Академический Документы

Профессиональный Документы

Культура Документы

Par-Test: Fluid Analysis

Загружено:

llereador0 оценок0% нашли этот документ полезным (0 голосов)

39 просмотров6 страницFluid Analysis has proven to be a critical tool for any preventive maintenance program. Fluid Analysis is able to identify potential problems that cannot be detected by human senses. Fluid sampling for Par-Test involves important steps to insure you are getting a representative sample.

Исходное описание:

Оригинальное название

ParkerTest.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документFluid Analysis has proven to be a critical tool for any preventive maintenance program. Fluid Analysis is able to identify potential problems that cannot be detected by human senses. Fluid sampling for Par-Test involves important steps to insure you are getting a representative sample.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

39 просмотров6 страницPar-Test: Fluid Analysis

Загружено:

llereadorFluid Analysis has proven to be a critical tool for any preventive maintenance program. Fluid Analysis is able to identify potential problems that cannot be detected by human senses. Fluid sampling for Par-Test involves important steps to insure you are getting a representative sample.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

Par-Test

Fluid Analysis

195

Fluid Analysis

Par-Test

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

196

Water Base Kit

Particle Count

Photomicrograph

Spectrometric Analysis

Viscosity Analysis

Neutralization Analysis

Petroleum Base Kit

Particle Count

Photomicrograph

Free Water Analysis

Spectrometric Analysis

Viscosity Analysis

Water Analysis (PPM)

Neutralization Analysis

Petroleum base fluid kit

(single test bottle) 927292

Petroleum base fluid kit

(Carton of 10 test bottles) 927293

Water base fluid kit

(single test bottle) 932995

How to Order

Description Part Number

Fluid analysis has proven to be a critical tool for

any preventive maintenance program. Fluid analysis

is able to identify potential problems that cannot be

detected by human senses. A comprehensive fluid

analysis program can

help prevent major

hydraulic or lube oil

system failures.

Par-Test is a

complete laboratory

analysis, performed

on a small volume of

fluid. The report you

receive is a neatly

organized three page

format. One may quickly

analyze the test results of an

individual sample and/or look at a trend

analysis for up to five different samples. Two types

of services are offered through Par-Test, a water

base fluid analysis kit or a petroleum base fluid

analysis kit. For both types of services the Par-Test

kit includes a pre-cleaned glass bottle, mailing

container with pre-addressed label, sample

information data sheet (to be completely filled

out by end user) and the following analysis:

Fluid sampling for Par-Test involves important

steps to insure you are getting a representative

sample. Often, erroneous sample procedures will

disguise the true nature of the system fluid. A

complete sampling

procedure is detailed

on the back of this

brochure. There also is

a National Fluid Power

Association standard

(NFPA T2.9.1-1972)

and an American

National Standards

Institute Standard

(ANSI B93.13-1972)

for extracting samples

from a fluid power system.

Fluid Analysis

Par-Test

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

197

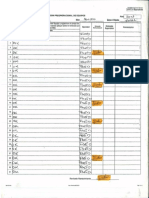

FLUID ANALYSIS REPORT

SAMPLE DATA

COMPANY NAME: XYZ Corporation

SYSTEM TYPE: Hydraulic System

EQUIPMENT TYPE: LOADER

MACHINE ID: x1111

FILTER ID:

SAMPLE DATE: 06-01-94

HOURS (on oil/unit): 100 / 100

SYSTEM VOLUME: 20 L

FLUID TYPE: CITGO AW 46

ANALYSIS PERFORMED: AI-BSTV4 (W)

Cleanliness

Code

Size Counts per ml.

