Академический Документы

Профессиональный Документы

Культура Документы

Solar Mounting Structure Design For BTS Site

Загружено:

AsadIdreesОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Solar Mounting Structure Design For BTS Site

Загружено:

AsadIdreesАвторское право:

Доступные форматы

SOLAR PV

MOUNTING STRUCTURES

Technical Application Papers - Vol. 6

ABSTRACT

There are a lot of key factors that should be taken into

consideration before designing the Solar PV Mounting

Structure. This version of Nizam Energys Technical

Application Papers explain the design criteria of our

Mounting Structures.

Asad Idrees

Assistant Project Coordinator

Nizam Energy

Table of Contents

Mounting Types

Influence Factors of Mounting System Design

Design Features of Nizam Energys Mounting Structure

Mounting Structure for BTS Sites

Classification of PV Mounting Structures

Fixed Installation Site Foundation Materials

Fixed Mounting

Solution

Ground Mounting Concrete Steel

Adjustable Solution Roof-top Mounting Spiral Piles Aluminum Alloy

Tracking Solution BIPV C Type Steel Fiberglass Reinforced Plastic

Carport Ballast Plastic

Composite Material

Influence Factors on PV Mounting Design

A. Environment (Wind, Snow, Soil/Rock Conditions, Frozen Soil

All environmental factors have to be considered in the design process for mounting

structures (above ground) and foundations. All environmental factors have a significant

impact on construction time and costs!

Structures (above ground)

Foundations (below

ground)

Strategies

Wind

Higher wind speeds

bigger profiles (20% more

wind speed leads to 50%

more load!!)

Higher loads on foundations

more or bigger

foundations

Strengthen the material and adopt

the front wall structure to reduce the

total cost.

Snow

Higher snow loads bigger

profiles

Higher loads on foundations

more or bigger

foundations

Strengthen the material , decrease

the post height and reduce the

component stress

Flood

Increase the height of

mounting structure

Flood Risk Increase the

height between module &

ground

Considering the impact loads of

flood and increase the height of

mounting structure

Frozen

soil

Need to be more stable Deeper foundation Foundation treatment

B. Influence of System Design (Module Layout, Type, Tilt Angle)

The layout, type and tilt angle of

module are the key factors to

affect the design of mounting

structure and foundation.

Description

Structures (above

ground)

Foundations (below

ground)

Strategies

Layout

No more than 4

modules in

vertical , the

span is less than

7m

Bigger Span bigger

profile cross section

Bigger Span bigger

foundations

select and optimize the

profile properly according to

the different layout of

modules

Type

Frameless

Module

Special Clamps

Different Module

different foundation

settlement

change the cross section of

profile, increase the

parameters of cross section

and reduce the deflection on

modules

Module with

Frame

Common Clamps

Special Module

Depending on the

situation

Tilt

Angle

0-60

bigger angle bigger

windward side and

cross section

Bigger angle bigger

foundations

considering the frond wind

effect and design separately

C. Atmosphere Corrosion Conditions

According to the environment classification, the loss rate of hot-galvanization layer in

different atmosphere conditions is as follows; (In accordance with the ISO14713

environment classification, the corrosion risk and loss rate of hot-galvanization layer)

Code Corrosivity category

Corrosion

risk

Corrosion rateAverage

thickness loss for zinc,

mm/year

C1 Interior: dry Very low 0.1

C2

Interior: occasional condensation

Low 0.1-0.7

Exterior: exposed rural inland

C3

Interior: high humidity, some air pollution

Medium 0.7-2

Exterior: urban inland or mild coastal

C4

Interior: swimming pools, chemical plants etc

High 2-4

Exterior: industrial inland or urban coastal

C5

Exterior: industrial with high humidity or high

salinity coastal

Very high 4-8

Im2 Sea water in temperate regions Very high 10-20

Design Features of our Mounting Structures

A. The Load Partition Design

Through aerodynamic software analysis, determine the load partition and the overall influence on solar farm

caused by wind flow, which can help save the cost of solar farm.

