Академический Документы

Профессиональный Документы

Культура Документы

Penguard ZP AO - English (Uk) - Issued.06.12.2007

Загружено:

Mohamed FaragАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Penguard ZP AO - English (Uk) - Issued.06.12.2007

Загружено:

Mohamed FaragАвторское право:

Доступные форматы

Penguard ZP AO Page 1 of 3

Technical Data

Penguard ZP AO

Product description

Penguard ZP AO is a high build, two-pack zinc phosphate pigmented epoxy coating based on epoxy resin with high

molecular weight.

Recommended use

As an anti corrosive primer and intermediate coating for corrosion protection of various substrates including steel.

Film thickness and spreading rate

Minimum Maximum Typical

Film thickness, dry (m) 40 60 50

Film thickness, wet (m) 75 115 95

Theoretical spreading rate (m/l) 13,25 8,83 10,6

Comments

To achieve the minimum DFT of 40 m, the coating should be thinned with Thinner No. 17 up to 15%.

Physical properties

Colour Yellow

Solids (vol %)* 53 2

Flash point 23C 2 (Setaflash)

*Measured according to ISO 3233:1998 (E)

Surface preparation

All surfaces should be clean, dry and free from contamination. The surface should be assessed and treated in

accordance with ISO 8504.

Bare steel

Cleanliness: Blast cleaning to Sa 2 (ISO 8501-1:2007). Roughness: using abrasives suitable to achieve grade Fine to

Medium G (30-85 m, Ry5) (ISO 8503-2)

Shopprimed steel

Clean, dry and undamaged approved shopprimer.

Coated surfaces

Clean, dry and undamaged compatible primer. Please contact your local Jotun office for more information.

Other surfaces

The surface must be sound, clean and dry. Surface contamination to be removed by detergent and fresh water

cleaning.

The coating may be used on other substrates. Please contact your local Jotun office for more information.

Penguard ZP AO Page 2 of 3

Condition during application

For steel substrate: The temperature of the substrate should be minimum 10C and at least 3C above the dew point of

the air, temperature and relative humidity measured in the vicinity of the substrate. For concrete: The moisture content

in the concrete should not exceed 4 % (by weight). The coating should not be exposed to oil, chemicals or mechanical

stress until fully cured.

Application methods

Spray Use airless spray

Brush Recommended for stripe coating and small areas, care must be taken to achieve the specified dry

film thickness.

Application data

Mixing ratio (volume) 4 parts of component A (base) to be thoroughly mixed with 1 part of component B

(hardener), half an hour prior to application.

Mixing hour prior to use.

Pot life (23C) 8 hours. (Reduced at higher temp.)

Thinner/Cleaner Jotun Thinner No. 17 Thin upto 15% with Jotun Thinner No. 17.

Guiding data airless spray

Pressure at nozzle Min. 150 kg/sq. cm (2100 p.s.i.)

Nozzle tip 0.46 - 0.69 mm (0.018-0.027")

Spray angle 65 - 85

Filter Check to ensure that filters are clean.

Drying time

Drying times are generally related to air circulation, temperature, film thickness and number of coats, and will be

affected correspondingly. The figures given in the table are typical with:

* Good ventilation (Outdoor exposure or free circulation of air)

* Typical film thickness

* One coat on top of inert substrate

Substrate temperature 10C 23C 40C

Surface dry 2 h 1 h 0.5 h

Through dry 14 h 6.5 h 4 h

Cured 14 d 7 d 3 d

Dry to recoat, minimum 8 h 4 h 2 h

Dry to recoat, maximum

1

1. Provided the surface is free from chalking and other contamination prior to application, there is normally no

overcoating time limit. If the coating has been exposed to direct sunlight for some time, special attention must be

paid to surface cleaning and mattening/removal of the surface layer in order to obtain good adhesion.

The given data must be considered as guidelines only. The actual drying time/times before recoating may be shorter or

longer, depending on film thickness, ventilation, humidity, underlying paint system, requirement for early handling and

mechanical strength etc. A complete system can be described on a system sheet, where all parameters and special

conditions could be included.

Typical paint system

Penguard ZP AO Page 3 of 3

Penguard ZP AO 1 x 50 m (Dry Film Thickness)

Penguard HB 2 x 100 m (Dry Film Thickness)

Hardtop AS 1 x 50 m (Dry Film Thickness)

Other systems may be specified, depending on area of use

Storage

The product must be stored in accordance with national regulations. Storage conditions are to keep the containers in a

dry, cool, well ventilated space and away from source of heat and ignition. Containers must be kept tightly closed.

