Академический Документы

Профессиональный Документы

Культура Документы

1 SATIP-W-017-01 Welding of API Tanks-Rev 1

Загружено:

khalid764Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1 SATIP-W-017-01 Welding of API Tanks-Rev 1

Загружено:

khalid764Авторское право:

Доступные форматы

Refer to Note 1 of the General Notes for S.

Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

MATERIAL RECEIVING

Random witnessing by S. Aramco at each calibration

cycle.

2.3

Positive Material Identification of Low

Alloy, Stainless Steel, Nickel & Copper

Based Materials (If Required)

SAIC-L-2010

SAIC-L-2010

SATR-L-2012

SATR-L-2013

H1 W2

W2

SAIC-W-2079

Production Weld Hardness Testing

Procedure

H1

SAIC-W-2080

SAIC-L-2004

See Remarks

2.2

Welding Equipment Calibration

Verification

1.8 Non-Destructive Testing Procedures

1.9

1.5

SAIC-W-2081

SAIC-W-2082

SATR-W-2009

SATR-W-2011

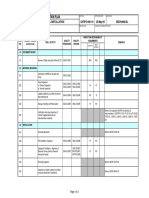

WELDING OF API TANKS

DOCUMENT REVIEW

2.0

Receiving Inspection and Verification of

Welding Consumables-(Properties, Type,

approve source, storage, etc.)

SAUDI ARAMCO TYPICAL INSPECTION PLAN

Welder & Welding Operator

Certifications (and Issuance of J CC)

SAIC-W-2035

QUALITY

PROCEDURE

1.0

SAIC-W-2075

ITEM

NO.

PROJ ECT TITLE:

1.2

1.1

Review of Procedure for Control of

Welding Consumables

Positive Material Identification Procedure

(Alloy Verification)

1.6

1.4 Weld J oint Identification System

1.7

1.3

APPROVED DATE

25-May-05

See SATIP No: W-014-01

SATIP No.

SATIP-W-017-01

QUALITY

RECORD

RH1

RH1

Welding Procedure

Specifications/Welding Procedure

Qualification Record (WPS/WPQR)

Method Statement & WPS for Weld

Repair

SAIC-W-2076

Post Weld Heat Treatment (PWHT)

Procedure

SAIC-W-2078

SAIC-W-2077

Welding of Overlays & Clad Materials

(If Required)

R1

RH1 RH1

RH1 RH1

RH1 RH1

RH1

DISCIPLINE:

REMARKS

INSPECTION RESPONSIBILITY

ASSIGNMENTS

MECHANICAL

PROJECT PHASE &

ACTIVITY CODE

TASK / ACTIVITY

CNTRCTR

RH1

CONTRACTOR/SUBCONTRACTOR

RH1

WBS/BI/J O/NO.

SAUDI

ARAMCO

3.0 INSTALLATION

SAIC-W-2082

Refer to the respective SATIP for NDE (SATIP-NDE-UT-

01, LPT-01, MPT-01, RT-01)

RH1 SATR-W-2004

RH1

RH1 R1

S. Aramco shall verify and inspect the first batch of

delivered consumables, then random inspection

thereafter.

SAIC-W-2081 H1 W2 2.1

3.1

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

Page 1 of 4

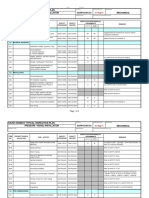

WELDING OF API TANKS

SAUDI ARAMCO TYPICAL INSPECTION PLAN

QUALITY

PROCEDURE

ITEM

NO.

PROJ ECT TITLE:

APPROVED DATE

25-May-05

SATIP No.

SATIP-W-017-01

QUALITY

RECORD

DISCIPLINE:

REMARKS

INSPECTION RESPONSIBILITY

ASSIGNMENTS

MECHANICAL

PROJECT PHASE &

ACTIVITY CODE

TASK / ACTIVITY

CNTRCTR

CONTRACTOR/SUBCONTRACTOR WBS/BI/J O/NO.

SAUDI

ARAMCO

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

SAIC-W-2089

SATR-W-2005

R1 S. Aramco reviews on weekly basis.

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

H1 W1/R1 3.11

Post Weld Heat Treatment Inspection (If

Required)

SAIC-W-2089

H1 W1 SAIC-W-2087

SAIC-W-2088

SAIC-W-2088

SATR-W-2007

3.9 Post-Welding Visual Inspection

3.15 Selection of Weld J oints for NDE (Tanks) H1

"W2"--Refer to Note 1 of the General Notes for

S.Aramco Inspection responsibility, then random

inspection thereafter.

