Академический Документы

Профессиональный Документы

Культура Документы

Installation & Operation Manual: Intuitive Reliable Efficient

Загружено:

Marcopolo Ponce FerminИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Installation & Operation Manual: Intuitive Reliable Efficient

Загружено:

Marcopolo Ponce FerminАвторское право:

Доступные форматы

To avoid product damage, personal injury, or even

possible death, carefully read, understand, and

follow all the instructions in the Installation and

the Operation manuals before installing this

product. Improper installation, adjustment, alteration, or

maintenance can cause injury, loss of life, and/or property

damage. This water heater should be installed and serviced

by a qualied technician. The lack of proper service can

result in a dangerous condition.

This manual contains safety information, installation instructions,

and maintenance procedures. It must be left with the homeowner

or placed near the water heater in a noncombustible place. The

homeowner should retain this manual for future reference.

Due to Hubbells policy of continuous product

improvement and technology, the design and/or technical

specihcations are subject to change without notice.

Serial Number: ___________________________________

Date of Installation: ___ / ___ / ______

WATER HEATERS SINCE 1920

I NSTALLATI ON &

OPERATI ON MANUAL

Hubbell Model

GX200 / GX200P

GX250 / G250P

I nt ui t i ve Rel i abl e Ef f i c i ent

WARNING

If the information in these instructions is not followed

exactly, a fire or explosion could result causing

property damage, personal injury, or death.

Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use

any phone in your building.

Immediately call your gas supplier from a

neighbors phone. Follow the gas suppliers

instructions.

If you cannot reach your gas supplier, call the

fire department.

Installation and service must be performed by

a qualified installer, service agency, or the gas

supplier.

Ne pas entreposer ni utiliser dessence ou

ni dautres vapeurs ou liquides inflammables

proximit de cet appareil ou de tout autre

appareil.

QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

Ne pas tenter dallumer dappareil.

Ne touchez aucun interrupteur; ne pas vous

servir des tlphones se trouvant dans

le btiment.

Appelez immdiatement votre fournisseur de gaz

depuis un voisin. Suivez les instructions

du fournisseur.

Si vous ne pouvez rejoindre le fournisseur,

appelez le service des incendies.

Linstallation et lentretien doivent tre assurs

par un installateur ou un service dentretien

qualifi ou par le fournisseur de gaz.

AVERTISSEMENT

Assurez-vous de bien suivre les instructions donnes

dans cette notice pour rduire au minimum le

risque dincendie ou dexplosion ou pour viter tout

dommage matriel, toute blessure ou la mort.

Energy Star and SQAQMD Certihed 2012 Low NOx

on Models GX200 / GX200P

3

TABLE OF CONTENTS

Table of Contents

TABLE OF CONTENTS. . . . . . . . . . . . . . . . . . . . . 3

ITEMS SHIPPED WITH WATER HEATER . . . . . . 4

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Icon Nomenclature. . . . . . . . . . . . . . . . . . . . . . 6

Personal Protection . . . . . . . . . . . . . . . . . . . . . . . . . 6

Prohibited Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Hazard Avoidance . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Operation and Installation Warnings . . . . . . . . . . . . . . 6

TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . 10

SPECIFICATIONS (NOMENCLATURE) . . . . . . . 12

DIMENSIONAL SPECIFICATIONS . . . . . . . . . . . 13

QUICK REFERENCE INSTALLATION GUIDE . . 14

PREPARATION BEFORE INSTALLATION. . . . . 16

Selecting an Installation Site . . . . . . . . . . . . . . . . . . . 16

High Elevation Installations . . . . . . . . . . . . . . . . . . 17

Water Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

WALL MOUNTING. . . . . . . . . . . . . . . . . . . . . . . . 19

Mounting Block Installation Method. . . . . . . . . . . . . . 19

Plywood Installation Method . . . . . . . . . . . . . . . . . . . 19

GAS CONNECTION. . . . . . . . . . . . . . . . . . . . . . . 20

GAS PIPE SIZING TABLES . . . . . . . . . . . . . . . . 21

Gas Pipe Sizing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Natural Gas Pipe Sizing. . . . . . . . . . . . . . . . . . . . . 21

LP Gas Pipe Sizing . . . . . . . . . . . . . . . . . . . . . . . . 21

COMBUSTION (FRESH) AIR INLET EXHAUST

OUTLET CONNECTIONS . . . . . . . . . . . . . . . . . . 22

VENTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Combustion (All) Air From the Outdoors . . . . . . . . 24

Outdoor Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Two Openings or Ducts. . . . . . . . . . . . . . . . . . . . 24

Size of Openings. . . . . . . . . . . . . . . . . . . . . . . . . 24

Attic Combustion Air . . . . . . . . . . . . . . . . . . . . . . 24

Under-oor Combustion Air. . . . . . . . . . . . . . . . . 24

Opening Requirements . . . . . . . . . . . . . . . . . . . . 24

Combustion (All) Air From Inside the Building . . . . 26

Required Volume. . . . . . . . . . . . . . . . . . . . . . . . . 26

Conned Space. . . . . . . . . . . . . . . . . . . . . . . . . . 26

Unusually Tight Construction . . . . . . . . . . . . . . . 26

Power Vent Installation Examples . . . . . . . . . . . . . 26

INSTAL HOT WATER LINES. . . . . . . . . . . . . . . . 27

INSTAL COLD WATER LINES . . . . . . . . . . . . . . 28

INSTALL CONDENSATE DRAIN . . . . . . . . . . . . 29

CONNECT ELECTRICAL POWER / INITIAL

STARTUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

MULTIPLE UNITS . . . . . . . . . . . . . . . . . . . . . . . . 31

MEASURING GAS PRESSURE . . . . . . . . . . . . . 36

PROPANE (LPG) CONVERSION . . . . . . . . . . . . 37

ADJUSTING THE CO

2

LEVEL. . . . . . . . . . . . . . . 39

Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Display Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Setting the Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Adjusting the Water Temperature . . . . . . . . . . . . . . . 44

Customer Screens. . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Domestic Heating Mode. . . . . . . . . . . . . . . . . . . . . 45

Programming ON/OFF Run Times. . . . . . . . . . . . . 45

WATER HEATER PROGRAMMING SECTION. . 45

Recirculation Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cascading (Daisy Chain). . . . . . . . . . . . . . . . . . . . . . 47

Technician Screens . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pressure Booster (pump models only . . . . . . . . . . 48

Fast Start Selection . . . . . . . . . . . . . . . . . . . . . . . . 48

Flow Booster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Blower Ramp Selection . . . . . . . . . . . . . . . . . . . . . 49

Flow Control Selection . . . . . . . . . . . . . . . . . . . . . . 50

Fuel Type Selection . . . . . . . . . . . . . . . . . . . . . . . . 50

Blower Override . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Diagnostic Code and Error Log Selection . . . . . . . 51

Diagnostic Code and Error Log Selection . . . . . . . 52

Adjusting CO

2

Levels Selection . . . . . . . . . . . . . . . 52

Commercial Heating Selection. . . . . . . . . . . . . . . . 52

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . 53

Cleaning the Inlet Water Y-Strainer . . . . . . . . . . . . . . 54

Draining the Water Heater. . . . . . . . . . . . . . . . . . . . . 54

Filling the Water Heater. . . . . . . . . . . . . . . . . . . . . . . 55

TROUBLESHOOTING CHART . . . . . . . . . . . . . . 55

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . 57

COMMERCIAL OPTIONS . . . . . . . . . . . . . . . . . . 58

Commercial Option #1 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #2 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #3 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #4 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #5 . . . . . . . . . . . . . . . . . . . . . . 59

Commercial Option #6 . . . . . . . . . . . . . . . . . . . . . . 59

OPERATIONAL DIAGRAM . . . . . . . . . . . . . . . . . 59

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Effective Start Date . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Heat Exchanger Coil . . . . . . . . . . . . . . . . . . . . . . . . . 61

All other Parts and Components . . . . . . . . . . . . . . . . 61

Labor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Shipping Costs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Denition of Potable Water . . . . . . . . . . . . . . . . . . . . 61

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Not Covered by this Warranty . . . . . . . . . . . . . . . . . . 62

Warranty Limitations . . . . . . . . . . . . . . . . . . . . . . . . . 62

How to Make a Claim . . . . . . . . . . . . . . . . . . . . . . . . 62

Requirements for the State of Massachusetts . . . . . 63

Notice Before Installation . . . . . . . . . . . . . . . . . . . . 63

NOTES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4

The following items are shipped with the water heater;

upper mounting bracket (1), condensate hose (2),

Operators manual (3), communication cable (4), O-rings

(5), and tee fitting (6).

