Академический Документы

Профессиональный Документы

Культура Документы

NPM S160 Specsheet

Загружено:

Electromate0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров2 страницыThis document provides specifications for the Nippon Pulse S160 linear shaft motor. It includes details on electrical specifications, thermal specifications, forcer specifications, force duty curves, shaft details, part numbering system, connector and cable specifications, and stroke length to total length ratios. The motor comes in D, T, and Q models with different continuous forces and various connector, cable, and housing options are available. Tolerances for dimensions and other technical details are also provided.

Исходное описание:

Brochure

Оригинальное название

NPM_S160_specsheet

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides specifications for the Nippon Pulse S160 linear shaft motor. It includes details on electrical specifications, thermal specifications, forcer specifications, force duty curves, shaft details, part numbering system, connector and cable specifications, and stroke length to total length ratios. The motor comes in D, T, and Q models with different continuous forces and various connector, cable, and housing options are available. Tolerances for dimensions and other technical details are also provided.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

27 просмотров2 страницыNPM S160 Specsheet

Загружено:

ElectromateThis document provides specifications for the Nippon Pulse S160 linear shaft motor. It includes details on electrical specifications, thermal specifications, forcer specifications, force duty curves, shaft details, part numbering system, connector and cable specifications, and stroke length to total length ratios. The motor comes in D, T, and Q models with different continuous forces and various connector, cable, and housing options are available. Tolerances for dimensions and other technical details are also provided.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

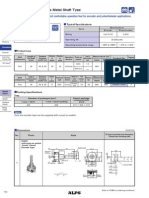

Serial Number

Mounting Surface Label

Gap

Bore

Motor Cable

Length

Support Length

Total Length

Movable Range

Forcer Length

Forcer Screw Pitch

Stroke Length

S

e

t

t

i

n

g

P

i

t

c

h

Bending Radius

dep

Nippon Pulse

Your Partner in Motion Control NPM

S160

Linear Shaft Motor

Electrical Specs S160D S160T S160Q

Continuous Force

1

10N 15N 20N

Continuous Current

1

0.6Arms 0.6Arms 0.6Arms

Peak Force

2

40N 60N 80N

Peak Current

2

2.5Arms 2.5Arms 2.5Arms

Force Constant (K

f

) 16N/Arms 24N/Arms 33N/Arms

Back EMF (K

e

) 5.4V/m/s 8.1V/m/s 11V/m/s

Resistance 25C,

3

21 33 43

Inductance

3

8.2mH 12mH 16mH

Electric Time Constant 0.39ms 0.36ms 0.37ms

Fundemental Motor Constant (K

m

) 3.51NW 4.20NW 4.96NW

Magnetic Pitch (North-North) 60mm 60mm 60mm

All specications are for reference only. Specications may change depending on servo driver selected. Consult Nippon Pulse.

1) Based on a temp rise of coil surface of 110K over 25C ambient temperature stalled forcer, and no external cooling or heat sinking

Addition of 25 cm x 25 cm x 2.5 cm aluminum heat sink increases continuous force by 20%

2) Can be maintained for a maximum of 40 seconds, higher forces and current possible for short periods of time, consult Nippon Pulse

3) All winding parameters listed are measured line-to-line (phase-to-phase)

Thermal Specs S160D S160T S160Q

Max Phase Temperature

4

135C 135C 135C

Thermal Resistance (Coil) (K

q

) 13.6C 8.7C 6.7C

4) The standard temperature difference between the coil and the forcer surface is 15C

Forcer Specs S160D S160T S160Q

Forcer Length (A) 80mm 110mm 140mm

Forcer Width 30mm 0.3 30mm 0.3 30mm 0.3

Forcer Screw Pitch (P) 70mm 100mm 130mm

Forcer Weight 0.15kg 0.20kg 0.30kg

Gap 0.50mm 0.50mm 0.50mm

S160D Force Duty Curve S160Q Force Duty Curve

L = See Shaft Length

L1 = Usable Stroke + A

L2 = See Shaft Support Length

A = See Moving Coil Length

P = See Moving Coil Screw Pitch

Unless Otherwise Specied:

Dimensions are in mm

Tolerances are as follows:

Dimension (mm)

- 6

7 - 30

31 - 120

121 - 315

316 - 1000

1001 - 2000

2000 -

Tolerance (mm)