B. Easy Installation

Through structure check installation test, we reduce the number of fittings required on site by delivering a pre-

assembled mounting structure in the form of different packages.

These Packages are classified to facilitate the material distribution on site.

C. Adjustability of the Mounting

The sliding columns and support of the mounting

Structure enable angle adjustments for the PV Modules

which are vital in maximizing the yields throughout the

year.

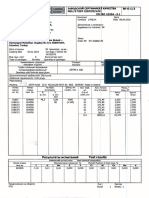

Mounting Structure Design for BTS Sites

Вам также может понравиться

- 2020 A wind load design method for ground-mounted multi-row solar arrays based on a compilation of wind tunnel experimentsДокумент23 страницы2020 A wind load design method for ground-mounted multi-row solar arrays based on a compilation of wind tunnel experimentsYanfei ZhuОценок пока нет

- Mounting StructureДокумент41 страницаMounting StructureAcharan Chandel100% (1)

- Wind Load Calculations for PV ArraysДокумент24 страницыWind Load Calculations for PV ArraysapirakqОценок пока нет

- Designing PV Systems For Environmental Extremes - SolarPro MagazineДокумент8 страницDesigning PV Systems For Environmental Extremes - SolarPro MagazinedivrtleeОценок пока нет

- Wind Load CalculationДокумент15 страницWind Load CalculationEr Nilesh Gajera100% (1)

- Solar RoofTOP System DesignДокумент16 страницSolar RoofTOP System DesignAbhyuday GhoshОценок пока нет

- Ground Mount PV SolarДокумент6 страницGround Mount PV SolarJohn Kamau Khalfani100% (1)

- Deployment of Hybrid Renewable Energy Systems in MinigridsОт EverandDeployment of Hybrid Renewable Energy Systems in MinigridsОценок пока нет

- Distribution and Substation: TransformersДокумент72 страницыDistribution and Substation: Transformersheatra2222Оценок пока нет

- FormatДокумент17 страницFormatkalpeshОценок пока нет

- Grid Connected Rooftop Solar PV System A Pre Feasibility Estimation Using Pvsol Premium and System Advisor ModelsamДокумент6 страницGrid Connected Rooftop Solar PV System A Pre Feasibility Estimation Using Pvsol Premium and System Advisor ModelsamRazvan SasuОценок пока нет

- Module Mounting StructureДокумент1 страницаModule Mounting StructureVasanth KumarОценок пока нет

- Mms Design PaperДокумент12 страницMms Design PaperkrishnaОценок пока нет

- Design Calculations For Foundations For A Solar MMSДокумент13 страницDesign Calculations For Foundations For A Solar MMSnimish.aquamarineОценок пока нет

- Nordic Solar PV Mounting Structure GuideДокумент13 страницNordic Solar PV Mounting Structure GuideHarish Kumar GОценок пока нет

- Solar Power Project-200 KVA Roof TopДокумент22 страницыSolar Power Project-200 KVA Roof TopRajesh ThulluriОценок пока нет

- Technical Q&A on Calculating Inter-Row Spacing for Ground Mounted PV ArraysДокумент2 страницыTechnical Q&A on Calculating Inter-Row Spacing for Ground Mounted PV ArraysNicholas OngОценок пока нет

- 100kw QuotationДокумент5 страниц100kw QuotationDishachi EnergyОценок пока нет

- Structure Design Calculation of Rooftop Solar ProjectДокумент13 страницStructure Design Calculation of Rooftop Solar ProjectSalauddinAnsari100% (1)

- Appendix 3-1 PV System Design ReportДокумент26 страницAppendix 3-1 PV System Design ReportDzevad FazlicОценок пока нет

- 199.8kWp Solar Plant Installation ProposalДокумент5 страниц199.8kWp Solar Plant Installation ProposalAbuzar BanderkarОценок пока нет

