler TroublesДокумент6 страницDisadvantages of Hard Water Boiler Troubleskhushboo goyalОценок пока нет

- Water ChemistryДокумент144 страницыWater ChemistryprashantshivanagiОценок пока нет

- Feed Water TankДокумент8 страницFeed Water Tankhansmru87Оценок пока нет

- Condensate Water Polishing SystemДокумент257 страницCondensate Water Polishing SystemHamza RaoОценок пока нет

- Final Suratgarh Report PDFДокумент39 страницFinal Suratgarh Report PDFpriyaОценок пока нет

- Gilman Boiler Control Expo06Документ41 страницаGilman Boiler Control Expo06Tapiwa MuzondoОценок пока нет

- Boiler Drum Level Control: Application NoteДокумент2 страницыBoiler Drum Level Control: Application NoteShahОценок пока нет

- Plant Startup Shutdown Sequence Description ForReleaseДокумент65 страницPlant Startup Shutdown Sequence Description ForReleaseAnkurОценок пока нет

- Boiler FundaДокумент37 страницBoiler FundaTanu SinghОценок пока нет

- Learn About Steam - Spirax SarcoДокумент20 страницLearn About Steam - Spirax SarcoGanesh KulalОценок пока нет