Академический Документы

Профессиональный Документы

Культура Документы

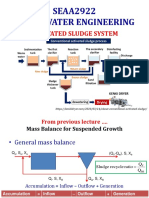

Screenprint Nitrogen Removal Thickening Digesting

Загружено:

Gerry RobertsИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Screenprint Nitrogen Removal Thickening Digesting

Загружено:

Gerry RobertsАвторское право:

Доступные форматы

Thickening and Digestion

Sht 1 of 2

3) Optimize the thickener - digestion system

MEt2 =

MET_eff =

MEt_q2 =

MEt1 =

MEt (q1+q2)=

Xt1 =

Xt2 =

q1 =

q2 =

686

80

606

0

606

0

4

0

152

kg TSS/d

kg TSS/d

kg TSS/d

kg TSS/d

kg TSS/d

kg TSS/m3

kg TSS/m3

m3/d

m3/d

MEv2 =

MEv_eff =

MEv_q2 =

MEva_q2

fav2 =

MEv1 =

MEva1 =

MEvna1 =

480

56

424

163

38%

0

0

0

kg VSS/d

kg VSS/d

kg VSS/d

kg VSS/d

(-)

kg VSS/d

kg VSS/d

kg VSS/d

Rdp =

Rdn =

MEd2 =

MEd1 =

MEd =

MNdi =

Ndi =

56%

16%

132

0

132

13

3,3

(-)

(-)

kg VSS/d

kg VSS/d

kg VSS/d

kg N/d

mg N/l

Rdi =

MEvae =

MEve =

MEte =

MSd =

fav (qdi) =

fat (qdi) =

12,7

31

292

474

199

0,10

0,06

days

kg VSS/d

kg VSS/d

kg TSS/d

kg COD/d

(-)

(-)

Cp =

dH Nat. Gas =

dH CH4 =

dH CH4 =

CH4 content =

Combust. Eff. =

MWCH4

4,2

35,0

810

50,6

65%

80%

16

MCH4 =

Avail. Energy =

Qbg =

Pgen (bg) =

k=

v0 =

Hth =

Sfth =

50

2012

107

23

0,445640024

155,4879808

3

1,5

kJ/(kg.degC)

MJ/m3 nat.gas

kJ/mol CH4

MJ/kg CH4

in biogas

as heat

kg/kmol

kg CH4/d

MJ/d

Nm3/d

kW

l/g TSS

m/d

m

(-)

Cth =

Cdi =

Cng =

Ann. Factor=

Tdes,di =

Tavg,amb =

Tavg,r =

Tmin,r =

876

824

0,35

11,3

30

12

17

12

Hdi

Hdi (b.gl.)

Hdi (a.gl.)

Hcone

6

2

4

3

876

824

0,35

11,3

degrees C

degrees C

degrees C

degrees C

m

m

m

m

Selection of optimal thickener/digester combination according to mimimum total volume; minimum total construction cost or minimum annualized total costs

Xth,r

Xth,l

Fl

Vth

qth

Vdi

Total Volume

Total Constr

Annualized

Energy req. Energy req. Energy Cost

kg/m3

kg/m3

kg/(m2*d)

m3

m3/d

m3

m3

Cost

Total Costs

kW (avg)

kW (max)

(opportunity)

12

9,0

101,4

27

51

642

669

553.000

57.000

25

49

7.900

13

10,1

78,1

35

47

593

628

519.000

53.000

22

44

6.800

14

11,2

59,2

46

43

550

597

494.000

50.000

19

39

5.800

15

12,3

44,2

62

40

514

575

477.000

47.000

16

35

5.000

16

13,3

32,7

83

38

482

565

470.000

45.000

14

32

4.300

17

14,3

23,9

114

36

453

567

473.000

46.000

11

29

3.600

18

15,4

17,3

157

34

428

586

491.000

46.000

10

26

3.000

19

16,4

12,5

219

32

406

624

526.000

49.000

8

23

2.500

20

17,4

8,9

306

30

385

691

585.000

54.000

7

21

2.100

21

18,4

6,3

430

29

367

797

679.000

62.000

5

19

1.600

22

19,5

4,5

608

28

350

958

821.000

73.000

4

17

1.300

23

20,5

3,2

863

26

335

1198

1.032.000

92.000

3

16

900

24

21,5

2,2

1232

25

321

1553

1.343.000

120.000

2

14

600

25

22,5

1,5

1765

24

308

2073

1.799.000

159.000

1

13

300

26

23,5

1,1

2537

23

296

2833

2.465.000

218.000

0

12

27

24,5

0,7

3659

22

285

3944

3.439.000

303.000

-1

10

20028

25,5

0,5

5294

22

275

5569

4.861.000

429.000

-2

9

50029

26,5

0,4

7680

21

266

7946

6.943.000

612.000

-2

8

70030

27,6

0,2

11172

20

257

11429

9.993.000

881.000

-3

7

900Steps:

a) Select the target thickened sludge concentration for minimum total volume, minimum construction costs or minimum annualized construction costs including heating

b) Compare the average available energy with the average energy requirements for heating the digester. Adapt the operational digester temperature if needed.

c) Check the hydraulic residence time in the thickener: adapt settling chars, H, Sf, Xth if required

Minimum total constr. cost solution =

Minimum annualized total cost solution =

Minimum total volume solution =

Selected

470.000

45.000

565

m3

for Xth,r =

for Xth,r =

for Xth,r =

16

16

16

kg TSS/m3

kg TSS/m3

kg TSS/m3

Rhth =

Rhth =

Rhth =

13

13

13

hr

hr

hr

m3

m3/d

kg TSS/d

kg TSS/m3

m3/d

Nett. En. Req.=

14

32

33

78

46

69

kW (avg)

kW (max)

m3/d (avg)

m3/d (max)

kW (avg)

kW (max)

Minimum total annualized costs

Xth,r =

qth =

Vth =

Rhth =

Hth =

Ath =

Dth =

16

38

83

13

3

28

6,0

kg TSS/m3

m3/d

m3

hr

m

m2

m

Vdi =

qdi =

Xte =

Xtdw =

qdw =

482

38

12,5

300

1,6

Nat. Gas req. =

Pgen (tot) =

eur/m3

eur/m3

eur/Nm3 n.g.

(avg of C/M/I)

Annualized

Constr. Cost

49.000

46.000

44.000

42.000

41.000

42.000

43.000

46.000

52.000

60.000

72.000

91.000

119.000

159.000

218.000

303.000

429.000

613.000

882.000

Thickening and Digestion

Sht 2 of 2

Material and insulation:

Fixed steel covers; 6 mm thick; not insulated

Plain concrete wall (below ground); surrounded by moist earth

Plain concrete walls (above ground); 300 mm; insulation

Plain concrete floors; 300 mm; in contact with dry earth

Cover

Walls (b.gl.)

Walls (a.gl)

Floor

Tavg

12

12

12

10

Tmin

0

0

0

-5

Tdi - Tavg

18

18

18

20

Calculation of heating requirements digester

Digester size

Surface area

H

D

Wall (a.gl) Wall (b.gl)

m

m

m2

m2

6

11,7

147

73

6

11,2

141

70

6

10,8

136

68

6

10,4

131

66

6

10,1

127

64

6

9,8

123

62

6

9,5

120

60

6

9,3

117

58

6

9,0

114

57

6

8,8

111

55

6

8,6

108

54

6

8,4

106

53

6

8,3

104

52

6

8,1

102

51

6

7,9

100

50

6

7,8

98

49

6

7,6

96

48

6

7,5

94

47

6

7,4

93

46

Tdi - Tmin

30

30

30

35

U

4,7

1,25

0,7

1,7

Floor

m2

120

112

105

99

93

89

84

81

77

74

71

69

66

64

62

60

58

57

55

Roof

m2

107

99

92

86

80

76

71

68

64

61

58

56

54

51

49

48

46

44

43

Heat loss

Avg.

kW

16,6

15,5

14,6

13,7

13,0

12,3

11,8

11,2

10,8

10,3

9,9

9,6

9,3

8,9

8,7

8,4

8,2

7,9

7,7

MJ/d

1438

1342

1259

1186

1123

1066

1016

971

930

893

859

828

799

773

748

726

705

685

666

Max.

kW

28,1

26,2

24,6

23,2

21,9

20,8

19,8

19,0

18,2

17,4

16,8

16,2

15,6

15,1

14,6

14,2

13,8

13,4

13,0

MJ/d

2426

2264

2124

2001

1894

1799

1714

1638

1569

1506

1449

1397

1348

1304

1263

1224

1188

1155

1124

Influent Heating

Avg.