Handling

Handle with care. Stir well before use.

Packing size

16 litres Comp. A (base) in a 20 litre container and 4 litres Comp. B (curing agent) in a 5 litre container

Packing may vary from country to country according to local requirements.

Health and safety

Please observe the precautionary notices displayed on the container. Use under well ventilated conditions. Do not

breathe or inhale mist. Avoid skin contact. Spillage on the skin should immediately be removed with suitable cleanser,

soap and water. Eyes should be well flushed with water and medical attention sought immediately.

For detailed information on the health and safety hazards and precautions for use of this product, we refer to

the Material Safety Data Sheet.

DISCLAIMER

The information in this data sheet is given to the best of our knowledge based on laboratory testing and practical

experience. However, as the product is often used under conditions beyond our control, we cannot guarantee anything

but the quality of the product itself. We reserve the right to change the given data without notice.

Jotun is a World Wide company with factories, sales offices and stocks in more than 50 countries. For your nearest local Jotun address

please contact the nearest regional office or visit our website at www.jotun.com

ISSUED 6 DECEMBER 2007 BY JOTUN

THIS DATA SHEET SUPERSEDES THOSE PREVIOUSLY ISSUED

Вам также может понравиться

- Risk Assesment For Shifting of MEP Services and Re-Installations 26-03-2022Документ5 страницRisk Assesment For Shifting of MEP Services and Re-Installations 26-03-2022Zameer Basha Navzath AliОценок пока нет

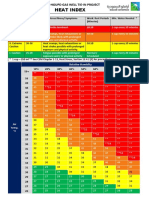

- Aramco Heat Index A4Документ1 страницаAramco Heat Index A4DLPS HSEОценок пока нет

- Working at Heights: Dr.P.MuralidharДокумент48 страницWorking at Heights: Dr.P.MuralidharRituraj SinghОценок пока нет

- Radiography Examination ProdureДокумент29 страницRadiography Examination ProdureNguyen Phuc100% (1)

- Ultrasonic Wall Thickness Report Feb.27-28,20062 - 2Документ32 страницыUltrasonic Wall Thickness Report Feb.27-28,20062 - 2Endickk Screamo PoreperrОценок пока нет

- Astm A488Документ1 страницаAstm A488Mohamed FaragОценок пока нет

- Jib Crane Assembly ManualДокумент76 страницJib Crane Assembly ManualRobert Cumpa100% (1)

- Radiation Safety Program 2Документ16 страницRadiation Safety Program 2Ahmed shabanОценок пока нет

- Vc-Api 650 PDFДокумент6 страницVc-Api 650 PDFShinta ShowiantariОценок пока нет

- 10.1 Jha Box-Up Spool or Valve 19.11.15Документ6 страниц10.1 Jha Box-Up Spool or Valve 19.11.15RahimОценок пока нет

- Heat Stress1Документ3 страницыHeat Stress1Zaki AziziОценок пока нет

- Procedure of UT-TestДокумент2 страницыProcedure of UT-TestJohn ShermanОценок пока нет

- S.V. Kulkarni, S.A. Khaparde Transformer and Inductor Design Handbook 2004Документ532 страницыS.V. Kulkarni, S.A. Khaparde Transformer and Inductor Design Handbook 2004Gianpiero Boccato0% (1)

- Copper Alloys For Marine EnvironmentsДокумент32 страницыCopper Alloys For Marine EnvironmentsMohamed FaragОценок пока нет

- Copper Alloys For Marine EnvironmentsДокумент32 страницыCopper Alloys For Marine EnvironmentsMohamed FaragОценок пока нет

- MSDS Iridium-192 Sealed Sources (Special Form) REV 2018.12.05Документ4 страницыMSDS Iridium-192 Sealed Sources (Special Form) REV 2018.12.05Nafiah -Оценок пока нет

- Asme Sec V A-15-2006Документ4 страницыAsme Sec V A-15-2006Muhammed Abo-FandoodОценок пока нет

- 41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFДокумент10 страниц41-JSA-Construction of Access Road and Structure Pads - Backfilling Leveling Compaction Activities-MLCC PDFFarhan MОценок пока нет

- Gold Advanced Progress Test 5Документ6 страницGold Advanced Progress Test 5BernardОценок пока нет

- Magnetic Particle Inspection - Use and Implementation of ASTM-E-1444Документ17 страницMagnetic Particle Inspection - Use and Implementation of ASTM-E-1444jaga67Оценок пока нет

