Академический Документы

Профессиональный Документы

Культура Документы

Futera XLF Brochure (FXLF-4) 1

Загружено:

Sunil Pawar0 оценок0% нашли этот документ полезным (0 голосов)

26 просмотров6 страницThe futera xlf-4 is a high-efficiency water heater and boiler. It features integral HeatNet (r) control that can act as a boiler management system. XLF can even be networked with other boiler types, including condensing units.

Исходное описание:

Оригинальное название

Futera XLF Brochure (FXLF-4)1

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe futera xlf-4 is a high-efficiency water heater and boiler. It features integral HeatNet (r) control that can act as a boiler management system. XLF can even be networked with other boiler types, including condensing units.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

26 просмотров6 страницFutera XLF Brochure (FXLF-4) 1

Загружено:

Sunil PawarThe futera xlf-4 is a high-efficiency water heater and boiler. It features integral HeatNet (r) control that can act as a boiler management system. XLF can even be networked with other boiler types, including condensing units.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

High Efficiency

Water Heaters and Boilers

FXLF-4

Efficient Power, Sized to Your Vision

The XLF features integral HeatNet

control that can act as a

boiler management system, networking up to sixteen units

without requiring any external control panel. Such advanced

performance in such a small space can benefit older boiler

systems by adding contemporary efficiency for either heating

systems or domestic hot

water. For new construc-

tion, XLF makes

possible a modular con-

figuration that is un-

matched for output

relative to size. It can even

be networked with other

boiler types, including

condensing units: adding

XLF to a condensing

installation can reduce the

number of condensing

units required to meet

load during peak heating

months, when condensing

units efficiency drops.

This application, called

base loading or front-end

loading, can significantly

reduce first costs without

compromising fuel

efficiency.

The Futera XLF is designed with 5-to-1 turndown, up to 88% efficiency, and backed by RBI

reliability and ease of service. Those are just a few of the ways we are helping you solve

todays commercial design challenges. And having double the power in the same compact

dimensions width, depth, and height doesnt hurt either.

Rugged & Reliable: The Turbo Pilot

Another investment in the reliable performance thats

built into the XLF is its patent-pending Turbo Pilot system.

Far more durable than any Hot Surface Ignition and

more robust than a simple direct spark system, the

Turbo Pilot gives burner ignition a sure, powerful source.

UV detection keeps system diagnostics informed

about performance; a technician can also use the

observation port to confirm spark/flame without

removing the pilot or burner assembly. And if

maintenance does need to be performed, a few seconds

is all thats needed to pull, clean, or adjust the pilot.

Smart Controls,

Simplified Diagnostics

The Futera XLF comes standard with HeatNet on board,

ready on installation for a variety of configurations:

stand-alone, part of a Master/Member network using

HeatNet protocol, member in a system for up to 16

boilers, or linked to a BMS. HeatNet maximizes

turndown rates to maintain peak efficiency utilizing

four temperature sensor inputs: outside air, supply

(outlet) temperature, return (inlet) temperature, and

header temperature. It eliminates wall-mounted control

panels and offers an easy-to-read display and intuitive

control menus.

Easy access to control and diagnostic components

speeds installation and service

Four-button touchpad with plain-English

display and intuitive menus simplifies

programming and diagnostics

XLF simplifies service with a special manometer diag-

nostic port that allows technicians to take multiple

pressure readings from a single connection: pilot gas,

pilot air, rate signal, and feedback

XLF Near

Condensing Efficiency

Big-Time Components,

Small Diameter Vent

Like all RBI products, the Futera XLF is built with the

highest-grade components and materials. The heat

exchangers solid bronze headers prevent rust and

corrosion for the life of the unit. XLFs symmetric

air/fuel coupling provides a high degree of safety

while ensuring consistent combustion quality

regardless of changes to fuel or air flow. In addition

to its compact dimensions enabling 2.5 or 4 million

Btuhs to be installed in a small space, its small vent

diameter is easy to work with and reduces vent

material costs. Removal of top and front panels is

simple, streamlining installation and service.

