Академический Документы

Профессиональный Документы

Культура Документы

Six Steps To Successful GT Repair Part 2

Загружено:

raharjoitbОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Six Steps To Successful GT Repair Part 2

Загружено:

raharjoitbАвторское право:

Доступные форматы

COMBINED CYCLE JOURNAL, Third Quarter 2005 OH-7

2006 OUTAGE HANDBOOK

SI X STEPS TO SUCCESSFUL GT REPAI R, Part 2

W

hen selecting a repair

facility to refurbish

parts for your plants

GTs, keep in mind that

costthe variable upon which

many decisions are basedis

only one of several important

considerations. Shop capabili-

ties, experience of employees,

vendor performance on sim-

ilar jobs, quality control, and

other factors are equally impor-

tantperhaps even more so.

A thorough evaluation of alter-

native service companies is criti-

cal to selecting the best repair

facility for the work required

in support of your next outage.

The sector of the GT services

industry concerned with parts

refurbishment is dynamic in

nature. Most companies are

small, so it is common for

them to be acquired, relocate,

expand through acquisition,

or close with little or no public

disclosure.

Dont assume the facilities

that did an acceptable job of

repairing compressor, com-

bustor, and hot-section parts

for your last outage are nec-

essarily the best partners for

the next overhaul. Likewise, a

company rejected previously

may have acquired new capa-

bilities, hired new people, etc,

and deserves reconsideration.

The competitive nature of the

GT-based generation busi-

ness suggests the need for con-

tinual monitoring of service com-

panies.

Every experienced plant man-

ager has his or her methodology

for evaluating alternative repair

shopsprocedures that may dif-

fer depending on the GT compo-

nent, work to be performed, and

schedule. For someone with lim-

ited vendor auditing experience,

the guidance offered here for

evaluation of (1) experience and

reputation, (2) in-house and sub-

contractor technical capabilities,

and (3) HR and management sys-

tems, will help you get started.

The scorecards provided are par-

ticularly valuable and should be

customized to suit your specific

requirements.

Experience and

reputation

Generally, it is in your best inter-

est to select a repair facility with

experience both on your type of experience both on your type of

GT and on the specific compo-

nents requiring refurbishment.

Such experience helps the end

user because the service provider

has a better understanding of has a better understanding of

the condition of the components,

what the critical dimensions are,

which coating systems will

provide the level of protec-

tion desired, etc.

If a candidate facility

does not have direct expe-

rience on your machine,

perhaps it has done com-

parable work on models

similar in design, base

material, and coating

and cooling systems. The

facilitys reference list of facilitys reference list of

projects completed over

the last three to five years

pertinent to the work you

require should contain

adequate detail for follow-

up due diligence and deci-

sion-making.

Valuable insights on

the performance of repair

facilities can be gained

3-1. Special fixtures are designed to facilitate

repair and inspection of transition pieces

S

u

l

z

e

r

H

i

c

k

h

a

m

I

n

c

Selecting the appropriate vendor

to refurbish parts for your turbines

By Hans van Esch, TEServices (www.TEServices.us)

This is the second in a series of four articles defin-

ing the six critical steps to successful refurbishment

of industrial gas-turbine (GT) parts. The first two

steps, which were presented in the last issue of the

COMBINED CYCLE Journal (2Q/2005), covered

onsite assessment of component condition and

development of repair specifications (access at www.

psimedia.info/ccjarchives.htm). This article, Step psimedia.info/ccjarchives.htm). This article, Step

3, provides guidelines for selecting the appropriate

repair vendors to meet your plants specific needs.

The third article (4Q/2005) will cover Step 4, the

vendor verification process for incoming inspection; vendor verification process for incoming inspection;

the final article (1Q/2006), vendor verification of the final article (1Q/2006), vendor verification of

repairs, coatings, and inspections performed during repairs, coatings, and inspections performed during

the refurbishment process of your components (Step

5), and final inspection (Step 6).

OH-8 COMBINED CYCLE JOURNAL, Third Quarter 2005

SI X STEPS TO SUCCESSFUL GT REPAI R, Part 2

2006 OUTAGE HANDBOOK

by interviewing the can-

didates customerspast

and present. One of the

most important things to

learn is how the prospec-

tive facility resolves qual-

ity issues. All repair facili-

ties will run into problems

at some point, but how

quickly the company com-

municates and responds to

problems, and the methods

it uses to address them, is

of vital importance to you.