- Mes - MMS Design ReportДокумент83 страницыMes - MMS Design Reportvasanth100% (2)

- 100kw Solar Design GuidelineДокумент10 страниц100kw Solar Design GuidelineankitОценок пока нет

- 1 MW WorkingДокумент4 страницы1 MW WorkingMohan ManiОценок пока нет

- PV Row SpacingДокумент2 страницыPV Row Spacingpandi27100% (1)

- Design Calculation Report For 2PX15 MMS Solar Structure-R1Документ285 страницDesign Calculation Report For 2PX15 MMS Solar Structure-R1Ranjeet Patel100% (3)

- Low Voltage Switch Disconnectors for Photovoltaic SystemsДокумент12 страницLow Voltage Switch Disconnectors for Photovoltaic SystemswasinchaiОценок пока нет

- Grid Connection Requirements For Wind Turbine Systems in Some Countries Comparison To TurkeyДокумент15 страницGrid Connection Requirements For Wind Turbine Systems in Some Countries Comparison To TurkeyHans De Keulenaer100% (7)

- Wind Loading On Full-Scale Solar PanelsДокумент97 страницWind Loading On Full-Scale Solar PanelsLucas de MedeirosОценок пока нет

- PVSYST - TutorialsДокумент102 страницыPVSYST - Tutorialsccwei713100% (1)

- Solar StructuresДокумент4 страницыSolar StructuresReliableIndia100% (1)

- Performance analysis of a grid-connected rooftop solar PV system in MalaysiaДокумент13 страницPerformance analysis of a grid-connected rooftop solar PV system in MalaysiaKENDALL PAUL LAUREANOОценок пока нет

- Techno - Commercial Proposal For 200 KWP Rooftop Solar Power Plant at AimtДокумент18 страницTechno - Commercial Proposal For 200 KWP Rooftop Solar Power Plant at AimtParwinder Singh100% (1)

- Hat PurlinДокумент3 страницыHat PurlinAniket DubeОценок пока нет

- SolarPro 7.6Документ88 страницSolarPro 7.6HanyОценок пока нет

- Determining Wind and Snow Loads For Solar PanelsДокумент17 страницDetermining Wind and Snow Loads For Solar PanelsPauloAndresSepulveda100% (2)

- Optimization and Performance of Bifacial Solar Modules: A Global PerspectiveДокумент19 страницOptimization and Performance of Bifacial Solar Modules: A Global PerspectiveajОценок пока нет

- Structural Design CAlculationsДокумент12 страницStructural Design CAlculationsnimish.aquamarineОценок пока нет

- Techno Commercial Offer - 4 KW Off Grid Solar PV SystemДокумент9 страницTechno Commercial Offer - 4 KW Off Grid Solar PV SystemUday Kumar ReddyОценок пока нет

- SMA Catalogo 2010 - 11 - en PDFДокумент222 страницыSMA Catalogo 2010 - 11 - en PDFluca2527Оценок пока нет

- Substation Building Design Report PDFДокумент57 страницSubstation Building Design Report PDFAnonymous fLgaidVBhzОценок пока нет

- Technical Specification of 480V-11KV IDT - CEL Project - R0Документ15 страницTechnical Specification of 480V-11KV IDT - CEL Project - R0Jitendra PathakОценок пока нет

- DWG Cable Trench - 850x800Документ1 страницаDWG Cable Trench - 850x800Anshuman PandeyОценок пока нет

- 2X4 STRUCTURE TABLE WIND ANALYSYS REPORT AT 200 KMPHДокумент16 страниц2X4 STRUCTURE TABLE WIND ANALYSYS REPORT AT 200 KMPHYashwant Raj VermaОценок пока нет

- Pole W Solar Panel - Design ReportДокумент62 страницыPole W Solar Panel - Design ReportGaurav Sharma100% (4)

