Академический Документы

Профессиональный Документы

Культура Документы

CZX 22G

Загружено:

snifer_170 оценок0% нашли этот документ полезным (0 голосов)

245 просмотров63 страницыNari CZX-22G interposing relay manual

Оригинальное название

CZX-22G

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документNari CZX-22G interposing relay manual

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

245 просмотров63 страницыCZX 22G

Загружено:

snifer_17Nari CZX-22G interposing relay manual

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 63

CZX-22G

Interposing Relay Set

Instruction Manual

NR Electric Co., Ltd.

Preface

CZX-22R Interposing Relay Set i

Date: 2011-04-12

Preface

Introduction

This guide and the relevant operating or service manual documentation for the equipment provide

full information on safe handling, commissioning and testing of this equipment.

Documentation for equipment ordered from NR is dispatched separately from manufactured goods

and may not be received at the same time. Therefore, this guide is provided to ensure that printed

information normally present on equipment is fully understood by the recipient.

Before carrying out any work on the equipment, the user should be familiar with the contents of

this manual, and read relevant chapter carefully.

This chapter describes the safety precautions recommended when using the equipment. Before

installing and using the equipment, this chapter must be thoroughly read and understood.

Health and Safety

The information in this chapter of the equipment documentation is intended to ensure that

equipment is properly installed and handled in order to maintain it in a safe condition.

When electrical equipment is in operation, dangerous voltages will be present in certain parts of

the equipment. Failure to observe warning notices, incorrect use, or improper use may endanger

personnel and equipment and cause personal injury or physical damage.

Before working in the terminal strip area, the equipment must be isolated.

Proper and safe operation of the equipment depends on appropriate shipping and handling,

proper storage, installation and commissioning, and on careful operation, maintenance and

servicing. For this reason, only qualified personnel may work on or operate the equipment.

Qualified personnel are individuals who:

Are familiar with the installation, commissioning, and operation of the equipment and of the

system to which it is being connected;

Are able to safely perform switching operations in accordance with accepted safety

engineering practices and are authorized to energize and de-energize equipment and to

isolate, ground, and label it;

Are trained in the care and use of safety apparatus in accordance with safety engineering

practices;

Are trained in emergency procedures (first aid).

Instructions and Warnings

The following indicators and standard definitions are used:

Preface

CZX-22R Interposing Relay Set ii

Date: 2011-04-12

DANGER!

It means that death, severe personal injury, or considerable equipment damage will occur if safety

precautions are disregarded.

WARNING!

It means that death, severe personal, or considerable equipment damage could occur if safety

precautions are disregarded.

CAUTION!

It means that light personal injury or equipment damage may occur if safety precautions are

disregarded. This particularly applies to damage to the device and to resulting damage of the

protected equipment.

WARNING!

The firmware may be upgraded to add new features or enhance/modify existing features, please

make sure that the version of this manual is compatible with the product in your hand.

WARNING!

During operation of electrical equipment, certain parts of these devices are under high voltage.

Severe personal injury or significant equipment damage could result from improper behavior.

Only qualified personnel should work on this equipment or in the vicinity of this equipment. These

personnel must be familiar with all warnings and service procedures described in this manual, as

well as safety regulations.

In particular, the general facility and safety regulations for work with high-voltage equipment must

be observed. Noncompliance may result in death, injury, or significant equipment damage.

DANGER!

Never allow the current transformer (CT) secondary circuit connected to this equipment to be

opened while the primary system is live. Opening the CT circuit will produce a dangerously high

voltage.

WARNING!

Exposed terminals

Do not touch the exposed terminals of this equipment while the power is on, as the high voltage

generated is dangerous

Preface

CZX-22R Interposing Relay Set iii

Date: 2011-04-12

Residual voltage

Hazardous voltage can be present in the DC circuit just after switching off the DC power supply. It

takes a few seconds for the voltage to discharge.

CAUTION!

Earth

The earthing terminal of the equipment must be securely earthed

Operating environment

The equipment must only be used within the range of ambient environment detailed in the

specification and in an environment free of abnormal vibration.

Ratings

Before applying AC voltage and current or the DC power supply to the equipment, check that they

conform to the equipment ratings.

Printed circuit board

Do not attach and remove printed circuit boards when DC power to the equipment is on, as this

may cause the equipment to malfunction.

External circuit

When connecting the output contacts of the equipment to an external circuit, carefully check the

supply voltage used in order to prevent the connected circuit from overheating.

Connection cable

Carefully handle the connection cable without applying excessive force.

Copyright

Version: R1.00

P/N: EN_CZXL3113.0086.0001

Copyright NR 2011. All rights reserved

NR ELECTRIC CO., LTD.

69 Suyuan Avenue. Jiangning, Nanjing 211102, China

Tel: +86-25-87178185, Fax: +86-25-87178208

Website: www.nrelect.com, www.nari-relays.com

Email: nr_techsupport@nari-relays.com

We reserve all rights to this document and to the information contained herein. Improper use in particular reproduction and dissemination to

third parties is strictly forbidden except where expressly authorized.

The information in this manual is carefully checked periodically, and necessary corrections will be included in future editions. If

nevertheless any errors are detected, suggestions for correction or improvement are greatly appreciated.

We reserve the rights to make technical improvements without notice.

Table of Contents

CZX-22R Interposing Relay Set iv

Date: 2011-04-12

Table of Contents

Preface ..................................................................................................... i

Introduction ................................................................................................................ i

Health and Safety ....................................................................................................... i

Instructions and Warnings ........................................................................................ i

Table of Contents .................................................................................. iv

1 Introduction ......................................................................................... 1

1.1 Application ........................................................................................................... 1

1.2 Features ............................................................................................................... 1

1.3 Ordering Options ................................................................................................ 1

2 Technical Data ..................................................................................... 3

2.1 Electrical Specifications ..................................................................................... 3

2.1.1 Power Supply ........................................................................................................................ 3

2.1.2 Binary Input ........................................................................................................................... 3

2.1.3 Binary Output ........................................................................................................................ 3

2.2 Mechanical Specifications ................................................................................. 4

2.3 Ambient Temperature and Humidity Range ...................................................... 4

2.4 Type Tests ............................................................................................................ 4

2.4.1 Environmental Tests .............................................................................................................. 4

2.4.2 Mechanical Tests................................................................................................................... 4

2.4.3 Electrical Tests ...................................................................................................................... 5

2.4.4 Electromagnetic Compatibility ............................................................................................... 5

2.5 Certifications ....................................................................................................... 6

2.6 Relay Performance.............................................................................................. 6

3 Operation Theory ................................................................................ 7

Table of Contents

CZX-22R Interposing Relay Set v

Date: 2011-04-12

3.1 Schematic Diagrams ........................................................................................... 7

3.1.1 Auto-Reclosing and Manual Closing Circuit .......................................................................... 7

3.1.2 Phase-Segregated Closing Circuit ........................................................................................ 8

3.1.3 Phase-Segregated Tripping Circuit (Group 1) ....................................................................... 9

3.1.4 Phase-Segregated Tripping Circuit (Group 2) ..................................................................... 10

3.1.5 Trip and Auto-reclosing Target Circuit ................................................................................. 11

3.1.6 Low Pressure Blocking Circuit ............................................................................................ 12

3.1.7 Accelerated Circuit when Manual Closing ........................................................................... 12

3.1.8 Output Contacts .................................................................................................................. 13

3.2 Power Supply .................................................................................................... 15

3.3 Closing Circuits ................................................................................................. 16

3.3.1 Auto-reclosing Circuit .......................................................................................................... 16

3.3.2 Manual and Remote Closing Circuit .................................................................................... 16

3.3.3 Phase-Segregated Closing Circuit ...................................................................................... 16

3.4 Trip Circuit ......................................................................................................... 17

3.4.1 Manual and Remote Trip ..................................................................................................... 18

3.4.2 Three Phase Trip Signal Inputs from Protection .................................................................. 18

3.4.3 Phase-Segregated Trip Circuit 1 ......................................................................................... 18

3.4.4 Phase-Segregated Trip Circuit 2 ......................................................................................... 20

