Академический Документы

Профессиональный Документы

Культура Документы

Handout - 2086 - SE2086 Beyond Buildings Handout

Загружено:

Errian Nadezhda TangОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Handout - 2086 - SE2086 Beyond Buildings Handout

Загружено:

Errian Nadezhda TangАвторское право:

Доступные форматы

Bey

in th

Hkon F

SE208

This cla

Autodes

industry

usually

projects

show ho

betwee

Robot, o

Learni

At the e

Des

List

Use

Use

About

Hakon i

structur

serving

involved

stadium

At TDA

structur

Autodes

Robot

hfb@td

yond Bu

he Offs

Frank Barda

86

ass covers th

skRobot

y rather than

require adva

s and explain

ow the Robo

n various ana

or another si

ing Object

end of this cla

scribe the us

t and define t

e different mo

e the Revit S

the Speak

is a structura

ral engineer a

the offshore

d in various p

m, hydropowe

he has taken

res and dema

sk dealer he

Structural A

a.as

uilding

shore In

rson TDA

e use of sev

Structural A

the traditiona

anced finite e

n the workflow

ot API (applic

alysis and m

milar FEM a

tives

ass, you will

efulness of R

the possibiliti

odeling tools

tructure-Rob

ker

al engineer w

as well as the

e industry with

projects durin

er plants, buil

n the Autode

ands for adva

is responsib

Analysis Prof

s: Adv

ndustry

AS

eral software

Analysis Profe

al building in

element meth

w between th

ation program

odeling tools

nalysis tool,

be able to:

Revit Structur

ies of the Ro

to push the

bot link and d

with a Master

e Autodesk p

h advanced e

ng his 14 yea

ldings, damn

esk BIM solut

anced FEM a

ble for classes

fessional.

vanced

y

e products, in

essional, for

dustry. Thes

hod (FEM) an

he different s

ming interfac

s for complete

and be open

re and Robot

bot API

perceived bo

escribe its lim

degree from

product mana

engineering s

ars of working

ns, bridges to

tion beyond m

analysis. As t

s and suppor

FEM A

ncluding Auto

applications

se structures

nalysis. We s

oftware prod

ce) can be us

e detail engin

n to API prog

t for special,

oundaries

mitations

m the Universi

ager at TDA,

services for m

g as a structu

o fan wheels

mere building

the Autodesk

rt for Autodes

Analysi

odeskRevit

in the offsho

are often ste

show exampl

ducts used in

seful for impr

neering. You

ramming.

non-standar

ity of Washin

a Norwegian

more than 30

ural engineer

and lifting eq

gs into a field

k product ma

skRevita

is and

tStructure

ore energy an

eel dominated

es from relev

the projects

roved workflo

u should be fa

rd structures

ngton. He wo

n engineering

0 years. He h

r ranging from

quipment.

d with comple

anager for a N

and Autodes

BIM

and

nd marine

d and

vant

. We also

ow

amiliar with

orks as a

g company

has been

m sport

ex

Norwegian

k

Beyond Buildings: Advanced FEM Analysis and BIM in the Offshore Industry

2

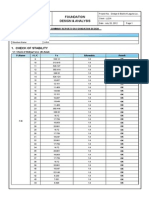

Non standard structures in Revit and Robot

Modeling structures that are not typical buildings with straight vertical walls and horizontal floors is

possible to make in to do in both Revit and Robot Structural Analysis even though at first glance both

programs are very building focused.

Each program has his advantages and weaknesses and being able to move the model between different

modeling tools is becoming more and more feasible as the programs are developed with this in mind.

Sometimes a little bit of creativity is all that is needed to make the model.

What we look at here is a jacket foundation for an offshore wind turbine. These structures are made with

steel profiles. Typically three or four legs with cross braces that transfer the horizontal load down to the

seabed. Top piece of the jacket is a transition piece and on top of that is the tower holding the turbine.

Pictures from Ormonde Offshore Windfarm out from the Irish coast

Typically the jackets are many and the area that they are placed in has various depth and ground

conditions. A few models are made with different heights and footprints. Revit is a good tool to start

modeling this as using grid lines and levels it is easy to change the geometry and therefor easy to make

many models from one base model. The braces can be connected to the legs and refer to the levels so

changing levels and or footprint is easy and requires minimal remodeling.

Revit model of the jacket part

Beyond Buildings: Advanced FEM Analysis and BIM in the Offshore Industry

3

Revit to Robot link

Moving the model then to Robot is straight forward with the link inside Revit. The link will transfer the

analytical model of standard beam, column, brace elements as well as wall and floor elements from the

Revit model to Robot. Even though we can do all kinds of custom made objects in Revit we can not

transfer them over to Robot unless they are based on the standard elements that contain the analytical

lines or plans.

