Академический Документы

Профессиональный Документы

Культура Документы

DG Packaged Systems Steam Boiler

Загружено:

adrianahoukiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DG Packaged Systems Steam Boiler

Загружено:

adrianahoukiАвторское право:

Доступные форматы

Packaged Systems

D-36

Steam Boiler Selection Guidelines

CES & CSSB

CMB

CHS

CHPES

kW 3 6 15 100 150 180 1000 1500 1620 2000

Lbs/Hr

1

9 18 45 301 452 542 3010 4515 4883

F Psig

406 250

388 200

366 150

338 100

298 50

212 0

CAS

Steam Boilers

Overview

Steam Pressures to 235 psig

Hot Water Temp. to 240F

Steam Capacities to 4,890

Lbs/Hr and 235 psig

3 - 1,620 kW (10 - 5,527 Mbh)

120 - 600 Volt, 1 & 3 Phase

Applications

Chromalox Packaged Electric Steam and

Hot Water Boilers are safe and versatile heat

sources that produce low or high pressure

steam or hot water for commercial and

industrial processes and for comfort heating

applications. Chromalox electric boilers can be

used anywhere steam is required and electric

power is available. They are packaged units

that operate from existing distribution volt-

ages, making installation simple.

Electric boiler applications encompass all

types of commercial and industrial enterprises

such as hospitals, breweries, surgical centers,

bakeries, utilities, etc. Chromalox electric

boilers are used for food processing, hu-

midication, sterilization, process drying and

particularly in the manufacture of chemicals,

paints, paper, textiles, petroleum products,

pharmaceuticals and plastics. Some specic

applications include:

Supplying steam for storage tanks and

jacketed vessels to process waxes, parafn,

glues, resins, varnishes, dyestuffs, molasses

and vegetable oils.

Supplying steam for reaction and distillation

vessels, retorts, autoclaves and sterilizers.

Supplying steam for pipe tracing, to keep

viscous materials owing in asphalt plants,

in fuel oil lines, jacketed pumps, strainers

and valves and provide antifreeze protection.

Supplying steam to heat rolls for paper coat-

ing, calendering, laminating, corrugating and

embossing.

Supplying steam heat for platens, dies

and molds used for laminating wood and

plastics, molding and forming of elastomers

and plastic materials, plastic extrusions and

curing of epoxies and Fiberglas

materials.

Supplying steam for comfort heating and

humidication.

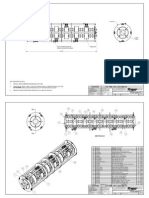

Boiler Selection

Chromalox steam boilers are available in the

following ranges to accommodate any process

or application: 3 to 1620 kW, 9 to 4883

pounds of dry saturated steam per hour,

0 to 235 psig.

Boiler selection is usually based on the operat-

ing pressure (psig) and steaming capacity

(Lbs/Hr). When the pressure or temperature

and kilowatt rating or Lbs./Hr. of steam re-

quirements are known, the recommended boil-

er can be determined from the following Boiler

Selection Chart. If these operating parameters

are not known, contact your Local Chromalox

Sales ofce for assistance in calculating the

steam requirements and for recommendations

on the proper size steam boiler.

Notes

1. Mbh is ASME & ANSI standard for thousand British thermal units per hour.

Packaged Systems

D-37

B

O

I

L

E

R

S

Steam Boilers

Selection Guidelines

With the pressure and capacity known, con-

tinue the selection process by consulting the

detailed product pages for the models listed in

the accompanying table.

Advantages

Chromalox Packaged Electric Boilers offer the

advantage of electricity as the heat source to

provide low or high pressure steam or hot wa-

ter. Building and installation costs are reduced

substantially over fuel red boilers since fuel

tanks, chimneys, ues, vents and complex

piping required for fossil fuel red boilers are

eliminated.

Packaged boilers comply with all the require-

ments of relevant UL and CSA Standards and

the ASME Boiler and Pressure Vessel Code.

Boilers are completely assembled and tested

under operating conditions to rigid quality

standards prior to release for shipment. Chro-

malox electric boilers are ready to install and

need only a water feed source and an electric

power hook-up to produce fast, economical

high-quality steam. Energy conversion ef-

ciencies approaching 100% are possible.

Cleanliness No fumes or products of

combustion. Boilers may be installed in

alcoves, under counters or in other restricted

spaces.

Simple, Safe Operation Most electric

boilers can be operated by custodial personnel

with a minimum of training.