> 2 m 353242.0

> 5 m 34434.0

> 10 m 2342.0 26/22/14

> 15 m 154.0

> 25 m 17.0

> 50 m 1.0

YES

NO X

PARTEST Fluid Analysis Service

Parker Hannifin Corporation

16810 Fulton County Road #2

Metamora, OH 43540

Tele:(419)644-4311

Fax:(419)644-6205

SAMPLE CODE: 1034 DATE: 06-01-94

XYZ Corporation

12345 Middleton Rd.

Anywhere USA 41114

Attn:

SIZE (microns)

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

2 5 10 15 20 25 30 40 50 60 80 100

107

5.0

4.0

3.0

2.0

1.5

106

5.0

4.0

3.0

2.0

1.5

105

5.0

4.0

3.0

2.0

1.5

104

5.0

4.0

3.0

2.0

1.5

103

5.0

4.0

3.0

2.0

1.5

102

5.0

4.0

3.0

2.0

1.5

101

5.0

4.0

3.0

2.0

1.5

100

5.0

4.0

3.0

2.0

1.5

10-1

5.0

4.0

3.0

2.0

1.5

10-2

N

u

m

b

e

r

o

f

p

a

r

t

i

c

l

e

s

p

e

r

m

l

>

s

i

z

e

ISO CHART

RANGE

CODE

ISO Chart

Graphically illustrates

the particle count on a

graph. The recommended

cleanliness code level, if

given on the submittal

form, is shown by a broken

line on the ISO chart.

Sample Data

Information supplied by the

user regarding the fluid to

be analyzed. Complete and

accurate information is

crucial for a useful analysis.

Particle Count

Results are reported over

6 different particle size

ranges and expressed as

an ISO code (modified).

The counts are per milliliter

of fluid and the reporting is

cumulative; ie. The particle

count in the >2 micron row

includes the number of

particles greater than 5, 10,

15, 25 and 50 microns as

well as particles between

2-5 microns in size. Particle

resuspension method is

utilized for water based

fluid samples.

Free Water Analysis

Determines if the water

present is beyond the

saturation point of the

fluid. At the saturation

point, the fluid can no

longer dissolve or hold any

more water. Its appearance

becomes cloudy or milky.

Many hydraulic oils saturate

between 500 and 1000 PPM

of water.

Photo Analysis

A photomicrograph of a small

volume of fluid (20 ml) magnified

100X. This analysis gives a quick

glance at the contamination

present in the fluid. Each line

of the graduated scale represents

20 microns in size.

The full color photomicrograph

helps identify particles which

would otherwise be grouped

by class.

WARNING

1. The recommended CLEANLINESS Code is not met. Clean-up

maintenance may be warrant.

2. Dotted graph line indicates recommended ISO Code level.

PHOTO ANALYSIS

Mag.: 100x Vol.: 20 ml Scale: 1 div = 20 m

REMARKS REMARKS REMARKS REMARKS REMARKS

AUTOMATIC PARTICLE COUNT SUMMARY FREE FREE FREE FREE FREE

W WW WWA AA AATER TER TER TER TER

PRESENT PRESENT PRESENT PRESENT PRESENT

Fluid Analysis

Par-Test

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

198

FLUID ANALYSIS REPORT

SAMPLE CODE:1034 DATE: 06-01-94

XYZ Corporation

12345 Middleton Rd.

Anywhere USA 41114

Attn:

PARTEST Fluid Analysis Service

Parker Hannifin Corporation

16810 Fulton County Road #2

Metamora, OH 43540

Tele:(419)644-4311

Fax:(419)644-6205

SSU @ 100 F: 100.0 CST @ 40c: 21.6

Water Content (ppm): 101.0

TAN: 0.1

1) Please check spectrometric analysis for

abnormal conditions

IRON 120.0 H

COPPER 510.0 H

CHROMIUM < 1.0 N

LEAD < 1.0 N

ALUMINUM 1.0 N

TIN < 1.0 N

SILICON < 1.0 N

ZINC 423.0 N

MAGNESIUM < 1.0 N

CALCIUM 540.0 H

PHOSPHORUS 10.0 L

BARIUM 1.0 N

BORON < 1.0 N

SODIUM < 1.0 N

MOLYBDENUM < 1.0 N

SILVER < 1.0 N

NICKEL < 1.0 N

TITANIUM < 1.0 N

MANGANESE < 1.0 N

ANTIMONY < 1.0 N

WEAR METALS

AND ADDITIVES

PPM BY WEIGHT STATUS*

* These levels are based on average industry stan-

dards and may not be applicable to your particular

system.