0.1

0.2

0.3

0.5

0.8

1.2

1.5

0

10

20

30

40

50

60

70

80

90

0 20 40 60 80 100

F

o

r

c

e

(

N

)

Duty(%)

Force - Duty Curve

S160D

20 C

40 C

60 C

80 C

110 C

0

20

40

60

80

100

120

140

160

180

0 20 40 60 80 100

F

o

r

c

e

(

N

)

Duty(%)

Force - Duty Curve

S160Q

20 C

40 C

60 C

80 C

110 C

* Note 1

Cable length 300mm

The bending radius of the motor cable

should be 26.4mm (wire diameter 4.4 * 6)

as suggested by the wire manufacturer.

This radius should be maintained. Use

supplied connector to attach the proper

high ex cable as required by your application.

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Shaft Size (D) Forcer Size (A) Usable Stroke Options Options

S X XXXX XX XX

Stroke S160D S160T S160Q

100 230 260 290

150 280 310 340

200 330 360 390

250 380 410 440

300 430 460 490

350 480 510 540

400 560 590 620

450 610 640 670

500 660 690 720

550 710 740 770

600 760 790 820

650 810 840 870

700 860 890 920

750 910 940 970

800 960 990 1020

850 1050 1080 1110

900 1100 1130 1160

950 1150 1180 1210

1000 1200 1230 1260

1050 1250 1280 1310

1100 1300 1330 1360

1150 1350 1380 1410

1200 1400 1430 1460

1250 1450 1480 1510

1300 1500 1530 1560

1350 1550 1580 1610

1400 1600 1630 1660

1450 1650 1680 1710

1500 1700 1730 1760

1550 1750 1780 1810

1600 1800 1830 1860

1650 1850 1880 1910

1700 1900 1930 1960

1750 1950 1980 2010

1800 2000 2030 2060

Shaft Length (mm) Shaft Mass (kg)

Shaft Diameter (D) - 16mm 0.1

Stroke Support Length Max. bending

0~350 25mm 0.00mm

351~500 40mm 0.30mm

501~800 40mm 0.50mm

801~max 60mm 0.50mm

Support and Bending

Wire Type UL 2464

Wire AWG 24

U Phase Orange

V Phase White

W Phase Gray

Lead Wire

300mm lead wire bare leads

The bending radius of the motor ca-

ble should be 26.4mm as suggested

by the wire manufacturer.

Receptacle Housing XMR-03V

Plug Housing XMP-03V

Retainer XMS-03V

Pin Contact SXM-001T-P0.6

Socket Contact SXA-001T-P0.6

Connector (Motor Cable)

To be installed by the user

Spec S160T S160Q

Forcer Spacing Distance 10mm 10mm

Pole (N/S) Distance 30mm 30mm

Forcer Length 110mm 140mm

Flip Forcers No Yes

Forcer Spacing Distance

Forcer Spacing Distance

D: Double (2) windings

T: Triple (3) windings

Q: Quadruple (4) windings

100-1800mm ST: Standard

WP: Waterproof

DA: Digital Hall Effect

CE: CE type motor

Blank: Standard

FO: Forcer Only

SO: Shaft Only

XX: Two digit for custom motor

Part Numbering System

Wire Type UL 1330

Wire AWG 24

U Phase Red

V Phase White

W Phase Black

Ground Wire UL 1330

Wire AWG 20

Frame Ground Green/Yellow

CE Type Motor Cable

300mm lead wire bare leads

The bending radius of the motor cable

should be 16.96mm as suggested by the wire

manufacturer.

* Note 1

The bending radius of the motor cable should be R27.6mm (wire diameter 4.6 * 6) as

suggested by the wire manufacturer. This radius should be maintained. Use supplied

connector to attach the proper high ex cable as required by your application.

Wire Type UL 758

Wire AWG 28

VCC White/Red

GND White/Black

Sensor 1 Orange/Red

Sensor 2 Orange/Black

Sensor 3 Gray/Red

No Connec. Gray/Black

Hall Effect Cable

400mm lead wire bare leads

The bending radius of the motor ca-

ble should be 10.72mm as suggested

by the wire manufacturer.

