Академический Документы

Профессиональный Документы

Культура Документы

C - Test 5.6.14 PDF

Загружено:

Suban MukhopadhyayОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

C - Test 5.6.14 PDF

Загружено:

Suban MukhopadhyayАвторское право:

Доступные форматы

www.hilti.in Profis Anchor 2.4.

7

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

08-Jul-14

Specifier's comments:

1 Input data

Anchor type and diameter: HSA-R M16 hnom2

Effective embedment depth: h

ef

= 80 mm, h

nom

= 92 mm

Material: A4

Evaluation Service Report: ETA 11/0374

Issued I Valid: 19-Jul-12 | 19-Jul-17

Proof: design method ETAG (No. 001 Annex C/2010)

Stand-off installation: e

b

= 0 mm (no stand-off); t = 20 mm

Anchor plate: l

x

x l

y

x t = 345 mm x 350 mm x 20 mm; (Recommended plate thickness: not calculated)

Profile: no profile

Base material:

uncracked concrete, C25/30, f

cc

= 30.00 N/mm

2

; h = 375 mm

Reinforcement: no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

no longitudinal edge reinforcement

Reinforcement to control splitting according to ETAG 001, Annex C, 5.2.2.6 present.

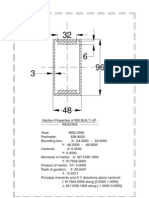

Geometry [mm] & Loading [kN, kNm]

www.hilti.in Profis Anchor 2.4.7

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

2

08-Jul-14

2 Load case/Resulting anchor forces

Load case: Design loads

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Anchor Tension force Shear force Shear force x Shear force y

1 2.233 0.000 0.000 0.000

2 2.233 0.000 0.000 0.000

3 12.412 0.000 0.000 0.000

4 12.412 0.000 0.000 0.000

max. concrete compressive strain: 0.08 []

max. concrete compressive stress:

2.39 [N/mm

2

]

resulting tension force in (x/y)=(0/68): 29.289 [kN]

resulting compression force in (x/y)=(0/-163): 14.289 [kN]

Tension

Compression

1 2

3 4

x

y

3 Tension load (ETAG, Annex C, Section 5.2.2)

Load [kN] Capacity [kN] Utilization

bbbbN

[%] Status

Steel Strength* 12.412 62.643 20 OK

Pullout Strength* N/A N/A N/A N/A

Concrete Breakout Strength** 29.289 47.051 63 OK

Splitting failure** 29.289 57.246 52 OK

* anchor having the highest loading **anchor group (anchors in tension)

3.1 Steel Strength

N

Rk,s

[kN]

gM,s

N

Rd,s

[kN]

N

Sd

[kN]

87.700 1.400 62.643 12.412

3.2 Concrete Breakout Strength

A

c,N

[mm

2

]

A

0

c,N

[mm

2

]

c

cr,N

[mm]

s

cr,N

[mm]

163560 57600 120 240

e

c1,N

[mm]

yec1,N

e

c2,N

[mm]

yec2,N

ys,N

yre,N

k

1

0 1.000 68 0.639 0.983 1.000 10.100

N

0

Rk,c

[kN]

gM,c

N

Rd,c

[kN]

N

Sd

[kN]

39.584 1.500 47.051 29.289

3.3 Splitting failure

A

c,N

[mm

2

]

A

0

c,N

[mm

2

]

c

cr,sp

[mm]

s

cr,sp

[mm]

yh,sp

178600 78400 140 280 1.500

e

c1,N

[mm]

yec1,N

e

c2,N

[mm]

yec2,N

ys,N

yre,N

k

1

0 1.000 68 0.674 0.942 1.000 10.100

N

0

Rk,c

[kN]

gM,sp

N

Rd,sp

[kN]

N

Sd

[kN]

39.584 1.500 57.246 29.289

www.hilti.in Profis Anchor 2.4.7

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

3

08-Jul-14

4 Shear load (ETAG, Annex C, Section 5.2.3)

Load [kN] Capacity [kN] Utilization

bbbbV

[%] Status

Steel Strength (without lever arm)* N/A N/A N/A N/A

Steel failure (with lever arm)* N/A N/A N/A N/A

Pryout Strength* N/A N/A N/A N/A

Concrete edge failure in direction ** N/A N/A N/A N/A

* anchor having the highest loading **anchor group (relevant anchors)