Whether to add efficient low-demand output to a larger existing system, or to

build a highly space- and energy-efficient heat and hot water system from the

ground up, the RBI Futera XLF gives you the power to

develop a solution that fits any design.

DEPENDABLE, EFFICIENT PERFORMANCE

High efficiency, up to 88%

Full modulation with smooth, 5:1 turndown

Sealed combustion/direct vent

Symmetrically air/fuel coupled

Commercial-quality combustion controls

Linked operating control system for multiple unit applications

Gasketless heat exchanger assembly

Low NOx

STANDARD FEATURES

2,500 4,000 MBH

Finned copper tube heat exchanger, ASME 160

psi max WP, 4-pass design

Stainless steel jacket panels

Cast iron headers (boilers)

Bronze headers (water heaters)

Variable speed blower

Digital text annunciator

Mounted & wired flow switch

Mounted & wired low water cutoff

Quick-release service latches

Multiple venting options

Category II or IV

Allows differential pressure zones for

intake air and exhaust

Sealed combustion

Direct vent

Common venting of multiple boilers

Seismic restraint base assembly

HeatNet integrated boiler management system

Modbus protocol for BMS communications

Turbo Pilot (patent-pending design)

Honeywell RM7800 Series flame safeguard

OPTIONAL FEATURES

Cupro-Nickel Finned Tubes

Freeze protection package

BACnet or LonWorks interface module

Honeywell keyboard display module S7800

Outdoor sensor with housing

A Small Step that Makes

Big Plans Possible

The demands of the market changemore energy

efficiency, less mechanical room spaceand your

plans need to change with them. Making a sizable

difference in this evolving market is difficult. But the

latest innovation from RBI will bring your projects

design challenges down to size.

We take pride in engineering a higher degree of

performance from our boilers and water heaters.

But what architects, engineers, installers, and

building owners take from it is something else

entirely: a better way to get their job done.

With the Futera XLF, a new level of performance will

help change the way mechanical room space is

planned forand how domestic hot water and

hydronic heat load is accounted for.

7555 Tranmere Dr., Mississauga, Ontario L5S 1L4 | Tel. 905-670-5888 | Fax 905-670-5782

260 North Elm Street, Westfield, MA 01085 | Tel. 413-568-9571 | Fax 413-568-9613

RBI is a division of Mestek, a leader in commercial and residential HVAC technologies

www.rbiwaterheaters.com

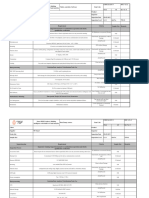

FUTERA XLF

Dimensions & Ratings

*Flow exceeds recommended maximum; use a greater temperature rise or consult manufacturer. Cupronickel heat exchanger should be considered.

Front Left Rear

NOTE: Dimensions are

approximate and

should not be used to

rough-in equipment.

A B C D E F

Model In. cm In. cm In. cm In. cm In. cm In. cm

MB/MW2500 29

1

/8 74.0 55

1

/2 141.0 31

1

/8 79.1 40

1

/4 102.2 33

5

/16 84.8 46

1

/2 118.1

MB/MW3000 29

1

/8 74.0 60 152.4 31

1

/8 79.1 44

3

/4 113.7 37

13

/16 96.0 51 129.5

MB/MW3500 29

1

/8 74.0 64

1

/2 163.8 31

1

/8 79.1 25

9

/16 64.9 42

5

/16 107.5 55

1

/2 141.0

MB/MW4000 29

1

/8 74.0 69 175.3 31

1

/8 79.1 28

5

/8 72.7 46

13

/16 118.9 60 152.4

Dimensions

Dimensions & Ratings

Temperature Rise

Model 40F 22C 60F 33C 80F 44C 100F 56C 120F 67C 140F 78C

MB/MW2500 6445 24397 4297 16265 3223 12199 2578 9759 2148 8132 1841 6971

MB/MW3000 7707 29175 5138 19450 3854 14587 3083 11670 2569 9725 2202 8336

MB/MW3500 9002 34077 6001 22718 4501 17038 3601 13631 3001 11359 2572 9736

MB/MW4000 10300 38990 6867 25993 5150 19495 4120 15596 3443 12997 2943 11140

Hourly Recovery Capacity T (GPH & LPH)