S160

Linear Shaft Motor

Tandem Forcer

Hall Effect Specs

Wire Type UL 758

Wire AWG 28

VCC White/Red

GND White/Black

Sensor 1 Orange/Red

Sensor 2 Orange/Black

Sensor 3 Gray/Red

The bending radius of the sensor

cable should be R 26.4mm (wire

diameter 4.4 * 6) as suggested

by the wire manufacturer. This

radius should be maintained. At-

tach the proper high ex cable as

required by your application.

Sensor Cable Specs

Total Length (L)=Stroke (S)+Forcer Length (A)+(Support Length (L2)x2)

Stroke S160D S160T S160Q

100 0.28 0.33 0.37

150 0.35 0.4 0.44

200 0.42 0.47 0.51

250 0.49 0.54 0.58

300 0.56 0.61 0.58

350 0.64 0.68 0.72

400 0.72 0.77 0.81

450 0.79 0.84 0.88

500 0.86 0.91 0.95

550 0.93 1 1

600 1 1 1.1

650 1.1 1.1 1.2

700 1.1 1.2 1.2

750 1.2 1.3 1.3

800 1.3 1.3 1.4

850 1.4 1.4 1.5

900 1.5 1.5 1.5

950 1.5 1.6 1.6

1000 1.6 1.6 1.7

1050 1.7 1.7 1.7

1100 1.7 1.8 1.8

1150 1.8 1.9 1.9

1200 1.9 1.9 2

1250 2 2 2

1300 2 2.1 2.1

1350 2.1 2.2 2.2

1400 2.2 2.2 2.3

1450 2.3 2.3 2.3

1500 2.3 2.4 2.4

1550 2.4 2.4 2.5

1600 2.5 2.5 2.6

1650 2.6 2.6 2.6

1700 2.6 2.7 2.7

1750 2.7 2.7 2.8

160

ELECTROMATE

Toll Free Phone (877) SERVO98

Toll Free Fax (877) SERV099

www.electromate.com

sales@electromate.com

Sold & Serviced By:

Вам также может понравиться

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1От EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Рейтинг: 4.5 из 5 звезд4.5/5 (3)

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- IX Iron Core Linear MotorДокумент20 страницIX Iron Core Linear MotorjuliangoalОценок пока нет

- CAHB 31 DatasheetДокумент4 страницыCAHB 31 DatasheetAndreaDeCrescenzoОценок пока нет

- I72E en 01+JunmaServoMotor+DatasheetДокумент4 страницыI72E en 01+JunmaServoMotor+DatasheetAvinash PaiОценок пока нет

- Kompakt Prekidaci General Electric English Ed02 2006Документ69 страницKompakt Prekidaci General Electric English Ed02 2006d.olivericОценок пока нет

- IAI LSAS N10 N15 SpecsheetДокумент15 страницIAI LSAS N10 N15 SpecsheetElectromateОценок пока нет

- HB Stepper Motor EДокумент19 страницHB Stepper Motor Eartpirate003_5420882Оценок пока нет

- Datasheet Panasonic Msma042Документ39 страницDatasheet Panasonic Msma042thiagofininhoОценок пока нет

- YTWДокумент2 страницыYTWwpt_meОценок пока нет

- Iai Rca Ss5d SpecsheetДокумент2 страницыIai Rca Ss5d SpecsheetElectromateОценок пока нет

- Micro Precision Positioning Table IKOДокумент8 страницMicro Precision Positioning Table IKOhexapodo2Оценок пока нет

- AC Servo Motor User ManualДокумент13 страницAC Servo Motor User ManualOscar Vazquez EspinosaОценок пока нет

- 20120224043147Документ8 страниц20120224043147Dương Trương Tấn100% (1)

- Tecnotion UM Series SpecsheetДокумент2 страницыTecnotion UM Series SpecsheetElectromateОценок пока нет

- Terazaki TZS-68 - Earth Leakage RelayДокумент2 страницыTerazaki TZS-68 - Earth Leakage RelayJon Carlo DelmarОценок пока нет

- 110 Series Ordering GuideДокумент4 страницы110 Series Ordering GuideElectromateОценок пока нет

- HB Stepper Motor EДокумент22 страницыHB Stepper Motor EEthan ColeОценок пока нет

- Data 3863 CR Motores PDFДокумент2 страницыData 3863 CR Motores PDFRaul CruzОценок пока нет