3.5 KKJ ..................................................................................................................... 21

3.6 Pressure Supervision ....................................................................................... 21

3.6.1 Low Pressure to Block Trip ................................................................................................. 22

3.6.2 Low Pressure to Block Auto-reclosing ................................................................................. 22

3.6.3 Low Pressure to Block Closing ........................................................................................... 22

3.6.4 Low Pressure to Block Switching ........................................................................................ 23

3.7 Pole Disagreement ............................................................................................ 23

3.8 Control Circuit Failure ...................................................................................... 23

3.9 Spare Relays ...................................................................................................... 23

4 Hardware ........................................................................................... 25

Table of Contents

CZX-22R Interposing Relay Set vi

Date: 2011-04-12

4.1 Overview ............................................................................................................ 25

4.2 Device Layout .................................................................................................... 25

4.3 Front View .......................................................................................................... 25

4.4 Terminals ........................................................................................................... 27

4.4.1 Definition of Connector A .................................................................................................... 28

4.4.2 Definition of Connector B .................................................................................................... 29

4.4.3 Definition of Connector C .................................................................................................... 30

4.4.4 Definition of Connector D .................................................................................................... 31

4.4.5 Definition of Connector E .................................................................................................... 32

4.4.6 Definition of Connector F .................................................................................................... 33

4.4.7 Definition of Connector G .................................................................................................... 34

4.4.8 Definition of Connector H .................................................................................................... 35

4.4.9 Definition of Connector I ..................................................................................................... 35

4.5 Adjustment Method for Latching Current of Tripping & Closing .................. 37

5 Installation ......................................................................................... 39

5.1 Overview ............................................................................................................ 39

5.2 Safety Information............................................................................................. 39

5.3 Check the Shipment .......................................................................................... 40

5.4 Material and Tools Required ............................................................................ 41

5.5 Device Location and Ambient Conditions ...................................................... 41

5.6 Mechanical Installation ..................................................................................... 41

5.7 Electrical Installation ........................................................................................ 42

5.7.1 Grounding Guidelines ......................................................................................................... 42

5.7.2 Cubicle Grounding .............................................................................................................. 43

5.7.3 Making Electrical Connections ............................................................................................ 44

6 Commissioning ................................................................................. 45

6.1 Overview ............................................................................................................ 45

6.2 Safety Instructions ............................................................................................ 45

Table of Contents

CZX-22R Interposing Relay Set vii

Date: 2011-04-12

6.3 Insulation Test (if required) .............................................................................. 46

6.4 Product Checks ................................................................................................. 46

6.4.1 General Description ............................................................................................................ 46

6.4.2 Visual Inspection ................................................................................................................. 47

6.4.3 Check the Jumpers ............................................................................................................. 47

6.4.4 External Wiring .................................................................................................................... 48

6.4.5 Auxiliary Supply ................................................................................................................... 48

6.5 Final Check ........................................................................................................ 48

7 Maintenance ...................................................................................... 49

7.1 Routine Check ................................................................................................... 49

7.2 Replace Failed Modules ................................................................................... 49

7.3 Cleaning ............................................................................................................. 50

7.4 Storage ............................................................................................................... 50

8 Decommissioning and Disposal ...................................................... 51

8.1 Decommissioning ............................................................................................. 51

8.2 Disposal ............................................................................................................. 51

9 Manual Version History .................................................................... 53

Table of Contents

CZX-22R Interposing Relay Set viii

Date: 2011-04-12

1 Introduction

CZX-22R Interposing Relay Set 1

Date: 2011-04-12

1 Introduction

1.1 Application

CZX-22G interposing relay set provides auxiliary relays for switching of circuit breaker with two

group phase-segregated tripping circuits, one group phase-segregated closing circuit and an

accelerated circuit when manual closing and selecting faulty feeder. The device can be used for

circuit breaker with one and a half breakers arrangement. Protection device, BCU and other

relevant devices can trip or close circuit breaker via this device.

1.2 Features

The device is an IEC standard 4U high and 19 wide rack with modular structure. It uses an

integral faceplate and plug terminal blocks on rear panel for external connections. It has features

of compact design, high security, flexibility and convenience.

Sealed relays with high impedance and low power dissipation are used in this device. As a result,

the power dissipation and heating is reduced largely, moisture proof is improved, ensuring a long

life even in extreme mechanical and ambient conditions.

Seal-in current of trip and close circuit can be configured easily by jumpers on site according to the

rated current of trip and close coil.

A special relay is equipped in the relay set, which will pick up and latch when circuit breaker is

closed manually, and reset when circuit breaker is tripped manually. The contacts of this special

relay can be used by substation automation system to issue an accident signal whenever the

circuit breaker is tripped un-manually. Moreover, together with normal closed auxiliary contact of

circuit breaker (52b), the contacts of this special relay can also be used to initiate auto-reclosing in

case that circuit breaker trips especially without any trip commands from protection and manual

switch.

Spare relays are provided for future application.

For these circuits, initiating AR and BFP, initiating BFP but not AR, three-phase circuit of machnical

protection, manual tripping, manual closing and auto-reclosing, their initiation power are all greater

than 5W.

1.3 Ordering Options

Four options are available for rated auxiliary voltage: 250V, 220V, 125V, 110V.

The rated current of target and seal-in relays in trip and closing circuit can be configured as

0.5-4.0A with a step of 0.5A. They should be selected based on the amount of current the trip and

closing circuit drawn when operated.

1 Introduction

CZX-22R Interposing Relay Set 2

Date: 2011-04-12

The rated auxiliary voltage and nominal current of trip and close coil shall be claimed clearly when

ordering.

2 Technical Data

CZX-22R Interposing Relay Set 3

Date: 2011-04-12

2 Technical Data

2.1 Electrical Specifications

2.1.1 Power Supply

Rated Voltage 110Vdc, 125Vdc, 220Vdc, 250Vdc

Variation (80%~120%)Un

Ripple in the DC

auxiliary voltage

Max 15% of the DC value. Per IEC 60255-11:1979

Voltage dips and voltage

short interruptions

Per IEC 60255-11:1979

20ms for interruption without de-energizing, dips 60% of Un

without reset up to 100ms

Burden

Quiescent condition <40W

Operating condition <70W

2.1.2 Binary Input

Rated Voltage 110Vdc 125Vdc 220Vdc 250Vdc

Pickup voltage 77.0Vdc 87.5Vdc 154Vdc 175.0Vdc

Dropout voltage 60.5Vdc 68.8Vdc 121Vdc 137.5Vdc

Maximum permitted

voltage

150Vdc 150Vdc 300Vdc 300Vdc

Withstand 2kVac

Resolving time for logic

input

1ms

2.1.3 Binary Output

Contact Type Tripping contact Signal contact

Output mode Potential free contact

Rated Voltage 250Vac/dc 250Vac/dc

Test voltage across

open contact

> 1000Vac rms

Continuous carry 8A 5A

Short duration current

(200ms)

50A

Pickup time (Typ/Max) 5ms/10ms 10ms/15ms

Dropout time (Typ/Max) 4ms/10ms 8ms/10ms

Bounce time < 1ms < 1ms

Breaking capacity at

250Vdc

0.4A resistance

0.2A inductive (L/R=40ms)

0.2A resistance

0.05A inductive (L/R=40ms)

2 Technical Data

CZX-22R Interposing Relay Set 4

Date: 2011-04-12

Durability

Loaded contact

Unloaded contact

100,000 operations minimum

10,000,000 operations minimum

2.2 Mechanical Specifications

Enclosure dimensions

(WHD)

482.6177308 (unit: mm)

Trepanning dimensions

(WH)

450179, M6 screw

Mounting Way Flush mounted

Weight per device Approx. 10kg

Housing material Aluminum

Housing color Silver grey

Location of terminal Rear panel of the device

Protection class: Per IEC60529:1989

Front side IP40, Up to IP51 (Flush mounted)

