Академический Документы

Профессиональный Документы

Культура Документы

Consurv OSIsoft Progress Report

Загружено:

TongWuNg0 оценок0% нашли этот документ полезным (0 голосов)

164 просмотров9 страницPorgress report for OSIsoft project under Consurv Technic

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPorgress report for OSIsoft project under Consurv Technic

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

164 просмотров9 страницConsurv OSIsoft Progress Report

Загружено:

TongWuNgPorgress report for OSIsoft project under Consurv Technic

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 9

Consurv Technic (M) Sdn Bhd

Lot C12A-4 Jalan Ampang Utama 1/1

68000 Ampang, Selangor, Malaysia

Tel.: 03 4256 4254

Fax: 03 4256 5254

Industrial Internship

Project Progress Report

June 2012 August 2012

Consurv Technic (M) Sdn. Bhd.

Title : OSIsoft PI System Pilot Project

for PETRONAS Group Technical

Solutions (GTS)

Name : Ng Tong Wu

Matric ID : 13513

Course : ICT

UTP Supervisor : En. Saipunidzam b. Mahamad

Intern Supervisor : En Faiz H. Hussin

Consurv Technic (M) Sdn Bhd

Lot C12A-4 Jalan Ampang Utama 1/1

68000 Ampang, Selangor, Malaysia

Tel.: 03 4256 4254

Fax: 03 4256 5254

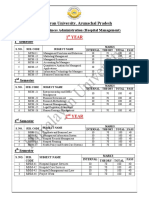

TABLE OF CONTENTS

1. PROJECT BACKGROUND

i. Introduction ... 1

ii. Problem Statement . 1

iii. Feasibility of Project 2

2. LITERATURE REVIEW

i. Literature Review . 3

3. METHODOLOGY

i. Project Activities ... 4

ii. Gantt Chart .. 5

4. RESULTS AND DISCUSSION

i. Data Gathering and Analysis 6

5. PROJECT ACHIEVEMENT AND PROGRESS

i. Project Achievement and Progress .. 7

Consurv Technic (M) Sdn Bhd

Lot C12A-4 Jalan Ampang Utama 1/1

68000 Ampang, Selangor, Malaysia

Tel.: 03 4256 4254

Fax: 03 4256 5254

1. PROJECT BACKGROUND

Introduction

Oil and gas industry relies on real time and reliable data to engage precise

process control in order to regulate risks associated in its upstream and

midstream activities.

OSIsofts PI System is a plant information system that can help oil and gas

companies to maximize their process and production efficiency in order to face

extremely high production costs.

OSIsoft PI System deploys an architecture that provide real time data

infrastructure and collaboration tools to maximize asset performance through

real time monitoring, periodical reporting, and also historical trend analysis.

This project aims to develop and install the OSIsoft PI System in a pilot

project to show to the client, PETRONASs Group Technical Solutions,

Technology and Engineering Department its capabilities and advantages.

PETRONAS Penapisan (Melaka) Sdn. Bhd. which is an existing OSIsoft PI

System user will be the host to allow our team to read and extract real time

data from their PI AF Server. iPerintis which is the technical team of

PETRONAS will be the supporting arm to handle all the connectivity and

security issues between all parties.

All of the PETRONAS production facilities or plants have existing plant

information systems, either Honeywell or Aspentech. However, none of these

existing PI systems provide the extensive capabilities and features offered by

OSIsoft.

As a system integrator and / or agent to OSIsoft, Consurv Technic (M) Sdn.

Bhd. notices the business opportunity. We decided to establish a team of IT

staffs and made a proposal to the Technology and Engineering Department of

GTS to kick start this pilot project in order to demonstrate the capabilities and

features of the OSIsoft PI System.

Problem Statement

Conventional plant information systems lacked in terms of reporting features

as offered by OSIsofts PI System. It has the capability to generate reports

and custom views in its PI Process Book component. Trends and 2D Plant

and Instrumentation Diagram (PNI Diagram) with real time data can be

generated.

OSIsofts PI System allows sharing of data across platform and data

availability in real time. The OSIsoft PI Web Parts allows content provider to

build Microsoft Sharepoint System to share information across the enterprise

while PI Coresight allows user to generate custom data views through

Silverlight enabled browser.