- UT Inspection of WeldsДокумент2 страницыUT Inspection of WeldsPablo GonzalezОценок пока нет

- Poly Cell Adhesive: Main ApplicationДокумент2 страницыPoly Cell Adhesive: Main ApplicationHung Mai VanОценок пока нет

- Shrikant B. Moje CVДокумент6 страницShrikant B. Moje CVPaul PhiliphsОценок пока нет

- Pipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerДокумент2 страницыPipeline Repair Products: Repair Patch, Melt Stick, Epoxy Primer and Mastic FillerCherif GhalebОценок пока нет

- Scaffold TowerДокумент20 страницScaffold TowerAndhika HerdiawanОценок пока нет

- Rigaku Radioflex RF-EGM2 Series Brochure - VISCOДокумент4 страницыRigaku Radioflex RF-EGM2 Series Brochure - VISCOrhinemineОценок пока нет

- SWP CHECKLISTS - Welding Cutting and HeatingДокумент3 страницыSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- Temperature Controllers: Installation and MaintenanceДокумент5 страницTemperature Controllers: Installation and MaintenanceJose Uriel Ortega LeonОценок пока нет

- Fir-001 - 10 03 18Документ1 страницаFir-001 - 10 03 18Kartik SolankiОценок пока нет

- Material Safety Data Sheet: Poly Cell AdhesiveДокумент8 страницMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoОценок пока нет

- Magnetic Particle InspectionДокумент11 страницMagnetic Particle InspectionLuis Guevara0% (1)

- Steel Section Fire Resistant-HpA ValueДокумент14 страницSteel Section Fire Resistant-HpA Valuekingson719Оценок пока нет

- Scope of WorksДокумент3 страницыScope of WorksGovindraj KrishnanОценок пока нет

- Ultrasonic Report: Probe Details and Position (Fig 1)Документ2 страницыUltrasonic Report: Probe Details and Position (Fig 1)BALA GANESH100% (1)

- Mezzanine Installation InstructionДокумент19 страницMezzanine Installation InstructionfaustomariottОценок пока нет

- Industrial Rope Access ChecklistДокумент12 страницIndustrial Rope Access ChecklistPaulОценок пока нет

- Wfp291338 For Quality and Quantity Inspection of FoodsДокумент14 страницWfp291338 For Quality and Quantity Inspection of FoodsOzlem MepОценок пока нет

- StyreneДокумент2 страницыStyreneBiju_PottayilОценок пока нет

- Exertus Circa Operation Manual MKT - OM - CIRCA (Rev.01) - enДокумент32 страницыExertus Circa Operation Manual MKT - OM - CIRCA (Rev.01) - enmuni fatuzzahrohОценок пока нет

- W14-661 (0 To 40 Bar) PDFДокумент3 страницыW14-661 (0 To 40 Bar) PDFBalaji BobadeОценок пока нет

- Penguard PrimerДокумент5 страницPenguard PrimerPutroedidohОценок пока нет

- ISO Index Welding Standards - 1Документ1 страницаISO Index Welding Standards - 1Waqas WaqasОценок пока нет

- Is 9902 2004Документ11 страницIs 9902 2004cbbasakОценок пока нет

- ABB Scaffold Competent TestДокумент4 страницыABB Scaffold Competent Testvasucristal100% (2)

- WIWA Airless Spray GunsДокумент52 страницыWIWA Airless Spray Gunsosvaldo lopezОценок пока нет

- 27h Radiography PermitДокумент1 страница27h Radiography PermitMohammed MinhajОценок пока нет

- Procedure For UtДокумент12 страницProcedure For UtMohammad SyeduzzamanОценок пока нет

- JSA For ONGC PhotographyДокумент1 страницаJSA For ONGC PhotographyPanchdev KumarОценок пока нет

- Job Safety Analysis (Jsa) : CONTRACT N° .Документ1 страницаJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelОценок пока нет

- Finecoat HR 703 QDДокумент2 страницыFinecoat HR 703 QDKarishma PrabhuОценок пока нет

- Pttep Painitng of Offshore FacilitiesДокумент66 страницPttep Painitng of Offshore FacilitiesSufianОценок пока нет

- Excavation ManuallyДокумент1 страницаExcavation ManuallyJack PОценок пока нет

- Tube Expanders CatalogДокумент20 страницTube Expanders Catalognathanielek1989Оценок пока нет