Other sides IP30

Rear side, connection

terminals

IP20

2.3 Ambient Temperature and Humidity Range

Standard IEC 60255-6:1988

Operating temperature -25C~+60C

Transport and storage

temperature range

-40C~+70C

Permissible humidity 5%~95%, condensation not permissible

2.4 Type Tests

2.4.1 Environmental Tests

Dry cold test IEC 60068-2-1:1974 Test Ad for 16 h at -25C

Dry heat test

IEC 60068-2-2:1990 Test Bd for 16 h at +55C

Damp heat test, cyclic

IEC 60068-2-30:1980 Test Db Two (12+12) hour cycles 95%RH,

low temperature +25C, high temperature +55C

2.4.2 Mechanical Tests

Vibration IEC60255-21-1:1988 Class I

Shock and bump IEC 60255-21-2:1988 Class I

2 Technical Data

CZX-22R Interposing Relay Set 5

Date: 2011-04-12

2.4.3 Electrical Tests

Dielectric tests IEC 60255-5:2000 Test voltage 2kV, 50Hz, 1min

Impulse voltage tests

IEC 60255-5:2000 Test voltage 5kV, unipolar impulses waveform

1.2/50s,source energy 0.5J

Insulation resistance

measurements

IEC 60255-5:2000 Isolation resistance >100M, 500Vdc

2.4.4 Electromagnetic Compatibility

1MHz burst disturbance

test

Per IEC 60255-22-1:1988 (idt IEC61000-4-12:1995)

Common mode: class III 2.5KV

Differential mode: class III 1.0KV

Electrostatic discharge

test

Per IEC60255-22-2:1996 (idt IEC 61000-4-2:2006) class IV

For contact discharge: 8kV

For air discharge: 15kV

Radio frequency

interference tests

Per IEC 60255-22-3:2000 (idt IEC 61000-4-3:1995) class III

Frequency sweep

Radiated amplitude-modulated

10V/m (rms), f=801000MHz

Spot frequency

Radiated amplitude-modulated

10V/m (rms), f=80MHz/160MHz/450MHz/900MHz

Radiated pulse-modulated

10V/m (rms), f=900MHz

Fast transient

disturbance tests

Per IEC 60255-22-4:2002 (idt IEC 61000-4-4:2004)

Power supply, I/O, Earth: Class IV, 4kV, 2.5 kHz, 5/50ns

Communication terminals: Class IV, 2kV, 5 kHz, 5/50ns

Surge immunity test

Per IEC 60255-22-5:2002 (idt IEC 61000-4-5:1995) class III

Power supply, AC input, I/O port: 2kV, line to earth; 1kV line to

line, 1.2/50us

Conducted RF

Electromagnetic

Disturbance

Per IEC 60255-22-6:2001

Power supply, AC, I/O, Comm. Terminal: Class III, 10Vrms, 150

kHz~80MHz

Power Frequency

Magnetic Field Immunity

Per IEC 61000-4-8:1993

Class V: 100A/m for 1min, 1000A/m for 3s

Pulse Magnetic Field

Immunity

Per IEC 61000-4-9:1993

Class V: 6.4/16s, 1000A/m for 3s

Damped oscillatory

magnetic field immunity

IEC 61000-4-10:1993

Class V: 100kHz & 1MHz100A/m

2 Technical Data

CZX-22R Interposing Relay Set 6

Date: 2011-04-12

2.5 Certifications

1. ISO9001: 2000

2. ISO14001:2004

3. OHSAS18001:1999

4. ISO10012:2003

5. CMMI L3

6. EMC: 89/336/EEC, EN50263:2000

7. Products safety(PS): 73/23/EEC, EN61010-1: 2001, EN60950: 2002

2.6 Relay Performance

Seal-in current of trip & closing circuit: 0.5A~4.0A (Configurable with a step of 0.5A)

Drop-off time of manual closing relay (21SHJ, 22SHJ, 23SHJ): >0.4s

Drop-off time of low pressure blocking relay for auto-reclosing (21YJJ, 22YJJ): >0.3s

Drop-off time of low pressure blocking relay for closing (3YJJ): >0.3s

Pulse width of trip relay 11TJF, 12TJF, 21TJF, 22TJF0.3S

Power supply burden: <25W

Pickup voltage of relay: 55%~70% of nominal voltage

3 Operation Theory

CZX-22R Interposing Relay Set 7

Date: 2011-04-12

3 Operation Theory

3.1 Schematic Diagrams

3.1.1 Auto-Reclosing and Manual Closing Circuit

Spare relays

Group 1

Group 2

Auto-reclosing

Manual closing

Manual tripping

Initiate AR and

BFP

F

o

r

t

r

i

p

p

i

n

g

c

o

i

l

(

G

r

o

u

p

1

)

T

h

r

e

e

-

p

h

a

s

e

t

r

i

p

p

i

n

g

KKJ

Initiate BFP but

not AR

S

u

p

e

r

v

i

s

i

o

n

o

n

D

C

p

o

w

e

r

n6

Not initiate AR

and BFP

F

o

r

t

r

i

p

p

i

n

g

c

o

i

l

(

G

r

o

u

p

2

)

Initiate AR and

BFP

Initiate BFP but

not AR

Not initiate AR

and BFP

Figure 3.1-1 Auto-reclosing and manual closing circuit

3 Operation Theory

CZX-22R Interposing Relay Set 8

Date: 2011-04-12

3.1.2 Phase-Segregated Closing Circuit

Closing

Open state

supervision

A

-

p

h

a

s

e

c

l

o

s

i

n

g

c

i

r

c

u

i

t Anti-pump

O

p

e

r

a

t

i

o

n

m

e

c

h

a

n

i

s

m

o

f

c

i

r

c

u

i

t

b

r

e

a

k

e

r

Closing

Open state

supervision

B

-

p

h

a

s

e

c

l

o

s

i

n

g

c

i

r

c

u

i

t

Anti-pump

Closing

Open state

supervision

C

-

p

h

a

s

e

c

l

o

s

i

n

g

c

i

r

c

u

i

t

Anti-pump

Figure 3.1-2 Phase-segregated closing circuit

3 Operation Theory

CZX-22R Interposing Relay Set 9

Date: 2011-04-12

3.1.3 Phase-Segregated Tripping Circuit (Group 1)

Closed state

supervision

A-phase

tripping

O

p

e

r

a

t

i

o

n

m

e

c

h

a

n

i

s

m

o

f

c

i

r

c

u

i

t

b

r

e

a

k

e

r

T

r

i

p

p

i

n

g

c

i

r

c

u

i

t

(

G

r

o

u

p

1

)

Closed state

supervision

B-phase

tripping

Closed state

supervision

C-phase

tripping

Figure 3.1-3 Phase-segregated tripping circuit (Group 1)

3 Operation Theory

CZX-22R Interposing Relay Set 10

Date: 2011-04-12

3.1.4 Phase-Segregated Tripping Circuit (Group 2)

Closed

state

supervision

A-phase

tripping

O

p

e

r

a

t

i

o

n

m

e

c

h

a

n

i

s

m

o

f

c

i

r

c

u

i

t

b

r

e

a

k

e

r

Closed

state

supervision

B-phase

tripping

C-phase

tripping

Closed

state

supervision

T

r

i

p

p

i

n

g

c

i

r

c

u

i

t

(

G

r

o

u

p

2

)

Figure 3.1-4 Phase-segregated tripping circuit (Group 2)

3 Operation Theory

CZX-22R Interposing Relay Set 11

Date: 2011-04-12

3.1.5 Trip and Auto-reclosing Target Circuit

A-phase

tripping

Auto-

reclosing

Manual reset

T

a

r

g

e

t

c

i

r

c

u

i

t

(

G

r

o

u

p

1

)

T

a

r

g

e

t

c

i

r

c

u

i

t

(

G

r

o

u

p

2

)