Consurv Technic (M) Sdn Bhd

Lot C12A-4 Jalan Ampang Utama 1/1

68000 Ampang, Selangor, Malaysia

Tel.: 03 4256 4254

Fax: 03 4256 5254

PI Notification has the capability to deliver real time desktop alert, alarm,

and / or email notification upon breaching of parameters. This will allow for

immediate and accurate decisions to control and mitigate the risks.

Also, existing plant information system has been in used for a long time and is

getting compatibility issues with newer equipment. OSIsofts PI system

promises new features while maintaining backward compatibility for older

equipment. It can easily replace obsolete and / or aging plant information

technology.

Another feature of current plant information systems is they lacked the ability

to integrate with Microsoft Office applications. Whereas OSIsofts PI System

is built around Microsoft Office components to allow user take advantage of

features they already familiar with.

Feasibility of Project

The project will be conducted over a period of six (6) months, which is from

June 2012 to December 2012.

As this is a pilot project, trial licenses for each of OSIsoft PI System

components have been issued and expiry date is 31

st

December 2012.

This project has been proposed since the month June 2011 to PETRONAS GTS

and was kick started in the month of May 2012.

Consurv Technic (M) SDn. Bhd. aimed to gain not just monetary profit from

this pilot project but also the recognition from client as the preferred vendor

for OSIsoft PI System. However, all costs and fees involved in the process of

the project will be carried by the client.

Consurv Technic (M) Sdn Bhd

Lot C12A-4 Jalan Ampang Utama 1/1

68000 Ampang, Selangor, Malaysia

Tel.: 03 4256 4254

Fax: 03 4256 5254

2. LITERATURE REVIEW

John Baier, Director of Project Management from OSIsoft said: Wish you

knew how to predict the future? The answer lies in the past.

Many incidents in a production facility are repeating and / or happening after

certain symptoms. Maintenance work or mitigation process should be made

when symptoms that have history of leading to an incident occurs.

Comparative analysis of current equipment status with historical data is

beneficial to predict incidents and prevent them.

According to The Role of Predictive Analytics in Asset Optimization for the Oil

and Gas Industry published by R. Nicholson, C. Madden, J. Flebowitz, and R.

Bigliani (2001), an analysis on the financial statements of the 5 major oil and

gas companies in the USA reveals the 51% of their assets consist of plants,

equipments, and properties. Therefore, it can be deduced that proper asset

management will help to optimize the cost of production in the industry.

This is supported by the ERG Group, a clientele of OSIsofts PI System. The

ERG Group is Italys main independent energy and petroleum group. They

reported to have achieved reduction in downtime and cost saving by shifting to

condition based maintenance, which means maintenance done based on

early detected symptoms instead of periodical maintenance. ERG: Driving out

unnecessary costs by shifting ot Condition Based Maintenance and reducing

downtime.

OSIsofts PI System is a comprehensive asset monitoring tool that is able to

help the user to optimize the production and increase efficiency in the value

chain, especially in the Oil and Gas industry where production costs is

extremely huge and downtime is crucial.

Consurv Technic (M) Sdn Bhd

Lot C12A-4 Jalan Ampang Utama 1/1

68000 Ampang, Selangor, Malaysia

Tel.: 03 4256 4254

Fax: 03 4256 5254

3. METHODOLOGY

Project Activities

1. Planning

- Discussion with GTS (client) to identify business requirements.

- Discussion with iPerintis and PPMSB to identify technical requirements.

- Discussion with OSIsoft (Singapore) to acknowledge and acquire trial

licenses.

2. Analyze & Design

- Project feasibility study and costing (internal).

- Submission of project feasibility report to GTS.

- Submission of commercial impact (quotation) report to GTS.

- Submission of finalized Terms of Reference (TOR) to GTS.

3. Building

- Procurement and initial set up of PI System components on a server.

- Set up networking to access PPMSB PI Server through PETRONAS

intranet.

- Build AF Tree in PI System Explorer.

- Build customized dashboard view in PI Process Book.

- Export PI Process Book entry to Microsoft Office Excel file.

- Build Microsoft Sharepoint System based on PI Web Parts.

- Build web portal based on PI Coresight.

- Progress report for each session at GTS office.

4. Testing

- Test planning.

- System Integration Testing.

- Application Testing.

