Академический Документы

Профессиональный Документы

Культура Документы

Dental Lab 3D Scanners - How They Work and What Works Best

Загружено:

GouveiaFernandes0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров5 страницThis article is written to provide readers with a basic understanding of 3D scanner technology. Laser scanners generate multiple lines by moving the scan head along a precise linear axis. White light scanners have a fixed scan head but project several shifted line patterns.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis article is written to provide readers with a basic understanding of 3D scanner technology. Laser scanners generate multiple lines by moving the scan head along a precise linear axis. White light scanners have a fixed scan head but project several shifted line patterns.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

23 просмотров5 страницDental Lab 3D Scanners - How They Work and What Works Best

Загружено:

GouveiaFernandesThis article is written to provide readers with a basic understanding of 3D scanner technology. Laser scanners generate multiple lines by moving the scan head along a precise linear axis. White light scanners have a fixed scan head but project several shifted line patterns.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

1 / 5

Dental Lab 3D Scanners

How they work and what works best

Dr. Karl Hollenbeck, Dr. Thomas Allin, Dr. Mike van der Poel

3Shape Technology Research, Copenhagen

Followers of the dental 3D scanner market are bombarded with a hail of different and confusing

claims. Much too often, professionals seeking information are left hanging with difficult key questions

such as What is the difference between laser and white light scanners? and Can I compare the

claimed accuracy between the different scanners? This article is written to provide readers with

a basic understanding of 3D scanning technology, thereby enabling them to better challenge 3D

scanner manufactures and make a much more educated choice when purchasing a new scanner.

This article primarily covers the scanning technology and only briefly touches on the aspects of the

CAD software that is often included with the scanner.

The basic principle of a 3D scanner

With one exception, all dental 3D scanners are constructed

on the same basic principle. Fundamentally, a 3D scanner

consists of a light source, one or more cameras, and a

motion system supporting several axes for positioning

the scanned object towards the light source and

camera(s). The light source projects well-defined lines

onto the surface of the object, and the camera(s) acquire

images of the lines. Based on the known angle and

distance between camera and light source (jointly called

the scan head), the 3D position(s) where the projected

light is reflected can be calculated using trigonometry.

This measurement-principle is known as triangulation.

The basic principle works with one camera only, but two

cameras improve scan speed, accuracy and scan coverage.

Each line of projected light yields one 3D contour

line. Therefore, the relative motion of the scan head

and object yield multiple lines, and hence multiple

3D contours. Laser scanners generate multiple

lines by moving the scan head along a precise linear

axis (Figure 1, left), while white light scanners

have a fixed scan head, but project several shifted

line patterns from a central position consecutively

(Figure 1, right). As can be seen from figure 1,

the basic principles used in laser and white light

scanners are the same. Hence, based on general

scanner principle alone, it is impossible to claim

that white light technology is better than laser

technology or vice-versa.

Figure 1: The 3D scanner principle. Left: A 3D laser scanner with two rotation axes and one linear axis The laser scanner generates

a line of light, which is moved across the object using the linear axes. Right: A white light scanner with two rotation axes. The light

source generates multiple lines of light and thus an entire view from a single position.

January 2012

2 / 5

Figure 3: Point cloud (left, 164,475 points) is used to generate the triangle based surface (middle; 55.380 triangles). Smart triangle

reduction algorithms can be used to intelligently reduce the number of triangles (right; 13.845 triangles) while preserving excellent

coping and margin line fit.

Each relative position of scan head and object, i.e., each

set of contours, yields a single 3D view. All scanners

run a predefined motion script moving the scan head

relatively into several positions/views required to capture

the surface from all sides (Figure 2). Some 3D scanners

support a high-quality mechanical motion system, where

all 3D views can be directly transformed into a common

coordinate system and then simply appended to each

other. Other 3D scanners, with less accurate mechanics

do not rely on the motion systems quality but instead

virtually align the 3D views by detecting similar 3D

structures in overlapping regions of at least one pair of

views. Software alignment thus works best for objects

with pronounced structures, e.g. molars.

Triangulation requires sharply projected light patterns.

These can in principle be obtained by both laser and white

light scanners. Lasers can achieve minimal line widths of

any illumination source (which is why they are perfect

for use in pointers), but if not controlled carefully, they

display speckle - a slight randomness in light intensity.

