Академический Документы

Профессиональный Документы

Культура Документы

Introduction To Profibus Profinet

Загружено:

soewinaungОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Introduction To Profibus Profinet

Загружено:

soewinaungАвторское право:

Доступные форматы

Introduction to PROFIBUS and

PROFINET

Andy Verwer

Technical Officer for PROFIBUS UK

Verwer Training & Consultancy Ltd

Gold distributor

Page 2 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

PROFIBUS Characteristics

PROFIBUS is a bi-directional digital communication

network for field devices.

Multi-drop network, many devices on one cable

communicates not only process values but also diagnostics,

device parameters, calibration and performance data etc.

The data can represent analogue values and/or

discrete (on/off) values.

But all data is digitally encoded and transmitted.

PROFIBUS is extensively specified.

All PROFIBUS devices are interoperable.

Multi vendor systems are easily constructed.

Best of breed devices can be selected.

Common set of tools for maintenance and engineering.

Page 3 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

PROFIBUS

PROFIBUS is the worlds leading fieldbus system:

Over 40 million devices installed world wide.

Approximately 3,000 products from over 300 different

suppliers.

PROFIBUS has been around for almost 25 years.

Over that period the specification has been extended and

refined (in a backwardly compatible way) so that new

application areas have been opened up.

High speed synchronised servo applications (Robotics and

NC machines).

Functional safety systems (process safety, interlocking).

Operation in hazardous environments (intrinsic safety).

High availability systems (reliability and redundancy).

Etc.

Page 4 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

The PROFIBUS Family

PROFIBUS DP - Decentralised Periphery

Low cost, simple, high speed field-level communications.

Generally designed for internal use

(cabinet mounting).

Page 5 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

The PROFIBUS Family

PROFIBUS PA - Process Automation

Developed specifically for the process industry to

replace 4-20mA transmission.

Two-wire connection carrying both power and data.

Generally designed for external use (field mounting).

Page 6 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

The PROFIBUS Family

PROFINET

Standardised Industrial Ethernet

High speed highly deterministic and capable networking.

Generally designed for internal use (just like DP)

Page 7 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Connection Technologies

PROFIBUS DP uses 2-core RS485

screened twisted pair wiring.

9-pin sub-D or M12 connectors

extensively used.

DP can also use plastic or glass fibre

optic cabling.

BFOC (ST) connectors widely used

PROFIBUS PA uses Manchester Bus

Powered (MBP) cabling over 2 cores.

Glanded screw or M12 connection

normally used

PROFINET uses 4-core Ethernet

sreened twisted pair cabling.

RJ45 or M12 connectors

universally used.

Page 8 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Application areas

Manufacturing Automation

Car manufacturing

Bottling systems

Storage systems

Robotics

Building Automation

Traffic automation

Heating, air-conditioning

Process Automation

Water and sewage treatment

Chemical and petrochemical plant

Paper and textile industries

Power industry

Power plants

Switchgear

Functional safety systems

High reliability systems

Redundancy.

Car manufacture

Water Treatment

and sewage

Bottling Plants

Pipelines

Paper and Printing

Industry

Food Industry

Polymer production

and Storage Robotics

Brewing industry

Gas & Oil

Building

Automation

Page 9 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

The PROFIBUS family

PROFIBUS DP

RS485 PROFIBUS PA - MBP

DP

cells

Actuators

Drives Transmitters Control

valves

Remote

I/O

Sensors

TCP/IP

Ethernet

Exi

HMI

Field level

Cell/control level

Factory/plant level

High speed,

modest data

Demanding tasks,

extensive data

PLC

PC

DP/PA coupler

Master

Slaves

Page 10 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

The PROFIBUS family

PROFIBUS DP PROFIBUS PA

DP

cells

Actuators

Drives Transmitters Control

valves

Remote

I/O

Sensors

TCP/IP

Ethernet

Exi

Field level

Cell/control level

Factory/plant level

High speed,

modest data

Demanding tasks,

extensive data

PLC

PC

PROFInet

Other

fieldbus

networks

AS-i

HMI

Page 11 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Class-2

master

Class-1

master

Levels of Access

Operator Manager

Control

Drives Instruments Valves Actuators

Engineer

Ethernet

PROFIBUS DP PROFIBUS PA

Monitoring Engineering

Page 12 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Levels of Access

Control

Requires regular cyclic update of process values.