3.8 In-Process Weld Inspection SAIC-W-2086

S. Aramco's responsibilities varies as follows:

a) "S" - Generally is a surveillance activity for Saudi

Aramco, except in welding of stainless steel tanks and

tanks in low temp service.

b) "W2" - S. Aramco inspects and verifies Heat Input at

random or on routine basis for low temp service and for

stainless steel welding.

SAIC-W-2086

SATR-W-2007

W1

S/W2

(See

remarks)

H1 W2 3.7 Pre-Welding Inspection SAIC-W-2085

SAIC-W-2085

SATR-W-2006

SAIC-W-2084

SAIC-W-2084

SATR-W-2006

H1

3.5

Control of Welding Consumables-

Storage, Handling, Issuance &

Conditioning

SAIC-W-2083

See SATIP No: W-016-01

3.4 Welding of piping appurtenances See SATIP-W-011-01

H1 S

W1/H1

Saudi Aramco inspection responsibility varies from H1

to W1:

a) " W1" -for build-up thickness not exceeding 1/3

of the metal thickness or 10mm whicever is

less.

b) " H1" - for build-up thickness exceeding the above

and requiring CSD's approval.

See SATIP N0: W-016-01 or other SATIP-W series as

required

Welding of Strip Linings

(If Required)

Buttering or Weld Build-Up of J oints

Welding of Special Corrosion-Resistant

Materials

(If Required)

SAIC-W-2083

SATR-W-2010

3.3

3.2

3.6

Page 2 of 4

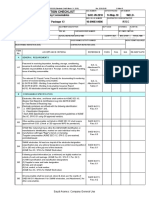

WELDING OF API TANKS

SAUDI ARAMCO TYPICAL INSPECTION PLAN

QUALITY

PROCEDURE

ITEM

NO.

PROJ ECT TITLE:

APPROVED DATE

25-May-05

SATIP No.

SATIP-W-017-01

QUALITY

RECORD

DISCIPLINE:

REMARKS

INSPECTION RESPONSIBILITY

ASSIGNMENTS

MECHANICAL

PROJECT PHASE &

ACTIVITY CODE

TASK / ACTIVITY

CNTRCTR

CONTRACTOR/SUBCONTRACTOR WBS/BI/J O/NO.

SAUDI

ARAMCO

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

W1 & R1

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

3.12 Weld Repair Verification and Inspection SAIC-W-2091

S. Aramco reviews on weekly basis. 3.15

Weekly Reporting of the following:

a) Production Weld and Welder

b) Welder Repair Rate

c) Welder repair Assessment & Tracer

Welds

SAIC-W-2090

SAIC-W-2090

SATR-W-2013

SATR-W-2018

SATR-W-2019

H1

3

Witness: QA/QC organization shall be notified of the timing of Inspection or test in advance. However, the inspection or test shall be performed as scheduled if the QA/QC organization

representative is not present.

4 Hold: QA/QC organization shall be notified of the timing of inspection or test in advance. Inspection or test shall not be carried out without the QA/QC organization representative in attendance.

3.13

3.12

SAIC-W-2092

SATR-W-2012

SAIC-L-2010

SAIC-W-2092

Positive Material Identification (PMI) of

Deposited Weld for alloyed materials

within the scope of SAES-A-206.

SAIC-L-2010

SATR-L-2012

SATR-L-2013

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged

witnessing shall be agreed upon.

W1 & R1 H1

W1/R1 H1

Verification of Hardness Testing

Application and Results (If Required)

4.0

4.1

3.14

Verification of Non-Destructive

Examination Method Application and

Evaluation of Results

See Remarks W1/RH1 W1/R1

R1

SAIC-W-2091

SATR-W-2012

H1

Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged or

random Review shall be agreed upon.

* Use the applicable SATIPS:

a) SATIP-D-100-01

b) SATIP-NDE-LPT-01

c) SATIP-NDE-MPT-01

d) SATIP-NDE-RT-01

e) SATIP-NDE-UT-01

**Refer to Note 1 of the General Notes for S.Aramco

Inspection responsibility, afterwhich pre-arranged or

random Witnessing shall be agreed upon.