kW

MJ/d

31,8

2746

29,3

2534

27,2

2353

25,4

2196

23,8

2059

22,4

1938

21,2

1830

20,1

1734

19,1

1647

18,2

1569

17,3

1498

16,6

1432

15,9

1373

15,3

1318

14,7

1267

14,1

1220

13,6

1177

13,1

1136

12,7

1098

Max.

kW

44,0

40,6

37,7

35,2

33,0

31,1

29,3

27,8

26,4

25,1

24,0

23,0

22,0

21,1

20,3

19,6

18,9

18,2

17,6

MJ/d

3801

3509

3258

3041

2851

2683

2534

2401

2281

2172

2074

1983

1901

1825

1755

1690

1629

1573

1521

Вам также может понравиться

- Test Supplement 13Документ16 страницTest Supplement 13jimmys45Оценок пока нет

- Basic Equations For Me 200: de Q-W-M H+V /2+gz + M H+V /2+gz DTДокумент2 страницыBasic Equations For Me 200: de Q-W-M H+V /2+gz + M H+V /2+gz DTVenkatОценок пока нет

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportОт EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportОценок пока нет

- Dwnload Full Physical Chemistry Principles and Applications in Biological Sciences 5th Edition Tinoco Solutions Manual PDFДокумент36 страницDwnload Full Physical Chemistry Principles and Applications in Biological Sciences 5th Edition Tinoco Solutions Manual PDFsithprisus100% (11)

- L7 Activated Sludge SystemДокумент38 страницL7 Activated Sludge SystemNurul AlizaОценок пока нет

- HW 12 Solutions Spring 2012Документ4 страницыHW 12 Solutions Spring 2012Pravallika KolliparaОценок пока нет

- 2 Units Conversion FactorsДокумент2 страницы2 Units Conversion FactorsRalph Saint PierreОценок пока нет

- Physical Chemistry Principles and Applications in Biological Sciences 5th Edition Tinoco Solutions ManualДокумент36 страницPhysical Chemistry Principles and Applications in Biological Sciences 5th Edition Tinoco Solutions Manuallelandsmith4rzm100% (20)

- Appendix C C. Formulae A. Chapter 1 Relations: E 2 - 14 3 2 2 2 E 24 E 6 2 C M 2 F Avog 26 26Документ17 страницAppendix C C. Formulae A. Chapter 1 Relations: E 2 - 14 3 2 2 2 E 24 E 6 2 C M 2 F Avog 26 26Ivelin ValchevОценок пока нет

- Global Vegetation Dynamics: Concepts and Applications in the MC1 ModelОт EverandGlobal Vegetation Dynamics: Concepts and Applications in the MC1 ModelDominique BacheletОценок пока нет

- EXAMPLE1 UASBTreatment Process SWUSTДокумент8 страницEXAMPLE1 UASBTreatment Process SWUSTYannis Thomas100% (1)

- Lecture 18aДокумент4 страницыLecture 18aPankaj SainiОценок пока нет

- KTP Untuk: 1. 2. - G .P 3. V : Praktikum Mekanika Fluida Koefisien LiftДокумент6 страницKTP Untuk: 1. 2. - G .P 3. V : Praktikum Mekanika Fluida Koefisien LiftDedy's StyaОценок пока нет

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsРейтинг: 4 из 5 звезд4/5 (9)

- CLW 10 - 11 - Anaerobic Digestion - Text - 3 Solved ExercisesДокумент10 страницCLW 10 - 11 - Anaerobic Digestion - Text - 3 Solved ExercisesHosea100% (1)

- Logical progression of twelve double binary tables of physical-mathematical elements correlated with scientific-philosophical as well as metaphysical key concepts evidencing the dually four-dimensional basic structure of the universeОт EverandLogical progression of twelve double binary tables of physical-mathematical elements correlated with scientific-philosophical as well as metaphysical key concepts evidencing the dually four-dimensional basic structure of the universeОценок пока нет

- Formula Energi AsДокумент1 страницаFormula Energi Asmigont1690Оценок пока нет

- Interactions between Electromagnetic Fields and Matter: Vieweg Tracts in Pure and Applied PhysicsОт EverandInteractions between Electromagnetic Fields and Matter: Vieweg Tracts in Pure and Applied PhysicsОценок пока нет