Viscosity Analysis

Viscosity is a very important pro-

perty of a fluid in terms of system

performance. Viscosity expresses

the internal friction between mole-

cules in the fluid. Typically a break-

down in viscosity will be seen as

an increase. Both SSU at 100 F

and cSt at 40 C are reported.

Water Analysis

Karl Fischer test gives accurate

measure of water concentration

in the sample fluid. The results

are reported in parts per million

(PPM) and allow for detection

of water levels well below the

saturation point.

Neutralization Analysis

Referred to as the Total Acid

Number (TAN) this titration test

measures the acid level of the

sample fluid. The production of

acidic material causes oxidation

degradation or aging of most fluids.

This activity is promoted by elevat-

ed temperatures, presence of

entrained metal particles, and inti-

mate contact with air. It is the rate

of increase of the TAN during any

given time period that is significant,

not just the absolute value.

Remarks

Quick statements or alerts about

any unusual results from one of the

tests reported on this page.

Spectrometric Analysis

Results obtained by Rotating Disk

Electrode (ROE) Spectrometer and

reported in terms of parts per mil-

lion (PPM). Twenty different wear

metals and additives are analyzed

to help determine the condition of

the fluid. The spectrometric test is

limited to identifying particles

below 5-7 micron in size. Base line

(new) fluid samples should be sent

in for each different fluid to be

analyzed. This will be used to

determine the status.