ITEMS SHIPPED WITH WATER HEATER

IMPORTANT

Condensate drain hose(2) has zip ties to keep

loop. Do not undo or cut these zip ties

5

WARNING

Hubbell cannot anticipate every circumstance that might

involve a potential hazard and our warnings are, therefore, not

all-inclusive. Proper installation, operation, and service is your

responsibility.

You must be satisfied that the operation and settings of the

water heater are safe for you and for others.

To avoid product damage, personal injury, or even

possible death, carefully read, understand, and

follow all the instructions in the Installation and

Operation manual and on the water heater before

installation, operation, or service.

IGT-LBL-0001-01

Pour viter un dommage au produit, une blessure personnelle

ou mme la mort, lire avec soin, comprendre et suivre toutes

les instructions dans le manuel d'installation et de fonction-

nement et sur le chauffe-eau avant l'installation, le fonction-

nement ou l'entretien.

Hubbell ne peut pas prvoir toutes les circonstances qui

pourraient impliquer un danger potentiel et par consquent,

nos avertissements ne comprennent pas tout. L'installation, le

fonctionnement et l'entretien correct sont votre

responsabilit.

Vous devez tre certain que le fonctionnement et les rglages

du chauffe-eau sont scuritaires pour vous et pour les autres.

Safety Alert Symbols

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey

all safety messages that follow this symbol to

avoid possible injury or death.

This manual contains DANGERS, SAFETY

INSTRUCTIONS, CAUTIONS, IMPORTANT NOTICES,

and NOTES which must be followed to prevent the

possibility of improper service, damage to the equipment,

personal injury, or death. The following key words call the

readers attention to potential hazards.

Hazards are identied by the Safety Alert Symbol

and followed by a signal word such as DANGER,

WARNING, or CAUTION.

DANGER

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury. This signal word is limited to

the most extreme situations.

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE

Indicates that equipment or property damage can result if

instructions are not followed.

SAFETY

INSTRUCTIONS

Safety instructions (or equivalent) signs indicate specific safety-

related instructions or procedures.

NOTE: Contains additional information important

to a procedure.

SAFETY

IMPORTANT

Indicates that equipment or property damage can

result if instructions are not followed.

NOTE: Provides additional information that is

helpful for installation or operation of the water

heater.

6

Safety Icon Nomenclature

Icons signal a type of hazard and warn of personal

protection issues, prohibited actions, and hazard

avoidance.

Personal Protection

Read the manual

Eye protection

High water temperature

Fill water tank before connecting to electrical

power

Disconnect power

Connect power

Close gas valve

Open gas valve

5

Wait ve minutes

Use two people when lifting heavy objects

Prohibited Actions

No open ame

Use proper tools

Do not use if submerged under water

No liquid around electrical component

Hazard Avoidance

Disconnect power electrical hazard

Electrocution or shock hazard

Hot liquid, burn hazard

Hot surface

Lifting hazard

Pressurized liquid

Safety alert symbol

Slipping injury

Tripping injury

Fire hazard

Explosion hazard

Provide proper ventilation

Operation and Installation Warnings

To avoid serious injury or death, read, understand and

follow all the precautions listed here.

DANGER

Vapors from flammable liquids will explode and can

cause a fire, resulting in personal injury or death. The

water heater has a burner that can come on at any

time and ignite vapors. DO NOT use or store flammable

liquids around the water heater.

Improper venting can cause a build-up of carbon monoxide.

Breathing carbon monoxide can result in brain damage or

death. DO NOT operate the water heater unless it is properly

vented to the outside and has an adequate fresh air supply

for safe operation. Inspect the exterior exhaust gas outlet port and

fresh air inlet port on a regular basis to ensure they are functioning

properly.

A concentration of carbon monoxide as small as 0.04% (400

parts per million) in the air can be fatal. When making high

fire or low fire adjustments, CO levels must be monitored

using a flue gas analyzer such that a CO level of no more

than 400 ppm is exceeded at any time during operation.

Adjusting the low fire offset or the main flow restrictor in

small increments can result in a significant increase in CO

concentration. To avoid serious injury or death, DO NOT

make any adjustments to the gas valve without monitoring

the exhaust gases with a fully functional and calibrated flue gas

analyzer.

WARNING

The Hubbell water heater must be installed by a licensed plumber,

licensed gas fitter, and/or professional service technician. Improper

installation and/or operation can cause a potentially hazardous

situation, which, if not avoided, could result in serious injury or

death, and will void the warranty.

Proper care is your responsibility. Carefully read and

understand the Operation Information in this manual before

operating the Hubbell water heater.

Make sure you know the location of the gas shut-off valve

and how to operate it. Immediately close the gas shut-off

valve if the water heater is subjected to fire, overheating,

flood, physical damage, or any other damaging condition that

might affect the operation of the unit. Have the water heater checked

by a qualified technician before resuming operation.

SAFETY

7

WARNING

Do not power up the unit unless the gas and water supply

valves are fully opened. Make sure the fresh air intake port

and exhaust gas port are open and functional.

DO NOT attempt to install, service, or repair this water heater

yourself. There are no serviceable parts which can be

changed by the owner. Contact a qualified technician if your

water heater needs repair or maintenance. Ask your gas

supplier for a list of qualified service providers.

Keep the area around the water heater clean and free of all

materials that can burn. DO NOT store or place gasoline, oils,

spray paint, or other flammable products near the water heater.

DO NOT use spray paint, hair spray, or any other flammable

spray near the water heater or near the exterior fresh air inlet

port. DO NOT place any items in or around the exterior

exhaust gas outlet port and/or fresh air inlet port that could

restrict or block the flow in or out of the vent system.

DO NOT store or place newspapers, laundry, or other

combustible items near the water heater or the exterior

exhaust gas outlet and/or fresh air inlet port.

The owner should inspect the system monthly for damage,

water stains, signs of rust, corrosion, and exhaust vent and

air intake blockage. If inspection of the unit shows signs of

damage, the water heater should be shut off until the problem

is repaired by a qualified technician.

DO NOT allow children to operate this unit. DO NOT use this

unit if it does not appear to be operating correctly.

A qualified technician should service and inspect the water

heater annually.

The water heater temperature is factory set to 120F (49C).

To avoid scalding, always check the temperature of the hot

water before bathing, showering, washing, etc. DO NOT

adjust the water temperature while the Hubbell water heater

is being used by other persons.

Do not use the water heater if any part has

been under water. Immediately call a qualified service

technician and have the unit inspected. Replace any

components that have been under water.

The Hubbell water heater is equipped with a three prong plug. It

should only be plugged directly into a properly grounded three

prong receptacle. DO NOT remove the ground prong from the plug.

DO NOT alter or modify the water heater or water heater controls.

This can be dangerous and will void the warranty.

SAFETY

IMPORTANT

8

Always read and follow all warnings on water heater safety

decals and in the manual. If the Installation and Operation manual

is missing, go to our website at: www.hubbellheaters.com or

contact Hubbell (203-378-2659) for a replacement.

Use this water heater at your own risk. The outlet

temperature of the Hubbell water heater is factory

preset to 120F (49C). The temperature can only be

changed by using the control panel on the front of the

water heater.

Do not store or use gasoline or other

f ammable vapors and liquids in the

vicinity of this or any other appliance.

Flammable vapors can ignite and

cause serious damage or injury.

This water heater is factory preset for NATURAL GAS.

For propane conversion, refer to the manual.

Connecting the water heater to any other gas supply can result

in property damage, serious injury, and even death.

Suitable for water (potable) heating and

space heating. The water heater MUST NOT be

connected to any heating system or components previously

used with a nonpotable water heating appliance.

Do not use toxic chemicals, such as used for boiler

treatment, in potable water space heating systems.

This appliance must be installed in accordance with

local codes or, in the absence of local codes, the

National Fuel Gas Code, ANSI Z223.1/NFPA 54 or the

CSA B149.1, Natural Gas and Propane Installation Code.