In contrast, white-light scanners suffer from blur due to

the fact that the different color components that exist

in white light are refracted slightly differently (chromatic

aberration, a rainbow effect).

A 3D scanners recording of sharply projected light

patters can be no better than the quality delivered by the

cameras. High-quality in both optics and image sensors

are therefore a must in 3D scanners for professional use.

Today, the trend is turning towards developing scanners

with high-resolution sensors some up to 5 megapixels.

In the final processing step, the point cloud obtained from

all views is converted into a 3D surface of fine triangles

(Figure 3). This is an approximation method that is also

used in computer graphics. Smart surface generation

algorithms are preferable, i.e., those that preserve

relevant features such as edges. Using smart algorithms

the number of triangles can be significantly reduced

without sacrificing accuracy. In general, reducing the

number of triangles is desirable because the time it takes

the CAD design software to process the 3D image is

highly dependent on the number of triangles generated.

For example, doubling the number of triangles could

easily increase the softwares processing time at least

by a factor of four or in some cases, processing can even

fail completely.

White light and laser 3D scanning technologies are also

widely used in industrial applications and metrology.

However, laser scanning systems dominate the segment

for coordinate measurement machines and other high-

accuracy applications.

View 1 View 2 Combined view

Raw Point Cloud High-density surface Medium-density surface Edge preserving

reduction

Figure 2: In high-accuracy mechanical-motion-systems, the

different views are appended. Less accurate systems apply

software alignment of the different views. Software alignment

relies on matches in the surface structure in overlapping areas.

This makes software alignment prone to errors in areas that are

small or display a smooth and less defined structure.

3 / 5

Accuracy

Currently, there is no common standard for measuring

and validating the accuracy of dental scanners. Most

scanner manufacturers do not even disclose how

they measure their accuracy claims. Hence, claimed

accuracies typically in the area of 20 microns - cannot

be compared nor even confirmed.

The science of high accuracy measurement - metrology

- applies reference objects with accuracies much higher

than the scanner. These objects can only be manufactured

by specialized accredited companies or metrology

laboratories. By defining and introducing proper mutual

reference objects such as these, it becomes clear that

different scanner brands perform quite differently, and

many alarming results are revealed for example, some

scanners can round an edge incorrectly with an error

margin of over 20 microns (Figure 4).

With implant bar reference objects, tests reveal an error

of less than 3 microns along the insertion direction - i.e.

in the level of the implants seating surface (Figure 5). This

scanning error is the first in the CAD tolerance chain

that in total, should reach less than a 10 micron vertical

misfit between the framework and the abutments (the

ideal passive fit). While it has been debated whether

10 microns is a realistically achievable value, there are at

least some scanners that seem to be able to bring this

ideal within reach.

Figure 4: Two scanner brands measurements (blue line, orange line) of a nominally sharp edge in a custom-made ceramic reference

tooth object (middle). Note the relatively large difference in accuracy around the sharp edges.

Figure 5: Left: Reference measurements with a high-end coordinate measurement machine (accuracy 3 microns). Right: Scan of an

implant bar reference object with errors in the insertion direction [in microns].

60 micron!

4 / 5

It is an undeniable law of physics that all materials and

thus also scanner hardware will expand and contract

according to changes in temperature. Scanner hardware

can also be affected by rough handling such as during

transportation. For demanding work, such as long span

bridges and implant bars, it is especially important that

a scanner is re-calibrated when moved or when the labs

temperature changes. State-of-the-art scanners come

with special calibration objects with a known accuracy

factor that is much higher than the scanners accuracy

capability. Software algorithms cannot compensate for

temperature effects because the scanner hardware itself

contains weldings, fasteners, glued sections, varying

loads, etc., and is thus prone to highly complex expansion

and contraction.

Accuracy also depends on how well the scanner is

manufactured. Larger 3D scanner manufacturers

typically have better production facilities and tools, and

can automate parts of the assembly steps including

outgoing quality inspection. They can thereby reduce

product variability to lower levels than those achievable

through human manufacturing operations alone. Larger

manufacturers are also usually financially stable and are

thus most likely to remain in business and provide long-

term support.