- Torque Systems MDM Stainless Steel Series Product GuideДокумент4 страницыTorque Systems MDM Stainless Steel Series Product GuideElectromateОценок пока нет

- DX B Ironless Linear Motor - PBASystemsДокумент28 страницDX B Ironless Linear Motor - PBASystemsjuliangoalОценок пока нет

- Linear Motion Slide Toothed Belt DriveДокумент20 страницLinear Motion Slide Toothed Belt DrivePetar HosticОценок пока нет

- Dyadic Mechatronics Cylinder CatalogДокумент16 страницDyadic Mechatronics Cylinder CatalogElectromateОценок пока нет

- Hydraulic Cylinders CHДокумент8 страницHydraulic Cylinders CHStoianovici CristianОценок пока нет

- Electrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Документ234 страницыElectrovalva SMC - Eng 3 - 1 - 2 - 1 - SY3000-5000-7000-9000Canea Mihai CaiusОценок пока нет

- Fender Accessories (Panels, Chains, Brackets) Catalogue en V1.3Документ10 страницFender Accessories (Panels, Chains, Brackets) Catalogue en V1.3loicdertyОценок пока нет

- Kollmorgen - Nema 23 T - SpecsheetДокумент4 страницыKollmorgen - Nema 23 T - SpecsheetElectromateОценок пока нет

- SL-1210MK2 Service ManualДокумент39 страницSL-1210MK2 Service ManualgiosiolasОценок пока нет

- ZF2 Belt Drive Slide: Product Finder Home PageДокумент6 страницZF2 Belt Drive Slide: Product Finder Home PageawemetalОценок пока нет

- PRONET User Manual V1Документ88 страницPRONET User Manual V1Tülay Mutlu100% (1)

- Lo-Cog DC Servo Motors: Series 8000Документ20 страницLo-Cog DC Servo Motors: Series 8000papaandiОценок пока нет

- I47E en 01+SigmaServoMotors+DatasheetДокумент18 страницI47E en 01+SigmaServoMotors+Datasheetarzoo105Оценок пока нет

- ActuatorsДокумент89 страницActuatorsDavid CalleОценок пока нет

- In Oerlikon CitolineДокумент10 страницIn Oerlikon CitolineJavid Ibrahim MohamedОценок пока нет

- Minas A DriverДокумент14 страницMinas A DriverPham Long100% (1)

- Globe Motor Spec SheetДокумент4 страницыGlobe Motor Spec Sheetargh112Оценок пока нет

- MCCB - XS 2000 - 3200 NeДокумент7 страницMCCB - XS 2000 - 3200 NeFernando SantanaОценок пока нет

- MK 2 PiДокумент7 страницMK 2 PiA Whick Bumbum TralalaОценок пока нет

- 1SBC100179C0201 Main Catalog Motor Protection and Control PDFДокумент160 страниц1SBC100179C0201 Main Catalog Motor Protection and Control PDFMuji OnoОценок пока нет

- Model Code: SB-JR 1-80M42: Outline DrawingДокумент1 страницаModel Code: SB-JR 1-80M42: Outline DrawingYoqi Indra RahmansyahОценок пока нет

- Mitsubishi S-N ContactorsДокумент7 страницMitsubishi S-N Contactorsmanbkk100% (1)

- Catalog Contacor SiemensДокумент49 страницCatalog Contacor Siemenstayantrungquoc100% (2)

- Switch-Disconnector-Fuse Switch-Disconnector: Type FNДокумент21 страницаSwitch-Disconnector-Fuse Switch-Disconnector: Type FNdshemanthkumarОценок пока нет

- EC20A RK203: 20mm Size Metal Shaft TypeДокумент4 страницыEC20A RK203: 20mm Size Metal Shaft TypeshyhuОценок пока нет

- 2.0" DM Dotmatrix 5X7: Kwality Photonics Private LimitedДокумент1 страница2.0" DM Dotmatrix 5X7: Kwality Photonics Private LimitedKike GutierrezОценок пока нет

- Appendix VSL Construction SystemsДокумент18 страницAppendix VSL Construction SystemsGiải Phóng Kết CấuОценок пока нет

- Type FN 125 Mechanical Operating CycleДокумент19 страницType FN 125 Mechanical Operating CycleDivyanshu MittalОценок пока нет