PRE-COMMISSIONING

H1 R1

GENERAL NOTES

1

The first three incidents of each Inspection or testing activity listed require 100 % participation by Saudi Aramco Site Inspection Personnel. After this period, Saudi Aramco Inspection may adjust the

levels of Saudi Aramco participation based upon the Contractors performance.

Final Welding Inspection & Document

Verification (Welding Summary Report/

Record & Weld Map)

SATR-W-2008

(or equiv)

Page 3 of 4

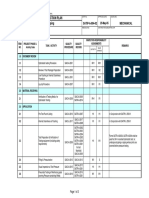

WELDING OF API TANKS

SAUDI ARAMCO TYPICAL INSPECTION PLAN

QUALITY

PROCEDURE

ITEM

NO.

PROJ ECT TITLE:

APPROVED DATE

25-May-05

SATIP No.

SATIP-W-017-01

QUALITY

RECORD

DISCIPLINE:

REMARKS

INSPECTION RESPONSIBILITY

ASSIGNMENTS

MECHANICAL

PROJECT PHASE &

ACTIVITY CODE

TASK / ACTIVITY

CNTRCTR

CONTRACTOR/SUBCONTRACTOR WBS/BI/J O/NO.

SAUDI

ARAMCO

SAUDI ARAMCO ID/PID - REV 1 - 5/18/05 (Standards Cutoff - August 2004)

5

R1

H1 100% Hold Point for QC Inspection or Test R2 Sample Review of Documents

100% Review of Documents

If the Main Contractor delegates the assigned responsibility to the Subcontractor, then the Main Contractor will have the same degree of responsibility as assigned to Saudi Aramco.

LEGEND

W1 100% Witness Inspection/Test H2 Sample Hold Point for QC Inspection or Test

W2 Sample Witness Inspection/Test

100% Review and Approval of Documents RH1

RH2 Sample Review and Approval of Documents

S Surveillance

Page 4 of 4

Вам также может понравиться

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1Документ3 страницы1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1JithuJohn100% (1)

- Saic L 2007 PDFДокумент7 страницSaic L 2007 PDFHesham HelalОценок пока нет

- SATIP D 001 01 (Revision 4)Документ3 страницыSATIP D 001 01 (Revision 4)Anonymous 4e7GNjzGW100% (1)

- 1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1Документ4 страницы1 SATIP-W-016-01 Welding of S C R M & Duplex SS - Rev 1JithuJohnОценок пока нет

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFДокумент4 страницы1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnОценок пока нет

- SAIC-L-2136 Rev 0Документ3 страницыSAIC-L-2136 Rev 0philipyapОценок пока нет

- SATIP-A-004-01 Rev 7Документ2 страницыSATIP-A-004-01 Rev 7Bebin Mathew100% (1)

- Saudi Aramco Gravity Sewer TIPДокумент3 страницыSaudi Aramco Gravity Sewer TIPMuhammad Farukh ManzoorОценок пока нет

- Saudi Aramco welding inspection planДокумент12 страницSaudi Aramco welding inspection planspravin231Оценок пока нет

- Saudi Aramco Inspection ChecklistДокумент2 страницыSaudi Aramco Inspection ChecklistJoni Carino SuniОценок пока нет

- Saep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsДокумент12 страницSaep-1160 (NDT - Tracking and Reporting of Welding, NDT and Pressure Testing For Capital ProjectsShajin Mohammed Shamsudhin88% (8)

- SatipДокумент5 страницSatipMuhammad Abdul Kadher100% (3)

- Saudi Aramco Typical Inspection PlanДокумент10 страницSaudi Aramco Typical Inspection Plankarthi51289Оценок пока нет

- Saudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalДокумент11 страницSaudi Aramco Typical Inspection Plan: Pipelines - Wellhead Piping Installation SATIP-L-410-01 17-Mar-16 MechanicalSasi Head OfficeОценок пока нет

- Satip A 004 03Документ3 страницыSatip A 004 03Anonymous 4e7GNjzGW100% (1)

- Saudi Aramco PMI checklist ensures alloy purityДокумент5 страницSaudi Aramco PMI checklist ensures alloy puritykarioke mohaОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент3 страницыSaudi Aramco Inspection ChecklistAbdul HannanОценок пока нет

- Saudi Aramco Typical Inspection PlanДокумент2 страницыSaudi Aramco Typical Inspection PlanMAZHARULОценок пока нет

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGДокумент6 страницTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGAbu BindongОценок пока нет