- Tutorial 6 - Solution Mixtures Winardi Sani : CO N 2 O 2Документ13 страницTutorial 6 - Solution Mixtures Winardi Sani : CO N 2 O 2wanpudinОценок пока нет

- Catalyst Final CalculationsДокумент47 страницCatalyst Final CalculationsPrable SekhriОценок пока нет

- Merle C. Potter - Termodinâmica - Soluções em InglêsДокумент11 страницMerle C. Potter - Termodinâmica - Soluções em InglêsAdautozanata0% (2)

- Solution of Assignment 3: Bar P K TДокумент6 страницSolution of Assignment 3: Bar P K TMohammad UsmanОценок пока нет

- Example CoagulFloccu1Документ3 страницыExample CoagulFloccu1Adarsh Agrawal100% (3)

- Answers of Problems: Biochemical Engineering: A Textbook For Engineers, Chemists and BiologistsДокумент32 страницыAnswers of Problems: Biochemical Engineering: A Textbook For Engineers, Chemists and BiologistsMcLovin .MOHОценок пока нет

- Chapter 1Документ6 страницChapter 1ampalacios1991100% (2)

- Gases Tutorial 2Документ4 страницыGases Tutorial 2Idil WarsameОценок пока нет

- H, T T T C, T T T: Result & CalculationДокумент8 страницH, T T T C, T T T: Result & CalculationNur' AyuniОценок пока нет

- Chapter03 PDFДокумент61 страницаChapter03 PDFymailioОценок пока нет

- Full Calculations and DiscussionsДокумент27 страницFull Calculations and DiscussionsBudak TescoОценок пока нет

- WW ClarifierДокумент5 страницWW ClarifierrashaesharpeОценок пока нет

- Appendix C C. Formulae A. Chapter 1 Relations: E 2 - 14 3 2 2 2 E 24 E 6 2 C M 2 F Avog 26 26Документ17 страницAppendix C C. Formulae A. Chapter 1 Relations: E 2 - 14 3 2 2 2 E 24 E 6 2 C M 2 F Avog 26 26Ferry BudiОценок пока нет

- Tutorial C5 AnswerДокумент7 страницTutorial C5 AnswerAustin Phua Yun HockОценок пока нет

- Chap3 1Документ4 страницыChap3 1Jose Eduardo MoralesОценок пока нет

- Q L Min X X X M X KG .° C X (40.4 30.1) °C: CalculationДокумент11 страницQ L Min X X X M X KG .° C X (40.4 30.1) °C: CalculationSyasya ZulkipliОценок пока нет

- Cell Kinetics and Fermenter Design 2Документ17 страницCell Kinetics and Fermenter Design 2rhia81% (16)

- Heat Exchanger - Effectiveness - NTU MethodДокумент15 страницHeat Exchanger - Effectiveness - NTU MethodhendiyrОценок пока нет

- Exam 2 Equation Sheet (7697)Документ4 страницыExam 2 Equation Sheet (7697)ZHENGUO LIUОценок пока нет

- CH 02Документ16 страницCH 02alejandra258Оценок пока нет

- Conversion TableДокумент2 страницыConversion Tablemahmood0901instaОценок пока нет

- Chapter 03Документ61 страницаChapter 03JohnJaye100% (7)

- sm8 113Документ1 страницаsm8 113Sadie HnatowОценок пока нет

- Me200 - Eqnsheet 12 Jun 2012Документ2 страницыMe200 - Eqnsheet 12 Jun 2012klinОценок пока нет

- Tester, Modell - Answers To Selected ProblemsДокумент12 страницTester, Modell - Answers To Selected ProblemsCoronel Mustang100% (1)

- 304-Notes 8 BioTreat 2013Документ53 страницы304-Notes 8 BioTreat 2013Harrison WoodwardОценок пока нет

- Conversions CPCДокумент5 страницConversions CPCVoora GowthamОценок пока нет

- Equations of PhysicsДокумент12 страницEquations of PhysicsSingleFemaleLawyerОценок пока нет

- Speed I: Data 1 (Dihitung Oleh Depi Nugraha S)Документ9 страницSpeed I: Data 1 (Dihitung Oleh Depi Nugraha S)Aditya Perdana KusumaОценок пока нет

