Академический Документы

Профессиональный Документы

Культура Документы

Etm API 600 Trim Material

Загружено:

mayukhguhanita20100 оценок0% нашли этот документ полезным (0 голосов)

53 просмотров1 страницаasdasdas

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документasdasdas

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

53 просмотров1 страницаEtm API 600 Trim Material

Загружено:

mayukhguhanita2010asdasdas

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

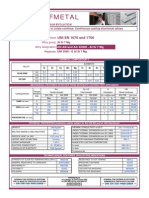

ETM VALVE CO.

,LTD Europe Technology Manufacturer Add:Oubei town, YongJia county,WenZhou City,

ZheJiang province,China Post code:325102 e-mail:info@etmvalve.com website: www.etmvalve.com

ETM Valve

Europe Technology Manufacturer

API 600 TRIM MATERIALS

DISC / WEDGE SEAT RING STEM SMALL

SEAT SURFACES SURFACES HINGE PIN BACK SEAT INTERNAL

(1) (1) (2) PARTS

1 13Cr 13Cr 13Cr 13Cr 13Cr

General erosive or non-corrosive service

between -100 C and 400 C

2 18Cr - 8Ni 18Cr - 8Ni 18Cr - 8Ni 18Cr - 8Ni 18Cr - 8Ni

For moderate pressure in non-erosive,

corrosive service between -265 C and 320

3 25Cr - 20Ni 25Cr - 20Ni 25Cr - 20Ni 25Cr - 20Ni 25Cr - 20Ni

For moderate pressure in corrosive or non

corrosive service between -265 C and 450

4 Hard 13Cr Hard 13Cr 13Cr 13Cr 13Cr As trim No. 1 but for medium pressure

5 HF HF 13Cr 13Cr 13Cr

High pressure sligthly erosive and

corrosive service between -265 C and 650

5A HF (A) HF (A) 13Cr 13Cr 13Cr As trim No. 5 where Co is not allowed

6 13Cr NiCu alloy 13Cr 13Cr 13Cr As trim No. 1

7 13Cr Hard 13Cr 13Cr 13Cr 13Cr As trim No. 1 for moderate pressure

8 13Cr HF 13Cr 13Cr 13Cr As trim No. 5 for moderate pressure

8A 13Cr HF (A) 13Cr 13Cr 13Cr As trim No. 5A for moderate pressure

9 NiCu alloy NiCu alloy NiCu alloy NiCu alloy NiCu alloy

Very corrosive fluids, erosive-corrosive

service between -240 C and 480 C

10 18Cr - 8Ni - Mo 18Cr - 8Ni - Mo 18Cr - 8Ni - Mo 18Cr - 8Ni - Mo 18Cr - 8Ni - Mo As trim No. 2

11 NiCu alloy HF NiCu alloy NiCu alloy NiCu alloy As trim No. 9 but for medium pressure

12 18Cr - 8Ni - Mo HF 18Cr - 8Ni - Mo 18Cr - 8Ni - Mo 18Cr - 8Ni - Mo As trim No. 10 but for medium pressure

13 19Cr - 29Ni 19Cr - 29Ni 19Cr - 29Ni 19Cr - 29Ni 19Cr - 29Ni

Very corrosive service, for moderate

pressure between -45 C and 320 C

14 19Cr - 29Ni HF 19Cr - 29Ni 19Cr - 29Ni 19Cr - 29Ni As trim No. 13 but for medium pressure

15 HF HF 18Cr - 8Ni 18Cr - 8Ni 18Cr - 8Ni As trim No. 2

16 HF HF 18Cr - 8Ni - Mo 18Cr - 8Ni - Mo 18Cr - 8Ni - Mo As trim No. 10

17 HF HF 18Cr - 10Ni 18Cr - 10Ni 18Cr - 10Ni As trim No. 2

18 HF HF 19Cr - 29Ni 19Cr - 29Ni 19Cr - 29Ni As trim No. 13

MATERIAL TYPE

SERVICE

API 600

TRIM No.

All data, subject to technical changes, are only for information and not for official use.

1) The base materials of disc, wedge and seat ring shall be, at least, equal in corrosion resistance

to that of the body material. (Acc. to API Standard 600)

2) Stemshall be wrought material.

Cr = chromium; Ni = nickel; Co = cobalt; Mo = molybdenum.

HF = Hard Facing using CoCr (commercial name Stellite ) welding wire or electrode AWS a 5.13 E-Co-Cr-A hb >= 350; thickness 1.6 mm

NiCr welding alloy. The suffix Aapplies to NiCr (5A..8A..)