Your interviews will

reveal that most repair

facilities are willing to

develop repair methods

and coating applications

to suit specific needs. This

is positive; however, if

your components are the

first articles repaired by

a new method, more time

and resources must be put

against this effort than

required by a proven pro-

cedure. And dont forget

to consider the end-users

risks associated with any

new procedure.

As part of your assessment,

be sure to inquire about the fix-

tures available to facilitate the

inspection and repair of compo-

nents (Table 3-1). Fixtures can

pay dividends in the inspection

of complex components, such

as transition pieces (Fig 3-1),

while reducing shop time. Also,

the availability of fixtures offers

an indication of how much work

a particular shop does, or has

done, on specific components for

a given GT model.

Record-keeping is another

area to investigate. After repairs

are complete, you want documen-

tation on the condition of your

components (ID by serial num-

ber) as received and final,

in addition to certifications for

important process stepssuch as

heat treatments, stripping, coat-

ing, and shot-peening.

During the request-for-quota-

tion process the evaluation of

repair facilities can be confirmed.

Facilities with good experience

will come up with some intel-

ligent questions and offer some

options to reduce the costs or

prolong the lives of your compo-

nents.

Technology and

subcontracting

The assessment of GT compo-

nents conducted as part of Step

1 and the repair scope devel-

oped in Step 2 provide informa-

tion of value for determining the

optimum technologies for parts

refurbishment. At this stage,

keep in mind that it is not always

necessary to apply the same coat-

ing system provided by the OEM

(see sidebar for definition of acro-

nyms) on new parts. For exam-

ple, MCrAlY typically is applied

on advanced blades and buck-

ets with LPPS or VPS (Fig 3-2),

but for most applications HVOF-

applied MCrAlY is sufficient.

Information gathered from

the onsite visual inspection, and

from the as received NDT and

metallurgical inspection at the

repair facility, sometimes sug-

gests a customized repair and

coating solution that can reduce

the expected cost of refurbish-

ment and/or extend the service

life of components. Make sure

you dont miss an opportunity

for competitive advantage by

selecting a service provider that

will partner with you to advise

unselfishly on repairs and coat-

ing systems (Table 3-2). An inde-

pendent consultant could also be

helpful in this.

Refurbishment of GT compo-

nents for late-model machines

often requires sophisticated

repair technologies that are

expensive to install and sup-

port. Thus many shops are not

equipped to perform all repair

and coating steps in-house for

all GT models and they rely on

subcontractors for certain tasks.

To illustrate: Chemical stripping

of GT components poses environ-

mental and health concerns and

is often subcontracted to a spe-

cialty shop (Fig 3-3).

To have certain repair or coat-

ing steps performed by a special-

ized subcontractor can be advan-

tageous. However, your repair

facility is still responsible for

final product quality and must

monitor the subcontractor to

ensure conformance to specifica-

tions. And, since the subcontrac-

tor is an extension of the primary

company, it should be audited as

part of your capabilities assess-

ment.

Table 3-1. Experience and reputation assessment

Rating points

1 3 5

Field service experience Similar unit < 3 years > 3 years

Conducted overhaul Similar unit < 3 years > 3 years

Performed incoming < 2 years < 5 years > 5 years

inspection of part

Performed repair on part 1 year < 5 years > 5 years

Fixtures available for your In development Available Qualified

specific components

(inspection, repair, and coating)

Coated part 1 year < 5 years

Technician/supervisor with > 2 years > 4 years > 8 years

company (the person who

will direct your repairs)

Quality as seen by customers Not meeting Not meeting Meets specs and

specifications expectations expectations

Resolving quality issues Unwilling, must Willing, but Proactive,

be forced slow highest priority

Delivery time Within two Always

weeks of date on time

promised

Documentation of repair Critical Summarized Summarized

and coating inspection and and complete,

steps complete in digital format

OH-10 COMBINED CYCLE JOURNAL, Third Quarter 2005

SI X STEPS TO SUCCESSFUL GT REPAI R, Part 2

2006 OUTAGE HANDBOOK

Table 3-2. Technology and subcontractor experience

assessment

Rating points

1 3 5

Nondestructive testing Technologies Technologies Technologies

(see sidebar for < 3 years < 5 years > 5 years

alternative technologies)