- Process Design of CondenserДокумент5 страницProcess Design of CondenserVivek VĩvĕОценок пока нет

- Appendix A: Conversion FactorsДокумент18 страницAppendix A: Conversion FactorsJose Fernando Solanilla DuqueОценок пока нет

- Thermodynamics II FormulasДокумент2 страницыThermodynamics II FormulasEvita PhillipsОценок пока нет

- Sirvole K T 2007Документ117 страницSirvole K T 2007Gerry RobertsОценок пока нет

- Analysis of A 27-Year Rainfall Data 1977-2003 in TДокумент13 страницAnalysis of A 27-Year Rainfall Data 1977-2003 in TGerry RobertsОценок пока нет

- International Hydrogeological Map of Europe: Sheet D6 "Athina"Документ10 страницInternational Hydrogeological Map of Europe: Sheet D6 "Athina"Gerry RobertsОценок пока нет

- OmanДокумент1 страницаOmanAlexander Krivov100% (5)

- 134-Article Text-264-1-10-20150927Документ5 страниц134-Article Text-264-1-10-20150927Gerry RobertsОценок пока нет

- Development of Design Storm Hyetographs in Hyper Arid and Arid Regions: Case Study of Sultanate of OmanДокумент11 страницDevelopment of Design Storm Hyetographs in Hyper Arid and Arid Regions: Case Study of Sultanate of OmanGerry RobertsОценок пока нет

- Seeing It in Flow-MotionДокумент16 страницSeeing It in Flow-MotionGerry RobertsОценок пока нет

- Breakwater Design Equations Rubble MoundДокумент5 страницBreakwater Design Equations Rubble MoundGerry RobertsОценок пока нет

- Alg Pap2Документ37 страницAlg Pap2Gerry RobertsОценок пока нет

- 5847104Документ10 страниц5847104ofelix505Оценок пока нет

- Conceptual Design For The Breakwater SystemДокумент16 страницConceptual Design For The Breakwater SystemKremen Mitov100% (1)

- Screenprint Nitrogen Removal AerationДокумент1 страницаScreenprint Nitrogen Removal AerationGerry RobertsОценок пока нет

- 5847104Документ10 страниц5847104ofelix505Оценок пока нет

- 5847104Документ10 страниц5847104ofelix505Оценок пока нет

- 9255 eДокумент38 страниц9255 eGerry RobertsОценок пока нет

- CH 14 - Flow Estimation & RoutingДокумент32 страницыCH 14 - Flow Estimation & RoutingGerry RobertsОценок пока нет

- Effect of Vertical Curvature of Flow at Weir Crest On Discharge CoefficientДокумент14 страницEffect of Vertical Curvature of Flow at Weir Crest On Discharge CoefficientMadusha TisseraОценок пока нет

- 9255 eДокумент38 страниц9255 eGerry RobertsОценок пока нет

- MICHASДокумент8 страницMICHASGerry RobertsОценок пока нет

- What New in HEC-RAS 50 BetaДокумент5 страницWhat New in HEC-RAS 50 BetaGerry RobertsОценок пока нет

- Effect of Vertical Curvature of Flow at Weir Crest On Discharge CoefficientДокумент14 страницEffect of Vertical Curvature of Flow at Weir Crest On Discharge CoefficientMadusha TisseraОценок пока нет

- Screenshots Spreadsheet A1Документ9 страницScreenshots Spreadsheet A1Gerry RobertsОценок пока нет

- What New in HEC-RAS 50 BetaДокумент5 страницWhat New in HEC-RAS 50 BetaGerry RobertsОценок пока нет

- TECH PAPER4 2010 WithcalculationsДокумент14 страницTECH PAPER4 2010 WithcalculationsGerry RobertsОценок пока нет

- Screenprint Nitrogen Removal CostsДокумент1 страницаScreenprint Nitrogen Removal CostsGerry RobertsОценок пока нет

- Grohmann Etal 2009 Geomorphometry09 Surface Roughness-LibreДокумент9 страницGrohmann Etal 2009 Geomorphometry09 Surface Roughness-LibreGerry RobertsОценок пока нет