Pressure Relief Valve

A pressure relief valve complying with the Standard for

Relief Valves for Hot Water Supply Systems, ANSI Z21.22

or CAN1-4.4 Temperature, Pressure, Temperature and Pressure

Relief Valves and Vacuum Relief Valves must be installed in a

proper outlet port of water heater at the time of installation

according to local codes.

No valve is to be placed between the relief valve and the

water heater.

The discharge from the temperature/pressure relief valve

should be directed to the ground or into a drain system

which will prevent a burn hazard or property damage. The

piping must not have a reducing coupling or other restriction

in the discharge line. The discharge line must be installed to

allow complete drainage of both the valve and line.

If the system requires water for space heating at

temperatures higher than required for other uses, a

mixing valve must be installed to temper the water for those

other uses in order to reduce scald hazard potential.

The pressure relief valve must not be removed or

plugged.

FOR YOUR SAFETY READ BEFORE OPERATING

OPERATING INSTRUCTIONS

TO TURN OFF GAS TO WATER HEATER

If you do not follow these instructions exactly, a f re or explosion

may result, causing property damage, personal injury, or loss of life.

A. This water heater does not have a pilot. It is

equipped with an ignition device which automatically

lights the burner. Do not try to light burner manually.

B. BEFORE OPERATING, smell all around the water

heater area for gas. Be sure to smell next to the

f oor because some gas is heavier than air and will

settle on the f oor.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electric switch; do not use any phone

in your building.

Immediately call your gas supplier from a neighbors

phone. Follow the gas suppliers instructions.

If you cannot reach your gas supplier, call the f re or police

department.

C. Use only your hand to turn manual gas shut-off valve.

Never use tools. If manual gas shut-off valve will not

turn by hand, dont try to repair it, call a qualif ed

service technician. Force or attempted repair may result in a

f re or explosion.

D. Do not use this water heater if any part has been under

water. Immediately call a qualif ed service technician

to inspect water heater and replace any part of control

system and any gas control which has been under water.

DANGER

DANGER

WARNING

1. Turn OFF electrical power to water heater.

2. Turn manual gas shut-off valve to OFF position.

Hot water temperature over 125F (52C) can

cause severe burns instantly or death from

scalding. Children, disabled, and elderly are at

the highest risk of being scalded. Do not leave

children or the inf rm unsupervised. Check

temperature of hot water before taking a shower

or bath. To control water temperature to a

particular faucet, temperature limiting valves can be installed

by your service professional.

If water heater is not operating, follow these instructions. This

appliance is equipped with an ignition device which automati-

cally lights the burner. Do not try to light the burner manually.

1.

2.

3.

4.

5.

5

6.

7.

8.

If water heater will not operate, follow instructions To Turn Off

Gas To Water Heater and call your service technician or gas

supplier.

STOP! Read the safety information above on this

label.

Never use water heater unless it is completely f lled

with water.

Turn OFF electrical power supply to the water heater.

Turn gas shut-off valve clockwise to OFF position.

Do not force.

Wait f ve (5) minutes to clear out any gas. If you then

smell gas, STOP! Follow step B above on this

label. If you dont smell gas, go to next step.

Turn manual gas shut-off valve to ON position.

Turn ON electrical power to unit.

Wait until default temperature (120) is displayed.

Set desired water temperature. Turn on hot water

faucet.

Phone: 203-378-2659

IGT-LBL-0002-01

SAFETY

Hubbell

www.hubbellheaters.com

SAFETY

Utiliser ce chauffe-eau vos propres risques. La temprature

de sortie du chauffe-eau Hubbell est rgle en usine 49 C

(120 F). La temprature peut tre modifie seulement en

utilisant le panneau de commande l'avant du chauffe-eau.

Ne pas entreposer ou utiliser de gazoline

ou autres vapeurs ou liquides

inflammables proximit de cet appareil

ou autre. Les vapeurs inflammables

peuvent s'enflammer et causer un

dommage srieux ou une blessure.

Vapeurs inflammables

Soupape de sur pr essi on

DANGER

AVERTISSEMENT

Hubbell

www.hubbellheaters.com

Tlphone: 203-378-2659

GT-LBL-0003-01

Toujours lire et suivre tous les avertissements sur les

dcalcomanies de scurit sur le chauffe-eau et dans le

manuel. Si le manuel d'installation et de fonctionnement

n'est pas disponible, visiter le www.hubbellheaters.com ou

contacter Hubbell (203) 378-2659 pour un remplacement.

Une temprature d'eau chaude de plus de 52 C

(125 F) peut causer des brlures svres instan-

tanment ou la mort par bouillantage. Les enfants,

les personnes handicapes et les personnes ges

sont les plus risque d'tre bouillantes. Ne pas

laisser les enfants ou les infirmes sans supervision.

Vrifier la temprature de l'eau chaude avant de

prendre une douche ou un bain. Des vannes rgulatrices de

temprature peuvent tre installes par votre professionnel

d'entretien afin de contrler la temprature de l'eau sur un robinet en

particulier.

Ce chauffe-eau est prrgl en usine pour le GAZ

NATUREL. Pour la conversion au propane, se rfrer au

manuel. Connecter le chauffe-au toute autre alimentation

en gaz peut causer un dommage la proprit, une blessure

srieuse et mme la mort.

Une soupape de surpression conforme la norme Relief

Valves for Hot Water Supply Systems, ANSI Z21.22 ou

CAN1-4.4 Temperature, Pressure, Temperature and

Pressure Relief Valves and Vacuum Relief Valves doit tre

installe dans le bon port de sortie du chauffe-eau au moment de

l'installation conformment aux codes locaux.

La dcharge de la soupape de temprature/surpression

devrait tre dirige vers le sol ou dans un systme de drain

qui empchera un risque de brlure ou un dommage la

proprit. La tuyauterie ne doit contenir aucun raccord rducteur

ou autre restriction dans la ligne de dcharge. La ligne de

dcharge doit tre installe afin de permettre un drainage complet

de la vanne et de la ligne.

Convient pour le chauffage de l'eau (potable) et le chauffage

des locaux. Le chauffe-eau NE DOIT PAS tre connect un

systme de chauffage ou des composants utiliss pour un

appareil de chauffage d'eau non potable.

Ne pas utiliser de produits chimiques toxiques, comme

ceux utiliss pour le traitement de chaudire, dans des

systmes de chauffage de locaux et d'eau potable.

Aucune vanne ne doit tre place entre la soupape de

surpression et le chauffe-eau.

La soupape de surpression ne doit pas tre retire ou

bouche.

Cet appareil doit tre install conformment aux codes

locaux, ou , en l'absence de codes locaux, selon le National

Fuel Gas Code, ANSI Z223.1/NFPA 54 ou le Code

d'installation du gaz naturel et du propane, CSA B149.1.

Si le systme exige de l'eau pour le chauffage de locaux

des tempratures plus leves que celles pour d'autres

usages, une vanne de mlange doit tre installe pour

temprer l'eau pour ces autres usages afin de rduire la possi-

bilit de blessure par bouillantage.

POUR VOTRE SCURI T, LI RE AVANT D' UTI LI SER

I NSTRUCTI ONS DE FONCTI ONNEMENT

POUR ARRTER L' ALI MENTATI ON

EN GAZ AU CHAUFFE-EAU

Si vous ne suivez pas ces instructions exactement, un incendie ou

une explosion pourrait rsulter causant des dommages la

proprit, une blessure personnelle ou une perte de vie.

A.

B.

QUE FAIRE SI VOUS SENTEZ DU GAZ

Ne pas essayer d'allumer aucun appareil

Ne toucher aucun interrupteur lectrique; n'utiliser aucun

tlphone dans votre difice.

Appeler immdiatement votre fournisseur de gaz partir du

tlphone d'un voisin. Suivre les instructions du fournisseur de gaz.

Si vous ne pouvez pas rejoindre votre fournisseur de gaz, appeler

le service d'incendie ou de police.

C.

D.

DANGER

1. METTRE HORS FONCTION l'alimentation lectrique au chauffe-eau.

2. Tourner la vanne d'arrt manuelle du gaz la position d'arrt (OFF).

1.

2.

3.

4.

5.

5

6.

7.

8.

Si le chauffe-eau ne fonctionne pas, suivre les instructions

Pour arrter l'alimentation en gaz au chauffe-eau et appeler

votre technicien d'entretien ou votre fournisseur de gaz.

ARRTEZ! Lire les renseignements de scurit

ci-dessus sur cette tiquette.