Metallurgical laboratory Qualified vendor Internal Internal

(experience of > 10 years > 3 years > 10 years

metallurgical engineer)

Stripping (similar coating, Qualified vendor Internal Internal

base material, design) > 10 years > 5 years > 10 years

Heat treatment: Vacuum Qualified vendor Internal Internal

(Nadcap, ISO) (Nadcap, ISO)

Heat treatment: Controlled Internal Internal

atmosphere, other (Nedcap, ISO)

Weld repair: TIG, plasma > 1 year > 3 years > 5 years

Weld repair: Plasma or EB Qualified vendor Internal

> 5 years > 3 years

Weld method/application Performed Performed to Up-to-date per

qualification ASME Section 9 ASME Section 9

Braze repair > 2 years > 4 years > 8 years

Braze method/application Performed External Published

qualification qualification

Machining: Conventional, Conventional And CNC And EDM or

CNC, EDM, laser laser

Coating: Thermal spray Qualified vendor Internal APS, Internal robotic

> 5 years HVOF application

> 3 years > 5 years

Coating: Diffusion Qualified vendor Pack True CVD

> 5 years segmentation > 3 years

> 3 years

Acronyms

defined

APSAir plasma spraying

CNCComputer

numeric control

CVDChemical vapor

deposition

EDMElectrical dis-

charge machining

GTGas turbine

EBElectron beam

HVOFHigh-veloc-

ity oxygen fuel

ISOInternational Organiza-

tion for Standardization

LPPSLow-pressure

plasma spraying

MCrAlYNickel, cobalt,

iron, or a combina-

tion of these elements,

plus chromium, alu-

minum, and yttrium

NDTNondestruc-

tive testing

ETEddy current test

PTLiquid penetrant

test, also called LPT

MTMagnetic particle test

RTRadiographic test

UTUltrasonic test

VTVisual test

Nadcap (see note

below)

OEMOriginal equip-

ment manufacturer

TIGTungsten inert gas

(same as GMAW)

VPSVacuum plas-

ma spraying

Nadcap began as an acronym

for National Aerospace and

Defense Contractors Accredi-

tation Program. Today that pro-

gram is international in scope

and known simply as Nadcap.

The Performance Review Insti-

tute (http://www.pri-network.

org/Nadcap), Warrendale, Pa,

administers the program, which

provides unbiased, indepen-

dent manufacturing process

and product assessment s

and certification services for

the purpose of adding value,

reducing total cost, and facili-

tating relationships between

primes and suppliers.

3-2. MCrAlY coating applied under vacuum requires sophisticated equipment

W

o

o

d

G

r

o

u

p

Stronger. Besides building and servicing gas-turbine engines

for marine and electric generating stations, we now manufacture

and repair other OEM's parts. Our parts are more durable, and

very often, considerably less expensive.

At Pratt & Whitney, we pioneer, we build, we serve.

www. pw. ut c. com

OH-12 COMBINED CYCLE JOURNAL, Third Quarter 2005

SI X STEPS TO SUCCESSFUL GT REPAI R, Part 2

2006 OUTAGE HANDBOOK

Human resources

and management

systems

Over the last several years, compe-

tition in the GT services sector has

forced the closure or sale of mar-

ginal companies and driven out of

work many capable engineers and

repair technicians. Some of these

people have joined forces and start-

ed small specialty shops, contribut-

ing to the relatively large number of

repair facilitieswell over a dozen

in the Houston area alone.

Currently, the end-users per-

spective is that the increasing

number of engines in service,

and growing production of GT-

based megawatt-hours has filled

the most competitive and capable

repair shops at times when out-

ages traditionally are conducted.

Result: Existing staff is

challenged by the work-

load, thereby creating

demand for experienced

managers, engineers, and

technicians. Such market

dynamics result in rotat-

ing of human resources

internally and through-

out the industry.