Ni-Cu alloy = Monel

NOTES:

ASTM

%

R S Ap.

Hastelloy B 61 -- 5 28 -- 0,05 1 -- -- -- -- 2,5 -- 588-902 343-392 15 - 50

Hastelloy C 54 -- 6 16 -- 0,08 15,1 -- -- -- 4 2,5 -- 549-892 353-471 10 - 49

Monel 8 400 63 - 68 remaining 3,0 -- 0,5 - 1,5 0,12 -- 3,5 - 4,0 0,05 -- -- -- -- 618-696 -- --

Monel K 500 63 - 70 27 - 33 2,0 -- 1,5 0,25 -- 1,0 0,01 -- -- -- 2,0 - 4,0 892-1049 559-755 30 - 20

Stellite N. 6 -- -- -- -- 0,25 1,40 29 1,20 -- -- 8 60 -- -- -- --

Inconel 625 min. 58 -- max. 5,0 8.0 - 10.0 max. 0,5 max. 0,1 22.0 - 23.0 max. 0,5 max. 0,015 max. 0,4 max. 1.0 max. 0,4 896 483 50

chemical composition % mechanical properties

designation Cu Fe C

Mpa

S W Co Al Mn Mo Ti Ni Cr Si

CHEMICAL COMPOSITION AND MECHANICAL PROPERTIES OF OTHER MATERIALS

Вам также может понравиться

- Materials Data for Cyclic Loading: Low-Alloy SteelsОт EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsРейтинг: 5 из 5 звезд5/5 (2)

- Trim API Materials PDFДокумент1 страницаTrim API Materials PDFleonjoanОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Etm Api 600 Trim Material PDFДокумент1 страницаEtm Api 600 Trim Material PDFbenabdallah131Оценок пока нет

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesОт EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesОценок пока нет

- API 600 Trim Materials Disc Wedge Seat RДокумент1 страницаAPI 600 Trim Materials Disc Wedge Seat RManan DesaiОценок пока нет

- Beric Valves Trim ChartДокумент1 страницаBeric Valves Trim ChartPoncho RmzОценок пока нет

- Trim Number Chart API ValveДокумент2 страницыTrim Number Chart API ValveJuliusMaximus12Оценок пока нет

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- API 600 Trim Number Chart API ValveДокумент2 страницыAPI 600 Trim Number Chart API ValveCésar Oswaldo Aguilera OjedaОценок пока нет

- FSH TigДокумент105 страницFSH TigChee WeiОценок пока нет

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985От EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985Оценок пока нет

- Electrode SelectionДокумент1 страницаElectrode SelectionAbhishek Nag100% (1)

- Monel K500 PDFДокумент6 страницMonel K500 PDFOZAIRTRADELINKОценок пока нет

- UTP Chemical GBДокумент12 страницUTP Chemical GBajaychackotecsoОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- STSДокумент50 страницSTSpcuycsОценок пока нет

- Al en Ab 42000 DatasheetДокумент2 страницыAl en Ab 42000 Datasheetc4pp3ll410_m4tt0Оценок пока нет

- Guia Practica Eleccion AporteДокумент26 страницGuia Practica Eleccion AporteNegrito RosarinoОценок пока нет

- Copper Casting Alloys - Foundry TechnologyДокумент16 страницCopper Casting Alloys - Foundry TechnologyOnilio Firmino de MedeirosОценок пока нет

- Metrode 410NiMo B-11Документ4 страницыMetrode 410NiMo B-11Claudia MmsОценок пока нет

- Data Sheet A-12Документ7 страницData Sheet A-12anon_928750560Оценок пока нет

- Wps PQRДокумент7 страницWps PQRsobariОценок пока нет

- Metrode Cryogenic 308lcf B-37Документ5 страницMetrode Cryogenic 308lcf B-37Claudia MmsОценок пока нет

- P91TPДокумент37 страницP91TPPhong ĐỗОценок пока нет

- URB25Документ4 страницыURB25malika_00Оценок пока нет

- Esab DublexДокумент8 страницEsab DublexSuphi YükselОценок пока нет

- Consumables For E911 Crmo Steel: En/Din AstmДокумент3 страницыConsumables For E911 Crmo Steel: En/Din Astmmohamed AdelОценок пока нет

- Bohler Welding Thermalpower - ENGДокумент24 страницыBohler Welding Thermalpower - ENGghostinshellОценок пока нет

- Aladin SДокумент4 страницыAladin SJeffrey BeanОценок пока нет

- Newco Cast Steel Valves Tech DataДокумент86 страницNewco Cast Steel Valves Tech Dataeduardo goveaОценок пока нет