Fast Start Up and Recovery Boilers can

be turned on and be up to pressure within

minutes. Long warm up times or complicated

start up procedures are unnecessary.

Minimal Maintenance Electric boilers

only require a periodic or daily blow down

to maintain their efciency. (An optional auto-

matic blow down system can be purchased to

ensure continuous reliability of

planned maintenance.)

Reduced Operating Costs Electric boilers

can provide steam on demand using auto-

matically controlled electric power. Operating

costs can be controlled by reducing or elimi-

nating idling or standby operation when

the boiler is not needed.

Steam Boilers Selection Guidelines

Maximum

Pressure

(psig)

Maximum

Temp.

(F) kW Description Model Page

90 331 3 -15 Compact CMB D-39

90 331 16 - 20 Special CAS D-42

90 331 6 - 180 Vertical CES-B D-40

90 331 6 - 180 Stainless Steel CSSB-A D-43

135 358 150 - 1,620 High Capacity CHS D-45

235 401 6 - 180 Medium Pressure CHPES-A D-46

Optional Equipment D-49

Custom Engineering & Manufacturing D-52

Electric Hot Water & Steam Boilers General Specications

Model Description

Operating

Pressure (psig)

Temp.

(F) kW Mbh

2

Vessel Pressure

Rating (psig)

Connection

Type

CMB Compact Steam Boiler 0 - 90 212 - 331 3 - 15 10 - 51 100 NPT

CES-B Vertical Steam Boiler 0 - 90 212 - 331 6 - 180 21 - 614 100 NPT

CAS Special Steam Boiler 0 - 90 212 - 331 16 - 20 55 - 68 100 NPT

CSSB-A Stainless Steel Steam Boiler 0 - 90 212 - 331 6 - 180 21-614 100 NPT

CHPES-A Medium Pressure Vertical Steam Boiler 0 - 235 212 - 401 6 - 180 21-614 250 NPT

CHS High Capacity Horizontal Steam Boiler 0 - 135 212 - 358 150 - 1,620 512-5,527 150 NPT and Flanged

GCH

1

Steam Superheater 0 - 150 212 - 800 1 - 350 3-1,194 150 NPT or Flanged

Notes

1. See Circulation Heater section.

2. Mbh is ASME & ANSI standard for thousand British thermal units per hour.

Packaged Systems

D-38

Steam Boilers

Features

Typical Closed-Loop System

Features

Chromalox Electric Steam and Hot Water Boil-

ers are efcient energy management systems

with specially designed heater bundles which

provide maximum element to water contact

and uniform circulation. Low or high pres-

sure steam is generated in pressure vessels

designed to minimize carry over of moisture

and impurities into the steam distribution sys-

tem. Chromalox packaged boilers are compact

in size with a small foot print and are ideal for

point of use applications in areas with limited

space. They are available in many sizes from

stock.

Heating Methods

Most steam heating applications can be

grouped into two categories, open loop and

closed loop. In an open-loop system, the

waste steam and condensate are not recov-

ered and are exhausted to the drain. These

are called pass through systems and are

frequently used for sterilizers. In a closed-loop

system, the waste steam and condensate are

recovered and recycled through the boiler.

Closed loop systems are the most efcient and

cost effective and are recommended for most

applications. (See above illustration.)

GCH In-Line Steam

Super Heater (Optional)

Water Supply

Alternate Feed Systems

Low Pressure

Water Feed

High Pressure Water

Feed Pump & Motor

Blow Down Separator

Cold Water

Supply

Drain

Automatic Blowdown

Drain

Water Supply

Check Valve

Condensate

Return Line

Steam

Outlet

Furnished

by Customer

Steam Trap

Process

Chromalox

Steam

Boiler

Condensate

Return Tank

Pump & Motor

Steam Pressures to 235 psig

Hot Water Temp. to 240F

Steam Capacities to 4,890

Lbs/Hr @ 235 psig

3 - 1,620 kW (10 - 5,527 Mbh)

120 - 600 Volt, 1 & 3 Phase

Pressure Vessels Carbon or

Stainless Steel ASME Section I

Carbon Steel ASME Section IV

Copper or INCOLOY

Sheath

Heating Elements

Mechanical (Float) and/or

Electronic (Probe) Water Level

and Limit Controls

Optional Control Transformers,

Water Feed Systems and Blow

Down Equipment

Third Party (UL, CSA) Listing,

Recognition or Certication

Reliability A rigid Quality Control Program

is maintained to assure compliance with the

ASME Code, Underwriters Laboratories, Inc.

requirements and engineering design speci-

cations. Each boiler is tested under power for

functional conformance, is subject to a high

potential dielectric test, hydrostatic pressure

test and must pass a Quality Control inspec-

tion before being released for shipment.