- 1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Документ2 страницы1 SATIP-A-004-02 Hydro Test of Plant Piping-Rev 1Ariel Anasco50% (2)

- Saep 324 PDFДокумент13 страницSaep 324 PDFArvind ShakyaОценок пока нет

- SAES-W-012 - Google Search3Документ1 страницаSAES-W-012 - Google Search3fayceal0% (1)

- Saudi Aramco Pressure Testing ProcedureДокумент21 страницаSaudi Aramco Pressure Testing ProcedureDilshad AhemadОценок пока нет

- Ad 036821 001Документ1 страницаAd 036821 001AmolОценок пока нет

- Saudi Aramco Typical Inspection PlanДокумент11 страницSaudi Aramco Typical Inspection PlanAhdal NoushadОценок пока нет

- SAIC-M-2003 Rev 7Документ57 страницSAIC-M-2003 Rev 7yugandhar100% (1)

- Saudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019Документ2 страницыSaudi Aramco Test Report: 25-May-05 Weld-Weekly Weld Status Report SATR-W-2019David RodriguesОценок пока нет

- SAUDICHECK - WELD TRACKING DATABASEДокумент5 страницSAUDICHECK - WELD TRACKING DATABASEManoj KumarОценок пока нет

- Satr-W-2010Документ1 страницаSatr-W-2010Joni Carino SuniОценок пока нет

- Weekly Welder ReportДокумент2 страницыWeekly Welder Reportkarthi51289Оценок пока нет

- Saudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 WeldДокумент1 страницаSaudi Aramco Inspection Checklist: Inprocess Welding Inspection - Offshore Structures SAIC-W-1313 Weldkartik_harwani4387Оценок пока нет

- SAIC-L-2035 Rev 6Документ2 страницыSAIC-L-2035 Rev 6biplabpal2009Оценок пока нет

- SAUDI ARAMCO LPT INSPECTION PLANДокумент3 страницыSAUDI ARAMCO LPT INSPECTION PLANDurga Jagan PuppalaОценок пока нет

- SAIC-A-2015 Saudi Aramco Inspection ChecklistДокумент8 страницSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289Оценок пока нет

- QMISДокумент14 страницQMISLopez Gardo0% (1)

- Saic L 2008 PDFДокумент4 страницыSaic L 2008 PDFHesham HelalОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент3 страницыSaudi Aramco Inspection ChecklistJoni Carino Suni100% (1)

- Saudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalДокумент12 страницSaudi Aramco Typical Inspection Plan: Valve Inspection, Testing & Installation SATIP-L-108-01 8-Nov-15 MechanicalAhdal NoushadОценок пока нет

- SAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld InspectionДокумент5 страницSAIC-W-OFFSHORE STRUCTURAL 2 In-Process Weld Inspectionاحمد حسنОценок пока нет

- Saudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalДокумент5 страницSaudi Aramco Typical Inspection Plan: Welding of On-Plot Piping SATIP-W-011-01 31-Dec-14 MechanicalpravinОценок пока нет

- Saudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldДокумент4 страницыSaudi Aramco Inspection Checklist: Validation of Welding Equipment (Plant Piping) SAIC-W-2011 21-Oct-18 WeldMAZHARULОценок пока нет

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGДокумент5 страницTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcОценок пока нет

- Saep 351Документ24 страницыSaep 351Raj KumarОценок пока нет

- Materials System SpecificationДокумент7 страницMaterials System Specificationaanouar77Оценок пока нет

- SAIC M 2007 Struct AlignДокумент1 страницаSAIC M 2007 Struct AlignAnonymous S9qBDVkyОценок пока нет

- Received Qty (KG) : SL# Electrode SizeДокумент34 страницыReceived Qty (KG) : SL# Electrode Sizepadinharethil50% (2)

- Saudi Aramco Test ReportДокумент4 страницыSaudi Aramco Test Reportkarthi51289Оценок пока нет

- Saudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingДокумент12 страницSaudi Aramco Inspection Checklist: Pre-Test Punch Listing of On-Plot Piping SAIC-A-2010 31-Aug-11 PipingAnonymous 4e7GNjzGWОценок пока нет

- Control of Welding Rejection Rate and NDT Backlog in MEGA ProjectДокумент10 страницControl of Welding Rejection Rate and NDT Backlog in MEGA ProjectMubeenОценок пока нет