Temperature Rise Across Heat Exchanger

20F 11.1C 25F 13.9C 30F 16.7C 35F 19.4C

Flow Rate Pres. Drop Flow Pres. Drop Flow Rate Pres. Drop Flow Pres. Drop Flow Rate Pres. Drop Flow Pres. Drop Flow Rate Pres. Drop Flow Pres. Drop

Model GPM Ft. Rate l/s kPa GPM Ft. Rate l/s kPa GPM Ft. Rate l/s kPa GPM Ft. Rate l/s kPa

MB/MW2500 217.5 10.05 13.7 29.6 174.0 6.45 11.0 19.0 145.0 3.71 9.1 10.9 124.3 2.79 7.8 8.2

MB/MW3000 261.0 15.20 16.5 44.8 208.8 9.73 13.2 28.7 174.0 6.75 11.0 19.9 149.1 4.65 9.4 13.7

MB/MW3500 304.5* 20.26 19.2 59.7 243.6 13.40 15.4 39.5 203.0 9.56 12.8 28.2 174.0 7.19 11.0 21.2

MB/MW4000 - - - - 278.4* 17.30 17.6 51.0 232.0 12.00 14.6 35.4 198.9 10.48 12.5 30.9

Temperature Rise/Pressure Drop

Input Output Flue Air Connections Weight

Model MBH kW MBH kW Vent Intake Gas Water Lbs Kg

MB/MW2500 2500 733 2148 629 8" 8" 1

1

/2" 4" 1300 590

MB/MW3000 3000 879 2568 752 8" 8" 1

1

/2" 4" 1400 635

MB/MW3500 3500 1026 3000 879 10" 10" 2" 4" 1500 680

MB/MW4000 4000 1172 3432 1006 10" 10" 2" 4" 1600 726

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Edr Designbriefs ChillerplantДокумент28 страницEdr Designbriefs ChillerplantAnonymous PkeI8e84RsОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Modlating Condensing Boiler With Revers ReturnДокумент7 страницModlating Condensing Boiler With Revers ReturnSunil PawarОценок пока нет

- Hot Water Systems Cleaver BrooksДокумент28 страницHot Water Systems Cleaver BrooksSunil Pawar100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Rbi 2000Документ40 страницRbi 2000Sunil PawarОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Futera XLF IOMДокумент44 страницыFutera XLF IOMSunil PawarОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Chiller, Boiler Control ApplicationДокумент108 страницChiller, Boiler Control Applicationthenshan100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- KN Series Control Manual (KNCT2-1011)Документ88 страницKN Series Control Manual (KNCT2-1011)Sunil PawarОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Dectron Indoor Pool Design GuideДокумент28 страницDectron Indoor Pool Design GuideMuhammad Sajid100% (2)

- 38ae-104 at GilpinДокумент16 страниц38ae-104 at GilpinSunil PawarОценок пока нет

- Controls HT800 ControllerInterfaceДокумент10 страницControls HT800 ControllerInterfaceSunil Pawar100% (1)

- 3C - Andrew Brooks Hot Water Piping in TankДокумент34 страницы3C - Andrew Brooks Hot Water Piping in TankSunil PawarОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- 3 Way Unimizer ValvesДокумент3 страницы3 Way Unimizer ValvesSunil PawarОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- List of Practicals Class Xii 2022 23Документ1 страницаList of Practicals Class Xii 2022 23Night FuryОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 3114 Entrance-Door-Sensor 10 18 18Документ5 страниц3114 Entrance-Door-Sensor 10 18 18Hamilton Amilcar MirandaОценок пока нет