Optional Equipment

Condensate Returns

Blow Down Separaters

Vacuum Breakers

Cold Water Feeds

Sequencers

Control Transformers

Custom Engineering

Chromalox can design and manufacture

your Packaged Electric Steam and Hot Water

Boilers. Contact your Local Chromalox Sales

ofce.

Note Refer to Optional Equipment in

this section.

Note Blow down separators and/or condensate return systems (optional equipment)

may be necessary in some installations. Check local and state codes.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 928G 6XR ElectricoДокумент4 страницы928G 6XR ElectricoRodney Richardson100% (3)

- 928G 6XR ElectricoДокумент4 страницы928G 6XR ElectricoRodney Richardson100% (3)

- Catalogo Kunkle ValveДокумент32 страницыCatalogo Kunkle ValveKelvyn RochaОценок пока нет

- Dubai Municipality Guidlines For The Control of LegionellaДокумент10 страницDubai Municipality Guidlines For The Control of LegionellaMiguell Dasenta0% (1)

- IGEM-G-5 Edition 2 - INSTALLATION PIPEWORK, GAS APPLIANCES ANDДокумент4 страницыIGEM-G-5 Edition 2 - INSTALLATION PIPEWORK, GAS APPLIANCES ANDAhmed Abo RashedОценок пока нет

- AL Codigos de FallaДокумент3 страницыAL Codigos de Fallaadrianahouki0% (1)

- Marine Boilers PDFДокумент21 страницаMarine Boilers PDFRavi Viknesh0% (1)

- DG Packaged Systems Large Tank HeatersДокумент2 страницыDG Packaged Systems Large Tank HeatersadrianahoukiОценок пока нет

- Katalog UFS 2012 enДокумент494 страницыKatalog UFS 2012 enadrianahoukiОценок пока нет

- DG Process Air HeatersДокумент1 страницаDG Process Air HeatersadrianahoukiОценок пока нет

- DG Packaged Systems Oil SystemsДокумент1 страницаDG Packaged Systems Oil SystemsadrianahoukiОценок пока нет

- Katalog LFS 2012 enДокумент476 страницKatalog LFS 2012 enadrianahoukiОценок пока нет

- Ecp DHS M 001Документ27 страницEcp DHS M 001adrianahoukiОценок пока нет

- Reference Data Temperature Pressure Equivalents and Conversions SPДокумент1 страницаReference Data Temperature Pressure Equivalents and Conversions SPguadalupeocanaОценок пока нет

- DG Immersion Heaters Over The SideДокумент3 страницыDG Immersion Heaters Over The SideadrianahoukiОценок пока нет

- DG Packaged Systems Heat Transfer SystemsДокумент3 страницыDG Packaged Systems Heat Transfer SystemsadrianahoukiОценок пока нет

- BSS Brandschutzleitfaden enДокумент120 страницBSS Brandschutzleitfaden enadrianahoukiОценок пока нет

- Katalog KTS 2012 enДокумент500 страницKatalog KTS 2012 enadrianahoukiОценок пока нет

- DG Comfort Heating Sizing GuideДокумент32 страницыDG Comfort Heating Sizing GuideadrianahoukiОценок пока нет

- Helical Catalog 2008Документ28 страницHelical Catalog 2008adrianahoukiОценок пока нет

- KTS Magic enДокумент24 страницыKTS Magic enadrianahoukiОценок пока нет

- Katalog Vbs 2012 Connection and Fastening enДокумент488 страницKatalog Vbs 2012 Connection and Fastening enadrianahoukiОценок пока нет

- BSS Brandschutzleitfaden enДокумент120 страницBSS Brandschutzleitfaden enadrianahoukiОценок пока нет

- Katalog EGS 2012 enДокумент235 страницKatalog EGS 2012 enadrianahoukiОценок пока нет

- Green: Green Products. Connecting and Fastening Technology From Renewable ResourcesДокумент8 страницGreen: Green Products. Connecting and Fastening Technology From Renewable ResourcesadrianahoukiОценок пока нет

- Katalog TBS 2012 enДокумент420 страницKatalog TBS 2012 enadrianahoukiОценок пока нет