Deterministic timing (not necessarily fast).

The most important cannot be interrupted!

Monitoring

Not necessarily regularly updated (cyclic or acyclic).

Interruptions can be tolerated.

Engineering

Active only when required (acyclic).

Non-deterministic communication OK.

But must not interrupt the above!

Page 13 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Class-1 Masters

The Class-1 master is responsible for cyclic or regular data

exchange. This provides all process values for control and

monitoring.

The Class-1 master must be configured to communicate

with the slaves.

Configuration is normally carried out using a proprietary

software tool supplied for the PROFIBUS master station.

All PROFIBUS equipment suppliers provide standard

General Station Description or GSD files.

GSD files can be read by the configuration tool to provide

detailed information on the devices being used on the bus.

GSD files make integration of devices from different

vendors in a bus system simple.

Page 14 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

GSD files

GSD GSD GSD GSD GSD

GSD

Master

Class I

PROFIBUS

Slaves

Configuration

tool

Network Configuration

Every PROFIBUS device is given a unique identification number

which identifies the type of device. The GSD file is specific to

the ID number.

Page 15 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Class-2 Masters

Class-2 masters can be used to access management

and engineering information from devices (acyclic

data).

This is particularly important in PA systems where

extensive device information can be accessed in a

standardised way.

Class-2 masters do not need configuration, however,

they do need information on the devices that are to be

accessed.

This information can be provided in two different

ways:

Electronic Device Descrition (EDD) files.

Device Type Manager (DTM) software.

Page 16 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

The PA Profile

The PROFIBUS PA Profile provides a mandatory

specification for all PA devices.

It specifies the organisation of the cyclic data so that

the process value for every device is standardised.

The Process Value is always communicated in a

standardised format:

Standard floating point format for analogue values.

Standard digital format for discrete values.

Plus a standardised status value which encodes the

quality of the measurement (good, bad, usable etc.)

The profile also specifies the organisation of the

acyclic data so that standard tools can be used to

access this data.

Page 17 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

What is PROFINET?

PROFINET is an open Industrial Ethernet standard

developed by the PROFIBUS Organisation.

PROFINET

is completely standard Ethernet (IEEE802.3).

operates at 100Mbit/s over twisted-pair copper or fibre-

optic cables,

makes use of TCP/IP and other IT standards for non-real-

time communications (i.e. configuration and parameters).

Provides a real-time channel for time-critical

communications (i.e. process data)

PROFINET is NOT PROFIBUS over Ethernet!

However, PROFINET is well thought out to

incorporate the requirements of modern systems

based on the lessons learned from PROFIBUS.

Page 18 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

PROFINET IO

PROFINET IO provides remote IO using Ethernet

connection and the PROFINET communication

protocol.

PROFINET IO uses Real-Time and Non Real-Time

communications.

PROFINET makes use of relevant TCP/IP protocols

for setup, configuration and maintenance functions:

DHCP Dynamic Host Configuration Protocol,

DNS Domain Name Service,

SNMP Simple Network Management Protocol,

ARP Address Resolution Protocol,

HTTP Web page access, and lots more!

Page 19 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

PROFINET

PROFINet stack

(OSI model):

Network

7 - Application Layer PROFINET Application Layer

6 - Presentation Layer

5 - Session Layer

4 - Transport Layer TCP/UDP

PROFINET

Real-time channel

3 - Network Layer IP

2 - Data Link Layer

Standard Fast Ethernet

IEEE802.3

1 - Physical layer

Non time-critical

communication

Real-time

communication

Page 20 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

PROFINET IO

The TCP/IP channel is used for non-time critical

tasks.