C-phase

tripping

B-phase

tripping

A-phase

tripping

C-phase

tripping

B-phase

tripping

Manual reset

n6

n98

n7 n143

n9 n99

n8 n144

Figure 3.1-5 Trip and auto-reclosing target circuit

3 Operation Theory

CZX-22R Interposing Relay Set 12

Date: 2011-04-12

3.1.6 Low Pressure Blocking Circuit

Low

pressure to

block trip

Low

pressure to

block auto-

reclosing

Low

pressure to

block

closing

Low

pressure to

block

switching

Figure 3.1-6 Low pressure blocking circuit

3.1.7 Accelerated Circuit when Manual Closing

AC voltage

circuit

Accelerated

circuit after

manual closing

Figure 3.1-7 Accelerated circuit after manual closing

3 Operation Theory

CZX-22R Interposing Relay Set 13

Date: 2011-04-12

3.1.8 Output Contacts

C

o

o

p

e

r

a

t

i

o

n

w

i

t

h

B

F

P

a

n

d

A

R

Spare

52b

Three-phase

tripping to initiate

BFP but not AR

Low pressure to

block AR

Block AR

To main

protection 1 of

line 1 (for

example 902 or

931)

Spare relays

To main

protection 2 of

line 1 (for

example 902 or

931)

To

independent

backup

protection (for

example 921)

To transfer trip

protection 1 of

line 1 (for

example 925)

To transfer trip

protection 2 of

line 1 (for

example 925)

Spare three-

phase

tripping relay

To main

protection 1 of

line 2 (for

example 902 or

931)

Spare relays

To main

protection 2 of

line 2 (for

example 902 or

931)

To

independent

backup

protection (for

example 921)

To transfer trip

protection 1 of

line 2 (for

example 925)

To transfer trip

protection 2 of

line 2 (for

example 925)

Spare three-

phase

tripping relay

Three-phase

tripping to initiate

AR and BFP

Loss power to block

AR

Figure 3.1-8 Output contacts (Part 1)

3 Operation Theory

CZX-22R Interposing Relay Set 14

Date: 2011-04-12

Pole disagreement

of circuit breaker or

pole discrepancy

condition

C

o

n

t

r

o

l

c

i

r

c

u

i

t

f

a

i

l

u

r

e

Group 1

Group 2

AR

S

i

g

n

a

l

c

i

r

c

u

i

t

T

r

i

p

p

i

n

g

o

u

t

p

u

t

Group 1

Group 2

DC power supply

failure (group 1)

DC power supply

failure (group 2)

Low pressure to block

tripping

Low pressure to block

auto-closing

Low pressure to block

closing

Low pressure to block

tripping and closing

Figure 3.1-9 Output contacts (Part 2)

3 Operation Theory

CZX-22R Interposing Relay Set 15

Date: 2011-04-12

CB position

R

e

m

o

t

e

s

i

g

n

a

l

KKJ spare contacts

KKJ post closing

S

i

g

n

a

l

c

i

r

c

u

i

t

52a

52b

CB position

R

e

c

o

r

d

e

r

Phase-

segregated

tripping

Three-phase

tripping

AR

Figure 3.1-10 Output Contacts (Part 3)

3.2 Power Supply

Please refer to Figure 3.1-1 and Figure 3.1-6. Two independent auxiliary power supplies are used.

Auxiliary power 1 is supplied via terminal n6 and n98 to power the following circuits: closing circuit,

manual trip repetition, trip and auto-reclosing circuit, and trip circuit 1.

Auxiliary power 2 is supplied via terminal n9 and n99 to power trip circuit 2.

These two power supplies are supervised by relays 12JJ & 2JJ respectively as shown in Figure

3.1-1, if the power supply fails, then an alarm will be issued by the normal closed contact of 12JJ

or 2JJ via terminal n82-n83 and n82-n84 respectively.

An additional power supply namely auxiliary power 3 comes from terminal n10 and n100. If

applicable, low pressure blocking circuit shown in Figure 3.1-6 and spare relays 1ZJ, 2ZJ in Figure

3.1-1 are powered by this supply. Normally, this power supply comes from a switchover circuit of

auxiliary power 1 and 2 via relay 11JJ refer to Figure 3.1-1.

3 Operation Theory

CZX-22R Interposing Relay Set 16

Date: 2011-04-12

3.3 Closing Circuits

3.3.1 Auto-reclosing Circuit

Please refer to Figure 3.1-1. When auto-reclosure issues a closing signal, it will connect power

supply to terminal n112, relays ZHJ and ZXJ will operate. ZHJ is a repetition relay of

auto-reclosing and ZXJ is a magnetic latching target relay. The normal open contacts of ZHJ will

energize phase-segregated closing circuits in figure 3-2. When ZXJ operates, as shown in Figure

3.1-5, a LED 1HX located in faceplate of the equipment will light to indicate an operation of

auto-reclosing circuit. This target relay can be reset by signal from n6-n143.

3.3.2 Manual and Remote Closing Circuit

When manual closing or remote closing signal arrives at terminal n101, 1SHJ, 21SHJ, 22SHJ and

23SHJ will operate, at the same time, the relay KKJ will operate and latch, please refer to section

3.5 for details of KKJ. The normal open contacts of 1SHJ will energize phase-segregated close

circuits as shown in Figure 3.1-2. The normal open contacts of 21SHJ will block auto-reclosure via

terminal n172-n173, as Figure 3.1-8 shows.

The normal open contacts of 22YJJ and 3YJJ in the circuit are provided to prevent manual closing

under low pressure. When the pressure is reduced to a limit that closing shall be blocked, these

two relays will drop out and cut the manual closing circuit. Please refer to section 3.6.

The normal open contact of 23SHJ in parallel with coils of 21SHJ, 22SHJ and 23SHJ provides the

path to charge the capacitors when pickup and this circuit will prolong the signal pulse to ensure

that it is longer than 0.4s. This is essential to provide signal to protective relays to initiate switch

onto fault protection.

3.3.3 Phase-Segregated Closing Circuit

Phase-segregated closing circuit is shown in Figure 3.1-2. Terminal n104, n106, and n108 shall

connect to phase closing coils (CC) in series with normal closed auxiliary contact of circuit breaker

(52b).

3.3.3.1 Circuit Breaker Open State and Close Coil Supervision

The auxiliary relays 1TWJa, 2TWJa, 3TWJa, 1TWJb, 2TWJb, 3TWJb, 1TWJc, 2TWJc, 3TWJc,

are applied to supervise the open state of circuit breaker when terminal n103, 105, 107 is

connected to the negative pole of power supply in series with normal closed auxiliary contact of

each phase of circuit breaker (52b).

In addition, if terminal n103, 105, 107 is connected to terminal n104, n106 and n108 respectively,

i.e. connected to normal closed auxiliary contact of circuit breaker (52b) and its close coil (CC) of

each phase respectively, these auxiliary relays can provide supervision on health of close coil as

well.

As Figure 3.1-8, Figure 3.1-9 and Figure 3.1-10 shows, these relays can be regarded as

multiplication relays of 52b, many contacts of these supervision relays are provided for protection

3 Operation Theory

CZX-22R Interposing Relay Set 17

Date: 2011-04-12

and auto-reclosing. Anyway, the protection and auto-reclosing can uses auxiliary contacts 52b

directly from circuit breaker. But this feature provides a convenient solution in case there arent

enough auxiliary contacts available.

The multiplication contacts of 52b for protection and auto-reclosure can be used in logic scheme of

pole discrepancy protection, switch onto fault protection, breaker 52b switch keying with echo for

pilot protection, auto-reclosing reclaim and initiation, and VT circuit supervision.

Some contacts are used in pole disagreement alarm and control circuit failure alarm, please refer

to section 3.7, section 3.8 and Figure 3.1-9.

3.3.3.2 Closing Signal

Whenever auto-reclosing or manual/remote closing signal comes, the contacts of ZHJ or 1SHJ will

energize phase-segregated closing circuits. Please refer to section 3.3.1 and section 3.3.2.

3.3.3.3 Low Pressure Blocking

11YJJ is the low pressure blocking contact. Please refer to section 3.6.1 for details. If this built-in

feature is not used, just shorten the associated normal open contacts of 11YJJ (terminal n6-n198).

3.3.3.4 Seal-in Relays

Seal-in relays SHJa, SHJb and SHJc are used in closing circuit. When closing signal disappears,

the normal open contacts of these relays will keep closing to maintain closing circuits working till

circuit breaker closed.