What this means to

end usersespeci al -

ly with regard to new

repair facilitiesis that

organizational charts,

job descriptions, quality

manuals and systems,

procedures, and qualifi-

cations are not always in

place. When conducting

vendor assessments, be

mindful that training and

qualification of inspec-

tors, welders, blenders,

and other technicians is

the foundation for quality

work. The scorecard pre-

sented in Table 3-3 offers

a valuable reminder of

items to investigate.

Important to remem-

ber with respect to small

organizations is that an

experienced core staff

is capable of perform-

ing quality repairs and

coatings at a competitive

price on specific GT com-

ponents. However, if the

repair process increas-

es in complexityas it

does for advanced compo-

nentsor when the orga-

nization grows too fast,

quality issues can arise.

When turn-around

time is important, a

small company may not

have the resources to

repair and coat your com-

ponents in time. On the

other hand, larger com-

panies may not always

give the attention that

you and your compo-

nents deserve. Therefore,

the best result some-

times can be achieved by

dividing the component

repair and coating work

to small, specialist facili-

ties. CCJ OH

Table 3-3. HR and management system assessment

Rating points

1 3 5

Years since last organizational > 2 > 4 > 8

change (location, ownership,

and/or management)

Organization chart Available Available and

up to date

Job descriptions Available Available and

up to date

Quality manual Available Available and

up to date

Quality system audit to ISO, Internal audit External audit External audit

Nadcap, etc > 5 years

Procedures (welding, coating, Available Available and In use

inspection) up to date

Workscopes Available Available and In use and

up to date signed off

Materials/parts tracking Order requires Verification Traceability

(replacement parts, filler, and certification

coating materials)

Subcontractor work (heat treat- Vendor audited First-article Verification of

ments, coating, shot peening) verification work performed

Engineering department (mech- One person Three people Five people

anical, metallurgical, process) > 10 years > 10 years (avg) > 10 years (avg)

Inspection department One Level II Three Level II More than three

(VT, PT, UT, MT, RT, ET) > 3 years per > 5 years per Level II/III

discipline discipline > 5 years per

discipline

TIG welding More than More than Five welders

(experience/qualifications for two welders five welders > 5 years

each material) > 3 years > 5 years qualified

experience (avg) experience (avg)

Blenders and experience Two blenders More than

> 3 years two blenders

> 5 years

Coating operators and Two operators More than Two robotics

experience > 3 years two operators operators

> 5 years > 5 years

3-3. Chemical stripping setup is audited at

subcontractors shop

G

o

o

d

r

i

c

h

Call today for all your Air Filtration requirements! 800-976-9382

www.camfilfarr-gt.com email: info.gt@camfilfarr.com

Patent Pending Technology

>

Fits Any Cartridge Filter Housing available as replacement upgrade cartridges

>

Saves Money & Time less maintenance and longer filter life

>

Highest Cartridge Filter Efficiency Available fewer engine cleanings required

>

Lower Pressure Drop (P) open pleat spacing improves airflow

>

Enhanced Pulse Cleaning trapped particles are ejected from deep within the pleats

For Gas Turbine filtration,

its an

Will your filters pay you a dividend?

HemiPleat Pulse-Jet filters can improve your GT performance

2006 OUTAGE HANDBOOK

SI X STEPS TO SUCCESSFUL GT REPAI R, Part 2

Call today for all your Air Filtration requirements! 800-976-9382

www.camfilfarr-gt.com email: info.gt@camfilfarr.com

Patent Pending Technology

>

Fits Any Cartridge Filter Housing available as replacement upgrade cartridges

>

Saves Money & Time less maintenance and longer filter life

>

Highest Cartridge Filter Efficiency Available fewer engine cleanings required

>

Lower Pressure Drop (P) open pleat spacing improves airflow

>

Enhanced Pulse Cleaning trapped particles are ejected from deep within the pleats

For Gas Turbine filtration,

its an

Will your filters pay you a dividend?