Scan Speed and productivity

Scan speed is an important parameter when choosing

a scanner, because scan time is an essential factor in

the overall productivity. As with accuracy, there are no

standards that make it easier to compare marketing

material and claims. While there is no common reference,

empirical comparisons show that claimed scan times can

vary from 30 seconds to several minutes for the same

basic die. The more serious manufacturers will disclose

their scan times for selected major indications. Generally

speaking, studying scan time values alone will not reveal

the scanners capabilities in terms of productivity. Labs

need to consider whole workflows, starting with order

creation and ending with a 3D scan that is fully ready for

CAD design. This naturally involves the scanner hardware

but also the system that drives it. Comparing different

scanner brands productivity from this angle will reveal

even larger performance variations.

A high degree of automation will allow the user to spend

less time on the overall scan process. Automation also

reduces the likelihood of human errors and thus helps

avoid remakes - the most time-consuming of all errors.

For example, manually controlled camera brightness-

adjustment can result in over-exposed images in which

projected lines of light can no longer be detected.

Some hardware features can save handling time. With a

die feeder or multi-die plate, a scanner can work without

an operator for many minutes. A single technician can

work with multiple scanners simultaneously or efficiently

use the spare time for designing restorations in the CAD

software. Good fixtures reduce the number of failures,

an annoying source of wasted time.

The most truthful sources of information for scan

speed are probably found in impartial user statements

(especially regarding failure rates) and in videos that

show entire scan processes.

Additional functionality

Besides accuracy and scan speed, there are several other

important differences between dental scanners. A major

factor labs should consider is the number of indications that

the scanner supports, e.g. long span bridges, Customized

Abutments, accurate Implant Bars and Removable Partial

Dentures. Too many low-end non-upgradable scanners will

only support the very basic indications and thus limit the lab

and represent a weak investment long-term.

Figure 6: Left: Example of a traditional impression scan result that is incomplete in the preparation proximal and contact areas,

and will thus jeopardize fit and clinical performance. Right: A complete and accurate scan after Adaptive Impression Scanning of

incomplete areas by automatically applying the optimal combination of two cameras and three-axis motion.

Before Adaptive scanning After Adaptive scanning

5 / 5

Unlike adaptive scanning, pre-defined motion scripts do

not at all guarantee complete coverage of the surface.

Based on high-resolution (5 MP) camera technology,

Texture Scanning captures 2D images of the gypsum

model surface and precisely overlays these on the

3D model, thereby enhancing visualization of surface

details and allowing technicians to include hand-drawn

design guidance markings in the digital design (Figure

7). This is particularly useful for capturing a hand-drawn

margin line penciled directly on the physical model or

for transferring RPD framework position markings from

the model into the CAD software. Texture scanning is

a new groundbreaking technology that is supported in

only the most advanced dental scanners.

Figure 7: Texture Scanning captures 2D images of the model surface and precisely overlays these on the 3D model.

The scanners supported indications cannot be viewed

on their own. The CAD software running with the

scanner will need to support them as well. In general,

manufacturers that develop both scanners and CAD

software will typically offer better and optimized

workflows with fully integrated solutions - especially in

terms of indication support and user-friendliness.

Looking forward, impression scanning is expected to

become the most widely used method for 3D scanning

in the lab, leaving conventional gypsum only

scanners obsolete. Impression scanning is particularly

challenging for a 3D scanner. The deep cavities make

it difficult for the camera and light source to both

illuminate and see deep surface points simultaneously,

a basic requirement for the reconstruction of the

3D model (Figure 6). Multiple cameras increase the

chance of being able to see the entire surface. There

is a proprietary technology (adaptive impression

scanning) that applies software to find the optimal

combination of cameras and positions to re-scan

uncovered areas. Other manufacturers use time-

consuming and heavy pre-defined motion scripts.

Dental scanners come with a built-in PC. Although this

reduces space requirements and eases transportation, it

presents a significant investment drawback.

Scanner PCs typically need to be upgraded every 2-3

years due to continuously increasing demands on

operating systems and CAD software and builtin PCs

are often difficult to upgrade.

Summary

Due to the lack of common standards for even the most

basic features in dental lab scanners, the 3D scanner

market can be confusing for many labs on the lookout

for the right device. Labs should consider the following

check list when comparing dental 3D scanners:

Accuracy documented by certified reference objects

Scan and workflow time for well defined indications

Range of supported indications long span bridges,

implant bars, removable bars

Useful features impression scanning, texture scanning,

die feeder, calibration object and 5 MP cameras.

Finally, it is highly recommended to always test the scanner

before making a final purchase. The advertisement and

brochure may have made all sorts of promises but these

may not always be fulfilled when getting down to real

work.