- 175 000003Документ1 страница175 000003zhangОценок пока нет

- Saudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 MechanicalДокумент12 страницSaudi Aramco Typical Inspection Plan: Cross Country Buried Pipeline (Mainline) SATIP-L-450-04 3-Jul-18 Mechanicalkarthi51289Оценок пока нет

- Saep 347Документ27 страницSaep 347Qaiser Mahmood100% (2)

- SAIC-W-2006 Rev 0 PDFДокумент4 страницыSAIC-W-2006 Rev 0 PDFMidhun K ChandraboseОценок пока нет

- SATR-W-2006 Rev 6Документ1 страницаSATR-W-2006 Rev 6Manoj KumarОценок пока нет

- SAIC-A-2015 Rev 7Документ8 страницSAIC-A-2015 Rev 7Bebin Mathew0% (1)

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CДокумент2 страницыSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyОценок пока нет

- 1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFДокумент4 страницы1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFWIZKHALIFAОценок пока нет

- 1 SATIP-F-001-04 Boiler - Packaged Type - 1Документ4 страницы1 SATIP-F-001-04 Boiler - Packaged Type - 1JithuJohnОценок пока нет

- SAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANДокумент3 страницыSAUDI ARAMCO CENTRIFUGAL PUMP INSPECTION PLANJithuJohn100% (1)

- Wiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsОт EverandWiley Practitioner's Guide to GAAS 2023: Covering All SASs, SSAEs, SSARSs, and InterpretationsОценок пока нет

- Pressure Test ProceduresДокумент5 страницPressure Test Procedureszaxader100% (1)

- Surface PrepДокумент7 страницSurface Prepkhalid764Оценок пока нет

- Hempadur 4714911150 En-UsДокумент11 страницHempadur 4714911150 En-Uskhalid764Оценок пока нет

- Explanatory NotesДокумент10 страницExplanatory Noteskhalid764Оценок пока нет

- 81970Документ2 страницы81970khalid764Оценок пока нет

- Hempel: Hempadur "No Slide" 369saДокумент2 страницыHempel: Hempadur "No Slide" 369sakhalid764Оценок пока нет

- Product DataДокумент2 страницыProduct Datakhalid764Оценок пока нет

- 06520Документ2 страницы06520khalid764Оценок пока нет

- HEMPADUR 47140: DescriptionДокумент2 страницыHEMPADUR 47140: DescriptionMashudi FikriОценок пока нет

- 12050Документ2 страницы12050khalid764Оценок пока нет

- 15550Документ2 страницы15550khalid764Оценок пока нет

- HEMPEL'S GLASSFIBRE MAT 690SA Product Data SheetДокумент1 страницаHEMPEL'S GLASSFIBRE MAT 690SA Product Data Sheetkhalid764Оценок пока нет

- HEMPEL'S GLASS BEADS Product Data SheetДокумент1 страницаHEMPEL'S GLASS BEADS Product Data Sheetkhalid764100% (1)

- 05500Документ6 страниц05500khalid764Оценок пока нет

- 05990Документ2 страницы05990khalid764Оценок пока нет

- 353 SaДокумент2 страницы353 Sakhalid764Оценок пока нет

- 15780Документ7 страниц15780khalid764Оценок пока нет

- 355 SaДокумент2 страницы355 Sakhalid764100% (1)

- 568 SaДокумент2 страницы568 Sakhalid764Оценок пока нет

- Hempel: Hempadur "No Slide" 369saДокумент2 страницыHempel: Hempadur "No Slide" 369sakhalid764Оценок пока нет

- 691 SaДокумент1 страница691 Sakhalid764Оценок пока нет

- 528MEДокумент1 страница528MEkhalid764Оценок пока нет

- HEMPADUR 47140: DescriptionДокумент2 страницыHEMPADUR 47140: DescriptionMashudi FikriОценок пока нет

- 133 SaДокумент2 страницы133 Sakhalid764Оценок пока нет

- HEMPEL'S THINNERS 08 Product Data SheetДокумент2 страницыHEMPEL'S THINNERS 08 Product Data Sheetkhalid764Оценок пока нет

- Hempel Group Health, Safety and Environmental PolicyДокумент1 страницаHempel Group Health, Safety and Environmental Policykhalid764Оценок пока нет

- HEMPADUR 47140: DescriptionДокумент2 страницыHEMPADUR 47140: DescriptionMashudi FikriОценок пока нет

- Hempel Colour ChartДокумент2 страницыHempel Colour Chartkhalid76467% (6)