- Proposal For Implementing Grid Connected Solar Power Plant of 1MW of EnergyДокумент15 страницProposal For Implementing Grid Connected Solar Power Plant of 1MW of EnergyAtul SinghОценок пока нет

- PFR - 5 MW Solar of Milisaty Vinimay Pvt. LTDДокумент11 страницPFR - 5 MW Solar of Milisaty Vinimay Pvt. LTDpvpavanОценок пока нет

- AS/NZS7000 STANDARD ELECTRICAL AND MECHANICAL DESIGN OF INSULATORSДокумент15 страницAS/NZS7000 STANDARD ELECTRICAL AND MECHANICAL DESIGN OF INSULATORSerkamlakar2234Оценок пока нет

- Design and Sizing of On-Grid PV Systems5Документ14 страницDesign and Sizing of On-Grid PV Systems5amrsah61083Оценок пока нет

- Wind Calculation ManДокумент12 страницWind Calculation ManannuvyasОценок пока нет

- 1424-S-RP-002 A Support Reactions and Anchor Bolt DesignДокумент15 страниц1424-S-RP-002 A Support Reactions and Anchor Bolt DesignAmarjit KulkarniОценок пока нет

- Staad Report - BracketДокумент7 страницStaad Report - BracketsanjeevОценок пока нет

- Wind Load Calculations For PV Arrays: Solar America Board For Codes and StandardsДокумент24 страницыWind Load Calculations For PV Arrays: Solar America Board For Codes and StandardsSalman KhanОценок пока нет

- Concrete Foundation DesignДокумент3 страницыConcrete Foundation DesignPradeep Kumar SukumaranОценок пока нет

- Car Parking Shade Design ReportДокумент28 страницCar Parking Shade Design Reportsiso hegoОценок пока нет

- India Solar Rooftop Guide 2014Документ72 страницыIndia Solar Rooftop Guide 2014Sheik Syed Najmal100% (2)

- Group member registration and solar power system sizingДокумент3 страницыGroup member registration and solar power system sizingAkankwasa RonaldОценок пока нет

- Seminar On " ": Pre Engineered BuildingsДокумент27 страницSeminar On " ": Pre Engineered BuildingsPrasad NbОценок пока нет

- Pre-Engineered Buildings Guide - Design, Components, AdvantagesДокумент27 страницPre-Engineered Buildings Guide - Design, Components, AdvantagesMadan YadavОценок пока нет

- Facade Engineering For Tall Buildings by Rajan GovindДокумент6 страницFacade Engineering For Tall Buildings by Rajan Govindpandey008Оценок пока нет

- String Inverters - SMAДокумент48 страницString Inverters - SMAAsadIdreesОценок пока нет

- IEC61724 PV MonitoringДокумент20 страницIEC61724 PV MonitoringAsadIdreesОценок пока нет

- String Inverters - SMAДокумент48 страницString Inverters - SMAAsadIdreesОценок пока нет

- 8086 ProgrammingДокумент16 страниц8086 ProgrammingHariPriyan71% (7)

- The Future..is For Islam..Документ262 страницыThe Future..is For Islam..AsadIdreesОценок пока нет

- Mcs 2010Документ196 страницMcs 2010rvillgОценок пока нет

- Band ItДокумент48 страницBand ItCentral HydraulicsОценок пока нет

- Formula One - Technical Regulations - 2017Документ91 страницаFormula One - Technical Regulations - 2017antoniocdof1Оценок пока нет

- Search ResultsДокумент3 страницыSearch ResultsSanjay MehtaОценок пока нет

- Optimization of Electroless Copper Coating Parameters On Graphite Particles Using Taguchi and Grey Relational AnalysisДокумент6 страницOptimization of Electroless Copper Coating Parameters On Graphite Particles Using Taguchi and Grey Relational AnalysisfacebookdeepuОценок пока нет

- 7.1 - Cooling Water SystemДокумент8 страниц7.1 - Cooling Water SystemSayem kaifОценок пока нет