5 Displacements (highest loaded anchor)

Short term loading:

N

Sk

= 9.194 [kN]

dN

= 0.695 [mm]

V

Sk

= 0.000 [kN]

dV

= 0.000 [mm]

dNV

= 0.695 [mm]

Long term loading:

N

Sk

= 9.194 [kN]

dN

= 0.909 [mm]

V

Sk

= 0.000 [kN]

dV

= 0.000 [mm]

dNV

= 0.909 [mm]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements are

valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not included in

this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

6 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Checking the transfer of loads into the base material is required in accordance with ETAG 001, Annex C(2010)Section 7! The software considers

that the grout is installed under the anchor plate without creating air voids and before application of the loads.

The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of ETAG 001, Annex C! For larger

diameters of the clearance hole see Chapter 1.1. of ETAG 001, Annex C!

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to be

followed to ensure a proper installation.

Fastening meets the design criteria!

www.hilti.in Profis Anchor 2.4.7

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

08-Jul-14

Coordinates Anchor [mm]

Anchor x y c

-x

c

+x

c

-y

c

+y

1 -75 -98 113 263 - 385

2 75 -98 263 113 - 385

3 -75 98 113 263 - 190

4 75 98 263 113 - 190

7 Installation data

Anchor plate, steel: - Anchor type and diameter: HSA-R M16 hnom2

Profile: no profile; 0 x 0 x 0 mm Installation torque: 0.080 kNm

Hole diameter in the fixture: d

f

= 18 mm Hole diameter in the base material: 16 mm

Plate thickness (input): 20 mm Hole depth in the base material: 100 mm

Recommended plate thickness: not calculated Minimum thickness of the base material: 160 mm

Cleaning: Manual cleaning of the drilled hole according to instructions for use is required.

7.1 Required accessories

Drilling Cleaning Setting

Suitable Rotary Hammer

Properly sized drill bit

Manual blow-out pump

Installation torque control bar with suitable

screw driver or torque wrench

Hammer

1 2

3 4

98 150 98

7

8

1

9

5

7

8

x

y

173 173

1

7

5

1

7

5

www.hilti.in Profis Anchor 2.4.7

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

|

Page:

Project:

Sub-Project I Pos. No.:

Date:

5

08-Jul-14

8 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas and

security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be strictly

complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted prior to using

the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the data you put in.

Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be put in by you.

Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly with regard to

compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an aid to interpret norms

and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or suitability for a specific

application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for the

regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do not use

the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software in each case

by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or damaged data or

programs, arising from a culpable breach of duty by you.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Harmony BrochureДокумент2 страницыHarmony BrochureSuban MukhopadhyayОценок пока нет

- Condition DischargeДокумент23 страницыCondition DischargeSuban MukhopadhyayОценок пока нет

- Lattice GirderДокумент85 страницLattice GirderSuban MukhopadhyayОценок пока нет

- Disclosure To Promote The Right To InformationДокумент12 страницDisclosure To Promote The Right To InformationSuban MukhopadhyayОценок пока нет

- 4923 1997Документ14 страниц4923 1997Jessica DickersonОценок пока нет

- Odesk Contractor Manual 2013Документ22 страницыOdesk Contractor Manual 2013Suban MukhopadhyayОценок пока нет

- SS304 304L Data SheetДокумент2 страницыSS304 304L Data SheetPrakash KumarОценок пока нет

- Technical DrawingДокумент58 страницTechnical Drawingamacarras95% (21)

- Test Insertplate RGДокумент2 страницыTest Insertplate RGnsureshbabuОценок пока нет

- End Semester Question Paper With Model SolutionДокумент16 страницEnd Semester Question Paper With Model SolutionSwapnil RahaneОценок пока нет

- Dow Corning SealantДокумент2 страницыDow Corning SealantSuban MukhopadhyayОценок пока нет

- BCi Unitized Advantage1Документ11 страницBCi Unitized Advantage1Suban MukhopadhyayОценок пока нет

- MS Built UpДокумент1 страницаMS Built UpSuban MukhopadhyayОценок пока нет

- Gate2014 Brochure PDFДокумент81 страницаGate2014 Brochure PDFsurabhidivyaОценок пока нет