- 951GBSДокумент4 страницы951GBSkhalid764Оценок пока нет

- Radiography Inspection NDT Sample Test Report Format PDFДокумент2 страницыRadiography Inspection NDT Sample Test Report Format PDFDanielRaoОценок пока нет

- E-Commerce Internship ReportДокумент29 страницE-Commerce Internship Reportvishu shuklaОценок пока нет

- Fundamentals of ManagementДокумент28 страницFundamentals of Managementnadiaezatty100% (2)

- Recommendation With Data Mining Algorithms For E-Commerce and M-Commerce ApplicationsДокумент4 страницыRecommendation With Data Mining Algorithms For E-Commerce and M-Commerce ApplicationsInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Work, An Illustrated Magazine...Документ16 страницWork, An Illustrated Magazine...Ricardo Luis Martin Sant'AnnaОценок пока нет

- Ferrartis Storage SolutionДокумент14 страницFerrartis Storage SolutionK.K GuptaОценок пока нет

- Masjid Balustrade Design ReportДокумент33 страницыMasjid Balustrade Design ReportKhurram Shahzad AmjadОценок пока нет

- G7 Pre Qualification Checklist Sheetfed v1.3Документ6 страницG7 Pre Qualification Checklist Sheetfed v1.3Ganjar RukmaОценок пока нет

- Project Communication List for Smelter Grade Alumina RefineryДокумент51 страницаProject Communication List for Smelter Grade Alumina RefineryGibran WijayaОценок пока нет

- Resume Vaishali 1Документ3 страницыResume Vaishali 1Vaishali NegiОценок пока нет

- Yale HoistДокумент94 страницыYale Hoistjohn_tigerОценок пока нет

- Building construction cost breakdown and permit feesДокумент20 страницBuilding construction cost breakdown and permit feesErnesto LopezОценок пока нет

- GoldMedal 2016 WebДокумент124 страницыGoldMedal 2016 WebPitonОценок пока нет

- Resume Shubham JainДокумент6 страницResume Shubham JainShubham GuptaОценок пока нет

- B.Tech Mechanical Engineer Seeks Challenging RoleДокумент2 страницыB.Tech Mechanical Engineer Seeks Challenging RoleDheeraj patidarОценок пока нет

- Engine Coolants (Antifreeze) : Technical HandbookДокумент16 страницEngine Coolants (Antifreeze) : Technical Handbookanil73100% (1)

- CuSum Chart ExplainedДокумент18 страницCuSum Chart ExplainedShanmuga RajaОценок пока нет

- Law office photocopy receipt formsДокумент2 страницыLaw office photocopy receipt formsLei MorteraОценок пока нет

- Zara Case PresentationДокумент50 страницZara Case PresentationFahlevi Dzulfikar100% (1)

- Ropanyl em 3 1 00+02 White As FGДокумент1 страницаRopanyl em 3 1 00+02 White As FGJonathan LujanОценок пока нет

- GT60M324 Datasheet en 20131101Документ6 страницGT60M324 Datasheet en 20131101Ronald YupanquiОценок пока нет

- Chapter Eight Tolerance ChartsДокумент37 страницChapter Eight Tolerance ChartsslitantОценок пока нет

- Worker-Machine Relationship ChartДокумент9 страницWorker-Machine Relationship ChartRegina Jazzmin QuesadaОценок пока нет

- Saep 341 PDFДокумент21 страницаSaep 341 PDFRami Elloumi100% (1)

- GSM Neighbour List Optimisation - Process and ProcedureДокумент1 страницаGSM Neighbour List Optimisation - Process and ProceduregchivandireОценок пока нет

- Tolerances and Clearances For Commercial Hollow Metal Doors and FramesДокумент16 страницTolerances and Clearances For Commercial Hollow Metal Doors and FramessouravrobinОценок пока нет

- 2 4+GHz+Directional Yagi Antenna DatasheetДокумент2 страницы2 4+GHz+Directional Yagi Antenna DatasheetCFDPОценок пока нет

- A Quick Introduction To Russian WatchesДокумент1 страницаA Quick Introduction To Russian Watchesejlamasv2Оценок пока нет

- lm25017 PDFДокумент31 страницаlm25017 PDFطه محمدОценок пока нет

- 4 Main Types of Plant Layouts ExplainedДокумент3 страницы4 Main Types of Plant Layouts ExplainedSikakolli Venkata Siva KumarОценок пока нет