Академический Документы

Профессиональный Документы

Культура Документы

Documents 5401 G 5

Загружено:

ductoan32Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Documents 5401 G 5

Загружено:

ductoan32Авторское право:

Доступные форматы

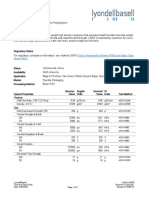

ELITE5401G

The Dow Chemical Company-Enhanced Polyethylene Resin Thursday, June 12, 2014

www.ides.com

UL and the UL logo are trademarks of UL LLC 2014. All Rights Reserved.

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial efforts to assure the accuracy

of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are validated with the

material supplier.

Page: 1 of 2

General Information

Product Description

ELITE 5401G Enhanced Polyethylene Resin is a copolymer produced via INSITE Technology from Dow. It offers a unique combination of low

seal initiation, moderate stiffness and low blocking for excellent performance on automated packaging equipment.

For food and specialty packaging films

Superior impact resistance and tear properties

Complies with:

U.S. FDA FCN 424

Canadian HPFB No Objection

EU, No 10/2011

Consult the regulations for complete details.

General

Material Status Commercial: Active

Availability Asia Pacific Latin America North America

Additive Antiblock (2500 ppm) Slip (1000 ppm)

Agency Ratings EU No 10/2011 FDA FCN 424 HPFB (Canada) No Objection

Forms Pellets

Processing Method Blown Film

ASTM & ISO Properties

1

Physical Nominal Value Unit Test Method

Specific Gravity 0.920 ASTM D792

Melt Mass-Flow Rate (190C/2.16 kg) 1.0 g/10 min ASTM D1238

Films Nominal Value Unit Test Method

Film Thickness - Tested 1.0 mil

Film Puncture Energy 15.0 inlb Internal Method

Film Puncture Force 8.00 lbf Internal Method

Film Puncture Resistance 110 ftlb/in Internal Method

Film Toughness - MD 850 ftlb/in ASTM D882

Film Toughness - TD 800 ftlb/in ASTM D882

Secant Modulus ASTM D882

1% Secant, MD 26000 psi

2% Secant, MD 23000 psi

Secant Modulus ASTM D882

1% Secant, TD 29000 psi

2% Secant, TD 24000 psi

Tensile Strength - MD (Yield) 1700 psi ASTM D882

Tensile Strength - TD (Yield) 1600 psi ASTM D882

Tensile Strength - MD (Break) 4900 psi ASTM D882

Tensile Strength - TD (Break) 4000 psi ASTM D882

Tensile Elongation - MD (Break) 400 % ASTM D882

Tensile Elongation - TD (Break) 450 % ASTM D882

Dart Drop Impact 450 g ASTM D1709A

Elmendorf Tear Strength - MD 250 g ASTM D1922

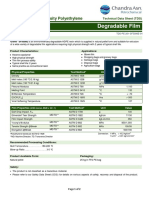

ELITE5401G

The Dow Chemical Company-Enhanced Polyethylene Resin

Thursday, June 12, 2014

www.ides.com

UL and the UL logo are trademarks of UL LLC 2014. All Rights Reserved.

The information presented on this datasheet was acquired by UL Prospector from the producer of the material. UL Prospector makes substantial efforts to assure the accuracy

of this data. However, UL Prospector assumes no responsibility for the data values and strongly encourages that upon final material selection, data points are validated with the

material supplier.

Page: 2 of 2

Films Nominal Value Unit Test Method

Elmendorf Tear Strength - TD 550 g ASTM D1922

Thermal Nominal Value Unit Test Method

Vicat Softening Temperature 212 F ASTM D1525

Melting Temperature (DSC) 253 F Internal Method

Optical Nominal Value Unit Test Method

Gloss (45) 33 ASTM D2457

Haze 22 % ASTM D1003

Processing Information

Extrusion Notes

Fabrication Conditions For Blown Film:

Screw Size: 3.5 in.

Screw Type: DSB II

Die Gap: 70 mil (1.8 mm)

Melt Temperature: 410F

Output: 12 lb/hr/in. of die circumference

Die Diameter: 8 in.

Blow-Up Ratio: 2.5:1

Screw Speed: 40 rpm

Frost Line Height: 47 in.

Notes

1

Typical properties: these are not to be construed as specifications.