- Gabions ch1Документ9 страницGabions ch1Gerry RobertsОценок пока нет

- Development of Intensity-Duration-Frequency Relationships For Abha City in Saudi ArabiaДокумент8 страницDevelopment of Intensity-Duration-Frequency Relationships For Abha City in Saudi ArabiaGerry RobertsОценок пока нет

- 1 s2.0 002216949390227Z MainДокумент15 страниц1 s2.0 002216949390227Z MainGerry RobertsОценок пока нет

- Final Project Proposal of Team KumakandaliДокумент9 страницFinal Project Proposal of Team KumakandaliIvy Rose FernandezОценок пока нет

- Mar Env:: Protection of The Marine EnvironmentДокумент9 страницMar Env:: Protection of The Marine EnvironmentHaeisy SimsuangcoОценок пока нет

- Sanggunian Res. No.-2015-110Документ2 страницыSanggunian Res. No.-2015-110Albert CongОценок пока нет

- PLI - Form Septic and Waste Water Systems Referral PDFДокумент1 страницаPLI - Form Septic and Waste Water Systems Referral PDFIsaac KeastОценок пока нет

- BE Monitoring ToolДокумент12 страницBE Monitoring ToolCRISTETA E IGUALDOОценок пока нет

- World's Dirtiest RiverДокумент1 страницаWorld's Dirtiest RiverJoyce PalmosОценок пока нет

- Ra 9003Документ101 страницаRa 9003Charles Rommel TadoОценок пока нет

- Fecal Sludge Management in Bangladesh PDFДокумент4 страницыFecal Sludge Management in Bangladesh PDFMd Zahid Hossain100% (1)

- Stand Alone MCQS: DearsirДокумент4 страницыStand Alone MCQS: DearsirDivyanshi KatiyarОценок пока нет

- RWPPN Sanitary ScheduleДокумент23 страницыRWPPN Sanitary ScheduleKhoa Minh NguyenОценок пока нет

- COP - Sewerage and Sanitary WorksДокумент64 страницыCOP - Sewerage and Sanitary WorksThet Lwin TunОценок пока нет

- Caribbean Studies IA CorrectДокумент27 страницCaribbean Studies IA CorrectSamantha CampbellОценок пока нет

- Scavengers of PayatasДокумент25 страницScavengers of PayatasMia KENA IslaОценок пока нет

- Smart Recycle BinДокумент11 страницSmart Recycle BinZuhairi MuhammadОценок пока нет

- Resume of P Sateesh Kumar PDFДокумент6 страницResume of P Sateesh Kumar PDFsateesh kumarОценок пока нет

- 18 - Method Statement Shop FittingДокумент2 страницы18 - Method Statement Shop FittingWoodsy12100% (3)

- Beswmc Action PlanДокумент3 страницыBeswmc Action PlanBarangay Cato100% (4)

- Carmona Ecology CenterДокумент3 страницыCarmona Ecology CenterMhare Oroceo CasanovaОценок пока нет

- LeatherДокумент7 страницLeatherAyaz BhattiОценок пока нет

- Guidelines For Non Rigid Scheduled Wastes ContainersДокумент17 страницGuidelines For Non Rigid Scheduled Wastes ContainersArika IvyОценок пока нет

- Recycling Construction Demolition Waste in The World and in VietnamДокумент10 страницRecycling Construction Demolition Waste in The World and in Vietnamham29021Оценок пока нет

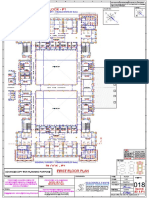

- General Surgery - Female Ward (30 Beds) : NorthДокумент1 страницаGeneral Surgery - Female Ward (30 Beds) : Northkiran raghukiranОценок пока нет

- Lately / in The Past Few Years As Not Only But Also D: in Recent Development Like TransmitsДокумент3 страницыLately / in The Past Few Years As Not Only But Also D: in Recent Development Like TransmitsALEXANDRA ROŞCAОценок пока нет

- How To Grow WheatДокумент2 страницыHow To Grow WheataajjaaОценок пока нет

- Cst945dnv SpecДокумент1 страницаCst945dnv SpecAlexander HidajatОценок пока нет

- Master Plan Engineering Design Criteria Deliverable#15Документ113 страницMaster Plan Engineering Design Criteria Deliverable#15Misama NedianОценок пока нет