Iron: Ferrous wear particle typically from

pumps, gears, cylinders, or rust

Copper: Brass (copper/zinc) and bronze

(copper/tin) in bearings and bushings

Chromium: (white non ferrous metal) Chrome

from cylinder rods, bearings, valve spools

Lead: Babbitt or copper lead bearings

Aluminum: White nonferrous metal from

pump bodies, bushings, bearings, and

grinding compounds

Tin: Babbitt bearings, plating

Silicon: Sand/dirt contamination or

antifoaming additive in oil

Zinc: Plating or anti-wear additive in oil

Magnesium: Detergent, dispersive additive in

oil, bearings, water

Calcium: Dispersant additive or acid

neutralizer

Phosphorous: Anti-wear or fire resistant

additive in fluid

Barium: Corrosion, rust inhibitor additive in oil

Boron: Detergent, dispersive additive in oil

Sodium: Detergent or coolant additive

Molybdenum: Alloy metal or anti friction

additive

Silver: White non ferrous metal

Nickel: Alloy metal

Titanium: White non ferrous metal

Manganese: White non ferrous metal

Antimony: Babbit bearings, greases

WEAR METALS AND ADDITIVES

SPECTROMETRIC ANALYSIS

L = LOW N = NORMAL H= HIGH

Viscosity Analysis - ASTM D445

Water Analysis - ASTM D1744

Neutralization Analysis - ASTM D794

REMARKS

Fluid Analysis

Par-Test

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

199

> 2m -

> 5m -

> 15m -

FLUID ANALYSIS REPORT

Legend

N

U

M

B

E

R

O

F

P

A

R

T

I

C

L

E

S

P

E

R

M

I

L

L

I

T

E

R

Page 3 of 3

DATE 04/11/94 4/30/94 05/24/94 06/01/94

PARTICLES>2 MICRONS 134444.0 214334.0 315543.0 353242.0

PARTICLES>5 MICRONS 10000.0 20222.0 32143.0 34434.0

PARTICLES>15 MICRONS 122.0 100.0 130.0 154.0

CLEANLINESS CODE 24/20/14 25/22/14 25/22/14 26/22/14

SAMPLECODE 1031 1032 1033 1034

REMARKS

107

5.0

4.0

3.0

2.0

1.5

106

5.0

4.0

3.0

2.0

1.5

105

5.0

4.0

3.0

2.0

1.5

104

5.0

4.0

3.0

2.0

1.5

103

5.0

4.0

3.0

2.0

1.5

102

5.0

4.0

3.0

2.0

1.5

101

5.0

4.0

3.0

2.0

1.5

100

5.0

4.0

3.0

2.0

1.5

10-1

5.0

4.0

3.0

2.0

1.5

10-2

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

RANGE

CODE

Range Code More than Up to and including

30 5,000,000 10,000,000

29 2,500,000 5,000,000

28 1,300,000 2,500,000

27 640,000 1,300,000

26 320,000 640,000

25 160,000 320,000

24 80,000 160,000

23 40,000 80,000

22 20,000 40,000

21 10,000 20,000

20 5,000 10,000

19 2,500 5,000

Range Code More than Up to and including

18 1,300 2,500

17 640 1,300

16 320 640

15 160 320

14 80 160

13 40 80

12 20 40

11 10 20

10 5 10

9 2.5 5

8 1.3 2.5

7 .64 1.3

6 .32 .64

Trend Analysis

Graphical history for up to

5 samples plotted for 2, 5

and 15 micron and greater

size particles. This analysis

is a valuable tool for tracking

the progress of a system

over a given time period.

Sample Code

Assigned to the test kit form

for a ready reference. This

code can be used to track the

sample from start to finish.

ISO Range Code

Index Number that is

associated with a range

of particles. Below is a list

of the range numbers and

the corresponding particle

quantities.

NUMBER OF PARTICLES PER ML

Fluid Analysis

Par-Test

Parker Hannifin Corporation

Hydraulic Filter Division

Metamora, OH

200

SAMPLING PROCEDURE

Obtaining a fluid sample for analysis

involves important steps to make

sure you are getting a representative

sample. Often erroneous sampling

procedures will disguise the true

nature of system cleanliness levels.

Use one of the following methods to

obtain a representative system sample.

I. For systems with a

sampling valve

A. Operate system for at least

1/2 hour.

B. With the system operating, open

the sample valve allowing 200 ml

to 500 ml (7 to 16 ounces) of

fluid to flush the sampling port.

(The sample valve design should

provide turbulent flow through

the sampling port.)

C. Using a wide mouth, pre-cleaned

sampling bottle, remove the bottle

cap and place in the stream of

flow from the sampling valve. Do

NOT rinse out the bottle with

initial sample.

D. Close the sample bottle immediate-

ly. Next, close the sampling valve.

(Make prior provision to catch

the fluid while removing the bottle

from the stream.)

E. Tag the sample bottle with pertinent

data; include date, machine

number, fluid supplier, fluid number

code, fluid type, and time elapsed

since last sample (if any).

II. Systems without a

sampling valve

There are two locations to obtain

a sample in a system without a

sampling valve: in-tank and in the

line. The procedure for both follows:

A. In the Tank Sampling

1. Operate the system for at least

1/2 hour.

2. Use a small hand-held vacuum

pump to extract sample. Insert

sampling device into the tank to

one half of the fluid height. You

will probably have to weight the

end of the sampling tube. Your

objective is to obtain a sample

in the middle portion of the tank.

Avoid the top or bottom of the

tank. Do not let the syringe or

tubing came in contact with the

side of the tank.

3. Put extracted fluid into an

approved, pre-cleaned sample

bottle as described in the previous

sampling valve method.

4. Cap immediately.

5. Tag with information as described

in sampling valve method.

B. In-line Sampling

1. Operate the system for at least

1/2 hour.

2. Locate a suitable valve in the

system where turbulent flow

can be obtained (ball valve is

preferred). If no such valve exists,

locate a fitting which can be easily

opened to provide turbulent flow

(tee or elbow).

3. Flush the valve or fitting sample

point with a filtered solvent. Open

valve or fitting and allow adequate

flushing. (Take care to allow for this

step. Direct sample back to tank or

into a large container. It is not nec-

essary to discard this fluid.)