Ne jamais utiliser le chauffe-eau moins qu'il soit

entirement rempli d'eau.

METTRE HORS FONCTION l'alimentation lectrique au

chauffe-eau.

Tourner la vanne d'arrt manuelle du gaz dans le sens

des aiguilles d'une montre la position d'arrt (OFF).

Ne pas forcer.

Attendre cinq (5) minutes pour laisser le gaz s'vaporer.

Si vous sentez du gaz, ARRTEZ! Suivre l'tape B

ci-dessus sur cette tiquette. Si vous ne sentez pas de

gaz, passer l'tape suivante.

Tourner la vanne d'arrt manuelle du gaz la position

de fonctionnement (ON).

METTRE EN FONCTION l'alimentation lectrique

l'appareil

Attendre jusqu' ce que la temprature

par dfaut (120) soit affiche. Rgler la temprature

dsire pour l'eau. Ouvrir le robinet d'eau chaude.

Ce chauffe-eau n'a pas de pilote. Il est muni d'un

dispositif d'allumage qui allume automatiquement

le brleur. Ne pas essayer d'allumer le brleur

manuellement.

AVANT D'UTILISER, sentir tout autour du chauffe-eau

pour dtecter une odeur de gaz. S'assurer de sentir

prs du plancher parce que certains gaz sont plus

lourds que l'air et retombent sur le plancher.

Utiliser seulement votre main pour tourner la vanne

d'arrt manuelle du gaz. Ne jamais utiliser d'outils. Si la

vanne d'arrt manuelle du gaz ne peut pas tre tourne

la main, ne pas essayer de la rparer, appeler un

technicien d'entretien qualifi. Une rparation force ou tente

pourrait causer un incendie ou une explosion.

Ne pas utiliser ce chauffe-eau si une partie de celui-ci a

t sous l'eau. Appeler immdiatement un technicien

d'entretien qualifi pour inspecter le chauffe-eau et

remplacer toute partie du systme de commande et

toute commande de gaz qui a t sous l'eau.

Si le chauffe-eau ne fonctionne pas, suivre ces instructions. Cet

appareil est muni d'un dispositif d'allumage qui allume automatique-

ment le brleur. Ne pas essayer d'allumer le brleur manuellement.

10

GX200 GX200P GX250 GX250P

Type

Fuel

Minimum / Maximum Input (Btu/h)

Combustion Efficiency

Thermal Efficiency

Energy Factor

Dimensions H x W x D (inches)

8 9 0 9 8 9 0 9 ) s b l ( t h g i e W

Water Inlet / Outlet Connection

Gas Inlet Connection

Minmum Flow Rate

Ignition

Venting Type

Venting Materials

Max 3 Vent Length - Single Pipe / Power Vent

Max 3 Vent Length - Two pipe / Direct Vent

Max 2 Vent Length - Single Pipe / Power Vent

(2 not allowed at elevations above 4,000 ft)

Max 2 Vent Length - Two Pipe / Direct Vent (2

not allowed at elevations above 4,000 ft)

Common Venting

Safety

Water Pressure Min / Max (PSI)

NG/LP- Minimum Static Gas Pressure 1/2"

NG/LP- Minimum Static Gas Pressure 3/4"

NG/LP - Maximum Static Gas Pressure

Gas Pressure for Adjustments

Electrical

Power Consumption

Features GX200 GX200P GX250 GX250P

Recirculation / Tank Loading No-Pump Built-In Pump No-Pump Built-In Pump

Cascading

Heat Exchanger

Performance GX200 GX200P GX250 GX250P

Hot Water Capacity (35F Rise)

Hot Water Capacity (45F Rise)

Hot Water Capacity (77F Rise)

Domestic Mode Temp. Settings

Commercial Mode Temp. Settings

Warranty (with recirculation)

200 ft, deduct 5 ft per 90 elbow 130 ft, deduct 5 ft per 90 elbow

100 ft, deduct 5 ft per 90 elbow 65 ft, deduct 5 ft per 90 elbow

21 ft, deduct 5 ft per 90 elbow

N/A

5" (non-corrugated, black iron) 6" (non-corrugated, black iron)

100 185F

5.0

13.2

10.3

6.0

Note:

1

Due to Hubbell's Policy of continuous product improvements, design, and technical specifications are subject to change

2

Energy Star and Low NOx are applicable to GX200 and GX200P models.

8.4

Masterless, 10 units

Expandable, Stainless 316L

100 140F

25.9 x 17.5 x 14.2 (3.7 cu. ft)

3/4" NPT

3/4" NPT

2.5" (non-corrugated, black iron)

No minimum flow rate for "P" models / 0.6 GPM

Sch. 40 PVC, Sch. 40 CPVC, Polypropylene, Stainless Steel

Residential - Heat Exchanger coil - 15 years, Parts 5 years, Labor 1 year

Commercial - Heat Exchanger coil 6 years, Parts 5 years, Labor 1 year

10.8

14

Yes

26 ft, deduct 5 ft per 90 elbow

Flame Rod, Thermal Fuse, Overheat Prevention Device, Fan Speed Monitor, Flue

Temperature Monitor, Blocked Vent Detector, Water Leak Detector, Water Shut-Off

Valve, 2X10A Fuse, Dual Flame Sensing

98%

Direct Vent (2 pipe - intake & exhaust), Power vent (1 pipe - exhaust only)

Electronic Spark Ignition

A / N 3 9 . 0

% 2 9 % 4 9

Parameters

0 0 0 , 0 5 2 / 0 0 0 , 0 3 0 5 9 , 9 9 1 / 0 0 0 , 0 3

Models

Indoor, Wall hung, Fully Condensing

Preset for NG / LP Convertible

30 / 150

500W (Max 4.2 Amps), 8W (Standby)

8" for NG, 11" for LP

120V AC, 60 Hz

TECHNICAL SPECIFICATIONS

In order for the water heater to operate properly and

efficiently, the clearances specified in the table below are

required.

Required Mounting Clearances

Location From

Combustibles

From Non-

Combustibles

Service

Clearance

1

Top 6 (15.2 cm) 2 (50.8 cm) 12 (30.4 cm)

Back

2

5/8 (15.8 mm) 5/8 (15.8 mm) 5/8 (15.8 mm)

Sides 1 (25.4 mm) 1/2 (12.7 mm) 5/8 (15.8 mm)

Front 2 (5.1 cm) 2 (5.1 cm) 30 (76.2 cm)

Bottom 12 (30.4 cm) 12 (30.4 cm) 12 (30.4 cm)

1

Service clearances are suggested dimensions to allow for normal

service of the unit.

2

Installing (hanging) the unit with the included brackets automatically

sets this dimension.

CO

2

and CO Standards

Description CO

2

Range (%) Max. CO Level (ppm)

Natural Gas

High Fire 8.8% to 9.1% < 200 ppm

Low Fire 8.6% to 8.9% < 60 ppm

LP Gas

High Fire 8.8% to 9.1% < 200 ppm

Low Fire 8.6% to 8.9% < 60 ppm

Top Connections

Description Specification

2

Gas Supply Inlet Connection 3/4 Male NPT

Cold Water Inlet Connection 3/4 Female NPT

Hot Water Outlet Connection 3/4 Female NPT

Exhaust Gas Vent 3 O.D. PVC Schedule 40

1

Fresh Air Intake 3 O.D. PVC Schedule 40

1

1

Requires a 3 to 2 reducer when using 2 venting pipe.

2

Using sizes other than specified can cause damage to the water

heater and will void the warranty.

Bottom Connections

Description Specification

1

Drain Connection 3/4 Female NPT

Condensate Drain Connection 3/4 Nipple (3/4 flex hose)

Power Supply 120V AC Power Cord

1

Using sizes other than specified can cause damage to the water

heater and will void the warranty.