- User Acceptance Testing.

5. End

- Project completion / termination meeting.

- Submission of final project report.

- Submission of invoice.

- Discussion on future collaborations / procurement.

Consurv Technic (M) Sdn Bhd

Lot C12A-4 Jalan Ampang Utama 1/1

68000 Ampang, Selangor, Malaysia

Tel.: 03 4256 4254

Fax: 03 4256 5254

Gantt Chart

Consurv Technic (M) Sdn Bhd

Lot C12A-4 Jalan Ampang Utama 1/1

68000 Ampang, Selangor, Malaysia

Tel.: 03 4256 4254

Fax: 03 4256 5254

4. RESULT AND DISCUSSION

Data Gathering and Analysis

Data gathered in this project is in terms of values of each tag. Each monitored

equipment will have a sensor that is reporting values to the Data Collector

Server (DCS), this sensor will have a specific tag name. The values of the tags

will be stored in the PI Server and can be retrieved using any OSIsoft PI

System component. The fundamental of the OSIsoft PI System is reading

the tag values using any components in a real time manner.

Using the PI System Explorer, we can generate and organize a tree view of

all the equipment in a hierarchical manner. The status of each equipment can

be viewed from its attributes.

Using the PI Process Book, we can generate a role based dashboard that

can view data in a graphical way corresponding to the levels of the user. Each

user will only need to see the data regarding his / her own department; no

unnecessary data will be distracting the knowledge worker.

PI Process Book will also be used as a tool to perform data analysis using its

trend building features that can include historical data from the start of

record.

Using PI Web Parts, information can be shared over the Microsoft Sharepoint

platform to all connected users.

PI Coresight is used to create a web portal that will allow end user to view

data from any place using browser that support the Silverlight platform. The

web portal is highly customizable by the end user. End user will be able to use

drag-and-drop gesture to create a customized view for needed data views.

Consurv Technic (M) Sdn Bhd

Lot C12A-4 Jalan Ampang Utama 1/1

68000 Ampang, Selangor, Malaysia

Tel.: 03 4256 4254

Fax: 03 4256 5254

5. PROJECT ACHIEVEMENT AND PROGRESS

The project team is now in the Building phase where we are focusing on the

task: Building dashboard using PI Process Book.

The project team had encountered several issues during the Analyze and

Design phase where the security certificate for the intranet connection is

being delayed. Also the tag configuration from the host server was not

released during the Analyze and Design phase. These two (2) issues had

caused a certain delay, but with proper control and support from the client,

iPerintis, and PPMSB, the Building phase is in progress as scheduled.

NO TASK STATUS

Planning

1.1 Discussion with GTS to identify business requirement DONE

1.2 Discussion with iPerintis and PPMSB to identify technical

requirement

DONE

1.3 Discussion with OSIsoft (Singapore) to acknowledge and acquire

trial licenses.

DONE

Analyze & Design

2.1 Project feasibility study and costing (internal) DONE

2.2 Submission of project feasibility report to GTS DONE

2.3 Submission of commercial impact (quotation) report to GTS DONE

2.4 Submission of finalized Terms of Reference (TOR) to GTS DONE

Building

3.1 Procurement and initial set up of PI System components on a

server

DONE

3.2 Set up networking to access PPMSB PI Server through

PETRONAS intranet

DONE

3.3 Build AF Tree in PI System Explorer DONE

3.4 Build customized dashboard view in PI Process Book WORKING

3.5 Export PI Process Book entry to Microsoft Office Excel file WORKING

3.6 Build Microsoft Sharepoint System based on PI Web Parts WORKING

3.7 Build web portal based on PI Coresight WORKING

3.8 Progress report for each session at GTS office WORKING

Testing

4.1 Test planning PENDING

4.2 System Integration Testing PENDING

4.3 Application Testing PENDING

4.4 User Acceptance Testing PENDING

End

5.1 Project completion / termination meeting PENDING

5.2 Submission of final project report PENDING

5.3 Submission of invoice PENDING

Вам также может понравиться

- SAP COPA ConfigurationДокумент0 страницSAP COPA ConfigurationDeepak Gupta50% (2)

- OQDExpressUserGuide Gen 2 V1Документ22 страницыOQDExpressUserGuide Gen 2 V1Ernie Gomez ColquichaguaОценок пока нет