- 87a-207-01-Stainless Steel Asme Class 150 Flanged Full Port Ball Valve - 1.5" Thru 2.5Документ1 страница87a-207-01-Stainless Steel Asme Class 150 Flanged Full Port Ball Valve - 1.5" Thru 2.5Hung NguyenОценок пока нет

- CIC API 570 (8) Api-578Документ44 страницыCIC API 570 (8) Api-578Ibrahim EldesokyОценок пока нет

- Collapsible Tube For PharmaДокумент8 страницCollapsible Tube For PharmaAbhishek Singh100% (1)

- Smartdek Design ManualДокумент48 страницSmartdek Design ManualranddyОценок пока нет

- 48,3x5,08 824000Документ2 страницы48,3x5,08 824000Mehmet ŞaHanОценок пока нет

- Advanced m52umCT2014Документ79 страницAdvanced m52umCT2014Anonymous ys297cBxОценок пока нет

- PDO SP-2217 Specification of Internal FBE and Liquid Coating Systems For Carbon Steel Piping and Line PipesДокумент41 страницаPDO SP-2217 Specification of Internal FBE and Liquid Coating Systems For Carbon Steel Piping and Line PipesMoin AltafОценок пока нет

- Sym Euro MX 125 (EN)Документ193 страницыSym Euro MX 125 (EN)manualsym0% (1)

- Communication With Laser BeamДокумент17 страницCommunication With Laser BeamJagruti MulayОценок пока нет

- Mouse monoclonal OC4-30 to Osteocalcin SDSДокумент6 страницMouse monoclonal OC4-30 to Osteocalcin SDSIna MarsomОценок пока нет

- As 1463-1988 Polyethylene Pipe Extrusion CompoundsДокумент6 страницAs 1463-1988 Polyethylene Pipe Extrusion CompoundsSAI Global - APACОценок пока нет

- Saes H 101VДокумент83 страницыSaes H 101Vacolombel100% (2)

- AMIAD Water Systems Arkal Spin Klin 7 X4" Galaxy User Guide: Installation and Operation InstructionsДокумент23 страницыAMIAD Water Systems Arkal Spin Klin 7 X4" Galaxy User Guide: Installation and Operation InstructionsLuongОценок пока нет

- Te ML 03 Am Pracovni Stroje Planetove Prevodovky en PDFДокумент12 страницTe ML 03 Am Pracovni Stroje Planetove Prevodovky en PDFMiroslav MilosevskiОценок пока нет

- Mechanical Engineering McqsДокумент319 страницMechanical Engineering McqsMuhammad AslamОценок пока нет

- SC2057 PDFДокумент3 страницыSC2057 PDFA MahmoodОценок пока нет

- South African Cotton Textile Pipeline Statistics 2016-2020Документ16 страницSouth African Cotton Textile Pipeline Statistics 2016-2020Siphumelele QithiОценок пока нет

- Valorizing Spent Coffee GroundsДокумент15 страницValorizing Spent Coffee GroundsJorge ZapataОценок пока нет

- Chemistry Paper 1 2009Документ7 страницChemistry Paper 1 2009Robert EdwardsОценок пока нет

- Firecel General Catalogue - 100-4Документ32 страницыFirecel General Catalogue - 100-4dinesh_kp7647Оценок пока нет

- Eeto Handheld Laser WelderДокумент6 страницEeto Handheld Laser WelderalbertОценок пока нет

- Geotechnical Engineering of LandfillsДокумент78 страницGeotechnical Engineering of LandfillsJoeAnn Av'rageОценок пока нет

- John Carlo Dela Cruz - CHEM - Q3 - W4Документ12 страницJohn Carlo Dela Cruz - CHEM - Q3 - W4johncarlodc99Оценок пока нет

- Borneman Pump ManualДокумент56 страницBorneman Pump Manualiskalkos100% (2)