- SpeechДокумент1 страницаSpeechbungaОценок пока нет

- The Ball Is Now in Their Hands': Lumumba Responds After City Council Rescinds Emergency DeclarationДокумент2 страницыThe Ball Is Now in Their Hands': Lumumba Responds After City Council Rescinds Emergency DeclarationWLBT NewsОценок пока нет

- SEE4217 Course Outline (2019-20 Sem B)Документ2 страницыSEE4217 Course Outline (2019-20 Sem B)sui sui mangОценок пока нет

- C1GravitySewers PDFДокумент7 страницC1GravitySewers PDFmobtelecomОценок пока нет

- Gut: the new and revised Sunday Times bestsellerОт EverandGut: the new and revised Sunday Times bestsellerРейтинг: 4 из 5 звезд4/5 (392)

- Summary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisОт EverandSummary: Outlive: The Science and Art of Longevity by Peter Attia MD, With Bill Gifford: Key Takeaways, Summary & AnalysisРейтинг: 4.5 из 5 звезд4.5/5 (42)

- The Obesity Code: Unlocking the Secrets of Weight LossОт EverandThe Obesity Code: Unlocking the Secrets of Weight LossРейтинг: 4 из 5 звезд4/5 (6)

- From Darkness to Sight: A Journey from Hardship to HealingОт EverandFrom Darkness to Sight: A Journey from Hardship to HealingРейтинг: 4 из 5 звезд4/5 (3)

- When the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisОт EverandWhen the Body Says No by Gabor Maté: Key Takeaways, Summary & AnalysisРейтинг: 3.5 из 5 звезд3.5/5 (2)

- The Marshmallow Test: Mastering Self-ControlОт EverandThe Marshmallow Test: Mastering Self-ControlРейтинг: 4.5 из 5 звезд4.5/5 (58)

- To Explain the World: The Discovery of Modern ScienceОт EverandTo Explain the World: The Discovery of Modern ScienceРейтинг: 3.5 из 5 звезд3.5/5 (51)

- Algorithms to Live By: The Computer Science of Human DecisionsОт EverandAlgorithms to Live By: The Computer Science of Human DecisionsРейтинг: 4.5 из 5 звезд4.5/5 (722)

- Why We Die: The New Science of Aging and the Quest for ImmortalityОт EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityРейтинг: 4 из 5 звезд4/5 (3)

- A Brief History of Time: From the Big Bang to Black HolesОт EverandA Brief History of Time: From the Big Bang to Black HolesРейтинг: 4 из 5 звезд4/5 (2193)

- Gut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)От EverandGut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Рейтинг: 4 из 5 звезд4/5 (378)

- Sully: The Untold Story Behind the Miracle on the HudsonОт EverandSully: The Untold Story Behind the Miracle on the HudsonРейтинг: 4 из 5 звезд4/5 (103)

- A Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsОт EverandA Brief History of Intelligence: Evolution, AI, and the Five Breakthroughs That Made Our BrainsРейтинг: 4 из 5 звезд4/5 (5)

- Summary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisОт EverandSummary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisРейтинг: 5 из 5 звезд5/5 (8)

- The Egoscue Method of Health Through Motion: A Revolutionary Program That Lets You Rediscover the Body's Power to Protect and Rejuvenate ItselfОт EverandThe Egoscue Method of Health Through Motion: A Revolutionary Program That Lets You Rediscover the Body's Power to Protect and Rejuvenate ItselfРейтинг: 4 из 5 звезд4/5 (8)

- Tales from Both Sides of the Brain: A Life in NeuroscienceОт EverandTales from Both Sides of the Brain: A Life in NeuroscienceРейтинг: 3 из 5 звезд3/5 (18)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseОт EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseРейтинг: 3.5 из 5 звезд3.5/5 (69)

- The Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceОт EverandThe Molecule of More: How a Single Chemical in Your Brain Drives Love, Sex, and Creativity--and Will Determine the Fate of the Human RaceРейтинг: 4.5 из 5 звезд4.5/5 (516)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessОт EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessОценок пока нет

- A Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceОт EverandA Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceРейтинг: 4 из 5 звезд4/5 (51)

- Lessons for Survival: Mothering Against “the Apocalypse”От EverandLessons for Survival: Mothering Against “the Apocalypse”Рейтинг: 5 из 5 звезд5/5 (2)