- DikhonditoДокумент394 страницыDikhonditoSuhan ChowdhuryОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- RUKUS April 2011Документ40 страницRUKUS April 2011RUKUS Magazine100% (2)

- QuantAssay Software Manual 11-Mar-2019Документ51 страницаQuantAssay Software Manual 11-Mar-2019LykasОценок пока нет

- Motor CAT C13 AcertДокумент3 страницыMotor CAT C13 AcertJosé Gonzalez100% (4)

- TS SR Chemistry Imp Questions PDFДокумент5 страницTS SR Chemistry Imp Questions PDFUnknown Khan100% (3)

- Ge Fairchild Brochure PDFДокумент2 страницыGe Fairchild Brochure PDFDharmesh patelОценок пока нет

- Chemical Bonds WorksheetДокумент2 страницыChemical Bonds WorksheetJewel Mae MercadoОценок пока нет

- Navy Supplement To The DOD Dictionary of Military and Associated Terms, 2011Документ405 страницNavy Supplement To The DOD Dictionary of Military and Associated Terms, 2011bateljupko100% (1)

- Final Thesis - Aris PotliopoulosДокумент94 страницыFinal Thesis - Aris PotliopoulosCristinaОценок пока нет

- Eating With Chloe Lets EatДокумент150 страницEating With Chloe Lets Eatemily.jarrodОценок пока нет

- Smoldering Combustion: Guillermo ReinДокумент20 страницSmoldering Combustion: Guillermo ReinAhmed HussainОценок пока нет

- Multiple Choice Enzymes Plant and Animal NutritionДокумент44 страницыMultiple Choice Enzymes Plant and Animal Nutritionliufanjing07Оценок пока нет

- 10th Aug. 2011 Structural Calculation (For Sub.) - 03Документ29 страниц10th Aug. 2011 Structural Calculation (For Sub.) - 03Nguyễn Tiến Việt100% (1)

- Updated SAP Cards Requirement JalchdДокумент51 страницаUpdated SAP Cards Requirement Jalchdapi-3804296Оценок пока нет

- IPC's 2 Edition of Guidance Manual For Herbs and Herbal Products Monographs ReleasedДокумент1 страницаIPC's 2 Edition of Guidance Manual For Herbs and Herbal Products Monographs ReleasedRakshaОценок пока нет

- Pre RmoДокумент4 страницыPre RmoSangeeta Mishra100% (1)

- Recycling Mind MapДокумент2 страницыRecycling Mind Mapmsole124100% (1)

- American University of BeirutДокумент21 страницаAmerican University of BeirutWomens Program AssosciationОценок пока нет

- Statistics and Probability Module 3Документ3 страницыStatistics and Probability Module 3Eftychia LeegleeОценок пока нет

- 9701 w09 QP 21Документ12 страниц9701 w09 QP 21Hubbak KhanОценок пока нет

- Module in Pe 103Документ79 страницModule in Pe 103Kym Dacudao100% (1)

- Tran-Effects of Assisted JumpingДокумент5 страницTran-Effects of Assisted JumpingyoungjessОценок пока нет

- Salem RPGДокумент16 страницSalem RPGabstockingОценок пока нет

- Natural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Документ2 страницыNatural Disasters Vocabulary Exercises Fun Activities Games Icebreakers Oneonone Activiti 42747Andrea Tercero VillarroelОценок пока нет

- BS746 2014Документ22 страницыBS746 2014marco SimonelliОценок пока нет

- YellowstoneДокумент1 страницаYellowstoneOana GalbenuОценок пока нет

- #Dr. Lora Ecg PDFДокумент53 страницы#Dr. Lora Ecg PDFمحمد زينОценок пока нет

- ST 36Документ4 страницыST 36ray72roОценок пока нет

- Chemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsДокумент5 страницChemistry Notes: SUBJECT: Leaving Cert Chemistry Level: TEACHER: Tara LyonsSevinc NuriyevaОценок пока нет

- GLP BmsДокумент18 страницGLP BmsDr.Subhashish TripathyОценок пока нет

- LPPДокумент4 страницыLPPMargarida ReisОценок пока нет