Вам также может понравиться

- Engineering MaterialДокумент169 страницEngineering MaterialfafaОценок пока нет

- AS 2269-2004 Plywood StructuralДокумент36 страницAS 2269-2004 Plywood StructuralBrad La Porta100% (1)

- Unbrako US Product Guide PDFДокумент144 страницыUnbrako US Product Guide PDFManju KОценок пока нет

- Steel Frame Design Manual: CSA-S16-14Документ118 страницSteel Frame Design Manual: CSA-S16-14dongheep811Оценок пока нет

- Design of Rigid Pavement PDFДокумент24 страницыDesign of Rigid Pavement PDFSayantan Chakraborty75% (4)

- PreviewДокумент101 страницаPreviewGood Ventura Rojas MurciaОценок пока нет

- L1 Piles Subject To Lateral Soil MovementДокумент32 страницыL1 Piles Subject To Lateral Soil Movementedward the iiiОценок пока нет

- 7 9layerblownfilmlinesДокумент6 страниц7 9layerblownfilmlinesductoan32Оценок пока нет

- Summary of Surface Blasting With Comparison of Two Mitigation Techniques - Presplitting and Smooth BlastingДокумент37 страницSummary of Surface Blasting With Comparison of Two Mitigation Techniques - Presplitting and Smooth BlastingBryan Franklin Vilca ChavezОценок пока нет

- D 1761 - 88 R00 - Rde3njeДокумент13 страницD 1761 - 88 R00 - Rde3njeAnonymous 6SHxUn1xd10% (1)

- Direct Shear Test S 30 1Документ10 страницDirect Shear Test S 30 1jems patel0% (1)

- 06 Calcs 10 R1 RepliesДокумент110 страниц06 Calcs 10 R1 RepliesAnirudh SabooОценок пока нет

- Datasheet T50-500 HDPE Stopcock HandleДокумент0 страницDatasheet T50-500 HDPE Stopcock HandleErick Venegas HerreraОценок пока нет

- Product Sheet Petlin LD N125y - 0Документ2 страницыProduct Sheet Petlin LD N125y - 0Manufaktur Sinar JoyoboyoОценок пока нет

- TDS Petlin LD C150y (E120900) PDFДокумент1 страницаTDS Petlin LD C150y (E120900) PDFTukangSantetОценок пока нет

- Product Sheet Petlin LD C150y - 0Документ2 страницыProduct Sheet Petlin LD C150y - 0121221042Оценок пока нет

- TRVX50X9Документ2 страницыTRVX50X9nimonhОценок пока нет

- POLYMER C150Y - Jan15 - New - Rev1Документ2 страницыPOLYMER C150Y - Jan15 - New - Rev1W I Prayogo100% (1)

- P54 LLLДокумент1 страницаP54 LLLMd MinhajОценок пока нет

- Document 1Документ2 страницыDocument 1renebbОценок пока нет

- GAIL (India) LTD.: High Density Polyethylene For OFC DuctsДокумент1 страницаGAIL (India) LTD.: High Density Polyethylene For OFC DuctsMd MinhajОценок пока нет

- E52A003 E52A003N: GAIL (India) LTDДокумент1 страницаE52A003 E52A003N: GAIL (India) LTDMd MinhajОценок пока нет

- Exxonmobil™ Hdpe Hta 108: High Density Polyethylene ResinДокумент2 страницыExxonmobil™ Hdpe Hta 108: High Density Polyethylene ResinCristian RodriguezОценок пока нет

- 3812 ExceedДокумент2 страницы3812 ExceedJimmys GothiqueОценок пока нет

- Petrothene: Low Density Polyethylene Film Extrusion GradeДокумент1 страницаPetrothene: Low Density Polyethylene Film Extrusion GradeGabriela Lopez MunozОценок пока нет

- TDS Pe 200 SF5007Документ2 страницыTDS Pe 200 SF5007Oktaviandri SaputraОценок пока нет

- Linear Low Density Polyethylene: Provisional Technical DatasheetДокумент2 страницыLinear Low Density Polyethylene: Provisional Technical DatasheetMohit MohataОценок пока нет

- Lldpe Hanwa 3120Документ1 страницаLldpe Hanwa 3120puipuiesperaОценок пока нет

- Braskem Braskem PP PCD 0140BR Polypropylene Impact CopolymerДокумент2 страницыBraskem Braskem PP PCD 0140BR Polypropylene Impact CopolymerBFCОценок пока нет

- TDS SteelMaster 1200WF GB English ProtectiveДокумент5 страницTDS SteelMaster 1200WF GB English Protective폴로 쥰 차Оценок пока нет

- 4011 TDДокумент2 страницы4011 TDFernando HalaburaОценок пока нет

- Polyethylene: For Blow Moulding & Blown Film GradeДокумент1 страницаPolyethylene: For Blow Moulding & Blown Film GradeRikinОценок пока нет

- ExxonMobil LLDPE LL 1002AY BlownДокумент2 страницыExxonMobil LLDPE LL 1002AY BlownOscar Tan IIIОценок пока нет

- Lldpe Ga564189Документ3 страницыLldpe Ga564189xy2zjgОценок пока нет

- F55HM0003 F55HM0003N: GAIL (India) LTDДокумент1 страницаF55HM0003 F55HM0003N: GAIL (India) LTDJaydeep JainОценок пока нет