Downloading of configuration, parameters,

Diagnostics,

Device management information, etc.

The Real-Time channel is used for time-critical data:

Cyclic process data,

Alarms and critical messages,

Communication monitoring.

Page 21 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

PROFINET IO

Many features that have been developed for

PROFIBUS devices have been directly incorporated

into PROFINET:

Standardised module and channel-related diagnostics,

Alarm and status information,

Identification and Maintenance (I&M) functions,

Time stamping,

Highly deterministic process cycle timing

(Isochronous),

Device description file (GSD) with configuration data

for the device and available modules PROFINET uses

XML.

Page 22 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Integration with Fieldbus

PROFIBUS devices are widely used in many different

application areas.

This investment is protected with PROFINET for both

manufacturers and end-users.

PROFINET provides a transparent interface with

PROFIBUS via a standardised gateway or Proxy.

The Proxy is a PROFINET IO device on one side and a

PROFIBUS master on the other.

PROFIBUS Configuration is integrated into the

PROFINET configurator and is downloaded via

Ethernet.

Page 23 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

PROFIBUS DP

PROXY

PROFIBUS PA

INTERBUS-S

PROXY

PROFINET

Other fieldbusses?

Integration with Fieldbus

Page 24 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Some Myths about

PROFINET

PROFIBUS runs at up to 12Mbit/s, whereas

PROFINET runs at 100Mbit/s. Therefore

PROFINET is about 8 times faster than PROFIBUS.

NOT TRUE!

PROFINET gives similar performance to

PROFIBUS.

PROFINET will replace PROFIBUS in the next five

years.

NOT TRUE!

PROFINET will replace some PROFIBUS DP

devices, but PROFIBUS PA will continue.

Both DP and PA will be supported for many years

to come.

Page 25 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Some Myths about

PROFINET

PROFINET is not standard Ethernet

NOT TRUE!

PROFINET always uses completely standard

Ethernet. It just doesnt always use TCP/IP

protocols only used for non time critical

communications.

PROFINET systems can be maintained by our IT

people.

TRUE, BUT NOT A GOOD IDEA!

PROFINET is much more than just an IT network.

Real time determinism, reliability, device

diagnostics and security are all much more

important than on IT systems

Page 26 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Functional Safety with

PROFIBUS & PROFINET

PROFIBUS and PROFINET also offer safety oriented

communication that allows for integrating safety

oriented components.

A second 'safety fieldbus' is not necessary.

ProfiSafe V2 can be used in systems that are

certified according to IEC61158 to Safety Integrity

Level 3 (SIL3).

ProfiSafe is used in a wide range of applications:

Factory Automation, Robotics, Materials storage.

Process Automation, Gas & Oil

Page 27 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Functional Safety with

PROFINET

Standard

PROFIBUS/NET

protocol

Standard

application

Safety

application

PROFISAFE

layer

Standard

PROFIBUS/NET

protocol

Standard

application

Safety

application

PROFISAFE

layer

PROFINET/

PROFIBUS

Black-

channel

PROFIsafe

layer

PROFIsafe V2 provides functional safety for both PROFIBUS and

PROFINET systems.

Suitable for use in SIL3 applications.

Page 28 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Benefits of

PROFIBUS/PROFINET

Totally standardised and interoperable.

Choose best of breed devices.

Ensures compatibility.

Protects your investment.

Flexible connection technologies.

Systems for internal or external use

Saves wiring but things often go wrong!

Training in design and installation is essential.

Levels of access.

Control & monitoring.

Engineering and management information.

Page 29 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Training

A wide range of PROFIBUS and PROFINET training

is available including:

Certified Installer Courses

basic courses for anyone involved in PROFIBUS or

PROFINET technology

Commissioning & Maintenance training

Practical troubleshooting for PROFIBUS & PROFINET.