TECHNICAL SPECIFICATIONS

Max Vent Length For Various Duct Sizes And

Number Of Units

Number

of Units

Venting

Type

Duct Size and Model

2 3 4 6 8

GX200(P) GX200(P) GX250(P) GX200(P) GX250(P) GX200(P) GX250(P) GX200(P) GX250(P)

1

1 pipe - PV 26 200 130 200 130

2 pipe - DV 21 100 65 100 65

2

1 pipe - PV 200 130

2 pipe - DV 100 65

3

1 pipe - PV 100 30 200 130

2 pipe - DV 50 30 100 65

4

1 pipe - PV 200 130

2 pipe - DV 100 65

5

1 pipe - PV 200 130

2 pipe - DV 100 65

6

1 pipe - PV 200 130

2 pipe - DV 100 65

7

1 pipe - PV 150 45

2 pipe - DV 75 45

8

1 pipe - PV 100 30 200 130

2 pipe - DV 50 30 100 65

9

1 pipe - PV 200 130

2 pipe - DV 100 65

10

1 pipe - PV 200 130

2 pipe - DV 100 65

PV = Power Vent

DV = Direct Vent

Note: Reduce the maximum equivalent length above by 5 feet per 90 elbow used and by 2 feet per 45 elbow.

Do not exceed the above set limits.

12

EXHAUST

INLET

CHECK

VALVE

CHECK

VALVE

HOT WATER

OUT

GAS LINE

TEMPERATURE

AND PRESSURE

VALVE

WATER HEATER

DRAIN VALVE

CONTROL

PANEL

CONDENSATE

DRAIN

GATE VALVE

COLD WATER

INLET

GAS LINE

WATER TRAP

COLD WATER

IN

CHECK

VALVE

GAS

LINE

HOT WATER

TO USAGE

POINT

STRAINER

HOT

WATER

STORAGE

TANK

IH-01

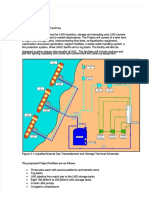

Typical installation of GX200P piped with storage tank.

DIP Switch Locations on Control Board

SW2

SW1 Propane

DIP Switch Settings (Rglages des commutateurs DIP)

Cascade Termination OFF

(Terminaison en cascade OFF)

Natural Gas

(Gaz naturel)

Cascade Termination ON

(Terminaison en cascade ON)

SPECIFICATIONS (NOMENCLATURE)

13

Selecting a Location

I

H

-

7

9

3

6

1

,

3

[

1

4

1

/

4

]

3

5

,

3

6

[

1

3

/

8

]

T

o

p

V

i

e

w

B

o

t

t

o

m

V

i

e

w

F

r

o

n

t

V

i

e

w

L

/

H

S

i

d

e

V

i

e

w

4

4

2

,

6

[

1

7

7

/

1

6

]

R

i

g

h

t

S

i

d

e

L

e

f

t

S

i

d

e

1

5

5

,

4

[

6

1

/

8

]

6

8

,

8

6

[

2

3

/

4

]

M

o

u

n

t

i

n

g

W

a

l

l

S

u

r

f

a

c

e

3

4

7

,

3

[

1

3

1

1

/

1

6

]

1

4

[

9

/

1

6

]

6

4

,

6

[

2

9

/

1

6

]

1

0

2

,

4

[

4

1

/

8

]

1

8

5

,

1

[

7

5

/

1

6

]

H

o

t

W

a

t

e

r

O

u

t

3

/

4

N

P

T

G

a

s

I

n

l

e

t

3

/

4

N

P

T

E

x

h

a

u

s

t

P

o

r

t

3

P

V

C

5

9

,

1

1

[

2

5

/

1

6

]

5

7

,

7

9

[

2

1

/

4

]

1

9

8

,

7

[

7

2

5

/

3

2

]

D

r

a

i

n

P

o

r

t

/

P

R

V

3

/

4

-

N

P

T

P

o

w

e

r

C

o

r

d

C

o

n

d

e

n

s

a

t

e

D

r

a

i

n

1

0

7

,

1

[

4

7

/

3

2

]

5

9

,

9

4

[

2

3

/

8

]

DIMENSIONAL SPECIFICATIONS

14

The quick reference illustrations show the installation

of two GX200P water heaters connected together

with a storage tank. Installation of a single unit or

up to five units is basically the same. When

installing multiple units, refer to the Multiple Units

section for additional information.

1. Select a location. Note that the piping can be

congured to enter or exit the unit from either the left or

right side, as viewed from the front.

2. Mount the water heater(s) to the wall.

a. Attach two 2x4 mounting blocks (at least 23 for a

single unit or 46 long for two units) to the wall. The

uppermost mounting boards should be at the

desired height for the top of the unit.

IH-80

b. Attach a second mounting block 14 (center to

center) below the upper mounting block.

c. Attach metal mounting bracket(s) to the upper

mounting block approximately 3 on either side

of the center and 1/2 down from the top of the

mounting block.

d. Adjust and tigthen the bottom bracket to the units so

that the unit to hangs vertically on the wall.

e. Hang the unit on the mounting bracket. If multiple

units are installed, the spacing between the units

should be approximately 6.

IH-81

3. Install the gas lines, as shown in the illustration.

IH-82

a. Temporarily place a short section of 3 schedule

40 PVC pipe on one of the air inlets in order to

judge clearance allowances as the gas piping is

assembled.

b. Due to limited wall clearance, connect the union as

your nal step of gas piping.

c. Check for gas leaks at this point in the assembly

process.

QUICK REFERENCE INSTALLATION GUIDE

15

4. Install the combustion air inlet and ue gas outlet PVC

piping.

Note: The inlet and outlet pipes from the unit are

3 diameter while the header piping is 4 diameter,

as shown in the illustration. The larger header

piping is required whenever multiple units are

installed.

IH-83

5. Install and connect the hot water lines. If an optional

hot water storage tank is required, connect the hot

water lines to this tank. If required, install a pressure

relief valve or a temperature and pressure relief valve.

IH-84

6. Install and connect the cold water lines.

IH-85

7. Connect and route the condensate trap and drain line

to an appropriate discharge site or drain.

8. Verify gas pressure.

9. Connect the 120 Volt power supply.

IH-85a

10. Test re the unit by opening all hot water faucets.

Water Connections QUICK REFERENCE INSTALLATION GUIDE

3" 3" 3" 3"

4"

4"

16

Selecting an Installation Site

1. Select an interior location for the installation. Each

installation is unique; therefore, take the time to nd the

best location for the water heater.

a. Install the water heater near locations that use hot

water, such as bathroom, kitchen, or laundry room

faucets.

b. Select a location that minimizes the length of the

water pipe.

c. If the distances are long or if the faucet or appliance

requires instant hot water, we recommend running

a recirculation line back to the water heater from the

furthest xture. Insulate the hot water supply and

recirculation lines.

IMPORTANT

When installing this water heater, follow all local

building codes and the current edition of the National

Fuel Gas Code (ANSI Z223.1/NFPA 54) in the USA or

National Gas and Propane Installation Code (CAN/CGA

B149.1) in Canada, when installing this product.

d. Select a location away from foot trafc and away

from areas where dust, debris, chemical agents, or

other combustible materials could accumulate.

e. Allow sufcient space for service and maintenance

access to all gas, water, and drain connections.

f. Make sure the location meets all building code

requirements.

g. Make sure the wall surface the water heater is

mounted onto will support the weight of the unit.

SAFETY

INSTRUCTIONS

The Hubbell .. 200 and GX250 water heaters weigh 90 lbs. The

GX200P and GX250P weigh 98 lbs.

2. Minimize the distance that the exhaust gas vent and

fresh air intake must travel to an exterior wall.

a. The exhaust vent outlet must not be located next to

a walkway, near soft vents, crawl space vents, or

other areas where condensate (water vapor) could

cause damage or create a hazard.

b. The fresh air inlet vent must be located at least 12

from the exhaust vent.

c. Contaminated or dirty air drawn into the intake

pipe can damage the water heater. The Hubbell

warranty does not cover damage caused by

airborne contaminants.

IMPORTANT

Reduce the maximum equivalent length by 5 feet

per 90 elbow and by 2 feet per 45 elbow. Intake

and exhaust venting pipes have the same allowable

lengths. Do not exceed these set limits.

EXAMPLE: A 3 vent line or fresh air intake line

(Model GX200) with the six 90 degree elbows

would be limited to a length of 70 feet in a twin

pipe configuration

3. Locate the unit close to a drain and near gas and water

connections.

The water heater produces a signi cant amount of

condensate during normal operation and should be

located near a suitable drain where damage from

a possible leak will be minimal. Installing the water

heater in a location without a drain will void the

warranty and Hubbell will not be responsible for

any resulting water damages that may occur as a

result. For additional information, refer to the Install

Condensate Drain section.