Normally a fair amount of work is needed to adjust the analytical model before it is ready to be transferred

into Robot. Autodesk has made huge improvements in the latest versions of Revit on how we can

manipulate the analytical model in Revit independently of the physical model. For a simple structure like

we have here there is not much we need to do to the analytical model but it is necessary to view the

analytical model to check if that is how we want our model to be as that is the model we are going to be

using.

For these structures we are not using the Robot Structural Analysis to do any structural calculations

because ANSYS ASAS does offer some features that Robot does not have and are needed for these

structures. Two of these features are fatigue calculation and stochastic wave loading.

ANSYS ASAS software is a general-purpose structural finite element system containing industry-specific

features to address the needs of offshore and marine engineers. ANSYS ASAS provides the capabilities

required to perform global structural assessment of most types of marine structures, including jackets.

ANSYS ASAS provides code checks as well as fatigue calculations for spectra, deterministic and time

history.

ANSYS ASAS is not a modeling tool and normally the models are typically made in ANSYS Direct

Modeling tool, ANSYS Structural Mechanical or FEMGV. The input in ANSYS ASAS is in a text file format

and therefor it is easy to make them from tabulated data. Before using the Robot API to make the input

files the standard method was to copy the tables out from Robot to excel and make the text files from

them.

We use Robot here to prepare the model for ANSYS ASAS by splitting the elements at required locations

naming the cross sections in a manner that is easy to size after and grouping different elements by using

the bar type properties and assigning them to the bars.

Robot model after splitting the members and naming them.

Beyond Buildings: Advanced FEM Analysis and BIM in the Offshore Industry

4

What can we use the Robot API to do?

The Robot API (Application Programming Interface) is basically how we can use other programs to use

the features and functions in Robot. The Robot API can for example be used for:

Automating repetitive tasks in Robot program

Creating applications that facilitate modeling of typical structures

Analyzing projects, creating own reports and printouts

Importing external data to Robot program

Integrating other programs with Robot program

Interpreting results and creating documentation

To use Robot API one does not need to be a programming expert. It is more important to know Robot

and what you can do in Robot. Most operations that you can do via the user interface you can also do

via the API.

We use Microsoft Visual Studio Express 2010 to program a simple program that reads the data we want

to use from the Robot model and writes the appropriate input files for ANYSIS ASAS. These input files

are simple text files with a certain format that can be read into the program.

Microsoft Visual Studio Express is a free software that can be downloaded from the Microsoft website

and can be used to program in several languages. To get started programming for Robot API a few

simple actions need to be done.

First of all you need a copy of Robot on your computer. Then when you have defined a new project in

Visual Studio you need to go to Project ->Add Reference and in the COM tap selecting the Robot Object

Model.

Then you need to write using Robot OM; in the top of your program file:

Beyond Buildings: Advanced FEM Analysis and BIM in the Offshore Industry

5

When this is done you can start writing the code that interacts with Robot. Writing code in Visual Studio is

very easy and often you only need to write the first letter and then you can scroll up and down to find the

correct variable or method that your are looking for.

The internet is full of information on how to write code in different programming languages, and if you

have once learned one language it is very easy to start using other languages even though there have

been a few years since you last wrote some code. The access to the information that you need to get

started is just a click in the browser away.

To get you started here is a simple method that activates when pressing the geomBtn button and makes

a new 2D frame project in Robot then creates 3 nodes and 2 bar elements between those nodes.

And this is how it looks in Robot after running the program:

Beyond Buildings: Advanced FEM Analysis and BIM in the Offshore Industry

6

If you install the Robot SDK (Software Development Kit) you will see a description of the variables and

methods in the Robot API as well as some code examples that can also be helpful in getting you started.

The Robot Software Development Kit can be installed from your product installation menu under Install

Tools & Utilities.

As I mentioned earlier we used Microsoft Visual studio to write a small program that uses the Robot API

to write the input files used in ANSYS ASAS. The program we wrote can write out five different files,

which the user can define the name for. It can either write out all of the nodes/beam elements or the

nodes/beam elements selected in Robot.

The format of the files is that one line typically defines an element and text after the * is a comment,

therefore ignored by ANSYS ASAS. The first file is the node file which includes the node number, and

coordinates in x, y and z.

Beyond Buildings: Advanced FEM Analysis and BIM in the Offshore Industry

7

The second one is the bar element file which sorts the bars after the type parameter and includes the

nodes that the bar connects to as well as the bar number and cross-section number. The text after the * is

just a comment.