The pickup current can be configured as 0.5-4.0A with a step of 0.5A, please refer to section 4.5.

3.3.3.5 Anti-pump Circuit

1TBUJa, 2TBUJa, 1TBUJb, 2TBUJb, 1TBUJc, 2TBUJc are applied to achieve anti-pump function.

In the event that a breaker is closed onto a fault, while the operator is applying a close signal via a

close control switch, the circuit breaker will trip and prevent closing again until the closing circuit

has been de-energized by the operators releasing the control switch.

When trip signal comes and at the same time close signal persists, the contacts of trip seal-in

relays 12TBIJa, 22TBIJa, 12TBIJb, 22TBIJb, 12TBIJc, 22TBIJc (please refer to section 3.4.3.4

and section 3.4.4.4) will close to activate 1TBUJa, 1TBUJb, 1TBUJc; then the contacts of 1TBUJa,

1TBUJb, 1TBUJc will activate 2TBUJa, 2TBUJb, 2TBUJc; 2TBUJa, 2TBUJb, 2TBUJc will operate

and keep sealed with their own normal open contacts until closing signal disappears. The normal

closed contacts of 1TBUJa, 2TBUJa, 1TBUJb, 2TBUJb, 1TBUJc, 2TBUJc will cut off closing

circuits to prevent any further closing.

If there are anti-pump circuits in circuit breaker itself, this built-in anti-pump function can be

released by shortening terminal n109-n104, n110-n106 and n111-n108 to bypass the normal

closed contacts of 1TBUJa, 2TBUJa, 1TBUJb, 2TBUJb, 1TBUJc, 2TBUJc.

3.4 Trip Circuit

3 Operation Theory

CZX-22R Interposing Relay Set 18

Date: 2011-04-12

3.4.1 Manual and Remote Trip

When manual trip or remote trip signal arrives at terminal n114, the interposing relays 1STJ, STJa,

STJb and STJc will operate, and the relay KKJ will drop out. Please refer to section 3.5 for the

details of KKJ. The normal open contacts of STJa, STJb, and STJc will energize

phase-segregated trip circuits, as shown in Figure 3.1-3 and Figure 3.1-4. The normal open

contact of 1STJ will block auto-reclosure via terminal n170-n171, as Figure 3.1-8 shows.

3.4.2 Three Phase Trip Signal Inputs from Protection

Please refer to Figure 3.1-1. Two groups of trip-signal correspond to two groups of trip-coil

respectively.

Two types of trip signals are adopted:

3.4.2.1 Three-phase Tripping and Initiate AR

This kind of trip signal from protective relays is desired to initiate auto-reclosing.

The first trip signal from terminal n115 will activate 11TJQ, 12TJQ and 13TJQ; the second trip

signal from terminal n124 will activate 21TJQ, 22TJQ and 23TJQ. The normal open contacts of

11TJQ, 12TJQ, 21TJQ, 22TJQ will energize two groups of phase-segregated trip circuits

respectively, as shown in Figure 3.1-3 and Figure 3.1-4. One group of their contacts is wired

through terminal n23-n24 to initiate auto-reclosure and breaker failure protection, and two spare

contacts are provided through terminal n61-n62, n65-n66, please refer to Figure 3.1-8.

3.4.2.2 Three-phase Tripping and Block AR

This kind of trip signal from protective relays is desired to block auto-reclosing.

The first trip signal from terminal n116 will activate 11TJR, 12TJR and 13TJR; the second trip

signal from terminal n125 will activate 21TJR, 22TJR and 23TJR. The normal open contacts of

11TJR, 12TJR, 21TJR, 22TJR will energize two groups of phase-segregated trip circuits

respectively, as shown in Figure 3.1-3 and Figure 3.1-4. One group of their contact is wired

through terminal n25-n26 to block auto-reclosure and initiate breaker failure protection, and two

spare contacts are provided through terminal n61-n62, n65-n66, please refer to Figure 3.1-8.

3.4.2.3 Mechanical Relay Three-phase Tripping

This kind of trip signal from mechanical protection is desired to tripping of mechanical protection of

main transformer.

The first trip signal from terminal n158 will activate 11TJF, 12TJF and 13TJF. The second trip

signal from terminal n159 will activate 21TJF, 22TJF and 23TJF. They are connected to two

groups of DC power supply. 11TJF, 12TJF and 13TJF will energize first group of

phase-segregated tripping circuit, and 21TJF, 22TJF and 23TJF will energized second group of

phase-segregated tripping circuit. The operating time of these relays is 0.3s, to prevent TJF circuit

from always active if mechanical tripping signal can not drops off in time.

3.4.3 Phase-Segregated Trip Circuit 1

Phase-segregated trip circuit 1 is shown in Figure 3.1-3. Terminal n118, n119, and n120 shall

3 Operation Theory

CZX-22R Interposing Relay Set 19

Date: 2011-04-12

connect to the first group of phase trip coils in series with normal open auxiliary contact of circuit

breaker (52a).

3.4.3.1 Circuit Breaker Closed State and Trip Coil Supervision circuit 1

The auxiliary relays 11HWJa, 12HWJa, 13HWJa, 11HWJb, 12HWJb, 13HWJb, 11HWJc, 12HWJc,

13HWJc are applied to supervise the closed state of circuit breaker when terminal n118, n119,

n120 are connected to the negative pole of power supply in series with normal open auxiliary

contact of each phase of circuit breaker (52a). Health of trip coils is monitored at the same time.

In Figure 3.1-9, some contacts are provided as multiplication of 52a. Some contacts are used in

pole disagreement alarm and control circuit failure alarm, please refer to section 3.7, section 3.8

and Figure 3.1-9.

LED PH A OK, PH B OK and PH C OK which located on the faceplate of the device indicate the

closed position and health of trip coil 1 of circuit breaker.

3.4.3.2 Trip Signal

Manual/remote trip signals come from the contacts of STJa, STJb, STJc, please refer to section

3.4.1.

Three phase trip signals of protection come from the contacts of 11TJQ, 12TJQ, 11TJR, 12TJR.

Please refer to section 3.4.2.

The first group of phase-segregated trip contacts from protective relays can be connected

between n198-n121 for phase A, n198-n122 for phase B and n198-n123 for phase C respectively.

3.4.3.3 Low Pressure Blocking

11YJJ is the low pressure blocking contact. Please refer to section 3.6.1 for details. If this built-in

feature is not used, just shorten the associated normal open contacts of 11YJJ (terminal n6-n198).

3.4.3.4 Seal-in Relays

Seal-in relays 11TBIJa, 12TBIJa, 11TBIJb, 12TBIJb, 11TBIJc, 12TBIJc are used in trip circuit.

When tipping signal disappears, the normal open contacts of these relays will keep closing to

maintain trip circuits working till circuit breaker tripped.

The pickup current can be configured as 0.5-4.0A with a step of 0.5A, please refer to section 4.5.

In addition, the contacts of 12TBIJa, 12TBIJb, 12TBIJc are also used in anti-pump logic scheme.

Please refer to section 3.3.3.5.

3.4.3.5 Target Relays

The normal open contacts of 11TBIJa, 11TBIJb, 11TBIJc will activate magnetic latching target

relays 1TXJa, 1TXJb and 1TXJc respectively, as Figure 3.1-5 shows. The contacts of 1TXJa,

1TXJb and 1TXJc will light LEDs 1TXa, 1TXb and 1TXc.

A group of contacts of 1TXJa, 1TXJb and 1TXJc are provided via n139-n140, n141, n142, for

event recording or central annunciation. A group of contacts of 1TXJa, 1TXJb and 1TXJc are

3 Operation Theory

CZX-22R Interposing Relay Set 20

Date: 2011-04-12

provided via n82-n80 for annunciation.

LEDs PH A TRIP, PH B TRIP and PH C TRIP located in faceplate of the device show that certain

protective relays have tripped circuit breaker via the first group of trip coils.

Please note that the contacts of STJa, STJb, and STJc are in series with the activating circuits of

1TXJa, 1TXJb, 1TXJc, that means manual/remote trip will not activate target relays.