- VOKSEL Power CablesДокумент33 страницыVOKSEL Power CablesAbyssus TntОценок пока нет

- Electrodes EnglishДокумент139 страницElectrodes Englishcostelino72Оценок пока нет

- Burndy CatalogДокумент79 страницBurndy CatalogRoger Carlos100% (1)

- item8-LNT NiCro60.20Документ1 страницаitem8-LNT NiCro60.20VVan TanОценок пока нет

- Cigweld-Deposited Rates PDFДокумент7 страницCigweld-Deposited Rates PDFNam_HitechОценок пока нет

- Module - НЕС01/Program-НЕС012 Technology and equipment for welding of heavy and power generation (including nuclear) engineeringДокумент11 страницModule - НЕС01/Program-НЕС012 Technology and equipment for welding of heavy and power generation (including nuclear) engineeringVishwas Rao MОценок пока нет

- Select Arc Catalogue Part 1Документ10 страницSelect Arc Catalogue Part 1lionheartedОценок пока нет

- CDA110 Specifaction SheetДокумент5 страницCDA110 Specifaction SheetGendakensОценок пока нет

- 1 Esab Selectin ChartДокумент14 страниц1 Esab Selectin ChartmohamedabubackerОценок пока нет

- ARTY - Aubert Et Duval - Produits - Longs - GB PDFДокумент6 страницARTY - Aubert Et Duval - Produits - Longs - GB PDFScott_B4UОценок пока нет

- Faslt 0020 enДокумент6 страницFaslt 0020 enshashikanth79Оценок пока нет

- Section 10 Useful Information: Steel GuideДокумент1 страницаSection 10 Useful Information: Steel GuideEasun - MR TechnicalОценок пока нет

- Böhler Nibas 625 PW-FD: DescriptionДокумент1 страницаBöhler Nibas 625 PW-FD: DescriptionBBalopesabbОценок пока нет

- Copper and Copper Alloy Ingots and CastingsДокумент2 страницыCopper and Copper Alloy Ingots and CastingspoopОценок пока нет

- SA 387 Grade 91 Class 2Документ4 страницыSA 387 Grade 91 Class 2briang-2Оценок пока нет

- Comprehensive Catalogue 2023 PRECITURN TOOLS NEW 加水印Документ176 страницComprehensive Catalogue 2023 PRECITURN TOOLS NEW 加水印Abdennadher MahdiОценок пока нет

- High Temp. Alloy UNS N02200 N07080: Uns No Description Brand/Trp ASTM EquivalentДокумент36 страницHigh Temp. Alloy UNS N02200 N07080: Uns No Description Brand/Trp ASTM Equivalent윤병택Оценок пока нет

- Valve Material EquivalentsДокумент3 страницыValve Material EquivalentsAndre Villegas Romero100% (1)

- High Temperature Brazing AlloysДокумент0 страницHigh Temperature Brazing AlloysvkmsОценок пока нет

- FST Consumables Guide Section PowdersДокумент34 страницыFST Consumables Guide Section PowdersAnonymous PPIsqPQErОценок пока нет

- Wall Colmonoy Surfacing Alloys Selector ChartДокумент3 страницыWall Colmonoy Surfacing Alloys Selector Chartmp87_ingОценок пока нет

- 27 AprvdGmaДокумент68 страниц27 AprvdGmacereferОценок пока нет

- P91 - Modified 9crmo: Data SheetДокумент7 страницP91 - Modified 9crmo: Data SheetpbanerjeeОценок пока нет

- Raffmetal: UNI EN 1676 and 1706Документ2 страницыRaffmetal: UNI EN 1676 and 1706Anshuman RoyОценок пока нет

- Jash Wall Thimble Mounted Cast Iron Flap Gates / ValvesДокумент2 страницыJash Wall Thimble Mounted Cast Iron Flap Gates / Valvesmayukhguhanita2010Оценок пока нет

- 15 16newДокумент1 страница15 16newmayukhguhanita2010Оценок пока нет

- Impellers SelectionДокумент0 страницImpellers Selectionpeach5Оценок пока нет

- Sigmacover 456: Description Principal CharacteristicsДокумент5 страницSigmacover 456: Description Principal Characteristicsmayukhguhanita2010Оценок пока нет

- ASTM International - Standards For Steel Pipes, Tubes and FittingsДокумент2 страницыASTM International - Standards For Steel Pipes, Tubes and Fittingsmayukhguhanita2010Оценок пока нет