With such an important and long-term investment for the

lab, it is only natural to thoroughly investigate the markets

and challenge poorly documented manufacturer claims.

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Descriptive Geometry 1 Lecture NotesДокумент63 страницыDescriptive Geometry 1 Lecture NotesGrigor Ciko100% (1)

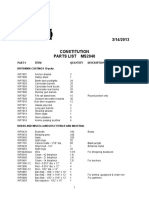

- MS2040 Constitution Parts ListДокумент6 страницMS2040 Constitution Parts ListTemptationОценок пока нет

- Bookdrive ProДокумент4 страницыBookdrive Provvenugopal74Оценок пока нет

- TOI Full Page - Dehradun Edition - May 2023Документ1 страницаTOI Full Page - Dehradun Edition - May 2023SakshamОценок пока нет

- 100 Tips From A Professional PhotographerДокумент3 страницы100 Tips From A Professional PhotographerKarachiFashion ReplicaОценок пока нет

- V Ray - ManualДокумент361 страницаV Ray - Manualthanhson1985Оценок пока нет

- Michael Mahler Incident ReportДокумент60 страницMichael Mahler Incident ReportMichael_Lee_RobertsОценок пока нет

- Acer x115h x125hДокумент2 страницыAcer x115h x125hAnonymous ZmRV6WqОценок пока нет

- Model Boat Warship Special 2014Документ132 страницыModel Boat Warship Special 2014desanca100% (8)

- FilmmakingДокумент70 страницFilmmakingKunal Chakraborty100% (4)

- Application FormДокумент1 страницаApplication FormAkshat AtrayОценок пока нет

- Animation - Definition: Animation Bring An Image To LifeДокумент10 страницAnimation - Definition: Animation Bring An Image To LifeThe Bhaukali GyanОценок пока нет

- Communications World 1976 Fall WinterДокумент100 страницCommunications World 1976 Fall WinterBenjamin DoverОценок пока нет

- How To Print Layouts in Sap Business OneДокумент65 страницHow To Print Layouts in Sap Business OneshellydreОценок пока нет

- Gby League Week Issue 37 2015Документ48 страницGby League Week Issue 37 2015Juano CeОценок пока нет

- Brooke Christy's ResumeДокумент1 страницаBrooke Christy's ResumebrookenchristyОценок пока нет

- STAR JPA Scholar UserManual 4.0Документ33 страницыSTAR JPA Scholar UserManual 4.0DyanAugustineОценок пока нет

- Wisteria Portfolio Issue Tomek CiesielskiДокумент26 страницWisteria Portfolio Issue Tomek CiesielskiGREENBOOKFACTORYОценок пока нет

- Main Specifications of PENTAX KДокумент5 страницMain Specifications of PENTAX KVBUPDF100% (2)

- Ann289 2 PDFДокумент6 страницAnn289 2 PDFRAHUL MITRAОценок пока нет

- Khorsabad II. The Citadel and The TownДокумент244 страницыKhorsabad II. The Citadel and The TownLeniad Wolfschanze MuñeiraОценок пока нет

- Print2CAD 2017 EnglishДокумент204 страницыPrint2CAD 2017 EnglishVictor MorenoОценок пока нет

- Grade 9 Unit 2 - StudentДокумент84 страницыGrade 9 Unit 2 - Studentapi-296701419100% (1)

- Spherical MirrorДокумент8 страницSpherical MirrorAtul VermaОценок пока нет

- Remote Sensing Geology (2nd Ed.) (R.P. Gupta, 2003) @geo PediaДокумент671 страницаRemote Sensing Geology (2nd Ed.) (R.P. Gupta, 2003) @geo PediaSyed Maaz100% (1)

- FRS3 Chapter 7Документ5 страницFRS3 Chapter 7Gielhene MinearОценок пока нет

- Kika - AlmodóvarДокумент7 страницKika - AlmodóvarpeperkonОценок пока нет

- GridsДокумент90 страницGridssevmoseОценок пока нет

- Fundacion Juan March - Julia Margaret Cameron PDFДокумент166 страницFundacion Juan March - Julia Margaret Cameron PDFmoises_generОценок пока нет

- Web Developer, Blogger and Thinker - Upload Images Into MySQL Database Using PHP CodeДокумент2 страницыWeb Developer, Blogger and Thinker - Upload Images Into MySQL Database Using PHP CodeHaikaiYahataОценок пока нет