4. Place in an approved, pre-cleaned

sample bottle under the stream of

flow per sampling valve methods.

5. Cap sample bottle immediately.

6. Tag with important information

per the sampling valve method.

Note: Select a valve or fitting

where the pressure is limited to

200 PSIG (14 bar) or less.

PLC-3000

ON-SITE FLUID ANALYSIS PRODUCT

Вам также может понравиться

- Oil AnalysisДокумент6 страницOil AnalysisVinicius SantosОценок пока нет

- Flowmeters & MonitorsДокумент12 страницFlowmeters & MonitorshotnatkapoorОценок пока нет

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceОт EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceОценок пока нет

- Hydraulic Oil Analysis: Monitor System Health and Detect ContaminationДокумент4 страницыHydraulic Oil Analysis: Monitor System Health and Detect Contaminationاتعلم ببساطةОценок пока нет

- Guide To Contamination StandardsДокумент12 страницGuide To Contamination StandardsFaizanОценок пока нет

- Eaton Internormen Condition Monitoring SystemsДокумент16 страницEaton Internormen Condition Monitoring SystemsEaton FiltrationОценок пока нет

- ELE Chemicals Rev 1Документ21 страницаELE Chemicals Rev 1diaccessltd_17172961Оценок пока нет

- Produced Water Chemical Treatment 101Документ6 страницProduced Water Chemical Treatment 101ImranShahzadkhanОценок пока нет

- 06 Oil AnalysisДокумент70 страниц06 Oil Analysissriabolfazl100% (8)

- Analyzer 204 V PDFДокумент2 страницыAnalyzer 204 V PDFLuis Cervantes BarradasОценок пока нет

- FanPro Special Tests Brochure IIДокумент8 страницFanPro Special Tests Brochure IIsubrahmanyam.knvОценок пока нет

- Unit ID: Fu1 Ops: Overall Condition RatingДокумент6 страницUnit ID: Fu1 Ops: Overall Condition RatingmanavjhplОценок пока нет

- Datasheet - Fluidscan Q1100Документ2 страницыDatasheet - Fluidscan Q1100ClydeA.SardoncilloОценок пока нет

- Water&Food AnalysisДокумент156 страницWater&Food AnalysisCorina StanculescuОценок пока нет

- Technical Service Bulletin Re-Print From Baldwin Filter CompanyДокумент2 страницыTechnical Service Bulletin Re-Print From Baldwin Filter Companyvoyager1Оценок пока нет

- Water and Food Analytics Catalogue - 2012 Merck PDFДокумент160 страницWater and Food Analytics Catalogue - 2012 Merck PDFtahirbchОценок пока нет

- Fluid purification solution for hydraulic oils, lubricants and coolant fluidsДокумент8 страницFluid purification solution for hydraulic oils, lubricants and coolant fluidshaggОценок пока нет

- Sensors Case StudiesДокумент36 страницSensors Case StudiesdarmawanpnОценок пока нет

- Amine Basic Practices Guideline PDFДокумент64 страницыAmine Basic Practices Guideline PDFrajeshpillai26787Оценок пока нет

- ATL AДокумент3 страницыATL AMelis AvşarОценок пока нет

- Separator PDSДокумент7 страницSeparator PDSprabhuarunkumarОценок пока нет

- Control de La Contaminacion CaterpillarДокумент7 страницControl de La Contaminacion Caterpillarnikle_DОценок пока нет

- OSCAR-III Treatment System O& M And: Troubleshooting Manual January 2019Документ14 страницOSCAR-III Treatment System O& M And: Troubleshooting Manual January 2019hard1833Оценок пока нет

- Axeon Mktf-112 m1 PB LRДокумент4 страницыAxeon Mktf-112 m1 PB LRSohail HanifОценок пока нет