- OM Manuals TemplateДокумент9 страницOM Manuals TemplatejanempatricioОценок пока нет

- Products: SystemsДокумент580 страницProducts: SystemscrcruzpОценок пока нет

- UptimeDowntimeEventTracking RTtech - SRowlandsДокумент56 страницUptimeDowntimeEventTracking RTtech - SRowlandsalisterjosephОценок пока нет

- Best Practices and Bench Marking of Control System Integrator SДокумент8 страницBest Practices and Bench Marking of Control System Integrator SHector TostadoОценок пока нет

- IotДокумент17 страницIotshwetasharma23Оценок пока нет

- PDMS Graphical Model Manipulation GuideДокумент140 страницPDMS Graphical Model Manipulation GuideGustavo Zuñiga50% (4)

- Catalogue PlantpAxДокумент16 страницCatalogue PlantpAxaharnishaОценок пока нет

- CPMS-AUT-EP-002 - Instrument and Controls Philosophy GuidelinesДокумент18 страницCPMS-AUT-EP-002 - Instrument and Controls Philosophy GuidelinesChrisОценок пока нет

- SCADA Design Dec2001Документ193 страницыSCADA Design Dec2001arthur_52948949Оценок пока нет

- Plantpax Process Automation Solution For Oil and GasДокумент24 страницыPlantpax Process Automation Solution For Oil and GaszkaticОценок пока нет

- Safety Data Sheet: Product Name: CAT DEO 15W-40 (DIESEL ENGINE OIL)Документ11 страницSafety Data Sheet: Product Name: CAT DEO 15W-40 (DIESEL ENGINE OIL)MichaelОценок пока нет

- IEEE GM Vision2050 Meeting FinalДокумент19 страницIEEE GM Vision2050 Meeting Finaljona12345Оценок пока нет

- ADM2372 Midterm F2018 Kadri SolutionsДокумент11 страницADM2372 Midterm F2018 Kadri SolutionstaylorОценок пока нет

- Whitepaper ARC Process Control PCS7+CPASДокумент30 страницWhitepaper ARC Process Control PCS7+CPASCuconnacht BookfacesuckОценок пока нет

- Developing Leaders in Your CompanyДокумент2 страницыDeveloping Leaders in Your CompanySyElfredGОценок пока нет

- Access Control ITPДокумент2 страницыAccess Control ITPehteshamОценок пока нет

- Marketing Test Bank Chap 4Документ52 страницыMarketing Test Bank Chap 4Ta Thi Minh ChauОценок пока нет

- Evaluation of Asset Integrity Management System (AIMS) : GuideДокумент28 страницEvaluation of Asset Integrity Management System (AIMS) : GuideEdwin TorresОценок пока нет

- ITP - 031 (Earthing)Документ2 страницыITP - 031 (Earthing)mohamed wahebОценок пока нет

- CSIKSДокумент52 страницыCSIKSGustavoSilvinoSilvinoОценок пока нет

- Questionnaire PDFДокумент5 страницQuestionnaire PDFAnique Ahmed Butt100% (1)

- Emulation of Automotive Communication Protocol Single Edge Nibble Transmission (SENT) Using Aurix Family of MicrocontrollersДокумент4 страницыEmulation of Automotive Communication Protocol Single Edge Nibble Transmission (SENT) Using Aurix Family of MicrocontrollersseventhsensegroupОценок пока нет

- PCT 1090229Документ42 страницыPCT 1090229new2trackОценок пока нет

- Control System - Dat - 20190416 - 005430269Документ10 страницControl System - Dat - 20190416 - 005430269Syed Mian Fahim KakakhailОценок пока нет

- Cimplicity SecureDeploymentGuide v2 PDFДокумент70 страницCimplicity SecureDeploymentGuide v2 PDFMOHAMMADОценок пока нет

- Enterprise HistorianДокумент5 страницEnterprise HistorianIsraelОценок пока нет

- ProcessPluginsOSIsoft For CBM PDFДокумент14 страницProcessPluginsOSIsoft For CBM PDFMushtaq BhattiОценок пока нет

- I&c Profile Scope.Документ6 страницI&c Profile Scope.anon_238993516Оценок пока нет