The water heater should be located in an area where

leakage from the unit or water pipes will not result in

damage to the area around the appliance or to lower

oors of the structure. When such locations cannot

be avoided, it is recommended that a suitable drain

pan, adequately drained, be installed under the water

heater. The pan must not restrict combustion air ow.

Gas Connection PREPARATION BEFORE INSTALLATION

17

4. Locate the water heater and all water pipes in an area

where the ambient temperature always remains above

freezing.

a. When the water heater is connected to an electrical

power supply, it will automatically prevent the water

inside the unit from freezing.

b. The units freeze protection system will not prevent

the water in surrounding pipes from freezing.

NOTICE

In cold climates, if there is a power failure, the units

freeze protection system will not operate, and can

result in water freezing inside the heat exchanger.

To prevent damage to the water heater, turn OFF the gas

supply and inlet water valve. Open the drain valve and

completely drain the unit.

Damage caused by freezing water is not covered by the

Hubbell warranty.

5. Select an appropriate location for the combustion air

and exhaust pipes to exit the house. Use the diagram

and chart on the next page to make this determination.

High Elevation Installations

For operation at elevations above 2,000 feet, Hubbell

model ratings should be reduced by 4% for each 1,000

feet above sea level.

Water Quality

Potable water is defined as drinkable water supplied from

utility or well water in compliance with EPA secondary

maximum contaminant levels (40 CFR part 143.3) as

shown in the table below. If your water contains

contaminants higher than outlined by EPA, then water

treatment is recommended and additional maintainence

may be required. If you suspect that your water is

contaminated in any way or water heater errors occur,

discontinue use of the water heater and contact an

authorized technician or licensed professional.

Contaminant Maximum Allowable Level

Total Hardness 200 mg/l (12 grains/gallon)

Aluminum 0.05 to 0.2 mg/l

Chloride 250 mg/l

Copper 1.0 mg/l

Iron 0.3 mg/l

Manganese 0.05 mg/l

pH 6.5-8.5

Sulfate 205 mg/l

Total Dissolved Solids (TDS) 500 mg/l

Zinc 205 mg/l

PREPARATION BEFORE INSTALLATION

18

Venting Connections

IH-31

B

K

F

B

J

G D

E

B

Fixed

Closed

Fixed

Closed

Operable

B

B

V

V

V

V

I

V

V

V

V

V

X X

B

C

H

L

A

A

M

Operable

Inside Corner

Detail

Air Inside Inlet

Vent Terminal

Area Where Terminal is Not Permitted

V

X

ANSI Z223.1 / NFPA 54 for USA and CAN/CSA B149.1 for Canada - Venting Requirements

USA Clearance Canada Clearance

Item Description Specification Specification

A Above grade, veranda, porch, deck, or balcony 1 ft 1 ft

B Window or door that may be opened 1 ft** 3 ft

C Permanently closed window * *

D Vertical clearance to a ventilated soffit, eves, or overhang 3 ft*** *

E Unventilated soffit, eves, or overhang 3 ft*** *

F Outside corner * *

G Inside corner * *

H Each side of centerline extended from meter/regulator * 3 ft within a height 15 ft above the

meter/regulator assembly

I Service regulator vent outlet * 3 ft

J Non mechanical air supply inlet or combustion air inlet

to any other appliance 1 ft** 3 ft

K Mechanical air supply inlet 3 ft above if 6 ft

within 10 ft

horizontally

L Above paved sidewalk or paved driveway on public property * 7 ft

M Under veranda, porch, deck, or balcony * 1 ft

*

Not specified in ANSI Z223.1 / NFPA 54 or CAN/CGA-B146.

Use clearances in accordance with local building codes and local gas supplier.

**

4 feet (1.2 m) below or to the side of opening and 1 foot (300 mm) above opening.

*** Hubbell recommendation.

PREPARATION BEFORE INSTALLATION

19

Secure the unit to the wall using either two wood

mounting blocks or one piece of 3/4 plywood, as

described in this section.

Mounting Block Installation Method

1. Attach two 2x4 or 2x6 mounting blocks (horizontal

framing), at least 18 inches long, to the wall.

a. In wood or steel construction, use adequate wood/

metal screws and secure the mounting blocks with

at least two screws in each vertical wall stud (four

screws total).

b. In concrete block or solid concrete wall construction,

attach the mounting blocks with at least four

masonry screws or suitable masonry wall anchors in

each mounting block.

IH-26

21

2

3

1

SAFETY

INSTRUCTIONS

The Hubbell water heaters weigh 90 to 100 lbs (40.8 to 45.4 kg) and

must be securely attached to the wall. Mounting hardware is

included and should be used to mount the unit.

2. Level upper bracket (2) and attach it to the mounting

block with at least four appropriately sized wood

screws (do not use drywall screws).

CAUTION

Lifting Hazard

According to the National Institute for Occupational

Safety and Health, the recommended maximum safe

lifting weight is 51 pounds, with all lifting conditions perfect

minimal forward reach, steady load close to the body, straight back,

load between knees and shoulders, and good grips. To avoid

personal injury, always use these proper lifting techniques and use

two people to move the water heater which weighs 80 pounds.

3. With assistance, hang the unit on the upper wall

bracket, interlocking bracket (1) on the back of the unit

and wall bracket (2).

4. Install two appropriately sized wood screws in lower

bracket (3) to secure the unit to the wall.

5. Make sure the unit is plumb and level and tighten the

four sheet metal screws on bottom bracket (3). When

properly installed, there should be a 5/8 air space

between the back of the water heater and the mounting

blocks.

Plywood Installation Method

1. Mount a piece of 3/4 plywood (at least 32 high x 20

wide) to the wall.

a. In wood or steel construction, use adequate wood/

metal screws and secure the plywood with at least

two screws in each vertical wall stud.

b. In concrete block or solid concrete wall construction,

attach the plywood with at least four masonry

screws or suitable masonry wall anchors.

IH-27

32

8

20

2

3

1

2. Follow Steps 2 through 5 in the above procedure to

complete the installation.

WALL MOUNTING

20

WARNING

FIRE AND/OR EXPLOSION HAZARD

To avoid serious injury or even death, the gas line

installation and the gas line inlet pressure test

must be done by a licensed professional.

Always match the water heater with the type of gas supplied to the

unit (natural gas or LP gas). The water heater is factory preset for

natural gas.

Make sure the gas line pressures are within normal limits. Pressures

outside normal limits can result in poor performance and hazardous

operating conditions.

1. Determine if the Hubbell water heater will use natural

gas (factory preset) or LP (propane) gas.

a. To convert the unit to propane, refer to the Propane

(LPG) Conversion section in this manual.

b. Make sure your gas supply matches the rating decal

located on the side of the water heater.

2. Make sure the gas pressure meets the requirements

for the unit, as shown in the tables.

Parameters

Models

GX200 GX00P GX250 GX250P

NG/LP- Minimum Static

Gas Pressure (1/2")

5 (non-corrugated,

black iron)

6 (non-corrugated,

black iron)

NG/LP- Minimum Static

Gas Pressure (3/4")

2.5 (non-corrugated, black iron)

NG/LP - Maximum

Static Gas Pressure

14

Gas Pressure for

Adjustments

8 for NG, 11 for LP

3. Make sure the supply line is correctly sized for the

maximum output of the water heater model being

installed. The Hubbell water heater should be the

f r st appliance to be connected to the gas supply line.

a. Determine the gas requirement of the water heater(s)

and other appliances requiring gas. The supply line

must be sized according to the COMBINED total

maximum BTUH draw for all the appliances as if they

were all operating at the same time.

IH-77

1/2

1/2

Hubbell

1 1 1

Gas

Meter

Home

Wall

Laundry Stove

Less then 40

Typical installation when using 1/2 gas line.

b. Measure the length of the gas supply line from the

gas meter to the water heater or other appliances

requiring gas.

c. Use the Gas Pipe Sizing tables in this manual or

refer to the gas line manufacturers sizing information

to determine the correct diameter for the supply pipe.

d. The diameter of the gas lines, shown in the

illustration, will vary according to the specic

installation requirements.

NOTE: Always clean the inside of the gas line of

any dirt or debris before connecting the piping to

the unit.

4. Install a gas union connection with a short piece of 3/4

NPT pipe.

5. Following local building codes, install a manual shut-off

valve.

6. Connect the manual shut-off valve to the gas supply

line. Also install a dirt pocket drip leg off of the main

supply line, as shown.