- Bombas InyectorasДокумент653 страницыBombas InyectorasANDRESОценок пока нет

- ASTM MNL 2 Manual On Vapor Degreasing 3rd EditionДокумент50 страницASTM MNL 2 Manual On Vapor Degreasing 3rd Edition320338100% (2)

- Oil Sample GuideДокумент16 страницOil Sample GuideMike RosemanОценок пока нет

- Basics of FiltersДокумент22 страницыBasics of FiltersneilstarОценок пока нет

- Cooling System Maintenance For Heavy Duty Engines: Technical Service Bulletin 88-1Документ3 страницыCooling System Maintenance For Heavy Duty Engines: Technical Service Bulletin 88-1Agus Setiawan Feat AvrОценок пока нет

- 06 Oil AnalysisДокумент70 страниц06 Oil AnalysisJo JoОценок пока нет

- F-801 Portable: Reverse Osmosis System 1580 Ml/minДокумент2 страницыF-801 Portable: Reverse Osmosis System 1580 Ml/mineduardoОценок пока нет

- Hydraulic Fluid Care GuideДокумент16 страницHydraulic Fluid Care GuidegabrieljuarezgОценок пока нет

- Recycling Engine CoolantДокумент9 страницRecycling Engine CoolantYendi Kesuma100% (1)

- Unit ID: Fu1 Ugb: Overall Condition RatingДокумент6 страницUnit ID: Fu1 Ugb: Overall Condition RatingmanavjhplОценок пока нет

- 5200 Trivector Analyzer: Machinery Health ManagementДокумент4 страницы5200 Trivector Analyzer: Machinery Health ManagementJunaid KhurshidОценок пока нет

- Project Standards and Specifications Crude Desalter Systems Rev01Документ6 страницProject Standards and Specifications Crude Desalter Systems Rev01muhammad_asim_10Оценок пока нет

- Hydraulic ContaminationДокумент5 страницHydraulic Contamination1sympatyagaОценок пока нет

- Reducing Particulate Emissions with a TurboVenturi ScrubberДокумент10 страницReducing Particulate Emissions with a TurboVenturi Scrubberjosedalceggio1955Оценок пока нет

- Amine Basis GuidelinesДокумент63 страницыAmine Basis Guidelinesgion_ro401Оценок пока нет

- Ifpm 71Документ2 страницыIfpm 71Anshuman AgrawalОценок пока нет

- 064640Документ314 страниц064640venalum90Оценок пока нет

- Turbine Oil Condition Monitoring Training GuideДокумент8 страницTurbine Oil Condition Monitoring Training Guidemauriciojj100% (1)

- CA-6 Colorimetric Analyzer: Lectro-Hemical EvicesДокумент18 страницCA-6 Colorimetric Analyzer: Lectro-Hemical EvicesSrinivasarao YenigallaОценок пока нет

- Filter Bodies EtcДокумент34 страницыFilter Bodies EtcpulilathaОценок пока нет

- Rexroth Oil Cleanliness Booklet PDFДокумент44 страницыRexroth Oil Cleanliness Booklet PDFJairoHernanLopera100% (1)

- Adv 885 Ro Pac M QuickrefguideДокумент8 страницAdv 885 Ro Pac M QuickrefguideAlejandroOdioCastilloОценок пока нет

- K & T Style Hydraulic System Test Analysers - ManualДокумент16 страницK & T Style Hydraulic System Test Analysers - Manualpravesh bhartiОценок пока нет

- Bay-Tech 2103 CatalogДокумент226 страницBay-Tech 2103 CatalogoxysubОценок пока нет

- Wearcheck Oil Analysis ReportДокумент2 страницыWearcheck Oil Analysis Reportapi-105696388100% (1)

- Rexroth Oil Cleanliness BookletДокумент44 страницыRexroth Oil Cleanliness BookletM S Gokul100% (7)

- HPLC Catalog 2009Документ63 страницыHPLC Catalog 2009Carousel SonОценок пока нет