- SICAM RTUs MTBF ENGДокумент18 страницSICAM RTUs MTBF ENGMessias De Oliveira SantosОценок пока нет

- LT IDCBookextractДокумент33 страницыLT IDCBookextractKurniawan SaputraОценок пока нет

- Add New Tech To Your Business!: Based On Up-To Date Addax Technology For Smart MeteringДокумент6 страницAdd New Tech To Your Business!: Based On Up-To Date Addax Technology For Smart MeteringFelipe SaldañaОценок пока нет

- Maximize Your Uptime: InsulgardДокумент8 страницMaximize Your Uptime: InsulgardAODVОценок пока нет

- 430 Pipeline SecurityДокумент39 страниц430 Pipeline SecuritydmansoorОценок пока нет

- Historian GlossaryДокумент28 страницHistorian GlossaryDuqueCKОценок пока нет

- A6V10221104 - Technical Manual, Complete - Automatic Fire Detectors - enДокумент64 страницыA6V10221104 - Technical Manual, Complete - Automatic Fire Detectors - enErikОценок пока нет

- Historian RetrievalДокумент213 страницHistorian RetrievalDuqueCK100% (1)

- F5 Oct13 Price ListДокумент5 страницF5 Oct13 Price ListRené FuentesОценок пока нет

- SF 06015Документ4 страницыSF 06015ricky100% (1)

- Research Paper 5Документ5 страницResearch Paper 5Prateik NimbalkarОценок пока нет

- Selection ChartДокумент2 страницыSelection Chartultrasonic81Оценок пока нет

- LCAM Whitepaper 204 PDFДокумент7 страницLCAM Whitepaper 204 PDFShashank JainОценок пока нет

- TS PcVue12 Communication Drivers enДокумент6 страницTS PcVue12 Communication Drivers enObby AryasuciОценок пока нет

- DellДокумент3 страницыDellAneesh VargheseОценок пока нет

- RCM vs. FMEA - There Is A Distinct Difference!: RCM - Reliability Centered MaintenanceДокумент4 страницыRCM vs. FMEA - There Is A Distinct Difference!: RCM - Reliability Centered Maintenanceg_viegasОценок пока нет

- Importance of Using SAP DMSДокумент2 страницыImportance of Using SAP DMSAmol NamjoshiОценок пока нет

- MODBUS-RTU Protocol GuideДокумент27 страницMODBUS-RTU Protocol GuidePau Andrea CОценок пока нет

- Creating and Managing Archestra Graphics User'S Guide: Invensys Systems, IncДокумент492 страницыCreating and Managing Archestra Graphics User'S Guide: Invensys Systems, IncSyed Mian Fahim KakakhailОценок пока нет

- Vendor Sample ProjectsДокумент10 страницVendor Sample ProjectsRrhh EstОценок пока нет

- FactoryTalk View ME and PanelView PlusДокумент2 страницыFactoryTalk View ME and PanelView PlusiedmondОценок пока нет

- Historian ScenariosДокумент30 страницHistorian ScenariosDuqueCKОценок пока нет

- Migration Users GuideДокумент78 страницMigration Users GuideVu Hai DangОценок пока нет

- NOA-NAMUR Open ArchitectureДокумент24 страницыNOA-NAMUR Open ArchitectureudhaiiОценок пока нет

- Product Range: Pump PerformanceДокумент32 страницыProduct Range: Pump PerformanceFlorin StarpituОценок пока нет

- COD & TOC AnalyserДокумент24 страницыCOD & TOC AnalyserSivakumar SelvarajОценок пока нет

- Development and Future of LNG in IndiaДокумент12 страницDevelopment and Future of LNG in IndiaRajat SОценок пока нет

- Elster-Instromet M2000 FCДокумент0 страницElster-Instromet M2000 FCsaid_rahmansyah4750Оценок пока нет

- 75b41c86-5865-4ec0-8614-f3affdcde169 (1)Документ93 страницы75b41c86-5865-4ec0-8614-f3affdcde169 (1)Satay ChillyОценок пока нет

- Developing an MPM Framework Using ANP for Maintenance Performance Indicator SelectionДокумент14 страницDeveloping an MPM Framework Using ANP for Maintenance Performance Indicator SelectionAlejandro100% (1)

- IBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionОт EverandIBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionОценок пока нет