- Wire Rope Cutting ChartДокумент8 страницWire Rope Cutting ChartAkash SharmaОценок пока нет

- Transport SpesificationДокумент10 страницTransport SpesificationJohn NainggolanОценок пока нет

- Vacuum Box Test Procedure: PurposeДокумент4 страницыVacuum Box Test Procedure: Purposesaravan1891Оценок пока нет

- Marathon XHBДокумент4 страницыMarathon XHBeskim00Оценок пока нет

- Syllabus Civil Qaqc Course Sdlinc 9600162099 PDFДокумент12 страницSyllabus Civil Qaqc Course Sdlinc 9600162099 PDFKamakhya MallОценок пока нет

- Introduction To NDT BasicДокумент27 страницIntroduction To NDT BasicAngela WalkerОценок пока нет

- Grit BlastingДокумент3 страницыGrit BlastingVelmurugan BalasubramanianОценок пока нет

- Penguard Stayer - English (Uk) - Issued.06.12.2007Документ3 страницыPenguard Stayer - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Penguard Special - English (Uk) - Issued.06.12.2007Документ3 страницыPenguard Special - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Penguard FC - English (Uk) - Issued.06.12.2007Документ4 страницыPenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- J Primer TdsДокумент3 страницыJ Primer Tdswey5316Оценок пока нет

- Jotafloor Sealer - English (Uk) - Issued.06.12.2007Документ3 страницыJotafloor Sealer - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Barrier ZepДокумент3 страницыBarrier ZepJairo Gómez SánchezОценок пока нет

- Vinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Документ3 страницыVinyguard Silvergrey 88 - English (Uk) - Issued.06.12.Mohamed FaragОценок пока нет

- Jotun Thinner No. 7 - English (Uk) - Issued.06.12.2007Документ2 страницыJotun Thinner No. 7 - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Gupco Project / Sidki P/L Project: Joint RegisterДокумент2 страницыGupco Project / Sidki P/L Project: Joint RegisterMohamed FaragОценок пока нет

- Penguard FC - English (Uk) - Issued.06.12.2007Документ4 страницыPenguard FC - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Bengalac Matt - English (Uk) - Issued.06.12.2007Документ3 страницыBengalac Matt - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Jotafloor Solvent Free Primer - English (Uk) - Issued.Документ3 страницыJotafloor Solvent Free Primer - English (Uk) - Issued.Mohamed FaragОценок пока нет

- Jotashine - English (Uk) - Issued.06.12.2007Документ3 страницыJotashine - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Marathon - English (Uk) - Issued.06.12.2007Документ5 страницMarathon - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Jotun Thinner No. 2 - English (Uk) - Issued.06.12.2007Документ3 страницыJotun Thinner No. 2 - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Jotatemp 650 - English (Us) - Issued.11.14.2008Документ4 страницыJotatemp 650 - English (Us) - Issued.11.14.2008Mohamed FaragОценок пока нет

- Spontan Varnish - English (Uk) - Issued.06.12.2007Документ3 страницыSpontan Varnish - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Jotun Thinner No. 7 - English (Uk) - Issued.06.12.2007Документ2 страницыJotun Thinner No. 7 - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- SeaQuantum Classic - English (Uk) - Issued.06.12.2007Документ3 страницыSeaQuantum Classic - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Safeguard Universal ES - English (Uk) - Issued.06.12.2Документ3 страницыSafeguard Universal ES - English (Uk) - Issued.06.12.2Mohamed FaragОценок пока нет

- Jotafloor Screed Primer - English (Uk) - Issued.06.12.Документ3 страницыJotafloor Screed Primer - English (Uk) - Issued.06.12.Mohamed FaragОценок пока нет

- Ansi B 16.11Документ34 страницыAnsi B 16.11Elangovan ArumugamОценок пока нет

- Jotaguard Special 90 - English (Uk) - Issued.06.12.200Документ3 страницыJotaguard Special 90 - English (Uk) - Issued.06.12.200Mohamed FaragОценок пока нет

- Se-Lett - English (Uk) - Issued.06.12.2007Документ3 страницыSe-Lett - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Futura Matt - English (Uk) - Issued.06.12.2007Документ3 страницыFutura Matt - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Marathon XHB - English (Uk) - Issued.06.12.2007Документ3 страницыMarathon XHB - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Balloxy HB Light - English (Uk) - Issued.27.06.2008Документ4 страницыBalloxy HB Light - English (Uk) - Issued.27.06.2008Mohamed FaragОценок пока нет