- Technical ManualДокумент22 страницыTechnical ManualKuldip PatelОценок пока нет

- Corrosion Prediction Request FormДокумент1 страницаCorrosion Prediction Request FormJohnSengsuОценок пока нет

- Handbook Filtration ParkerДокумент40 страницHandbook Filtration ParkerManuelVizcarra100% (3)

- Lube Oil Analysis TestsДокумент11 страницLube Oil Analysis TestsPrudhvi RajОценок пока нет

- Intro To DT&R - Drilling ToolsДокумент64 страницыIntro To DT&R - Drilling Toolsllereador100% (1)

- Define Your Plant SectionsДокумент2 страницыDefine Your Plant SectionsllereadorОценок пока нет

- Hart Student Manual For Print 10-2010 - 5923216 - 01Документ116 страницHart Student Manual For Print 10-2010 - 5923216 - 01llereador100% (1)

- Red Oxiacetilenica HBДокумент1 страницаRed Oxiacetilenica HBllereadorОценок пока нет

- Break-Out Machines Level 1Документ34 страницыBreak-Out Machines Level 1llereador100% (3)

- DT&R Maintenance OJT - 2M SpearДокумент1 страницаDT&R Maintenance OJT - 2M SpearllereadorОценок пока нет

- Hand Tool Safety TipsДокумент29 страницHand Tool Safety TipsllereadorОценок пока нет

- Hand Tool Safety TipsДокумент29 страницHand Tool Safety TipsllereadorОценок пока нет

- LM2 Tool AdditionДокумент11 страницLM2 Tool AdditionllereadorОценок пока нет

- Overhaul-A Lathe PDFДокумент6 страницOverhaul-A Lathe PDFllereadorОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Catalogo Aot PDFДокумент72 страницыCatalogo Aot PDFllereador100% (1)

- Edge Technology Quote Schlumberger 8 6 14 PDFДокумент1 страницаEdge Technology Quote Schlumberger 8 6 14 PDFllereadorОценок пока нет

- 2009 NDT CatalogДокумент32 страницы2009 NDT CatalogSilvia ValdiviaОценок пока нет

- Whip PDFДокумент49 страницWhip PDFllereadorОценок пока нет

- Par-Test: Fluid AnalysisДокумент6 страницPar-Test: Fluid AnalysisllereadorОценок пока нет

- Dapra BiaxScrapers PDFДокумент4 страницыDapra BiaxScrapers PDFllereadorОценок пока нет

- DS Fluke 355 SpecificationsДокумент3 страницыDS Fluke 355 SpecificationsllereadorОценок пока нет

- Pipe Cutter With KnifeES21 (1) .39808Документ36 страницPipe Cutter With KnifeES21 (1) .39808llereadorОценок пока нет

- NI-DAQmx Express VI TutorialДокумент12 страницNI-DAQmx Express VI TutorialBica RazvanОценок пока нет

- Bridge PlugES21 (1) .40044EДокумент24 страницыBridge PlugES21 (1) .40044EllereadorОценок пока нет

- Hy08 M1140 4Документ80 страницHy08 M1140 4llereadorОценок пока нет

- VB 2010 PreviewДокумент34 страницыVB 2010 PreviewllereadorОценок пока нет

- Daq Ni Usb 6009Документ30 страницDaq Ni Usb 6009ramiro_vicente_6Оценок пока нет

- TDS PSB 2&4Документ2 страницыTDS PSB 2&4llereadorОценок пока нет

- Wolfson Eup3 Ch09 Test BankДокумент15 страницWolfson Eup3 Ch09 Test BankifghelpdeskОценок пока нет

- Structure and Bonding IPADДокумент4 страницыStructure and Bonding IPADLarissa RubarajОценок пока нет

- ElectricityДокумент25 страницElectricityWeb BooksОценок пока нет

- CH04 - Heat Exchanger - AmanДокумент104 страницыCH04 - Heat Exchanger - AmanNabilah MustafaОценок пока нет