The magnetic latching target relays 1TXJa, 1TXJb and 1TXJc can be reset by signal from n6-n143,

as shown in Figure 3.1-5.

3.4.4 Phase-Segregated Trip Circuit 2

Phase-segregated trip circuit 2 is shown in Figure 3.1-4. Terminal n127, n128, and n129 shall

connect to the second group of phase trip coils in series with normal open auxiliary contact of

circuit breaker (52a).

3.4.4.1 Circuit Breaker Closed State and Trip Coil Supervision circuit 2

The auxiliary relays 21HWJa, 22HWJa, 23HWJa, 21HWJb, 22HWJb, 23HWJb, 21HWJc, 22HWJc,

23HWJc are applied to supervise the closed state of circuit breaker when terminal n127, n128,

n129 are connected to the negative pole of power supply in series with normal open auxiliary

contact of each phase of circuit breaker (52a). Health of trip coils is monitored at the same time.

In Figure 3.1-9, some contacts are provided as multiplication of 52a. Some contacts are used in

pole disagreement alarm and circuit failure alarm circuits, please refer to section 3.7, section 3.8

and Figure 3.1-9.

LED PH A OK, PH B OK and PH C OK which located on the faceplate of the device indicate the

closed position and health of trip coil 2 of circuit breaker.

3.4.4.2 Trip Signal

Manual/remote trip signals come from the contacts of STJa, STJb, STJc, please refer to section

3.4.1.

Three phase trip signals of protection come from the contacts of 21TJQ, 22TJQ, 21TJR, 22TJR.

Please refer to section 3.4.2.

The second group of phase-segregated trip contacts from protective relays can be connected

between n200-n130 for phase a, n200-n131 for phase b and n200-n132 for phase c respectively.

3.4.4.3 Low Pressure Blocking

11YJJ is the low pressure blocking contact. Please refer to section 3.6.1 for details. If this built-in

feature is not used, just shorten the associated normal open contacts of 11YJJ (terminal n9-n200).

3.4.4.4 Seal-in Relays

Seal-in relays 21TBIJa, 22TBIJa, 21TBIJb, 22TBIJb, 21TBIJc, 22TBIJc are used in trip circuit.

When tipping signal disappears, the normal open contacts of these relays will keep closing to

maintain trip circuits working till circuit breaker tripped.

3 Operation Theory

CZX-22R Interposing Relay Set 21

Date: 2011-04-12

The pickup current is be configured as 0.5-4.0A with a step of 0.5A, please refer to section 4.5.

In addition, the contacts of 22TBIJa, 22TBIJb, 22TBIJc are also used in anti-pump logic scheme.

Please refer to section 3.3.3.5.

3.4.4.5 Target Relays

The normal open contacts of 21TBIJa, 21TBIJb, 21TBIJc will activate magnetic latching target

relays 2TXJa, 2TXJb and 2TXJc respectively, as Figure 3.1-5 shows. The contacts of 2TXJa,

2TXJb and 2TXJc will light LEDs 2TXa, 2TXb and 2TXc.

A group of contacts of 2TXJa, 2TXJb and 2TXJc are provided via n139-n140, n141, n142, for

event recording or central annunciation. A group of contacts of 2TXJa, 2TXJb and 2TXJc are

provided via n82-n81 for annunciation.

LEDs PH A TRIP, PH B TRIP and PH C TRIP located in faceplate of the device show that certain

protective relays have tripped circuit breaker via the second group of trip coils.

Please note that the contacts of STJa, STJb, and STJc are in series with the activating circuits of

2TXJa, 2TXJb, 2TXJc, that means manual/remote trip will not activate target relays.

The magnetic latching target relays 2TXJa, 2TXJb and 2TXJc can be reset by signal from n9-n144,

as shown in Figure 3.1-5.

3.5 KKJ

Please refer to Figure 3.1-1. KKJ is a bistable auxiliary relay, which is called as post-closing

position relay. When circuit breaker is closed manually, the relay KKJ will pick up and latch. When

circuit breaker is tripped manually, the relay KKJ will reset. The contacts of this special relay can

be used by substation automation system to issue an accident signal whenever circuit breaker is

tripped un-manually. Moreover, together with normal closed auxiliary contact of circuit breaker

(52b), the contacts of this special relay can also be used to initiate auto-reclosure in case that

circuit breaker trips especially without any trip commands from protection and manual switch. The

contacts of KKJ are wired at terminal n213-n214 and n211-n212, as shown in Figure 3.1-1 and

Figure 3.1-10.

3.6 Pressure Supervision

Pressure supervision circuit is shown in Figure 3.1-6. This circuit is energized by the third power

supply from terminals n10-n100; please refer to section 3.2 for details.

Four levels of pressure are provided:

-Low pressure to block auto-reclosing from terminal n12/n68

-Low pressure to block closing from terminal n13/n70

-Low pressure to block trip from terminal n11/n67

-Low pressure to block switching (both closing and trip) from n14/n145

3 Operation Theory

CZX-22R Interposing Relay Set 22

Date: 2011-04-12

3.6.1 Low Pressure to Block Trip

If normal open contact of low pressure to block trip is applied, this contact can connect terminal

n67 and negative pole of auxiliary power; terminal n11 shall connect to positive pole of power

supply. While if normal closed contact of low pressure to block trip is applied, this contact can

connect terminal n11 and positive pole of auxiliary power; terminal n67 shall keep unconnected.

When the relay 4YJJ picks up, it will release 11YJJ and 12YJJ to block trip. 4YJJ is a low pressure

to block switching (both trip and closing), please refer to section 3.6.4 for details.

The normal open contacts of 11YJJ are used in phase-segregated closing circuit and

phase-segregated trip circuit to permit switch of circuit breaker. Please refer to Figure 3.1-2, Figure

3.1-3 and Figure 3.1-4. If this built-in feature is not used, just shorten the associated normal open

contacts of 11YJJ.

Another normal closed contact of 12YJJ is provided via terminal n82-n76 for annunciation shown

in Figure 3.1-9.

3.6.2 Low Pressure to Block Auto-reclosing

If normal open contact of low pressure to block auto-reclosing is applied, this contact can connect

terminal n68 and negative pole of auxiliary power; terminal n12 shall connect to positive pole of

power supply. While if normal closed contact of low pressure to block auto-reclosing is applied, this

contact can connect terminal n12 and positive pole of auxiliary power; terminal n68 shall keep

unconnected.

The diode, capacitors and resistor series-parallel connected with relay 21YJJ, 21YJJ and 22YJJ

in the circuit are used to delay the dropout of 21YJJ, 21YJJ and 22YJJ by not shorter than 0.3s.

This feature is useful to ensure a successful reclosing when circuit breaker pressure goes low

temporarily after the auto-reclosure being initiated.

In normal condition, the relays will operate and the normal open contact of 22YJJ will permit

closing, please refer to section 3.3.2.

One normal closed contact of 21YJJ is provided through terminal n25-n27 to block the

auto-relocsure if the pressure goes low to a certain limit, please refer to Figure 3.1-8.

Another normal closed contact of 22YJJ is provided via terminal n82-n77 for annunciation shown

in Figure 3.1-9.

3.6.3 Low Pressure to Block Closing

If normal open contact of low pressure to block closing is applied, this contact can connect

terminal n70 and negative pole of auxiliary power; terminal n13 shall connect to positive pole of

power supply. While if normal closed contact of low pressure to block closing is applied, this

contact can connect terminal n13 and positive pole of auxiliary power; terminal n70 shall keep

unconnected.

In normal condition, the relay 3YJJ will operate and the normal open contact of 3YJJ will permit

manual/remote closing, please refer to section 3.3.2.

3 Operation Theory

CZX-22R Interposing Relay Set 23

Date: 2011-04-12

The diode, capacitors and resistor in the circuit are used to delay the dropout of 3YJJ by not

shorter than 0.3s. This feature is useful to ensure a successful closing when circuit breaker

pressure goes low temporarily after the closing being initiated.

Another normal closed contact of 3YJJ is provided via terminal n82-n78 for annunciation shown in

Figure 3.1-9.