- Chemclear - English (Uk) - Issued.10.01.2008Документ3 страницыChemclear - English (Uk) - Issued.10.01.2008Mohamed FaragОценок пока нет

- Jotafloor Topcoat - English (Uk) - Issued.06.12.2007Документ4 страницыJotafloor Topcoat - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Pilot II - English (Uk) - Issued.06.12.2007Документ4 страницыPilot II - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Naviguard ME - English (Uk) - Issued.06.12.2007Документ3 страницыNaviguard ME - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- Jotun Thinner No. 25 - English (Uk) - Issued.06.12.200Документ2 страницыJotun Thinner No. 25 - English (Uk) - Issued.06.12.200Mohamed FaragОценок пока нет

- Marathon IQ GF - English (Uk) - Issued.06.12.2007Документ3 страницыMarathon IQ GF - English (Uk) - Issued.06.12.2007Mohamed FaragОценок пока нет

- IMS Institute BelgradeДокумент10 страницIMS Institute BelgradeBoško JanjuševićОценок пока нет

- BTL Info CNC ProgrammДокумент132 страницыBTL Info CNC ProgrammdieulafaitОценок пока нет

- Vol07 1 PDFДокумент275 страницVol07 1 PDFRurintana Nalendra WarnaОценок пока нет

- Noxim MANUALДокумент5 страницNoxim MANUALSAI NRUSIMHA DEEPAK BURRA SAI NRUSIMHA DEEPAK BURRAОценок пока нет

- Master Key Utbk Saintek 2022 (Paket 3) Bahasa InggrisДокумент5 страницMaster Key Utbk Saintek 2022 (Paket 3) Bahasa InggrisRina SetiawatiОценок пока нет

- K&J Magnetics - Demagnetization CurvesДокумент4 страницыK&J Magnetics - Demagnetization CurvessubbannachrsОценок пока нет

- CM1000 ManualДокумент12 страницCM1000 ManualyounesОценок пока нет

- 1 28701-FGC+101+3441+Router+6471+Datasheet+Rev+FДокумент2 страницы1 28701-FGC+101+3441+Router+6471+Datasheet+Rev+FВладимир ЕгоровОценок пока нет

- ManufactureДокумент2 страницыManufactureRahima Akter RakhiОценок пока нет

- Modular Air Handling Unit (FMA)Документ3 страницыModular Air Handling Unit (FMA)Salamet TeguhОценок пока нет

- EXP1POSTLABДокумент13 страницEXP1POSTLABGiane MagimotОценок пока нет

- Glacial Lakes of Himachal PradeshДокумент4 страницыGlacial Lakes of Himachal PradeshMonidipa DeyОценок пока нет

- Recetario TransistoresДокумент23 страницыRecetario TransistoresTitán SotoОценок пока нет

- Food - Forage - Potential - and - Carrying - Capacity - Rusa Kemampo - MedKonДокумент9 страницFood - Forage - Potential - and - Carrying - Capacity - Rusa Kemampo - MedKonRotten AnarchistОценок пока нет

- Digital Trail Camera: Instruction ManualДокумент20 страницDigital Trail Camera: Instruction Manualdavid churaОценок пока нет

- Latihan Soal BlankДокумент8 страницLatihan Soal BlankDanbooОценок пока нет

- Resource Access ControlДокумент19 страницResource Access Controlusamadar707Оценок пока нет

- TA1515VДокумент4 страницыTA1515VLeo LeiОценок пока нет

- Monthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)Документ20 страницMonthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)winda septiaraОценок пока нет

- ELC609F12 Lec0 IntroductionДокумент16 страницELC609F12 Lec0 IntroductionMohammed El-AdawyОценок пока нет

- Fatigue Consideration in DesignДокумент3 страницыFatigue Consideration in DesigngouthamОценок пока нет

- Disa Match: A Match You Can Count OnДокумент8 страницDisa Match: A Match You Can Count OngОценок пока нет

- Caption Sheet 4-Kailynn BДокумент4 страницыCaption Sheet 4-Kailynn Bapi-549116310Оценок пока нет

- 14 WosДокумент6 страниц14 WosATUL KURZEKARОценок пока нет

- Color Codes and Irregular MarkingДокумент354 страницыColor Codes and Irregular MarkingOscarGonzalezОценок пока нет

- PalmistryДокумент116 страницPalmistrymarinoyogaОценок пока нет

- 2606 PDFДокумент6 страниц2606 PDFzainab jehangirОценок пока нет