- 2015 2016AP Chemistry Summer AssignmentДокумент7 страниц2015 2016AP Chemistry Summer AssignmentBraden FarrellОценок пока нет

- Matrix CalculusДокумент9 страницMatrix CalculusAndrewОценок пока нет

- Photoelectric Effect: Jump To Navigation Jump To SearchДокумент10 страницPhotoelectric Effect: Jump To Navigation Jump To SearchSrynnEОценок пока нет

- Commercial Softener Specifications and Flow RatesДокумент1 страницаCommercial Softener Specifications and Flow Ratesrhusseinpos4765Оценок пока нет

- Chemical Bonding (F Only)Документ28 страницChemical Bonding (F Only)Raju SinghОценок пока нет

- 022 TT Short-Circuit PDFДокумент4 страницы022 TT Short-Circuit PDFwwe_himanshuОценок пока нет

- Millman Halkias - Integrated ElectronicsДокумент14 страницMillman Halkias - Integrated ElectronicsSushruti Richaa KashyapОценок пока нет

- Linear MotionДокумент29 страницLinear MotionElyna RedzuanОценок пока нет

- A New Shock Absorber Model With An Application in Vehicle Dynamics StudiesДокумент9 страницA New Shock Absorber Model With An Application in Vehicle Dynamics StudiesPaul WellsОценок пока нет

- Greek LettersДокумент15 страницGreek LettersPrasad DvssrОценок пока нет

- Lewis Structures: Molecular Structure and BondingДокумент83 страницыLewis Structures: Molecular Structure and Bondingحني اسفيانيОценок пока нет

- Atec Manual ElectronicДокумент73 страницыAtec Manual ElectronicMinaSaeed67% (3)

- Capacitors PDFДокумент84 страницыCapacitors PDFNaseerUddin100% (1)

- MATE464 W4 Tribology v2Документ87 страницMATE464 W4 Tribology v2Tuna CanОценок пока нет

- 6 - Francis Turbine PDFДокумент39 страниц6 - Francis Turbine PDFMohamed YaserОценок пока нет

- RDII - Chapter 5 HandoutДокумент8 страницRDII - Chapter 5 HandoutIlamurianОценок пока нет

- CSP Exam Equation Fully Explained DEMOДокумент33 страницыCSP Exam Equation Fully Explained DEMOFff63% (8)

- Torque and Equilibrium (40 charactersДокумент2 страницыTorque and Equilibrium (40 charactersEndai DesuОценок пока нет

- Estudio de Los Mecanismos de Adherencia Entre Escoria y Refractarios Mediante Ensayos de InmersiónДокумент6 страницEstudio de Los Mecanismos de Adherencia Entre Escoria y Refractarios Mediante Ensayos de InmersiónJorge MadiasОценок пока нет

- Principles of Finned Tube Heat Exchanger Design For Enhanced Heat TransferДокумент20 страницPrinciples of Finned Tube Heat Exchanger Design For Enhanced Heat Transferunknown8787Оценок пока нет

- Flow Assurance - Prof. Osman BasaranДокумент49 страницFlow Assurance - Prof. Osman BasaranWunkey WunkruОценок пока нет

- Fundamentals of Metallurgy by Seshadri SeetharamanДокумент1 страницаFundamentals of Metallurgy by Seshadri SeetharamanAmanda Ariesta ApriliaОценок пока нет

- 2008 HKCEE Physics P2 SolДокумент24 страницы2008 HKCEE Physics P2 SolAlex KongОценок пока нет

- 978 1 4419 5754 2 PDFДокумент458 страниц978 1 4419 5754 2 PDFLUIS ISAAC LEON PAROОценок пока нет

- MAGMA How To UseДокумент113 страницMAGMA How To Usepurushothaman1234566Оценок пока нет

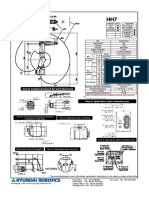

- Hh7 CatalogДокумент1 страницаHh7 Catalogjitender kumarОценок пока нет