Certified PROFIBUS or PROFINET Engineer

In depth training for experts.

Certified System Design Course

Covers essential and optimal design of all networked control

and automation systems

Page 30 Introduction to PROFIBUS and PROFINET, Instrumentation & Offshore, Aberdeen, September 2012

Training

Certified PROFIBUS and PROFINET training is

available from the UKs accredited training centres:

PROFIBUS International Competence Centre

Manchester Metropolitan University.

in Manchester, or a location of your choice.

(www.sci-eng.mmu.ac.uk/ascent/).

PROFIBUS International Training Centre

Verwer Training & Consultancy Ltd

On-site training.

(www.VerwerTraining.com)

Вам также может понравиться

- AFD ControlДокумент20 страницAFD Controlgertibaj100% (1)

- BR Safety 2014 en PDFДокумент40 страницBR Safety 2014 en PDFDicky EkaОценок пока нет

- Catalog Sheet T550 UH50 enДокумент21 страницаCatalog Sheet T550 UH50 enbeanxinhОценок пока нет

- 3BDD015188 en G Freelance DCS Product CatalogДокумент164 страницы3BDD015188 en G Freelance DCS Product Catalogckati100% (1)

- Poster MV Drives Drives For Every Demand 2017 enДокумент24 страницыPoster MV Drives Drives For Every Demand 2017 ensykimk8921Оценок пока нет

- Cat 620 PDFДокумент48 страницCat 620 PDFVictor BugrovОценок пока нет

- V20 LaunchedДокумент147 страницV20 LaunchedNguyễn Viết HùngОценок пока нет

- Programming Guideline DOC v15 en PDFДокумент120 страницProgramming Guideline DOC v15 en PDFjuneОценок пока нет

- How Do You Establish A Modbus - TCP Communication From A SIMATIC S7-300 - S7-400 and W... - ID - 22660304 - Industry Support SiemensДокумент2 страницыHow Do You Establish A Modbus - TCP Communication From A SIMATIC S7-300 - S7-400 and W... - ID - 22660304 - Industry Support Siemensshashank PathakОценок пока нет

- SIMATIC PCS 7 Cabinet Design: 6/2 6/2 6/3 Basic Cabinet 6/4 ET 200M I/O Unit 6/5 System UnitДокумент6 страницSIMATIC PCS 7 Cabinet Design: 6/2 6/2 6/3 Basic Cabinet 6/4 ET 200M I/O Unit 6/5 System UnitadelswedenОценок пока нет

- Basics of Profibus Operation Chapter1Документ20 страницBasics of Profibus Operation Chapter1kerusacba_2011Оценок пока нет

- Modbus EthernetДокумент47 страницModbus EthernetJeniffer Pozo100% (1)

- Hardware Installation PDFДокумент480 страницHardware Installation PDFRigoberto HerreraОценок пока нет

- Siemens s7 Mpi ManualДокумент16 страницSiemens s7 Mpi ManualhashempourОценок пока нет

- Simotion DДокумент3 страницыSimotion DHernan GardiazabalОценок пока нет

- Converting Primary/Secondary Chilled Water Systems To All Variable FlowДокумент4 страницыConverting Primary/Secondary Chilled Water Systems To All Variable Flowpitong_manningОценок пока нет

- SCHNEIDER Pricelist Mar2018Документ70 страницSCHNEIDER Pricelist Mar2018MuhammadFajarОценок пока нет

- Omron NBДокумент192 страницыOmron NBmodelador3dОценок пока нет

- Dvp-Plc-Program o en 20101119Документ618 страницDvp-Plc-Program o en 20101119Mohammed MagdyОценок пока нет

- Allen Bradley Micrologix Data LoggingДокумент16 страницAllen Bradley Micrologix Data LoggingwaltonchungОценок пока нет