HemiPleat Pulse-Jet filters can improve your GT performance

Вам также может понравиться

- 000000000001010231Документ50 страниц000000000001010231mlsimhanОценок пока нет

- Reliability of Safety Systems: Markov ApproachДокумент26 страницReliability of Safety Systems: Markov ApproachraharjoitbОценок пока нет

- EPRI Start Up, Lay Up & Shut Down Guidelines For ChemistДокумент256 страницEPRI Start Up, Lay Up & Shut Down Guidelines For Chemistraharjoitb100% (7)

- EPRI Cycle Chemistry Upsets During OperationДокумент42 страницыEPRI Cycle Chemistry Upsets During OperationraharjoitbОценок пока нет

- Introduction To ReliabilityДокумент22 страницыIntroduction To ReliabilityraharjoitbОценок пока нет

- Advances in Thermal Spray Coatings For Gas TurbineДокумент13 страницAdvances in Thermal Spray Coatings For Gas TurbineraharjoitbОценок пока нет

- A Non-Destructive Method To Assess A Degree of OverheatingДокумент8 страницA Non-Destructive Method To Assess A Degree of OverheatingraharjoitbОценок пока нет

- EPRI Guidelines For Upgrading ESP Vol 1Документ194 страницыEPRI Guidelines For Upgrading ESP Vol 1raharjoitbОценок пока нет

- Use of Biomass EnergyДокумент36 страницUse of Biomass EnergyraharjoitbОценок пока нет

- 1 Advancements in Gas TurbineДокумент5 страниц1 Advancements in Gas TurbineraharjoitbОценок пока нет

- Superalloys MaterialДокумент10 страницSuperalloys MaterialraharjoitbОценок пока нет

- L-1 Introduction To GambitДокумент26 страницL-1 Introduction To GambitraharjoitbОценок пока нет

- Alstom Power Industry Seminar - The Next Generation KA24GT24-USformat - v2Документ26 страницAlstom Power Industry Seminar - The Next Generation KA24GT24-USformat - v2raharjoitbОценок пока нет

- Six Steps To Successful GT Repair Part 1Документ5 страницSix Steps To Successful GT Repair Part 1raharjoitbОценок пока нет

- Challenges and opportunities for high-temperature materials developmentДокумент7 страницChallenges and opportunities for high-temperature materials developmentraharjoitbОценок пока нет

- Reliabilty Analysis ModelДокумент19 страницReliabilty Analysis ModelraharjoitbОценок пока нет

- Life Cycle ENgineeringДокумент2 страницыLife Cycle ENgineeringraharjoitbОценок пока нет

- Generalized Bubbling-Slugging Fluidized Bed Reactor ModelДокумент12 страницGeneralized Bubbling-Slugging Fluidized Bed Reactor Modelapi-3799861100% (1)

- Effect of Silica On Power Plant PerformanceДокумент9 страницEffect of Silica On Power Plant PerformanceraharjoitbОценок пока нет

- Analysis Bituminous CoalДокумент52 страницыAnalysis Bituminous CoalraharjoitbОценок пока нет

- Chapt2-1 Failure Mode IntroДокумент31 страницаChapt2-1 Failure Mode IntromasgrahaОценок пока нет

- Solid FluidizationДокумент11 страницSolid Fluidizationapi-3799861100% (1)

- Baseline Technical and Economic Assessment of A Commercial SДокумент79 страницBaseline Technical and Economic Assessment of A Commercial SraharjoitbОценок пока нет

- EvitaLegowo Biomass IndonesiaДокумент39 страницEvitaLegowo Biomass IndonesiaraharjoitbОценок пока нет

- Best Practice For Thermal Power PlantsДокумент186 страницBest Practice For Thermal Power Plantsnao100% (27)

- Integration DSM RE EE Vol 1Документ77 страницIntegration DSM RE EE Vol 1raharjoitbОценок пока нет

- GT2005-68014 Axial Compressor MaintenanceДокумент8 страницGT2005-68014 Axial Compressor MaintenanceraharjoitbОценок пока нет

- Energy Management Self AssessmentДокумент10 страницEnergy Management Self AssessmentHans De KeulenaerОценок пока нет

- Combustion and Extinction in The Stagnation Point Boundary Layer of A Condensed Fuel 1978 Combustion and FlameДокумент14 страницCombustion and Extinction in The Stagnation Point Boundary Layer of A Condensed Fuel 1978 Combustion and FlameraharjoitbОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Technical Proposal Template SampleДокумент12 страницTechnical Proposal Template SampleWrite Bagga100% (1)