3.6.4 Low Pressure to Block Switching

If normal closed contact of low pressure to block switching (both trip and closing) is applied, this

contact can connect terminal n145 and negative pole of auxiliary power; terminal n14 shall

connect to positive pole of power supply. While if normal open contact of low pressure to block

switching is applied, this contact can connect terminal n14 and positive pole of auxiliary power;

terminal n145 shall keep unconnected.

Whenever this signal comes, one normal open contact of 4YJJ will close and release 11YJJ and

12YJJ immediately to block both trip and closing circuit, please refer to section 3.6.1.

The other two contacts of 4YJJ are provided via terminal n168-n169 and n176-n177 for future

application in Figure 3.1-8.

Another normal open contact of 4YJJ is provided via terminal n82-n79 for annunciation shown in

Figure 3.1-9.

3.7 Pole Disagreement

Please refer to Figure 3.1-9. A series-parallel connected circuit is employed to provide a pole

disagreement signal via terminal n71-n73. Contacts of 2TWJa, 2TWJb, 2TWJc can be regarded

as multiplication of 52b, and 13HWJa, 13HWJb, 13HWJc, 23HWJa, 23HWJb, 23HWJc can be

regarded as multiplication of 52a.

Please refer to section 3.3.3, section 3.4.3.1 and section 3.4.4.1.

3.8 Control Circuit Failure

As mentioned in section 3.3.3.1 and section 3.4.3.1:

-The relays 3TWJa, 3TWJb, 3TWJc can supervise the health of closing coils in open state.

-The relays 11HWJa, 11HWJb and 11HWJc can supervise the health of trip coil 1 in closed state.

-The relays 21HWJa, 21HWJb and 21HWJc can supervise the health of trip coil 2 in closed state.

Whenever there is a failure in trip coil under closed state or a failure in closing coils under open

state, an alarm will be issued via terminal n72-n74, n72-n75, refer to Figure 3.1-9.

3.9 Spare Relays

Please refer to Figure 3.1-1. Two spare relays 1ZJ, 2ZJ are provided for future application. This

circuit is energized by the third power supply from terminals n10-n100; please refer to section 3.2

for details.

3 Operation Theory

CZX-22R Interposing Relay Set 24

Date: 2011-04-12

The diode, capacitors and resistor series-parallel connected with relay 1ZJ are used to prolong the

signal pulse to ensure that it is longer than 0.4s.

The contacts of 1ZJ and 2ZJ are shown in Figure 3.1-8.

4 Hardware

CZX-22R Interposing Relay Set 25

Date: 2011-04-12

4 Hardware

4.1 Overview

The device is an IEC standard 4U high and 19 wide rack with modular structure. It uses an

integral faceplate and plug terminal blocks on rear panel for external connections. It has features

of compact design, high security, flexibility and convenience.

There are 14 modules plugged into chassis of CZX-22G from the front side, and then an

integrated faceplate is fastened to cover these modules. From left to right in front view, these

modules are:

Table 4.1-1 Plug-in modules

Slot No. Item Description

1 QYBS

low pressure blocking circuit;

2 ST1B

three phases trip circuit (part 1)

3 ST2A

three phases trip circuit (part 2)

4 FTHL

trip circuit 1 of phase A

5 FTHL

trip circuit 1 of phase B

6 FTHL

trip circuit 1 of phase C

7 HZHL

manual closing, auto-reclosing circuits

8 FHHL

closing circuit of phase A

9 FHHL

closing circuit of phase B

10 FHHL

closing circuit of phase C

11 FTHL

trip circuit 2 of phase A

12 FTHL

trip circuit 2 of phase B

13 FTHL

trip circuit 2 of phase C

14 JDY

selecting accelerated bay when manual closing

15 EXT

Spare extend

16 Null

4.2 Device Layout

The case material of the device is constructed from pre-finished steel that has a conductive

covering of aluminum and zinc. This provides good earthing at all joints giving a low impedance

path to earth that is essential for performance in the presence of external noise.

Medium duty soldering plug terminal blocks are used for inputs, outputs and the power supply.

4.3 Front View

The front panel of the equipment includes 18 LEDs.

4 Hardware

CZX-22R Interposing Relay Set 26

Date: 2011-04-12

CZX-22

INTERPOSING RELAY SET

RECLOSE

PH B TRIP

PH B OK

TRIP CIRCUIT SUPERVISION 1

TRIP SIGNAL 1

PH A TRIP

PH A OK

PH C TRIP

PH C OK

AUX DC1

AUX DC2

PH A OK

CLOSE CIRCUIT SUPERVISION

PH B OK PH C OK

PH B TRIP

PH B OK

TRIP CIRCUIT SUPERVISION 2

TRIP SIGNAL 2

PH A TRIP

PH A OK

PH C TRIP

PH C OK

1

2

3

4

5

6

7

Figure 4.3-1 Panel Layout

In the figure above:

1. PH A OK, PH B OK, PH C OK

They are indicator LEDs that monitor phase A, B and C tripping circuit for the first group of trip coil

respectively.

2. PH A TRIP, PH B TRIP, PH C TRIP

They are indicator LEDs of phase A, B and C tripping signal for the first group of trip coil

respectively.

3. PH A OK, PH B OK, PH C OK

They are indicator LEDs that monitor phase A, B and C tripping circuit for the second group of trip

coil respectively.

4. PH A TRIP, PH B TRIP, PH C TRIP

They are indicator LEDs of phase A, B and C tripping signal for the second group of trip coil

respectively.

5. PH A OK, PH B OK, PH C OK

They are indicator LEDs that monitor phase A, B and C closing circuit of closing coil respectively.

6. RECLOSE

It is indicator LED of closing signal.

7. AUX DC1, AUX DC2

It is indicator LEDs that monitor the first and second group of DC power supplies.

Table 4.3-1 Left Group of Indicators

No. LED Function

1

PH A OK

ON: A-phase tripping closing is healthy and circuit breaker is on closed position,

OFF: A-Phase is open or A-phase trip coil 1 is broken

4 Hardware

CZX-22R Interposing Relay Set 27

Date: 2011-04-12

PH B OK

PH C OK

ON: B-phase tripping closing is healthy and circuit breaker is on closed position,

OFF: B-Phase is open or A-phase trip coil 1 is broken

ON: C-phase tripping closing is healthy and circuit breaker is on closed position,

OFF:C-Phase is open or A-phase trip coil 1 is broken

2

PH A TRIP

PH B TRIP

PH C TRIP

ON: Tripping A-phase of circuit breaker by trip coil 1 through this device, OFF:

under normal condition

ON: Tripping B-phase of circuit breaker by trip coil 1 through this device, OFF:

under normal condition

ON: Tripping C-phase of circuit breaker by trip coil 1 through this device, OFF:

under normal condition

3

PH A OK

PH B OK

PH C OK

ON: A-phase tripping closing is healthy and circuit breaker is on closed position,

OFF: A-Phase is open or A-phase trip coil 2 is broken

ON: B-phase tripping closing is healthy and circuit breaker is on closed position,

OFF: B-Phase is open or A-phase trip coil 2 is broken

ON: C-phase tripping closing is healthy and circuit breaker is on closed position,

OFF:C-Phase is open or A-phase trip coil 2 is broken

4

PH A TRIP

PH B TRIP

PH C TRIP

ON: Tripping A-phase of circuit breaker by trip coil 2 through this device, OFF:

under normal condition

ON: Tripping B-phase of circuit breaker by trip coil 2 through this device, OFF:

under normal condition

ON: Tripping C-phase of circuit breaker by trip coil 2 through this device, OFF:

under normal condition

5

PH A OK

PH B OK

PH C OK

ON: A-phase closing circuit is normal and circuit breaker is on open position,

OFF: A-phase is closed or A-phase closing coil is broken

ON: B-phase closing circuit is normal and circuit breaker is on open position,

OFF: B-phase is closed or B-phase closing coil is broken

ON: C-phase closing circuit is normal and circuit breaker is on open position,

OFF: C-phase is closed or C-phase closing coil is broken

6 RECLOSE ON: Closing circuit breaker through this device, OFF: under normal condition

7

AUX DC1

AUX DC2

ON: DC power supply 1 is normal, OFF: DC power supply 1 is abnormal

ON: DC power supply 2 is normal, OFF: DC power supply 2 is abnormal

4.4 Terminals

There are 9 30-pin connectors used as terminals of external connection mounted on rear plate of

the device. From right to left on the rear, they are denoted as connector A to connector I

respectively.