- AVEVA E3D2.1 - Supports Administration - LUIGIДокумент183 страницыAVEVA E3D2.1 - Supports Administration - LUIGIalessioОценок пока нет

- Interface Technology Engineer S Guide PDFДокумент162 страницыInterface Technology Engineer S Guide PDFJerry AramburoОценок пока нет

- Pds Deltav Sis CslsДокумент57 страницPds Deltav Sis CslslimresОценок пока нет

- Simatic Pcs7 BoxДокумент4 страницыSimatic Pcs7 BoxRaj ChavanОценок пока нет

- 6ra70 PDFДокумент232 страницы6ra70 PDFChowdary MnchowdaryОценок пока нет

- Delta Ia-Plc DVP-20PM PM en 20140212Документ580 страницDelta Ia-Plc DVP-20PM PM en 20140212Nguyen Quang DoanОценок пока нет

- s71200 System Manual en-US en-USДокумент1 352 страницыs71200 System Manual en-US en-USHoàng BửuОценок пока нет

- Siemens S7200 Modbus GuideДокумент6 страницSiemens S7200 Modbus GuideVinothОценок пока нет

- Modbus TCP PN CPU EnglishДокумент64 страницыModbus TCP PN CPU Englishgeorgel1605Оценок пока нет

- PID Modullar ControllerДокумент200 страницPID Modullar ControllerMohamed ElsayedОценок пока нет

- Silworx First Steps - Katalog4438Документ222 страницыSilworx First Steps - Katalog4438Jorge LuisОценок пока нет

- PLC K SaraswathiДокумент105 страницPLC K SaraswathiKoushik SgОценок пока нет

- GH Cp343-1ex30 76Документ67 страницGH Cp343-1ex30 76KoertBОценок пока нет

- s71200 System Manual en-US en-US PDFДокумент1 328 страницs71200 System Manual en-US en-US PDFVanessa Soria100% (1)

- Ois 40 Series Hardware Iioic43Документ79 страницOis 40 Series Hardware Iioic43buianhtuan1980Оценок пока нет

- Vav SystemsДокумент4 страницыVav SystemsJesus RoldanОценок пока нет

- DCS Practical 4Документ3 страницыDCS Practical 4Vj NadarОценок пока нет

- GFK1533-VersaMax DeviceNet Communication ModulesДокумент54 страницыGFK1533-VersaMax DeviceNet Communication ModulesSantosh GopalОценок пока нет

- h3ct 5uДокумент2 страницыh3ct 5uSampath KumarОценок пока нет

- PCS 7 Gas Turbine DCSДокумент2 страницыPCS 7 Gas Turbine DCSDr. Mohamed E. HarbОценок пока нет

- SIPROTEC4 PROFIBUS DP ServiceInfo Optical en PDFДокумент7 страницSIPROTEC4 PROFIBUS DP ServiceInfo Optical en PDFJorge MaloneОценок пока нет

- Air Conditioning: Web Interface BoardДокумент38 страницAir Conditioning: Web Interface BoardWahida BenzaОценок пока нет

- How To Make Your PLC System For DummiesДокумент36 страницHow To Make Your PLC System For Dummiesdavid carrilloОценок пока нет

- 30RBM-30RBP Chiller PSD PDFДокумент38 страниц30RBM-30RBP Chiller PSD PDFBilguun BurenjargalОценок пока нет

- OPC Server Help ManualДокумент8 страницOPC Server Help ManualSupriya Rohit Deshpande-BhurkeОценок пока нет

- Basic Programming Simatic S7-300Документ40 страницBasic Programming Simatic S7-300Mst ThangarajuОценок пока нет

- 2.7-3502-0001 Insulation Resistance Test Slip RingДокумент1 страница2.7-3502-0001 Insulation Resistance Test Slip RingSuresh RamanujaluОценок пока нет

- DV DVW Series - Catalog - For 2015Документ39 страницDV DVW Series - Catalog - For 2015adeel_akhtarОценок пока нет