The third file is the file which includes the cross section number, the cross section name and the beta

angle of the cross section.

Beyond Buildings: Advanced FEM Analysis and BIM in the Offshore Industry

8

The fourth file is the section file which includes information about the cross sectional properties of the

pipes Outer diameter and thickness. This we change manually when running the code checks and fatigue

calculations.

The fifth file is a file to write out the planar finite elements with nodal numbers, cross section name and

element number.

Beyond Buildings: Advanced FEM Analysis and BIM in the Offshore Industry

9

Here the program can write out both 3 noded or 4 noded shell elements with the appropriate definition for

ANSYS ASAS.

Pushing the boundary of the tools

When we use a certain modeling tool we are in some way limited to the options available in that program.

By being able to use different modeling tools and moving the models between them we are able to use

the strengths of one program to make for example the geometry and then use another program to

perform the calculations. In the previous example we used Revit and Robot to make the geometric model

while doing the finite element calculation in ANSYS programs.

Another example we can demonstrate is a finite element modeling of ship geometry for doing strength

and lifting analysis in Robot Structural Analysis. Robot does not offer the option of modeling surfaces that

have curvature in two plans like a typical ship structure has. But Robot can mesh such surfaces if they

can be imported into Robot. Making the surfaces in another modeling tool such as ANSYS SpaceClaim

Direct Modeler and then importing them to Robot makes it possible to do the analyses and code checks

in Robot.

Вам также может понравиться

- Mat Foundations Using STAADДокумент5 страницMat Foundations Using STAADSha Mas ShaОценок пока нет

- Odeh v6Документ4 страницыOdeh v6Errian Nadezhda TangОценок пока нет

- National Cad StandardsДокумент960 страницNational Cad Standardsrem_koolhaas100% (10)

- 2008 Wind SeismicДокумент87 страниц2008 Wind SeismicRo-bert MagoОценок пока нет

- GS 2006 Vol 1 Rev 16-130614Документ484 страницыGS 2006 Vol 1 Rev 16-130614Errian Nadezhda TangОценок пока нет

- 09 - Types of AnalysisДокумент56 страниц09 - Types of AnalysisAsraf MuidinОценок пока нет

- CAV Process For CHED and DFAДокумент2 страницыCAV Process For CHED and DFApennywiser0% (1)

- DBEManual (English)Документ133 страницыDBEManual (English)Errian Nadezhda TangОценок пока нет

- F 3Документ18 страницF 3Errian Nadezhda TangОценок пока нет

- Analysis & Design ReportДокумент1 страницаAnalysis & Design ReportErrian Nadezhda TangОценок пока нет

- Foundation Calculation Sheet One-Stop Solution For FoundationДокумент43 страницыFoundation Calculation Sheet One-Stop Solution For FoundationErrian Nadezhda TangОценок пока нет

- WSP Revit Structure Handout 001 - Part 1 of 2Документ45 страницWSP Revit Structure Handout 001 - Part 1 of 2Walter Jacobs0% (1)

- Transportation Engineering PDFДокумент116 страницTransportation Engineering PDFNipim JainОценок пока нет

- Foundation Design & Analysis: Project InformationДокумент224 страницыFoundation Design & Analysis: Project InformationErrian Nadezhda TangОценок пока нет

- Getting Started With AutoCAD® Structural Detailing, Steel ModuleДокумент49 страницGetting Started With AutoCAD® Structural Detailing, Steel ModuleAllan David100% (1)

- National GYP Construction GuideДокумент166 страницNational GYP Construction GuideDarcy BudworthОценок пока нет

- Manual Tekla Structures Ingles.Документ663 страницыManual Tekla Structures Ingles.Andres Hugo GalloОценок пока нет

- 01Документ11 страниц01Vitor Da FonsecaОценок пока нет

- Manual Tekla Structures Ingles.Документ663 страницыManual Tekla Structures Ingles.Andres Hugo GalloОценок пока нет

- CBR ValueДокумент39 страницCBR ValuemalumiusОценок пока нет

- Manual en Ingles Revit Estructure 2012Документ27 страницManual en Ingles Revit Estructure 2012Rey MartíОценок пока нет

- Tutorial AutoCad 2010 PDFДокумент600 страницTutorial AutoCad 2010 PDFSeptian Anggoro100% (1)

- WSP Revit Structure Handout 001 - Part 1 of 2Документ45 страницWSP Revit Structure Handout 001 - Part 1 of 2Walter Jacobs0% (1)

- 978 1 58503 807 7 7 PDFДокумент44 страницы978 1 58503 807 7 7 PDFErrian Nadezhda TangОценок пока нет