- Manual Uganda CatfishДокумент65 страницManual Uganda CatfishDare Kehinde100% (2)

- ServiceManuals LG Washing WD1015FB WD-1015FB Service ManualДокумент35 страницServiceManuals LG Washing WD1015FB WD-1015FB Service ManualMicu Adrian DanutОценок пока нет

- RIBA Plan of WorkДокумент2 страницыRIBA Plan of WorkSyed Moinullah Hussaini100% (2)

- Fund Chapter 6Документ18 страницFund Chapter 6aryabhatmathsОценок пока нет

- Samsung SF 750 and 755P Service ManualДокумент0 страницSamsung SF 750 and 755P Service ManualwcualumniОценок пока нет

- Your Energy Bill: Snapshot of What You OweДокумент8 страницYour Energy Bill: Snapshot of What You Owe衡治洲Оценок пока нет

- 1-M Vib Meas Hwp-A MotorДокумент3 страницы1-M Vib Meas Hwp-A MotorNovindra PutraОценок пока нет

- 2 Giuliano Forghieri Customisation vs. Standardisation Paradox in The Hospitality IndustryДокумент11 страниц2 Giuliano Forghieri Customisation vs. Standardisation Paradox in The Hospitality IndustryOnur YamanОценок пока нет

- Bearing Detail PDFДокумент1 152 страницыBearing Detail PDFJayesh MachhiОценок пока нет

- Certified CMMI Associate Exam ResultsДокумент8 страницCertified CMMI Associate Exam ResultsDaniel Softjoy MontjoyОценок пока нет

- Ose 5-91 2066-9001-200-Im PDFДокумент210 страницOse 5-91 2066-9001-200-Im PDFironite100% (1)

- PWHTДокумент118 страницPWHTSumedh Singh100% (19)

- Roopa Rani - Final PDFДокумент52 страницыRoopa Rani - Final PDFSrinivas SeenuОценок пока нет

- VSB6 SectionH Chassis PDFДокумент73 страницыVSB6 SectionH Chassis PDFMina RemonОценок пока нет

- Total Project Cost:: Professional Cost and Construction CostДокумент21 страницаTotal Project Cost:: Professional Cost and Construction CostMIKE ARTHUR DAVIDОценок пока нет

- Scrum PDFДокумент222 страницыScrum PDFvive_vt_vivasОценок пока нет

- EpicorAFR InstallGuide 905702EДокумент23 страницыEpicorAFR InstallGuide 905702EVictor MotoliniaОценок пока нет

- Resume SeetaRamДокумент2 страницыResume SeetaRamdasarinaveenОценок пока нет

- Cost and Pricing MGT For Competitive AdvantageДокумент45 страницCost and Pricing MGT For Competitive Advantageilona gabrielОценок пока нет

- Into The Abyss by Carol Shaben (Excerpt)Документ35 страницInto The Abyss by Carol Shaben (Excerpt)Random House of Canada100% (1)

- Volvo EeeeДокумент6 страницVolvo Eeeenarendra singh0% (1)

- Vertex Payroll Tax Q Series Integration With Oracle Fusion HCMДокумент2 страницыVertex Payroll Tax Q Series Integration With Oracle Fusion HCMsam22nowОценок пока нет

- API DocumentationДокумент115 страницAPI DocumentationEric ScrivnerОценок пока нет

- Hybris Software Developer - AgendaДокумент5 страницHybris Software Developer - Agendavidhyaa1011Оценок пока нет

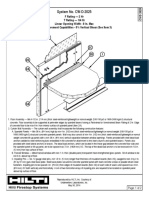

- System No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)Документ2 страницыSystem No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)aОценок пока нет

- Irpa SapДокумент13 страницIrpa SapDINESHОценок пока нет

- JOB SAFETY ANALYSIS (JSA) AND RISK ASSESSMENT FORMДокумент6 страницJOB SAFETY ANALYSIS (JSA) AND RISK ASSESSMENT FORMBeriandi HasanОценок пока нет

- Standard Hardwood Pallet SpecsДокумент2 страницыStandard Hardwood Pallet SpecsmnnfzОценок пока нет

- SBC1205 Instruction Manual A5 5Документ4 страницыSBC1205 Instruction Manual A5 5Phillip CragerОценок пока нет