Main Supply Line

Drip leg

Union

Manual

Shut-off

Valve

7. Leak test the gas line piping before placing the unit

in operation. Only use approved leak detector liquid

solutions to check for leaks.

IMPORTANT

Do not fire (operate) the water heater until all

connections have been completed and the heat

exchanger is filled with water.

GAS CONNECTION

21

Gas Pipe Sizing

This information is for reference only. Refer to gas pipe manufacturer specifications for actual delivery capacity. The DOE

standard for Natural Gas is 1100 BTU/ft

3

. Contact the local gas supplier for actual BTU/ft

3

rating.

1/2 Black Iron Sizing

The following table shows gas supply in cubic feet per hour (CFH) assuming a specific gravity of 0.6 for Natural Gas, 0.585

for propane, pressure drop of 4.6 WC, and 5.0 WC. Contact your gas supplier for BTU/ft

3

ratings. Use 1000 BTU/ft

3

for

estimates.

Length (Including fittings)

Gas Pipe Size 5 10 15 20 25 30 35 40

Natural Gas 1/2 571 404 330 286 255 233 216 202

LP 1/2 578 409 334 289 259 236 219 204

Natural Gas Pipe Sizing

Maximum Natural Gas Delivery Capacity Length of Black Iron Pipe in Feet

Pipe Cubic Feet per Hour (0.60 Specific gravity, 0.5 WC Pressure Drop)

Size 10 20 30 40 50 60 70 80 90 100 150 200

3/4 363 249 200 171 152 138 127 118 111 104 84 72

1 684 470 377 323 286 259 239 222 208 197 158 135

1-1/4 1404 965 775 663 588 532 490 456 428 404 324 278

1-1/2 2103 1445 1161 993 880 798 734 683 641 605 486 416

2 4050 2784 2235 1913 1696 1536 1413 1315 1234 1165 936 801

Maximum Natural Gas Delivery Capacity Length of Corrugated Stainless Steel Pipe in Feet

Pipe Cubic Feet per Hour (0.60 Specific gravity, 0.5 WC Pressure Drop)

Size 10 20 30 40 50 60 70 80 90 100 150 200

3/4 206 147 121 105 94 86 80 75 71 67 55 48

1 383 269 218 188 168 153 141 132 125 118 94 82

1-1/4 614 418 334 284 251 227 209 194 181 171 137 116

1-1/2 1261 888 723 625 559 509 471 440 415 393 320 277

2 2934 2078 1698 1472 1317 1203 1114 1042 983 933 762 661

LP Gas Pipe Sizing

Maximum LP Gas Delivery Capacity Length of Black Iron Pipe in Feet

Pipe Thousands of BTU/Hour, 0.5 WC Pressure Drop

Size 10 20 30 40 50 60 70 80 90 100 125 150 200

3/4 567 393 315 267 237 217 196 185 173 162 146 132 112

1 1071 732 377 323 286 259 239 222 208 197 174 252 213

1-1/4 2205 1496 775 663 588 532 490 456 428 404 358 511 440

1-1/2 3307 2299 1161 993 880 798 734 683 641 605 536 787 675

2 6221 4331 2235 1913 1696 1536 1413 1315 1234 1165 1033 1496 1260

Maximum LP Gas Delivery Capacity Length of Corrugated Stainless Steel Pipe in Feet

Pipe Thousands of BTU/Hour, 0.5 WC Pressure Drop

Size 10 20 30 40 50 60 70 80 90 100 150 200

3/4 325 232 191 166 149 136 126 118 112 106 87 76

1 605 425 344 297 265 241 222 208 197 186 143 129

1-1/4 971 661 528 449 397 359 330 307 286 270 217 183

1-1/2 1993 1404 1143 988 884 805 745 696 665 621 506 438

2 4638 3285 2684 2327 2082 1902 1761 1647 1554 1475 1205 1045

GAS PIPE SIZING TABLES

22

Fresh Air and Exhaust Piping Installation

SAFETY

INSTRUCTIONS

For information on combustion air, either from inside the building or

from the outside, refer to the Venting section in this manual.

1. Select an approved material for the combustion air

inlet. Refer to the table below for a list of approved

materials. Also select the appropriate diameter of pipe

based on length and number of units being installed,

as shown in the tables in the Technical Specications

section.

United States Vent Pipe Standards

Material Description

Vent Pipe

PVC Schedule 40

CPVC Schedule 40

Approved Polypropylene

Canadian Vent Pipe Standards

Material Description

Vent Pipe

Type BH Special Gas Vent Class IIA (PVC)

Type BH Special Gas Vent Class IIB (CPVC)

Type BH Special Gas Vent Class IIC (Polypropylene)

NOTE: Consult the following chart or the most

recent edition of ANSI Z223.1/NFPA 54 or CAN/

CGA B149.1, as well as all applicable local codes

and regulations when selecting vent pipe

materials.

For installation in Canada, installer-supplied plastic

vent piping must comply with CAN/CGA B149.1 and

be certified to the Standard For Type BH Gas Venting

Systems, ULC-S636. Components of this listed system

must not be interchanged with other vent systems or

unlisted pipes or fittings. All plastic components and

specified primers and glues must be from a single system

manufacturer and must not be intermixed with another

system manufacturers products

SAFETY

INSTRUCTIONS

Do not use cellular foam core pipe to vent exhaust gases.

IMPORTANT

On multiple unit installations, the piping from the

water heater can be 4 or larger piping. Use the

tables on page 11 to determine the diameter of the

common connecting piping between each individual water

heater.

2. Install the desired conguration of pipe for the

combustion air inlet. If the installation allows 2 pipe to

be used for this air inlet, install at least a 6 long piece

of 3 pipe with a 3 to 2 adapter.

IH-70

6"

3" Pipe

CAUTION

TOXIC FUMES HAZARD

If the inside of the pipe is not chamfered to remove all sharp

edges, the O-ring seals can be damaged during installation.

Damaged O-rings could allow combustion gases to leak

into the house.

a. Cut a 45 degree chamfer on the inside edge of the

3 pipe. Remove any shavings.

IH-70a

45

COMBUSTION (FRESH) AIR INLET EXHAUST OUTLET CONNECTIONS

b. Apply a small amount of water or liquid soap on

the chamfered surfaces to serve as a lubricant.

23

c. Install the pipe over the connector and dual o- ring

seals. Ensure that the o-ring seals are seated

correctly within the pipe and not pinched or pushed

out of the O-ring groove.

d. Secure the pipe to the walls or joists using a

suitable clamp (not supplied).

IH-35a

3. Continue the routing of the combustion air inlet.

a. For termination of the pipe to the outside, continue

installing the required pipe to a suitable outside

location. Glue all connections, making sure the

joints are sealed airtight.

b. To congure the unit for power vent, insert a 6

section of 3 pipe with a 90 elbow.

IH-69

3" Elbow

3" PVC Tube

3" x 2 Reducer

2" PVC Tube

4. Continue the routing of the exhaust gas outlet to a

suitable outside location.

a. Glue all connections, making sure the joints are

sealed airtight.

b. Install all horizontal exhaust gas vents with a

minimum 2 degree (1/4 per foot) slope back toward

the water heater. This allows any condensate that

accumulates in the exhaust outlet to properly drain

back into the unit.

5. Install suitable pipe support hangers every 4 to 5 feet,

or as local building codes require.

SAFETY

INSTRUCTIONS

Do not connect any other appliance vents to the water heater inlet

or outlet pipes.

IH-36b

6. If multiple units are installed, make sure the diameter of

the connecting exhaust outlet is properly sized for the

number of units being installed.

CAUTION

This water heater has a built-in control to limit the exhaust

temperature to 149F (65C). As a result, the Hubbell water heater

can be vented with Schedule 40 PVC. If the incoming (or

recirculation return) water temperature does not exceed 150F (66

C), the exhaust temperature will not exceed 149F (65C).

However, if you set the water heater at a temperature above 150F

(66C) and you are also incorporating either an external recirculation

loop or a combination heating system, the exhaust temperature can

exceed 149F (65C). In that case, you must use Schedule 40 CPVC

or Approved Polypropylene in the USA or Type BH Special Gas

Vent Class IIB (CPCV) or Class IIC (Polypropylene) that conforms to

ULC-S636 in Canada.