- Hella LED enДокумент28 страницHella LED enadrianahoukiОценок пока нет

- Xa Se100582 5Документ2 страницыXa Se100582 5adrianahoukiОценок пока нет

- Xa Se100582a 0Документ2 страницыXa Se100582a 0adrianahoukiОценок пока нет

- ProductCatalog N TRONДокумент24 страницыProductCatalog N TRONadrianahoukiОценок пока нет

- REC4281GДокумент307 страницREC4281GadrianahoukiОценок пока нет

- E - T3000 - p79 - 1047 Servo Pressure Controllers MARSH BELLOFRAMДокумент26 страницE - T3000 - p79 - 1047 Servo Pressure Controllers MARSH BELLOFRAMadrianahoukiОценок пока нет

- Evans Carman ThorndikeanticiteraДокумент39 страницEvans Carman ThorndikeanticiteraadrianahoukiОценок пока нет

- Navitron PanelsДокумент29 страницNavitron PanelsNickОценок пока нет

- First Quarter Science ActivitiesДокумент27 страницFirst Quarter Science ActivitiesMary Rose P. RiveraОценок пока нет

- Water-to-Water System Design Guide PDFДокумент68 страницWater-to-Water System Design Guide PDFJofel Dulguime SuanОценок пока нет

- 6ALBR5233JQOДокумент23 страницы6ALBR5233JQOpinticaniulian9042Оценок пока нет

- CPP Lab Report 4Документ11 страницCPP Lab Report 4Muhammad Danial KhairuddinОценок пока нет

- Laura ProductДокумент10 страницLaura ProductCatrinaОценок пока нет

- 686 BQ Plumbing Hydrant-TW.a-b (Rev.2) IbotДокумент49 страниц686 BQ Plumbing Hydrant-TW.a-b (Rev.2) IbotDwi Mego PrasetyoОценок пока нет

- 2018 UPC Insert Pages - FinalДокумент80 страниц2018 UPC Insert Pages - FinalRohan ChauguleОценок пока нет

- Cooling TowersДокумент10 страницCooling TowersAvipsita DasОценок пока нет

- Jake Hannah Anthony TaylorДокумент37 страницJake Hannah Anthony Taylorapi-290585590Оценок пока нет

- User Manual Asko D5434XL enДокумент20 страницUser Manual Asko D5434XL enasasasasОценок пока нет

- Amir Mohamed: Aramco For Khurais PipelineДокумент7 страницAmir Mohamed: Aramco For Khurais PipelineHatem HusseinОценок пока нет

- IMESA STC Commercial-Sheet LM-40-55 Evo - Line ENG R00Документ2 страницыIMESA STC Commercial-Sheet LM-40-55 Evo - Line ENG R00Jayantha SenevirathnaОценок пока нет

- 6 - Jeewan - S1 TypeДокумент23 страницы6 - Jeewan - S1 TypexmaniscomingОценок пока нет

- Series 174A, 374, 740 Specification SheetДокумент2 страницыSeries 174A, 374, 740 Specification SheetWattsОценок пока нет

- Smith CatalogДокумент100 страницSmith CatalogLuis DomdОценок пока нет

- Potterton Suprima 30,40,50,60,70,80Документ37 страницPotterton Suprima 30,40,50,60,70,80Martin Lee SmithОценок пока нет

- Ariston Clas24 30Документ76 страницAriston Clas24 30anca_dovleacОценок пока нет

- Practice Question P4 For OIIДокумент17 страницPractice Question P4 For OIIzoha.adilОценок пока нет

- Commercial/Industrial/Large Residential Service InformationДокумент2 страницыCommercial/Industrial/Large Residential Service Informationprathap394Оценок пока нет

- GROHE Bathroom Brochure PDFДокумент296 страницGROHE Bathroom Brochure PDFdmakaricОценок пока нет

- Medford Police Station Feasibility Study Appendix: Existing ConditionsДокумент799 страницMedford Police Station Feasibility Study Appendix: Existing Conditionsalex_ruppenthalОценок пока нет

- Hood Type Dishwasher with Guaranteed Rinse SystemДокумент3 страницыHood Type Dishwasher with Guaranteed Rinse SystemHibatulAwwalUlfaОценок пока нет

- IOSH AquatreatДокумент60 страницIOSH AquatreatNoor Muddassir KhanОценок пока нет

- Hoover HNL6166 ManualДокумент32 страницыHoover HNL6166 ManualAndrew David PalmerОценок пока нет

- Boilermate 2000 PDFДокумент9 страницBoilermate 2000 PDFvalenmanОценок пока нет