- Vepppalodai Power VerДокумент27 страницVepppalodai Power VerRajaDurai RamakrishnanОценок пока нет

- NPM SLP 35 SpecsheetДокумент2 страницыNPM SLP 35 SpecsheetElectromateОценок пока нет

- NPM SCR 75 SpecsheetДокумент2 страницыNPM SCR 75 SpecsheetElectromateОценок пока нет

- I.16.7 Electromagnetic Flow Meter-JIS 10KДокумент8 страницI.16.7 Electromagnetic Flow Meter-JIS 10KRikrik JajantaraОценок пока нет

- Dong Ho Do Luu Luong FlomagДокумент2 страницыDong Ho Do Luu Luong FlomagNguyễn Công BìnhОценок пока нет

- Heavy-Duty Slide 2 For Heavy LoadsДокумент2 страницыHeavy-Duty Slide 2 For Heavy LoadsawemetalОценок пока нет

- Datasheet Amt102 EncoderДокумент8 страницDatasheet Amt102 EncoderPablo Davila100% (1)

- Introducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionДокумент1 страницаIntroducing The New VLM-60 Absolute Multi-Turn Encoder From Netzer PrecisionElectromateОценок пока нет

- Electromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaДокумент1 страницаElectromate Partners With Spin Robotics To Offer Cobot Screwdriving Solutions in CanadaElectromateОценок пока нет

- Electromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseДокумент1 страницаElectromate Announces Pre-Order Availability of Universal Robots New UR30 Cobot Press ReleaseElectromateОценок пока нет

- Galil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesДокумент1 страницаGalil Achieves Prestigious UL-CSA Certification For Its Motion Controller SeriesElectromateОценок пока нет

- Exor X5 Wireless Press ReleaseДокумент1 страницаExor X5 Wireless Press ReleaseElectromateОценок пока нет

- Mecademic Robotics Releases New Firmware For Its Meca500 RobotДокумент2 страницыMecademic Robotics Releases New Firmware For Its Meca500 RobotElectromateОценок пока нет

- AMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMДокумент2 страницыAMC Release New Micro-Sized FlexPro Servo Drive Model FM060-60C-CMElectromateОценок пока нет

- Electromate Recertified As A Great Place To Work' Press ReleaseДокумент1 страницаElectromate Recertified As A Great Place To Work' Press ReleaseElectromateОценок пока нет

- New High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesДокумент2 страницыNew High-Performance Hollow Shaft Gear Unit From Harmonic Drive: The HPF SeriesElectromateОценок пока нет

- ADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesДокумент2 страницыADVANCED Motion Controls Releases 60A Continuous Micro-Sized FlexPro Servo DrivesElectromateОценок пока нет

- ADVANCED Motion Controls Introduces The FM-series FlexPro™ Digital Servo DrivesДокумент2 страницыADVANCED Motion Controls Introduces The FM-series FlexPro™ Digital Servo DrivesElectromateОценок пока нет

- New Large, Hollow-Shaft Gear Unit From Harmonic Drive LLCДокумент1 страницаNew Large, Hollow-Shaft Gear Unit From Harmonic Drive LLCElectromateОценок пока нет

- New LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsДокумент1 страницаNew LDL25 Series Linear Actuator From SMAC Moving Coil ActuatorsElectromateОценок пока нет

- Harmonic Drive Releases New CSF-ULW Ultra-Light Weight GearheadДокумент1 страницаHarmonic Drive Releases New CSF-ULW Ultra-Light Weight GearheadElectromateОценок пока нет

- Harmonic Drive Releases New CSF-ULW Ultra-Light Weight GearheadДокумент1 страницаHarmonic Drive Releases New CSF-ULW Ultra-Light Weight GearheadElectromateОценок пока нет

- Complete Guided Wheel Motion Solutions From BWC New Product Press ReleaseДокумент2 страницыComplete Guided Wheel Motion Solutions From BWC New Product Press ReleaseElectromateОценок пока нет

- Adc 0808Документ14 страницAdc 0808Vikas PatelОценок пока нет

- Ashtakavarga PredictionДокумент5 страницAshtakavarga Predictionmagicalseas40% (5)

- Wmwbqi J Cix Vi Cökœ de "Qvwi 2015-Avm÷ 2022Документ17 страницWmwbqi J Cix Vi Cökœ de "Qvwi 2015-Avm÷ 2022JuwelОценок пока нет