- PR VesselДокумент10 страницPR Vesselmayukhguhanita2010Оценок пока нет

- Garlock Gasket Tech Manual GSK3 1 EmpaquetaduraДокумент57 страницGarlock Gasket Tech Manual GSK3 1 EmpaquetaduraJavier AndrésОценок пока нет

- Is 1364 2 2002Документ19 страницIs 1364 2 2002mayukhguhanita2010Оценок пока нет

- 1 1 6 Blood Splatter Analysis Experimental DesignДокумент4 страницы1 1 6 Blood Splatter Analysis Experimental Designapi-343751193100% (1)

- Gardenia RedddДокумент44 страницыGardenia RedddYasmin Yvonne De Chavez100% (1)

- Chapter 3: Operating-System StructuresДокумент31 страницаChapter 3: Operating-System StructuresDiamond MindglanceОценок пока нет

- Getting Started With DockerДокумент8 страницGetting Started With DockerdenisaОценок пока нет

- As / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1Документ1 страницаAs / SG Gs / Ghe Dimensions For Couplings (Standard) Bore With Keyway According To DIN 6885 T1hadeОценок пока нет

- Fan Motor Basic PartsДокумент7 страницFan Motor Basic PartsMARIO BULANADIОценок пока нет

- Mdce InstallДокумент67 страницMdce Installrmehta26Оценок пока нет

- Invisible EyeДокумент16 страницInvisible EyeSushmita Paul0% (1)

- Payment Advice Outward Telegraphic Transfer: DateДокумент2 страницыPayment Advice Outward Telegraphic Transfer: DateRomanov DalsheОценок пока нет

- O21350 CMMKKДокумент2 страницыO21350 CMMKKwade.hynesoutlook.comОценок пока нет

- Series: 25 TON (222 KN)Документ2 страницыSeries: 25 TON (222 KN)Marius IlcaОценок пока нет

- Atm MachineДокумент7 страницAtm MachineNguyen TungОценок пока нет

- Riphah Project GuidelinesДокумент14 страницRiphah Project GuidelinesTanveer AhmedОценок пока нет

- Abstract Superstructure Conc - Frame WestgateДокумент2 страницыAbstract Superstructure Conc - Frame WestgateTashamiswa MajachaniОценок пока нет

- Experiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsДокумент24 страницыExperiment No. 1: Aim: Study of Tanner Tools THEORY: Tanner ToolsVarun GargОценок пока нет

- Aiwa RM-77 Service ManualДокумент9 страницAiwa RM-77 Service Manualcristianhumberto_reyesaguileraОценок пока нет

- 10 A103 SiteДокумент112 страниц10 A103 SiteGovindaraju HSОценок пока нет

- Professional CV FormatДокумент2 страницыProfessional CV FormatShawn ParkerОценок пока нет

- 9A01304 Fluid MechanicsДокумент4 страницы9A01304 Fluid MechanicssivabharathamurthyОценок пока нет

- Requisites of MISДокумент2 страницыRequisites of MISPrasanna Sharma67% (3)

- Tips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of PaperДокумент3 страницыTips On Printing Half-Sheet PDF Booklets: 1. Print 1 Page of A Booklet To A Full Sheet of Papermyco samОценок пока нет

- Project Goals/ ObjectivesДокумент51 страницаProject Goals/ ObjectivesJoyce Abegail De PedroОценок пока нет

- Colphenebswh 1816Документ2 страницыColphenebswh 1816vinoth kumar SanthanamОценок пока нет

- ' ' Shail Ahmad: Privet of India Acres N Inches List of ClientДокумент3 страницы' ' Shail Ahmad: Privet of India Acres N Inches List of Clientapi-243316402Оценок пока нет

- Spherical Pillow Block Manual (MN3085, 2018)Документ13 страницSpherical Pillow Block Manual (MN3085, 2018)Dillon BuyeОценок пока нет

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Документ2 страницыIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)AmriteshbhaskarОценок пока нет

- ToshibaДокумент316 страницToshibaRitesh SharmaОценок пока нет

- JFo 2 1 PDFДокумент45 страницJFo 2 1 PDFAkbar WisnuОценок пока нет

- A5 MSMD 400WДокумент1 страницаA5 MSMD 400WInfo PLSОценок пока нет

- Lexmark-E 321 Service ManualДокумент184 страницыLexmark-E 321 Service ManualRemysОценок пока нет

- University of Chicago Press Fall 2009 Distributed TitlesОт EverandUniversity of Chicago Press Fall 2009 Distributed TitlesРейтинг: 1 из 5 звезд1/5 (1)