4 Hardware

CZX-22R Interposing Relay Set 28

Date: 2011-04-12

Figure 4.4-1 Rear view

n1

n2

n3

n4

n5

n6

n7

n8

n9

n10

n11

n12

n13

n14

n15

n16

n17

n18

n19

n20

n21

n22

n23

n24

n25

n26

n27

n28

n29

n30

A B

n31

n32

n33

n34

n35

n36

n37

n38

n39

n40

n41

n42

n43

n44

n45

n46

n47

n48

n49

n50

n51

n52

n53

n54

n55

n56

n57

n58

n59

n60

n61

n62

n63

n64

n65

n66

n67

n68

n69

n70

n71

n72

n73

n74

n75

n76

n77

n78

n79

n80

n81

n82

n83

n84

n85

n86

n87

n88

n89

n90

C

n91

n92

n93

n94

n95

n96

n97

n98

n99

n100

n101

n102

n103

n104

n105

n106

n107

n108

n109

n110

n111

n112

n113

n114

n115

n116

n117

n118

n119

n120

D

n121

n122

n123

n124

n125

n126

n127

n128

n129

n130

n131

n132

n133

n134

n135

n136

n137

n138

n139

n140

n141

n142

n143

n144

n145

n146

n147

n148

n149

n150

E

n151

n152

n153

n154

n155

n156

n157

n158

n159

n160

n161

n162

n163

n164

n165

n166

n167

n168

n169

n170

n171

n172

n173

n174

n175

n176

n177

n178

n179

n180

F

n181

n182

n183

n184

n185

n186

n187

n188

n189

n190

n191

n192

n193

n194

n195

n196

n197

n198

n199

n200

n201

n202

n203

n204

n205

n206

n207

n208

n209

n210

G

n211

n212

n213

n214

n215

n216

n217

n218

n219

n220

n221

n222

n223

n224

n225

n226

n227

n228

n229

n230

n231

n232

n233

n234

n235

n236

n237

n238

n239

n240

H

n241

n242

n243

n244

n245

n246

n247

n248

n249

n250

n251

n252

n253

n254

n255

n256

n257

n258

n259

n260

n261

n262

n263

n264

n265

n266

n267

n268

n269

n270

I

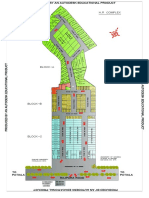

Figure 4.4-2 Rear terminal of CZX-22G

The definition and application of each terminal will be detailed below.

4.4.1 Definition of Connector A

Table 4.4-1 Definition of Connector A

Terminal No. Description

n1

AC voltage

n2

n3

n4

n5

n6 Positive pole of DC power supply (group 1)

n7

n8

n9 Positive pole of DC power supply (group 2)

n10 Positive pole of common DC power supply

n11 Tripping pressure

n12 Reclosing pressure

n13 Closing pressure

4 Hardware

CZX-22R Interposing Relay Set 29

Date: 2011-04-12

n14 Abnormal pressure

n15

Spare three-phase tripping contact

n16

n17

Spare pole disagreement contact

n18

n19

Open position of the circuit breaker (52b)

n20

n21

n22

n23

To initiate AR and BFP

n24

n25

To block AR and initiate BFP

n26

n27 Low pressure to block AR

n28 Spare

n29

Open position of the circuit breaker (52b)

n30

4.4.2 Definition of Connector B

Table 4.4-2 Definition of Connector B

Terminal No. Description

n31

Open position of the circuit breaker (52b)

n32

n33

Open position of the circuit breaker (52b)

n34

n35

n36

n37

Manual closing

n38

n39

Manual closing

n40

n41

Manual closing

n42

n43

n44

n45

n46

n47 Open position of the circuit breaker (52b)

4 Hardware

CZX-22R Interposing Relay Set 30

Date: 2011-04-12

n48

n49 Three-phase open position of circuit breaker (52b)

n50

Open position of the circuit breaker (52b)

n51

n52 Three-phase open position of circuit breaker (52b)

n53

Open position of the circuit breaker (52b)

n54

n55 Three-phase open position of circuit breaker (52b)

n56

Open position of the circuit breaker (52b)

n57

n58 Three-phase open position of circuit breaker (52b)

n59

n60

4.4.3 Definition of Connector C

Table 4.4-3 Definition of Connector C

Terminal No. Description

n60

Protection thee-phase tripping

n61

n62

n63

n64

n65

Protection thee-phase tripping

n66

n67 Tripping pressure

n68

Reclosing pressure

n69

n70 Closing pressure

n71 Pole disagreement signal

n72 Control circuit failure

n73 Pole disagreement signal

n74 Signal of control circuit failure (group 1)

n75 Signal of control circuit failure (group 2)

n76 Signal of low pressure to block tripping

n77 Signal of low pressure to block AR

n78 Signal of low pressure to block closing

n79 Signal of low pressure to block switching (tripping and closing)

4 Hardware

CZX-22R Interposing Relay Set 31

Date: 2011-04-12

n80 Tripping signal of group 1

n81 Tripping signal of group 2

n82 Common terminal of signal

n83 Signal of DC power supply supervision (group 1)

n84 Signal of DC power supply supervision (group 2)

n85

To initiate audio alarm

n86

n87

Closed position of the circuit breaker (52a)

n88

n89

n90

4.4.4 Definition of Connector D

Table 4.4-4 Definition of Connector D

Terminal No. Description

n91

Signal of closed position of circuit breaker (52a)

n92

n93

n94

n95

n96

n97

n98 Negative pole of DC power supply (group 1)

n99 Negative pole of DC power supply (group 2)

n100 Negative pole of common DC power supply

n101

To initiate manual closing relay

n102

n103

To closing circuit of circuit breaker

n104

n105

n106

n107

n108

n109

Spare anti-pump circuit of circuit breaker n110

n111

n112 To initiate repeat relay of AR

4 Hardware

CZX-22R Interposing Relay Set 32

Date: 2011-04-12

n113 Manual closing without controlled by pressure relay

n114 To initiate manual tripping relay

n115 Terminal Q of protection tripping (group 1)

n116 Terminal R of protection tripping (group 1)

n117 Spare

n118

Closed position supervision of circuit breaker (tripping coil 1) n119

n120

4.4.5 Definition of Connector E

Table 4.4-5 Definition of Connector E

Terminal No. Description

n121

Phase-segregated tripping circuit (tripping coil 1) n122

n123

n124 Terminal Q of protection tripping (group 2)

n125 Terminal R of protection tripping (group 2)

n126 Spare

n127

Closed position supervision of circuit breaker (tripping coil 2) n128

n129

n130

Phase-segregated tripping circuit (tripping coil 2) n131

n132

n133

Spare

n134

n135

Remote signal of CB position

n136

n137

n138

n139

Event recorder of protection tripping

n140

n141

n142

n143 Signals reset (group 1)

n144 Signals reset (group 2)

n145 Pressure abnormality

4 Hardware

CZX-22R Interposing Relay Set 33

Date: 2011-04-12

n146

To initiate spare intermediate relay

n147

n148

Open position of circuit breaker (52b)

n149

n150 Closed position of circuit breaker (52a)

4.4.6 Definition of Connector F

Table 4.4-6 Definition of Connector F

Terminal No. Description

n151 Closed position of circuit breaker (52a)

n152

Spare contacts of intermediate relay

n153

n154

n155

n156

n157

n158 Spare three-phase tripping of group 1

n159 Spare three-phase tripping of group 2

n160

Spare contacts of intermediate relay

n161

n162

n163

n164

n165

n166

n167

n168

Pressure abnormality contact

n169

n170

Manual tripping

n171

n172

Manual closing

n173

n174

Open position of circuit breaker (52b)

n175

n176

Pressure abnormality contact