- Old Man and The SeaДокумент10 страницOld Man and The SeaXain RanaОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Cognitive Coaching AdelaideДокумент3 страницыCognitive Coaching AdelaideBusiness-Edu100% (2)

- ARHAM FINTRADE LLP - Company, Directors and Contact Details Zauba CorpДокумент1 страницаARHAM FINTRADE LLP - Company, Directors and Contact Details Zauba CorpArun SonejiОценок пока нет

- C7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesДокумент13 страницC7.5 Lecture 18: The Schwarzschild Solution 5: Black Holes, White Holes, WormholesBhat SaqibОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- PTE Writing FormatДокумент8 страницPTE Writing FormatpelizОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- CA Level 2Документ50 страницCA Level 2Cikya ComelОценок пока нет

- Matter Around Me: SC1 - Teaching Science in ElementaryДокумент27 страницMatter Around Me: SC1 - Teaching Science in ElementaryYanna Marie Porlucas Macaraeg50% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- ETSI EG 202 057-4 Speech Processing - Transmission and Quality Aspects (STQ) - Umbrales de CalidaДокумент34 страницыETSI EG 202 057-4 Speech Processing - Transmission and Quality Aspects (STQ) - Umbrales de Calidat3rdacОценок пока нет

- Boeing SWOT AnalysisДокумент3 страницыBoeing SWOT AnalysisAlexandra ApostolОценок пока нет

- INDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor PositioningДокумент8 страницINDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor Positioningzeeshan ahmedОценок пока нет

- Quality Assurance Plan-75FДокумент3 страницыQuality Assurance Plan-75Fmohamad chaudhariОценок пока нет

- Jurnal Direct and Indirect Pulp CappingДокумент9 страницJurnal Direct and Indirect Pulp Cappingninis anisaОценок пока нет

- 8A L31 Phiếu BTДокумент7 страниц8A L31 Phiếu BTviennhuОценок пока нет

- A Mini-Review On New Developments in Nanocarriers and Polymers For Ophthalmic Drug Delivery StrategiesДокумент21 страницаA Mini-Review On New Developments in Nanocarriers and Polymers For Ophthalmic Drug Delivery StrategiestrongndОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Exam Ref 70 483 Programming in C by Wouter de Kort PDFДокумент2 страницыExam Ref 70 483 Programming in C by Wouter de Kort PDFPhilОценок пока нет

- July 2014Документ56 страницJuly 2014Gas, Oil & Mining Contractor MagazineОценок пока нет

- PC300-8 New ModelДокумент22 страницыPC300-8 New Modeljacklyn ade putra100% (2)

- Vmware It Academy Program May2016Документ26 страницVmware It Academy Program May2016someoneОценок пока нет

- By Vaibhav Pandya S R.information Security Consultant M.Tech Solutions (India) PVT - LTDДокумент22 страницыBy Vaibhav Pandya S R.information Security Consultant M.Tech Solutions (India) PVT - LTDtsegay.csОценок пока нет

- Jurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIДокумент9 страницJurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIMarsaidОценок пока нет

- ICON Finals Casebook 2021-22Документ149 страницICON Finals Casebook 2021-22Ishan ShuklaОценок пока нет

- Turbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Документ8 страницTurbine Flowmeters-Commonly Asked Questions and Answers: For Chemical Composition Information.)Alexander KlmОценок пока нет

- Integrated Management System 2016Документ16 страницIntegrated Management System 2016Mohamed HamedОценок пока нет

- Market Structure and TrendДокумент10 страницMarket Structure and TrendbillОценок пока нет

- Class 12 Unit-2 2022Документ4 страницыClass 12 Unit-2 2022Shreya mauryaОценок пока нет

- A Wicked Game by Kate BatemanДокумент239 страницA Wicked Game by Kate BatemanNevena Nikolic100% (1)

- Data SheetДокумент14 страницData SheetAnonymous R8ZXABkОценок пока нет

- Project Report On HeritageДокумент39 страницProject Report On HeritageBALA YOGESH YANDAMURIОценок пока нет