- FK1828Документ3 страницыFK1828dignityymartОценок пока нет

- Elite NG 5401BДокумент3 страницыElite NG 5401BAbdo WalidОценок пока нет

- TDS - TR144 - Astm (Eng)Документ2 страницыTDS - TR144 - Astm (Eng)Darwin Lenin Iza PradoОценок пока нет

- ELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinДокумент2 страницыELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinLeductoan LeОценок пока нет

- Adsyl 7623 XCP: Advanced Polyolefin Product DescriptionДокумент2 страницыAdsyl 7623 XCP: Advanced Polyolefin Product DescriptionLâm Quốc CườngОценок пока нет

- Steel Master 1200 WF PDSДокумент5 страницSteel Master 1200 WF PDSshameelОценок пока нет

- Lldpe FN810 (Octeno Sin Slip)Документ2 страницыLldpe FN810 (Octeno Sin Slip)Hữu LộcОценок пока нет

- TDS PP 305 HF10TQ 02Документ2 страницыTDS PP 305 HF10TQ 02Lungkoneng HRDОценок пока нет

- RCE111NPДокумент3 страницыRCE111NPdignityymartОценок пока нет

- AkzoNobel - QN102QF - Interpon ACE 2000Документ3 страницыAkzoNobel - QN102QF - Interpon ACE 2000Eslam FaroukОценок пока нет

- Lyondell Basell Moplen EP300RДокумент3 страницыLyondell Basell Moplen EP300RHung TranОценок пока нет

- Exxonmobil™ Lldpe Ll1001Xbu: Linear Low Density Polyethylene ResinДокумент2 страницыExxonmobil™ Lldpe Ll1001Xbu: Linear Low Density Polyethylene ResinchinchotarngОценок пока нет

- Tds of Ultra Lite 2009sf UsaДокумент2 страницыTds of Ultra Lite 2009sf UsaJuan Sebastián Fernández RamírezОценок пока нет

- Amplify Io 3701Документ2 страницыAmplify Io 3701Julio GarcíaОценок пока нет

- Low Density Polyethylene: DescriptionДокумент2 страницыLow Density Polyethylene: DescriptionlyesОценок пока нет

- Exceed 3518Документ2 страницыExceed 3518Amin PanОценок пока нет

- Plumbshield: For Use With Potable & Non-Potable Water ApplicationsДокумент5 страницPlumbshield: For Use With Potable & Non-Potable Water ApplicationsMychloesОценок пока нет

- Fusabond Dupont Pa Mo525dДокумент2 страницыFusabond Dupont Pa Mo525dedsonshmОценок пока нет

- Jotaprime 500: Technical Data SheetДокумент1 страницаJotaprime 500: Technical Data SheetTamerTamerОценок пока нет

- Belzona 1111ps EnglДокумент2 страницыBelzona 1111ps EnglNikolay GuerreroОценок пока нет

- TDS Pe 002 Uf1810t 03Документ2 страницыTDS Pe 002 Uf1810t 03qc jrpОценок пока нет

- BELZONA 1111 Product Specification SheetДокумент2 страницыBELZONA 1111 Product Specification Sheetsibi_s_rajОценок пока нет

- TDS Pe 008 Up4806hДокумент2 страницыTDS Pe 008 Up4806hariefОценок пока нет

- TDS Pe 003 Uf1810s1 03Документ2 страницыTDS Pe 003 Uf1810s1 03qc jrpОценок пока нет

- F2001AДокумент2 страницыF2001APratik GaikwadОценок пока нет

- C C14 LD2420F PlusДокумент3 страницыC C14 LD2420F PlusJaime222Оценок пока нет

- Dura Profile Technical SpecificationДокумент4 страницыDura Profile Technical Specificationec04017Оценок пока нет

- Technical Data SheetДокумент2 страницыTechnical Data SheetingindjorimaОценок пока нет

- Technical Data Sheet - IsOДокумент2 страницыTechnical Data Sheet - IsOAsrilОценок пока нет

- TDS Pe 201 Sf5008eДокумент2 страницыTDS Pe 201 Sf5008eOktaviandri SaputraОценок пока нет

- HFI 5110-Arya SasolДокумент2 страницыHFI 5110-Arya Sasolchirag.sanchetiОценок пока нет

- Cynpol LD4001Документ1 страницаCynpol LD4001Gabs GabrielaОценок пока нет

- 105 Ta D411-350Документ3 страницы105 Ta D411-350isaacalvareztejanoОценок пока нет

- Surlyn® - 8660Документ3 страницыSurlyn® - 8660Alan FerreiraОценок пока нет

- Optitemp HT 2 EP: DescriptionДокумент2 страницыOptitemp HT 2 EP: DescriptionWirawan Adi Setya RОценок пока нет