- InTouch Version 10 Service Pack 2 ReadmeДокумент7 страницInTouch Version 10 Service Pack 2 ReadmevishadkapadiaОценок пока нет

- Simaticpcs7 Stpcs7 Complete English 2010 02Документ404 страницыSimaticpcs7 Stpcs7 Complete English 2010 02Eliud RodriguezОценок пока нет

- Introduction To Profibus ProfinetДокумент31 страницаIntroduction To Profibus ProfinetSyariefОценок пока нет

- 02 PROFIBUS Technical PDFДокумент31 страница02 PROFIBUS Technical PDFGonzalo Fernández LemosОценок пока нет

- Infoplc Net Curso Profibus 1Документ18 страницInfoplc Net Curso Profibus 1Jair malandrinОценок пока нет

- Interfacecomponent SiemensДокумент16 страницInterfacecomponent Siemenssteam100deg1658Оценок пока нет

- Profibus Communication Interview Questions & Answers Instrumentation ToolsДокумент19 страницProfibus Communication Interview Questions & Answers Instrumentation ToolsProcurement PardisanОценок пока нет

- Introduction To Profibus & ProfinetДокумент15 страницIntroduction To Profibus & ProfinetAshish PatwardhanОценок пока нет

- Profibus Vs ProfinetДокумент6 страницProfibus Vs ProfinetmichaelОценок пока нет

- How To Use This TemplateДокумент7 страницHow To Use This TemplatesoewinaungОценок пока нет

- FlexZone Product Guide G6DA0102 EN PDFДокумент102 страницыFlexZone Product Guide G6DA0102 EN PDFsoewinaungОценок пока нет

- cUSTOMS tARIFF OF mYANMARДокумент729 страницcUSTOMS tARIFF OF mYANMARsoewinaung100% (1)

- IO Addressing Format in Omron PLCДокумент2 страницыIO Addressing Format in Omron PLCsoewinaungОценок пока нет

- User Manual PDFДокумент544 страницыUser Manual PDFsoewinaungОценок пока нет

- Difference Between GX Work-2 and GX DeveoperДокумент9 страницDifference Between GX Work-2 and GX DeveopersoewinaungОценок пока нет

- FAQ 28 How To Use VNC ServerДокумент1 страницаFAQ 28 How To Use VNC ServersoewinaungОценок пока нет

- 7.2.8 Packet Tracer - Verify IPv4 and IPv6 AddressingДокумент3 страницы7.2.8 Packet Tracer - Verify IPv4 and IPv6 AddressingBarry NgoОценок пока нет

- Stentofon Pulse: IP Based Intercom SystemДокумент22 страницыStentofon Pulse: IP Based Intercom SystemCraigОценок пока нет

- Spoto Ccie Lab Rs v5.0 h3 Diag Version 1.1Документ3 страницыSpoto Ccie Lab Rs v5.0 h3 Diag Version 1.1Mike CoolОценок пока нет

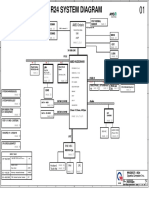

- R24 System Diagram: AMD OntarioДокумент36 страницR24 System Diagram: AMD OntarioRicardo SilvaОценок пока нет

- An Energy-Efficient Routing Protocol For The Internet of Things Networks Based On Geographical Location and Link QualityДокумент13 страницAn Energy-Efficient Routing Protocol For The Internet of Things Networks Based On Geographical Location and Link QualityHanaw BabashexОценок пока нет

- Cisco Catalyst 3750 QoS Configuration ExamplesДокумент35 страницCisco Catalyst 3750 QoS Configuration ExamplesGilles de PaimpolОценок пока нет

- Sublime Analog VideoДокумент34 страницыSublime Analog VideokarkeraОценок пока нет

- Hillstone VFW CloudEdge V5.5R8 ENДокумент4 страницыHillstone VFW CloudEdge V5.5R8 ENGustavo SantosОценок пока нет