COMBUSTION (FRESH) AIR INLET EXHAUST OUTLET CONNECTIONS

24

Combustion Air From the Outdoors

Hubbell water heaters may be installed using a standard

(direct vent) configuration or an optional (power vent)

configuration.

The information in this section provides the installer with

recommendations; however, venting requirements are

different in the USA and Canada for installing proper

exterior venting through the structures roof or exterior

wall. Therefore, the installer should also refer to local

building codes and the Venting of Equipment section of

the latest edition of ANSI Z223.1 / NFPA 54 Natural Gas

Code. In Canada, refer to the Venting Systems and Air

Supply for Appliances section in the CAN/CGA B149.1

Natural Gas and Propane Installation Code.

Do not operate the unit in an area that will draw in air

contaminated with high levels of dust, sawdust, aerosols

such as paint, or other airborne contaminants.

If necessary, purchase and install appropriate air screens

and follow a regular cleaning program to ensure an

adequate supply of clean, outside combustion air.

SAFETY

INSTRUCTIONS

Do not use cellular foam core pipe to vent exhaust gases.

Outdoor Air

When the space in which fuel-burning appliances are

located does not meet the criteria for indoor air, outside

combustion air shall be supplied as specified in the

following sections.

Size of Openings

When directly connected with the outdoors, or when

connected with the outdoors by means of vertical ducts,

each opening must have a free area of at least 1 square

inch per 4,000 Btu/per hour (550 mm

2

/kW) of total input

rating of all appliances in the space.

Minimum Recommended Air Supply

Model / Size Area of Outside Air Vents

GX200 / 199,950 14 sq.in.

GX250 / 250,000 17 sq.in.

Attic Combustion Air

Combustion air obtained from an attic area must be in

accordance with the following:

1. The attic ventilation must be sufcient to provide the

required volume of combustion air.

2. The combustion air opening must be provided with a

metal sleeve extending from the appliance enclosure to

at least 6 inches (152 mm) above the top of the ceiling

joists and ceiling insulation.

3. The end of ducts that terminate in an attic must not be

screened.

Under-floor Combustion Air

Combustion air obtained from under-floor areas must

have free opening areas to the outside equivalent to not

less than twice the required combustion air opening.

Opening Requirements

Outside combustion air openings must be covered with

corrosion-resistant screen or equivalent protection having

not less than 1/4 inch (6 mm) openings, and not greater

than 1/2 inch (13 mm) openings.

VENTING

25

Connections on Bottom of Unit

WARNING

TOXIC FUMES

To avoid serious injury or even death from exhaust gases

(carbon monoxide), make sure the water heater is properly

vented. Refer to all applicable local and national regulations,

mandates, and building codes for guidelines to install proper

venting.

1. Terminate the combustion air inlet with a 90 degree

elbow (angled down) or a tee tting.

a. On an exterior wall, use a fl ange and PVC

screen (not supplied).

b. For roof top installation, a suitable roof ashing and

vent cap (not supplied) will be required.

2. Terminate the exhaust gas outlet on the exterior wall.

a. Side wall outlets must be at least 12 above ground

and at least 12 apart, or as required by local

building codes. In areas of high snow fall, protect

the vent terminations from blockage.

b. For roof top installation, a suitable roof ashing and

exhaust vent cap (not supplied) will be required.

IH-34

12

Option A

Option B

12

IH-34a

Option C

15

Side Wall Termination

NOTE: Install a mesh screen made from stainless

steel or other suitable material no smaller than 1/4

opening on both air intake and exhaust pipes.

Concentric Wall Venting System

IH-33

If desired, an optional concentric venting system, which

uses one 5 opening in an exterior wall or roof, as

opposed to cutting two 3 openings can be used.

Follow all installation instructions included with the

concentric vent kit when installing this type of vent

system.

IH-51a

12 USA or

18 Canada

Over maximum

snow level or

as required by

local code

12 Minimum

3 Minimum

12 USA or

18 Canada

Over maximum

snow level or as

required by local

code

Intake

Exhaust

Intake

Fresh air

vent

Exhaust

12 USA or 18 Canada

Over maximum snow

level or as required by

local code

Concentric Roof Venting System

Venting the unit through the roof is also an option. With

this installation method, the terminations must extend

at least 12 over maximum potential snow levels, or as

required by local building codes. In areas of high snow

fall, protect the vent terminations from blockage.

VENTING

Use screen on all

openings for

intake & exhaust

Use screen on all

openings for

intake & exhaust

Exhaust

Exhaust

Exhaust

Intake

Intake

Intake

NOTE: Units must be installed to have an

equivalent exhaust run of 5 feet (minmum).

26

Combustion (All) Air From Inside the Building

Hubbell may be used in a power vent or direct vent

configuration. When used in a power vent configuration,

the water heater should be located in an area where there

is adequate air supply from inside the building for proper

combustion and ventilation. Please follow your local code

or NFPA54 where applicable.

Required Volume

Minimum Recommended Air Supply

Model / Size Area of Outside Air Vents

GX200 / 199,950 200 sq.in

GX250 / 250,000 250 sq.in

Power Vent Installation Examples

IH-71

Roof Flashing

Intake

Pipe

Exhaust

Pipe

12"

IH-72

Mortar or Silicone Caulk

Positive slope of

1/4" per foot (25%)

Vent Terminal

with 1/2 Mesh

Protective

Screen Inside

Exhaust Pipe

Pipe

Coupling

Wall

Thimble

12" Min.

Above Grade

or Snow Level

VENTING

In Canada use 18"

WARNING

If, at any time, the installation location could experience

negative pressure, there is a possibility of cold air drafting

back through the unit's heat exchanger. This situation

could lead to the freezing of the heat exchanger and

malfunction of the water heater.

Chimney Automation System

For More Information on the ENERVEX

System Visit: www.enervex.com

The CASV 009-315, Chimney Automation System is a demand

controlled exhaust system designed for commercial boilers and

water heaters in buildings where the exhaust is powered by a

chimney fan on the exterior of the building. It maintains a

precise draft by constantly adjusting the exhaust rate to meet

current needs. The concept can provide substantial operating

savings over gravity systems and offer significantly better draft

control which reduces emissions.

The CASV System can be combined with an MCAS, Modulating

Combustion Air-supply System and can also work with a

MODS, Modulating Over-draft Damper System

ENERVEX

CASV 009-315, Chimney Automation System

27

Install and connect the hot water lines. If an optional hot

water storage tank is required, connect the hot water lines

to this tank also.

IH-87

5

3

4

2

1

1. Connect a 3/4 NPT coupler (1) to the water heaters

hot water connection.

2. Install a 3/4 union connection (2).

3. Install a 3/4 tee tting (3). Install either a pressure

relief valve or a temperature and pressure relief valve

(4), as required by your local code.

IH-86

Temperature and Pressure Relief Valve

IMPORTANT

The pressure relief valve must be rated at 150 psi,

the maximum btu/h input of the unit, and comply

with all local building codes and standards. Do not

install any restrictions or other valves in the

pressure relief line.

4. Install and route a 3/4 discharge pipe from pressure

relief valve (4) to within 6 inches of the oor and

directed away from walkways or other appliances.

5. Following local building codes, install a manual shut-off

valve (5) using 3/4 with 3/4 NPT ttings.

6. Install a drain valve on the bottom of the unit.

IH-88

5

5

7. Connect the unit to the existing hot water lines.

If the existing plumbing is 1/2 pipe, adapters may be

used to transition from the 3/4 pipe. If multiple water

heaters are being installed, the diameter of both the

cold water lines and the hot water lines need to be

sized appropriately.

8. Leak test the water piping before placing the unit in

operation.

NOTE: For energy conservation, the hot water

pipes should be insulated. Also insulate any

recirculation water lines.

INSTALL HOT WATER LINES

28

Install and connect the cold water line. If an optional hot

water storage tank is required, connect the hot water lines

to this tank also.

NOTE: If the incoming water is known to have a

high mineral content or hardness (>15 ppm),

treatment is recommended upstream from the

water heater.

1. Connect a 3/4 NPT coupler to the water heaters cold

water connection.

2. Install a 3/4 union connection.

3. Install an inline wye-strainer. Make sure the strainer is

positioned to allow servicing of the strainer screen.

IH-62

4. Following local building codes, install a manual shut-off

valve with 3/4 NPT ttings.

5. Connect the unit to the existing cold water lines.