- Pulse Velocity Through Concrete: Standard Test Method ForДокумент4 страницыPulse Velocity Through Concrete: Standard Test Method ForErrian Nadezhda Tang100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Poetics: Ester Van Laar, Alexander J.A.M. Van Deursen, Jan A.G.M. Van Dijk, Jos de HaanДокумент14 страницPoetics: Ester Van Laar, Alexander J.A.M. Van Deursen, Jan A.G.M. Van Dijk, Jos de HaanViveka AshokОценок пока нет

- Wilson's TheoremДокумент7 страницWilson's TheoremJonik KalalОценок пока нет

- Adient Managment CSRДокумент68 страницAdient Managment CSRClaudia PEÑAОценок пока нет

- Examples and Non-ExamplesДокумент5 страницExamples and Non-ExamplesslidegaeОценок пока нет

- CSR of Pidilite PDFДокумент2 страницыCSR of Pidilite PDFtarang keraiОценок пока нет

- Please Complete The Information Requested Below: COMPANY NAME: X2 Logics Staffing Solution, IncДокумент2 страницыPlease Complete The Information Requested Below: COMPANY NAME: X2 Logics Staffing Solution, Incwasim riyazОценок пока нет

- Samsung 932GW PDFДокумент72 страницыSamsung 932GW PDFSaidfa FaОценок пока нет

- Surge CounterДокумент2 страницыSurge CounterJavier CuzcoОценок пока нет

- Chapter7 Ex PDFДокумент5 страницChapter7 Ex PDFSathish Kumar100% (1)

- UntitledДокумент44 страницыUntitledFrancesco TauroОценок пока нет

- Antennas L01Документ15 страницAntennas L01Domenico RizzoОценок пока нет

- Rack Interface Module 3500 20SДокумент71 страницаRack Interface Module 3500 20SmaheshОценок пока нет

- Laboratorios RoeДокумент11 страницLaboratorios RoeVioleta CubaОценок пока нет

- Activity On The Layers of The Earth 1Документ1 страницаActivity On The Layers of The Earth 1Ian MarianoОценок пока нет

- 1-Perceived Threat of Covid-19 and T.I (Reference Article)Документ10 страниц1-Perceived Threat of Covid-19 and T.I (Reference Article)Hassan NadeemОценок пока нет

- CertificateofAnalysis 2019 11 9 879766Документ2 страницыCertificateofAnalysis 2019 11 9 879766Trọng TínОценок пока нет

- CHCDIV001 - Student Assessment Booklet ECEC.v2.0Документ59 страницCHCDIV001 - Student Assessment Booklet ECEC.v2.0Dink DinkОценок пока нет

- ResearchДокумент12 страницResearchIsla, AltheaОценок пока нет

- DLL - English 5 - Q3 - W8Документ8 страницDLL - English 5 - Q3 - W8Merlyn S. Al-osОценок пока нет

- Future Christchurch: Solutions. Housing: Biran HeДокумент108 страницFuture Christchurch: Solutions. Housing: Biran HecamiayoungОценок пока нет

- Hotel Organizational StructureДокумент3 страницыHotel Organizational StructureChi LinhОценок пока нет

- Indian Council of Medical ResearchДокумент6 страницIndian Council of Medical Researchram_naik_1Оценок пока нет

- Complete-Crp SPC Shamli r01-1562323540Документ291 страницаComplete-Crp SPC Shamli r01-1562323540p nandyОценок пока нет

- Pdlgfu15: PDLGFU15 User's GuideДокумент327 страницPdlgfu15: PDLGFU15 User's Guidejose antonio carazoОценок пока нет

- 08 Saad Introduction Too o ConceptsДокумент26 страниц08 Saad Introduction Too o ConceptsMohammed ABDO ALBAOMОценок пока нет

- Cell Cycle Karyotyping Lab ReportДокумент11 страницCell Cycle Karyotyping Lab ReportRichie JustinОценок пока нет

- Pardoseli PVCДокумент72 страницыPardoseli PVCnasuemilОценок пока нет

- A HandBook On Finacle Work Flow Process 1st EditionДокумент79 страницA HandBook On Finacle Work Flow Process 1st EditionSpos Udupi100% (2)

- Pakistan Wapda - Power Wing: Standard Operating ProceduresДокумент8 страницPakistan Wapda - Power Wing: Standard Operating Procedureszahra batoolОценок пока нет

- Uniden Bearcat Scanner BC365CRS Owners ManualДокумент32 страницыUniden Bearcat Scanner BC365CRS Owners ManualBenjamin DoverОценок пока нет