- Finite Element and Theoretical Investigations On PVC-CFRP Confined Concrete Columns Under Axial CompressionДокумент42 страницыFinite Element and Theoretical Investigations On PVC-CFRP Confined Concrete Columns Under Axial CompressionShaker QaidiОценок пока нет

- Tracing The Location of A Typhon Lesson PlanДокумент4 страницыTracing The Location of A Typhon Lesson PlanJoh A Nna100% (2)

- Report 1 Water Quality Test TTS 301115 FinishedДокумент9 страницReport 1 Water Quality Test TTS 301115 FinishedJeana Lew SCОценок пока нет

- Experiencing Meanings in Spark S The Prime of Miss Jean BrodieДокумент18 страницExperiencing Meanings in Spark S The Prime of Miss Jean BrodieMaria AgusОценок пока нет

- Aravindhan PT CV CSWIP TrainerДокумент4 страницыAravindhan PT CV CSWIP TrainerGanesan RamamoorthyОценок пока нет

- Watson 2015Документ5 страницWatson 2015Perlyn Del Pilar OduyaОценок пока нет

- KTU BTech EEE 2016scheme S3S4KTUSyllabusДокумент41 страницаKTU BTech EEE 2016scheme S3S4KTUSyllabusleksremeshОценок пока нет

- MCE Cambridge Primary Maths 2E Stage6 PPT C05Документ25 страницMCE Cambridge Primary Maths 2E Stage6 PPT C05Novi YufitriОценок пока нет

- The Psychology of Worldviews: Mark E. Koltko-RiveraДокумент56 страницThe Psychology of Worldviews: Mark E. Koltko-RiveraPablo SeinerОценок пока нет

- DR TahaniCV 2012Документ5 страницDR TahaniCV 2012Yousif_AbdalhalimОценок пока нет

- PPT10-super and UltracapacitorДокумент22 страницыPPT10-super and UltracapacitorChaudhari Jainish100% (1)

- DISS TOS Q3 TESTДокумент3 страницыDISS TOS Q3 TESTMichelle GariandoОценок пока нет

- Module 2.1 Cultural Relativism-1Документ20 страницModule 2.1 Cultural Relativism-1Blad AnneОценок пока нет

- Expansion Joint SpecsДокумент1 страницаExpansion Joint SpecsFaisal MuhammadОценок пока нет

- Rizal MidtermsДокумент15 страницRizal MidtermsJerick JusayОценок пока нет

- Who Am I MemoДокумент2 страницыWho Am I Memoapi-652685391Оценок пока нет

- PRML 2022 EndsemДокумент3 страницыPRML 2022 EndsembhjkОценок пока нет

- 941112-001 Instal Q310 Rev4Документ72 страницы941112-001 Instal Q310 Rev4Sebin Kv0% (1)

- Abrasive Jet Machining Unit 2Документ7 страницAbrasive Jet Machining Unit 2anithayesurajОценок пока нет

- Performance-Based Engineering of Wood Frame Housing: Fragility Analysis MethodologyДокумент7 страницPerformance-Based Engineering of Wood Frame Housing: Fragility Analysis MethodologyJuanGrandonGoddardОценок пока нет

- Growth Mindset Intermediate Lesson Plans The Ned ShowДокумент16 страницGrowth Mindset Intermediate Lesson Plans The Ned ShowGôis Madson100% (2)

- Safety PledgeДокумент3 страницыSafety Pledgeapi-268778235100% (1)

- 4456 PDFДокумент978 страниц4456 PDFVentasVarias Antofa100% (1)

- Psycopathy Case StudyДокумент8 страницPsycopathy Case StudyNayab NoorОценок пока нет

- Project Risk ManagementДокумент104 страницыProject Risk Managementtsrinivasan5083Оценок пока нет

- Accomplishment Report FormДокумент43 страницыAccomplishment Report FormChristelle Mary SabanalОценок пока нет

- Multiphase FlowДокумент80 страницMultiphase FlowAnjo VasquezОценок пока нет

- University of Chicago Press Fall 2009 Distributed TitlesОт EverandUniversity of Chicago Press Fall 2009 Distributed TitlesРейтинг: 1 из 5 звезд1/5 (1)