- Unit 2-Introduction To Information Systems DevelopmentДокумент32 страницыUnit 2-Introduction To Information Systems Developmentjaq hit coolОценок пока нет

- The Impact of Business Intelligence Tools on Performance: A User Satisfaction ParadoxДокумент26 страницThe Impact of Business Intelligence Tools on Performance: A User Satisfaction ParadoxaymanОценок пока нет

- Understand The Principles and Theories of Management Information System (MIS) and Its Impact On OrganizationsДокумент11 страницUnderstand The Principles and Theories of Management Information System (MIS) and Its Impact On Organizationskaleb Deneke100% (1)

- قواعد تقييم المجلات والمؤتمرات222Документ113 страницقواعد تقييم المجلات والمؤتمرات222Ahmed NadyОценок пока нет

- Innovation Through Information Systems: Frederik Ahlemann Reinhard Schütte Stefan Stieglitz EditorsДокумент704 страницыInnovation Through Information Systems: Frederik Ahlemann Reinhard Schütte Stefan Stieglitz Editorsklauseln-verzetteln.0hОценок пока нет

- The University of Guyana: Faculty of Natural SciencesДокумент11 страницThe University of Guyana: Faculty of Natural SciencesSandra KhanОценок пока нет

- UPS Competes Globally With Information TechnologyДокумент6 страницUPS Competes Globally With Information TechnologyMuhammadYudithEddwina100% (2)

- NEW MBA Hospital Management - 2020Документ44 страницыNEW MBA Hospital Management - 2020adn paramedicalОценок пока нет

- Nccedu Bcis Top Up Uclan Programme Sheet Sep 2020Документ2 страницыNccedu Bcis Top Up Uclan Programme Sheet Sep 2020sawpyae PhyokyawОценок пока нет

- Chapter 7 Securing Information Systems.Документ10 страницChapter 7 Securing Information Systems.Hussein Abdou HassanОценок пока нет

- IBM 2021-2022 Session 4Документ32 страницыIBM 2021-2022 Session 4Fehim NadirliОценок пока нет

- CD Ict Worksheet La6 Form 5Документ36 страницCD Ict Worksheet La6 Form 5ummuasyrafОценок пока нет

- Adoption of Information Systems in OrganizationsДокумент7 страницAdoption of Information Systems in OrganizationsAshna WaseemОценок пока нет

- Operation Information 2010Документ305 страницOperation Information 2010npgovlkОценок пока нет

- Office automation systems features and componentsДокумент1 страницаOffice automation systems features and componentsAnuj VermaОценок пока нет

- ERP Class NotesДокумент136 страницERP Class NotesDr Pratosh BansalОценок пока нет

- MbaДокумент54 страницыMbasadathnooriОценок пока нет

- The Role of System Information Management (SIM) On Go-JekДокумент13 страницThe Role of System Information Management (SIM) On Go-JekFathinus Syafrizal100% (1)

- 00 Management Information Systems (MIS) .1Документ90 страниц00 Management Information Systems (MIS) .1rockpdОценок пока нет

- Available Courses For Ethiopian Students Who Wants To Study in EuropeДокумент6 страницAvailable Courses For Ethiopian Students Who Wants To Study in Europegetahun esubalewОценок пока нет

- Cape Notes Unit 2 Module 2 Reason For The Use of ItДокумент1 страницаCape Notes Unit 2 Module 2 Reason For The Use of Itrenell simonОценок пока нет

- Cit 208 Information SystemsДокумент200 страницCit 208 Information Systemsnuhu badamasiОценок пока нет

- Umt Mannual BookДокумент172 страницыUmt Mannual BookUmt BookОценок пока нет

- An Overview of Management Information System: Mr. Amsalu Keno (Asst. Prof.)Документ34 страницыAn Overview of Management Information System: Mr. Amsalu Keno (Asst. Prof.)baba lakeОценок пока нет

- Full Download Essentials of Systems Analysis and Design 5th Edition Valacich Solutions ManualДокумент36 страницFull Download Essentials of Systems Analysis and Design 5th Edition Valacich Solutions Manualscreamsoaring.pm7hcv100% (34)

- Accounting Information Systems (AISДокумент3 страницыAccounting Information Systems (AISCloudKielGuiangОценок пока нет