- Product Technical InformationДокумент3 страницыProduct Technical Informationtedak2Оценок пока нет

- List of Raw Material Suppliers: Product Function Description SupplierДокумент5 страницList of Raw Material Suppliers: Product Function Description Supplierductoan32Оценок пока нет

- Next Generation Collation Shrink Film Solutions From Dow: ® Trademark of The Dow Chemical CompanyДокумент4 страницыNext Generation Collation Shrink Film Solutions From Dow: ® Trademark of The Dow Chemical Companyductoan32Оценок пока нет

- A New Route For Evaluating Short Chain Branching Distribution of High Density Polyethylene by Measuring Crystallizability of Molar Mass FractionsДокумент6 страницA New Route For Evaluating Short Chain Branching Distribution of High Density Polyethylene by Measuring Crystallizability of Molar Mass Fractionsductoan32Оценок пока нет

- Special Characteristics:: Innoplus Ll7410DДокумент1 страницаSpecial Characteristics:: Innoplus Ll7410Dductoan32Оценок пока нет

- 5 9layerblownfilmlinesДокумент2 страницы5 9layerblownfilmlinesductoan32Оценок пока нет

- 05 4roisumДокумент13 страниц05 4roisumductoan32Оценок пока нет

- A4 Depliant Gradoadroit EngДокумент3 страницыA4 Depliant Gradoadroit Engductoan32Оценок пока нет

- Reinforced Concrete D-Load Culvert, Storm Drain, and Sewer PipeДокумент4 страницыReinforced Concrete D-Load Culvert, Storm Drain, and Sewer PipeFRANZ RICHARD SARDINAS MALLCOОценок пока нет

- Fem Analysis of Wooden Joints and Wooden Structure of The Electric Car's FrameДокумент16 страницFem Analysis of Wooden Joints and Wooden Structure of The Electric Car's FrameGlobal Research and Development ServicesОценок пока нет

- SPE 102211 Impact-Fatigue Correlation: Optimization On The Selection Criteria For Sucker-Rod MaterialsДокумент7 страницSPE 102211 Impact-Fatigue Correlation: Optimization On The Selection Criteria For Sucker-Rod MaterialsRicardo Pulido RamìrezОценок пока нет

- Installation Instructions RISE CableДокумент14 страницInstallation Instructions RISE CableABDUL GHAFOORОценок пока нет

- Sun JWB Asec98Документ8 страницSun JWB Asec98Angela CollinsОценок пока нет

- 4 Lab Izot TestДокумент11 страниц4 Lab Izot TestMax LuxОценок пока нет

- Preiss Core Standards in The Pressure Equipment Area 4668Документ42 страницыPreiss Core Standards in The Pressure Equipment Area 4668Jerome MellardОценок пока нет

- On The Physical and Chemical Stability of Shales PDFДокумент23 страницыOn The Physical and Chemical Stability of Shales PDFGisela RealОценок пока нет

- Axial Deformation: Strength of MaterialsДокумент10 страницAxial Deformation: Strength of MaterialsDon MatiasОценок пока нет

- Various Analyses of An Elbow Bracket: Solved With Comsol Multiphysics 3.5AДокумент3 страницыVarious Analyses of An Elbow Bracket: Solved With Comsol Multiphysics 3.5Atomica06031969Оценок пока нет

- Multiaxial Fatigue Life Prediction On S355 StructuДокумент12 страницMultiaxial Fatigue Life Prediction On S355 Structubaja2011Оценок пока нет

- Compressive Strength OF Cylindrical Concrete Specimens Aashto T 22Документ2 страницыCompressive Strength OF Cylindrical Concrete Specimens Aashto T 22anbertjonathanОценок пока нет

- Fatigue Life AnalysisДокумент42 страницыFatigue Life AnalysispoojaОценок пока нет

- Rag H Vendra Paper VJ ItДокумент16 страницRag H Vendra Paper VJ ItJollibee McdoОценок пока нет

- Machine Design - LESSON 3. DESIGN FOR STATIC LOADINGДокумент6 страницMachine Design - LESSON 3. DESIGN FOR STATIC LOADING9965399367Оценок пока нет

- MetalWork - Baileigh 2016Документ126 страницMetalWork - Baileigh 2016Peter DavidsonОценок пока нет

- Pangmalakasang Elements Sa MD Part3Документ100 страницPangmalakasang Elements Sa MD Part3Kezia Canonigo SalaОценок пока нет

- Ceramic BearingДокумент42 страницыCeramic BearingSHROUQ GAMALОценок пока нет

- The Effect of Pressuremeter Geometry On The Results of Tests in ClayДокумент11 страницThe Effect of Pressuremeter Geometry On The Results of Tests in Claycepi herdiyanОценок пока нет