- 5.1.4.3 Lab - Using Wireshark To Examine Ethernet FramesДокумент7 страниц5.1.4.3 Lab - Using Wireshark To Examine Ethernet FramesBenjamin Gm100% (4)

- 191-2000139 Aont1521 Product BriefДокумент2 страницы191-2000139 Aont1521 Product BriefSachin PatilОценок пока нет

- Deploying IP MPLS VPNsДокумент127 страницDeploying IP MPLS VPNsnits123100% (1)

- DT DTA Guidelines 20190122Документ9 страницDT DTA Guidelines 20190122Mohammad AftonОценок пока нет

- The Difference Between API Gateways and Service MeshДокумент26 страницThe Difference Between API Gateways and Service MeshchmorenorОценок пока нет

- SPC-6000 SPC 6000 Quick Set-Up Guide: Technical InformationДокумент6 страницSPC-6000 SPC 6000 Quick Set-Up Guide: Technical InformationOrlando BarretoОценок пока нет

- Datasheet Next Gen Firewall enДокумент6 страницDatasheet Next Gen Firewall enCharlesОценок пока нет

- Xirrus XR Series Array GuideДокумент250 страницXirrus XR Series Array GuideSteve AttwoodОценок пока нет

- Etherhaul™-1200Tl E-Band Radio: 700 Mbps Aggregated Carrier Grade, Best ValueДокумент2 страницыEtherhaul™-1200Tl E-Band Radio: 700 Mbps Aggregated Carrier Grade, Best ValueVanek505Оценок пока нет

- LLDP-MED and Cisco Discovery ProtocolДокумент13 страницLLDP-MED and Cisco Discovery ProtocolPhụng TỷОценок пока нет

- AIR Broadband ISAM Präsentation PDFДокумент38 страницAIR Broadband ISAM Präsentation PDFyouvsyouОценок пока нет

- 4.LTE Physical Layer ProcedureДокумент82 страницы4.LTE Physical Layer ProcedureTri Frida Ningrum100% (1)

- TL-SF1016D (Un) 5.0 PDFДокумент2 страницыTL-SF1016D (Un) 5.0 PDFdarkwolfbrОценок пока нет

- G7 WORKSHEET ICT Week 5 NEWДокумент4 страницыG7 WORKSHEET ICT Week 5 NEWEbb Lian AninoОценок пока нет

- Cisco Campus Fabric IntroductionДокумент65 страницCisco Campus Fabric IntroductionJohn LegendОценок пока нет

- Ar-2gm GPS TrackerДокумент2 страницыAr-2gm GPS TrackerOscar RamirezОценок пока нет

- 2013 - Usa - PDF - BRKCRS-3142 - Troubleshooting Cisco Catalyst 4500 Series SwitchesДокумент103 страницы2013 - Usa - PDF - BRKCRS-3142 - Troubleshooting Cisco Catalyst 4500 Series SwitchesCamilogbОценок пока нет

- OrbitMCR900 GEA12812Документ4 страницыOrbitMCR900 GEA12812Lan DraОценок пока нет

- LOGSДокумент18 страницLOGSguerrerokarina276Оценок пока нет

- Tdma FdmaДокумент15 страницTdma FdmaabenrajaОценок пока нет

- Seminar On Ipv6: Presented By:-Pranay Prakhar B.Tech Sem-Vii Comp-Ii Roll No - 11 Under Guidance Of: - Mr. U.C.PatkarДокумент16 страницSeminar On Ipv6: Presented By:-Pranay Prakhar B.Tech Sem-Vii Comp-Ii Roll No - 11 Under Guidance Of: - Mr. U.C.PatkarPranay PrakharОценок пока нет

- 100 COMPUTER NETWORKS Multiple Choice Questions and AnswerДокумент17 страниц100 COMPUTER NETWORKS Multiple Choice Questions and AnswervinodОценок пока нет